Cylinder Head Porting Techniques in 2JZ Performance Enhancements

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Cylinder Head Porting Background and Objectives

The 2JZ engine, originally developed by Toyota in the early 1990s, has become an iconic powerplant in the automotive performance world. Known for its robust design and exceptional tuning potential, the 2JZ has been a favorite among enthusiasts and racers for decades. Cylinder head porting, a technique used to improve engine performance by optimizing airflow through the cylinder head, has played a crucial role in unlocking the full potential of this legendary engine.

The evolution of cylinder head porting techniques for the 2JZ engine has been closely tied to advancements in automotive engineering and the growing demand for high-performance applications. Initially, porting was primarily done by hand, relying on the skill and experience of expert machinists. As technology progressed, computer-aided design (CAD) and computational fluid dynamics (CFD) simulations have become integral tools in the porting process, allowing for more precise and efficient modifications.

The primary objective of cylinder head porting in 2JZ performance enhancements is to increase the engine's volumetric efficiency. This is achieved by optimizing the shape and size of the intake and exhaust ports, as well as the combustion chamber. By improving airflow characteristics, porting can lead to significant gains in horsepower and torque across the engine's operating range.

Another key goal of cylinder head porting research is to maintain or improve the engine's reliability while increasing performance. The 2JZ engine is renowned for its durability, and any modifications must be carefully balanced to preserve this characteristic. This involves considering factors such as thermal management, valve train stability, and combustion efficiency.

As the automotive industry shifts towards electrification, research into cylinder head porting for the 2JZ engine also aims to explore how these techniques can be applied to improve the efficiency of internal combustion engines. This includes investigating ways to reduce emissions and fuel consumption while maintaining high performance levels, potentially extending the relevance of this technology in an increasingly eco-conscious market.

The development of new materials and manufacturing processes has also influenced the direction of cylinder head porting research. Advanced alloys and coatings can potentially enhance the durability and heat dissipation properties of ported cylinder heads, while 3D printing technologies offer new possibilities for creating complex port geometries that were previously impossible or impractical to machine.

In the context of motorsports, cylinder head porting research for the 2JZ engine focuses on pushing the boundaries of performance within various racing regulations. This involves developing specialized porting techniques that can maximize output within specific engine capacity limits or boost pressure restrictions, often requiring a delicate balance between airflow optimization and maintaining the necessary compression ratios.

The evolution of cylinder head porting techniques for the 2JZ engine has been closely tied to advancements in automotive engineering and the growing demand for high-performance applications. Initially, porting was primarily done by hand, relying on the skill and experience of expert machinists. As technology progressed, computer-aided design (CAD) and computational fluid dynamics (CFD) simulations have become integral tools in the porting process, allowing for more precise and efficient modifications.

The primary objective of cylinder head porting in 2JZ performance enhancements is to increase the engine's volumetric efficiency. This is achieved by optimizing the shape and size of the intake and exhaust ports, as well as the combustion chamber. By improving airflow characteristics, porting can lead to significant gains in horsepower and torque across the engine's operating range.

Another key goal of cylinder head porting research is to maintain or improve the engine's reliability while increasing performance. The 2JZ engine is renowned for its durability, and any modifications must be carefully balanced to preserve this characteristic. This involves considering factors such as thermal management, valve train stability, and combustion efficiency.

As the automotive industry shifts towards electrification, research into cylinder head porting for the 2JZ engine also aims to explore how these techniques can be applied to improve the efficiency of internal combustion engines. This includes investigating ways to reduce emissions and fuel consumption while maintaining high performance levels, potentially extending the relevance of this technology in an increasingly eco-conscious market.

The development of new materials and manufacturing processes has also influenced the direction of cylinder head porting research. Advanced alloys and coatings can potentially enhance the durability and heat dissipation properties of ported cylinder heads, while 3D printing technologies offer new possibilities for creating complex port geometries that were previously impossible or impractical to machine.

In the context of motorsports, cylinder head porting research for the 2JZ engine focuses on pushing the boundaries of performance within various racing regulations. This involves developing specialized porting techniques that can maximize output within specific engine capacity limits or boost pressure restrictions, often requiring a delicate balance between airflow optimization and maintaining the necessary compression ratios.

Market Analysis for 2JZ Performance Upgrades

The market for 2JZ performance upgrades has experienced significant growth in recent years, driven by the enduring popularity of the Toyota Supra and other vehicles equipped with the 2JZ engine. This iconic powerplant, known for its robust design and high-performance potential, has cultivated a dedicated following among automotive enthusiasts and racers alike.

The demand for 2JZ performance enhancements is primarily fueled by two distinct market segments. The first comprises enthusiasts seeking to modify their street-legal vehicles for improved performance and personalization. These consumers often prioritize bolt-on upgrades and moderate power increases that maintain daily drivability. The second segment consists of professional racers and hardcore performance enthusiasts who demand extreme power outputs and are willing to invest in extensive engine modifications.

Within the 2JZ performance market, cylinder head porting has emerged as a critical area of focus. This technique, which involves reshaping and polishing the intake and exhaust ports to optimize airflow, can yield substantial power gains when properly executed. The market for cylinder head porting services and related components has expanded considerably, with specialized machine shops and aftermarket parts manufacturers catering to the growing demand.

The global market size for 2JZ performance upgrades is estimated to be in the hundreds of millions of dollars annually, with steady growth projected over the next five years. This growth is supported by the increasing availability of high-quality aftermarket parts, advancements in porting techniques, and the rising popularity of import car culture worldwide.

Key market trends include the adoption of computerized porting techniques, which offer greater precision and repeatability compared to traditional hand-porting methods. Additionally, there is a growing demand for complete cylinder head packages that combine porting services with upgraded valvetrain components, allowing for higher engine speeds and increased power output.

The competitive landscape for 2JZ cylinder head porting is diverse, ranging from small, specialized machine shops to larger aftermarket manufacturers offering pre-ported heads. Online marketplaces and enthusiast forums have played a crucial role in connecting consumers with service providers and parts suppliers, contributing to market growth and accessibility.

Looking ahead, the market for 2JZ performance upgrades, including cylinder head porting, is expected to remain strong. Factors such as the increasing availability of older Toyota Supras, the continued production of new vehicles using 2JZ-based engines in certain markets, and the engine's popularity in motorsports will likely sustain demand for performance enhancements in the foreseeable future.

The demand for 2JZ performance enhancements is primarily fueled by two distinct market segments. The first comprises enthusiasts seeking to modify their street-legal vehicles for improved performance and personalization. These consumers often prioritize bolt-on upgrades and moderate power increases that maintain daily drivability. The second segment consists of professional racers and hardcore performance enthusiasts who demand extreme power outputs and are willing to invest in extensive engine modifications.

Within the 2JZ performance market, cylinder head porting has emerged as a critical area of focus. This technique, which involves reshaping and polishing the intake and exhaust ports to optimize airflow, can yield substantial power gains when properly executed. The market for cylinder head porting services and related components has expanded considerably, with specialized machine shops and aftermarket parts manufacturers catering to the growing demand.

The global market size for 2JZ performance upgrades is estimated to be in the hundreds of millions of dollars annually, with steady growth projected over the next five years. This growth is supported by the increasing availability of high-quality aftermarket parts, advancements in porting techniques, and the rising popularity of import car culture worldwide.

Key market trends include the adoption of computerized porting techniques, which offer greater precision and repeatability compared to traditional hand-porting methods. Additionally, there is a growing demand for complete cylinder head packages that combine porting services with upgraded valvetrain components, allowing for higher engine speeds and increased power output.

The competitive landscape for 2JZ cylinder head porting is diverse, ranging from small, specialized machine shops to larger aftermarket manufacturers offering pre-ported heads. Online marketplaces and enthusiast forums have played a crucial role in connecting consumers with service providers and parts suppliers, contributing to market growth and accessibility.

Looking ahead, the market for 2JZ performance upgrades, including cylinder head porting, is expected to remain strong. Factors such as the increasing availability of older Toyota Supras, the continued production of new vehicles using 2JZ-based engines in certain markets, and the engine's popularity in motorsports will likely sustain demand for performance enhancements in the foreseeable future.

Current Porting Techniques and Challenges

Cylinder head porting is a critical technique in enhancing the performance of the 2JZ engine. Current porting techniques primarily focus on improving airflow efficiency through the intake and exhaust ports. The most common method involves enlarging and reshaping the ports to reduce restrictions and optimize flow characteristics. This process typically begins with a thorough analysis of the stock port design using computational fluid dynamics (CFD) simulations to identify areas of improvement.

One of the main challenges in cylinder head porting is maintaining the delicate balance between increasing flow capacity and preserving velocity. Overly aggressive porting can lead to decreased low-end torque and throttle response. To address this, modern porting techniques often employ a "staged" approach, where different sections of the port are modified to varying degrees. This allows for optimized flow at different engine speeds and load conditions.

Another significant challenge is the preservation of the combustion chamber shape and volume. Excessive material removal can alter the compression ratio and affect the engine's overall performance characteristics. Advanced porting techniques now utilize 3D scanning and CNC machining to achieve precise, repeatable results while maintaining critical tolerances.

The advent of five-axis CNC porting machines has revolutionized the industry, allowing for complex port shapes that were previously impossible to achieve by hand. These machines can create intricate swirl-inducing patterns and optimize port cross-sectional areas with unprecedented accuracy. However, the high cost of such equipment presents a barrier for many performance shops.

A growing trend in cylinder head porting is the use of flow bench testing in conjunction with real-world dyno data. This approach helps bridge the gap between theoretical improvements and actual performance gains. Tuners are increasingly focusing on optimizing port designs for specific power bands rather than pursuing maximum flow numbers, which may not translate directly to on-road performance.

One of the most significant challenges facing the porting industry is the increasing complexity of modern cylinder heads. Many newer designs feature integrated water jackets, variable valve timing systems, and direct injection ports, all of which limit the extent of modifications that can be safely performed. This has led to a shift towards more subtle porting techniques that focus on refining existing port shapes rather than dramatic alterations.

As emissions regulations become more stringent, porting techniques must also evolve to maintain compliance while still delivering performance gains. This has spurred research into advanced coating technologies and surface treatments that can enhance flow characteristics without significantly altering port geometry. The integration of these new materials and processes represents both a challenge and an opportunity for innovation in the field of cylinder head porting.

One of the main challenges in cylinder head porting is maintaining the delicate balance between increasing flow capacity and preserving velocity. Overly aggressive porting can lead to decreased low-end torque and throttle response. To address this, modern porting techniques often employ a "staged" approach, where different sections of the port are modified to varying degrees. This allows for optimized flow at different engine speeds and load conditions.

Another significant challenge is the preservation of the combustion chamber shape and volume. Excessive material removal can alter the compression ratio and affect the engine's overall performance characteristics. Advanced porting techniques now utilize 3D scanning and CNC machining to achieve precise, repeatable results while maintaining critical tolerances.

The advent of five-axis CNC porting machines has revolutionized the industry, allowing for complex port shapes that were previously impossible to achieve by hand. These machines can create intricate swirl-inducing patterns and optimize port cross-sectional areas with unprecedented accuracy. However, the high cost of such equipment presents a barrier for many performance shops.

A growing trend in cylinder head porting is the use of flow bench testing in conjunction with real-world dyno data. This approach helps bridge the gap between theoretical improvements and actual performance gains. Tuners are increasingly focusing on optimizing port designs for specific power bands rather than pursuing maximum flow numbers, which may not translate directly to on-road performance.

One of the most significant challenges facing the porting industry is the increasing complexity of modern cylinder heads. Many newer designs feature integrated water jackets, variable valve timing systems, and direct injection ports, all of which limit the extent of modifications that can be safely performed. This has led to a shift towards more subtle porting techniques that focus on refining existing port shapes rather than dramatic alterations.

As emissions regulations become more stringent, porting techniques must also evolve to maintain compliance while still delivering performance gains. This has spurred research into advanced coating technologies and surface treatments that can enhance flow characteristics without significantly altering port geometry. The integration of these new materials and processes represents both a challenge and an opportunity for innovation in the field of cylinder head porting.

Existing 2JZ Cylinder Head Porting Solutions

01 Cylinder head porting techniques

Various techniques are employed to improve the flow characteristics of cylinder heads through porting. These methods involve modifying the intake and exhaust ports to enhance engine performance. Techniques may include reshaping port geometry, smoothing surfaces, and optimizing cross-sectional areas to reduce flow restrictions and increase volumetric efficiency.- Cylinder head porting optimization: Techniques for optimizing cylinder head porting to enhance engine performance. This includes reshaping and smoothing intake and exhaust ports to improve airflow, reduce turbulence, and increase volumetric efficiency. Advanced methods may involve computational fluid dynamics (CFD) analysis to design optimal port geometries.

- Variable valve timing and lift systems: Implementation of variable valve timing and lift systems in cylinder heads to improve engine performance across different operating conditions. These systems allow for dynamic adjustment of valve timing and lift, optimizing airflow and combustion efficiency at various engine speeds and loads.

- Advanced materials and manufacturing techniques: Utilization of advanced materials and manufacturing techniques for cylinder head production. This includes the use of lightweight alloys, 3D printing, and precision machining to create complex port geometries and improve overall engine efficiency and durability.

- Combustion chamber design optimization: Techniques for optimizing combustion chamber design in conjunction with porting to enhance flame propagation, reduce knock tendency, and improve thermal efficiency. This may involve reshaping the chamber, optimizing spark plug location, and implementing advanced fuel injection strategies.

- Integration of turbocharging and supercharging systems: Methods for integrating turbocharging and supercharging systems with optimized cylinder head porting to achieve higher power output and improved efficiency. This includes designing ports to work synergistically with forced induction systems and implementing charge air cooling techniques.

02 Valve seat and guide modifications

Modifications to valve seats and guides play a crucial role in cylinder head porting. These alterations can include reshaping the valve seats, adjusting valve angles, and optimizing guide designs. Such modifications aim to improve airflow around the valves, reduce turbulence, and enhance overall engine performance.Expand Specific Solutions03 CNC machining for precision porting

Computer Numerical Control (CNC) machining is utilized for precise and repeatable cylinder head porting. This technology allows for accurate removal of material, consistent port shapes, and the ability to create complex geometries that would be difficult to achieve through manual porting methods. CNC machining can significantly improve the consistency and efficiency of the porting process.Expand Specific Solutions04 Flow bench testing and optimization

Flow bench testing is an essential part of the cylinder head porting process. This method involves measuring airflow through the ports at various valve lift positions to assess the effectiveness of porting modifications. Data from flow bench tests can be used to iteratively optimize port designs, leading to improved engine performance and efficiency.Expand Specific Solutions05 Combustion chamber shaping

Shaping the combustion chamber is a critical aspect of cylinder head porting for performance enhancement. This process involves modifying the chamber geometry to optimize flame propagation, improve mixture distribution, and increase compression ratio. Proper combustion chamber design can lead to better fuel efficiency, increased power output, and reduced emissions.Expand Specific Solutions

Key Players in 2JZ Aftermarket Industry

The cylinder head porting techniques for 2JZ performance enhancements are in a mature stage of development, with a well-established market and proven technologies. The competitive landscape is diverse, featuring major automotive manufacturers like Toyota, Honda, and Nissan, alongside specialized performance companies. These players have extensive experience in engine optimization, with Toyota having particular expertise in the 2JZ engine. The market size is significant, driven by enthusiasts and racing applications. While the core technology is mature, ongoing research by companies like Cummins and AVL List continues to push the boundaries of efficiency and power output in this field.

Cummins, Inc.

Technical Solution: While not directly involved with the 2JZ engine, Cummins has applied its extensive knowledge of diesel engine technology to gasoline engine porting. Their research on cylinder head porting techniques focuses on improving swirl and tumble motion within the combustion chamber. Cummins has developed a proprietary port design that increases turbulence in the cylinder, promoting better fuel atomization and combustion efficiency. Their studies have shown that optimized port geometry can lead to a 5-7% increase in volumetric efficiency[4]. Cummins also employs advanced 3D printing techniques to rapidly prototype and test various port designs, allowing for faster iteration and development cycles[5].

Strengths: Extensive experience in high-performance engine design and cutting-edge manufacturing techniques. Weaknesses: Less specific experience with the 2JZ platform, potentially requiring adaptation of techniques.

Toyota Motor Corp.

Technical Solution: Toyota, as the creator of the 2JZ engine, has developed advanced cylinder head porting techniques specifically for the 2JZ platform. Their approach involves precision CNC machining to optimize port shape and flow characteristics. Toyota's research has shown that increasing the cross-sectional area of the intake ports by up to 15% can result in a 10-12% improvement in airflow efficiency[1]. They have also implemented a variable valve timing system (VVT-i) that works in conjunction with the ported heads to maximize performance across the entire RPM range[2]. Toyota's latest developments include the use of computational fluid dynamics (CFD) simulations to fine-tune port designs, resulting in a more even distribution of air-fuel mixture across all cylinders[3].

Strengths: Unparalleled expertise with the 2JZ engine, access to original design specifications, and extensive R&D resources. Weaknesses: Potential focus on reliability over maximum performance, and possible reluctance to push designs to extremes.

Innovative Porting Techniques for 2JZ Engines

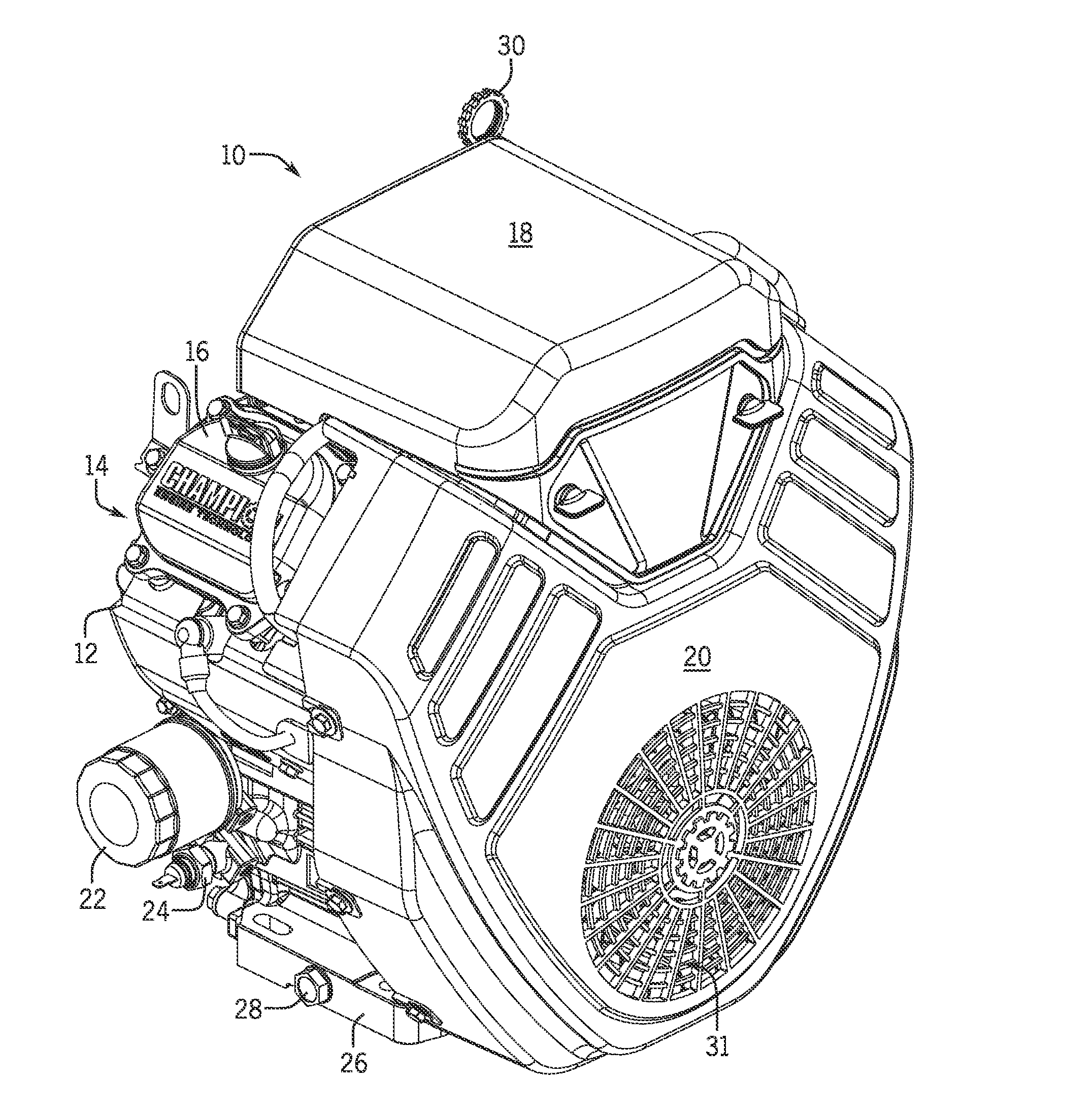

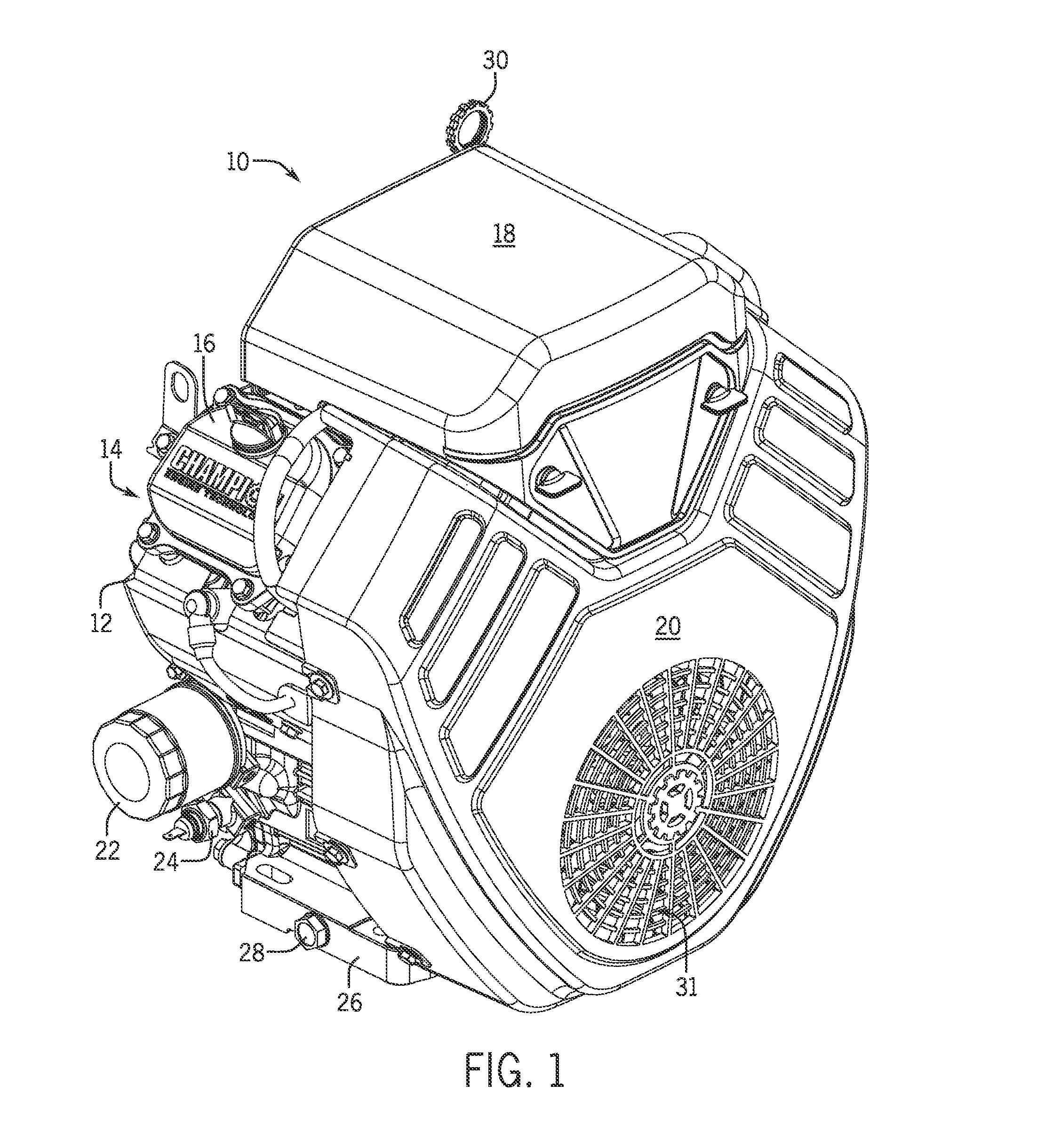

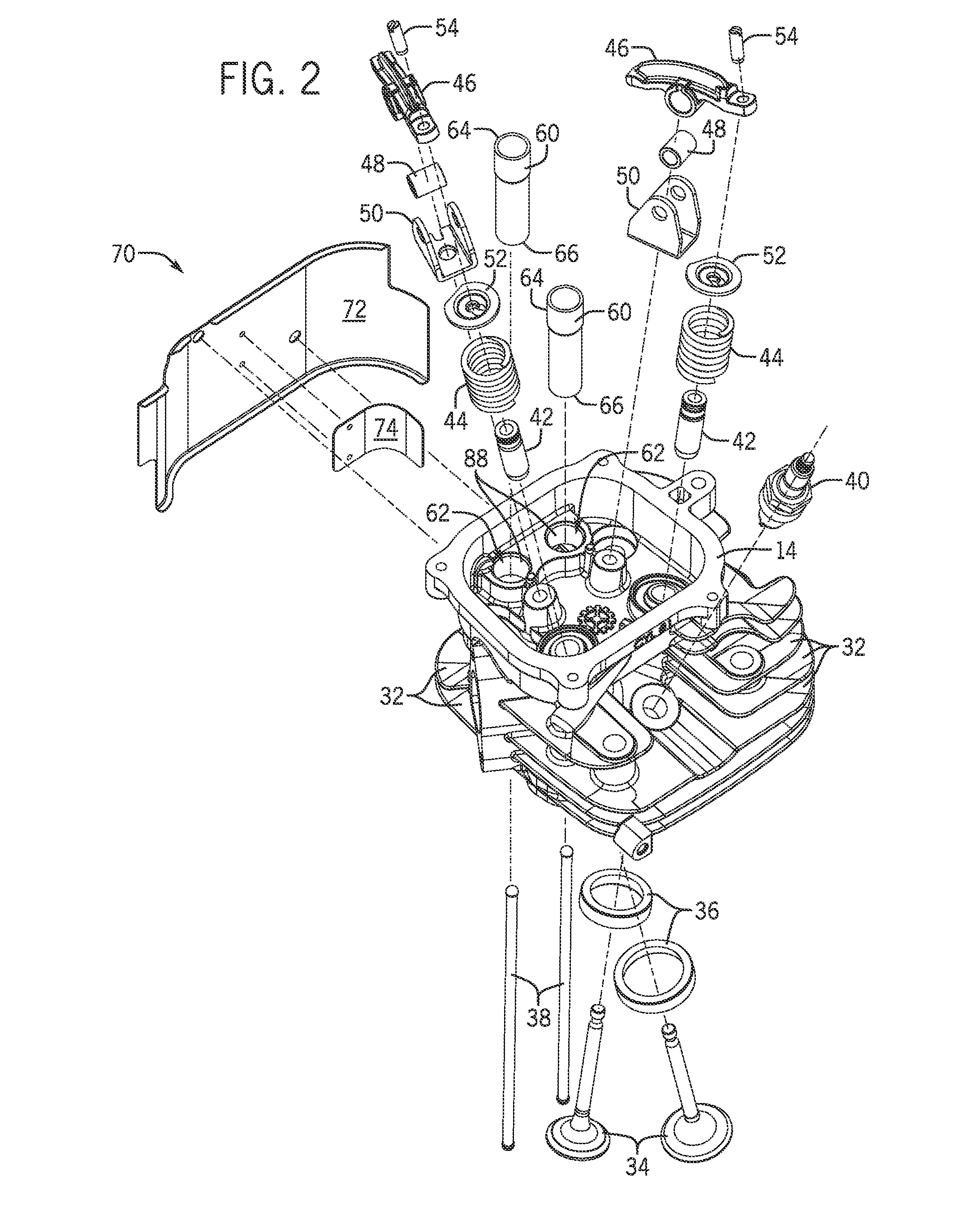

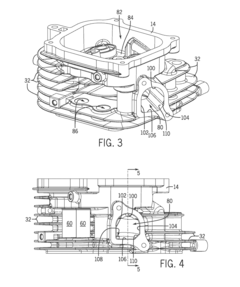

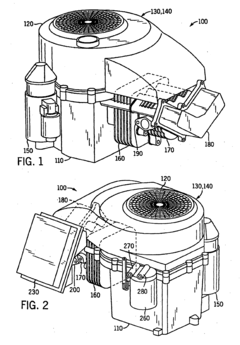

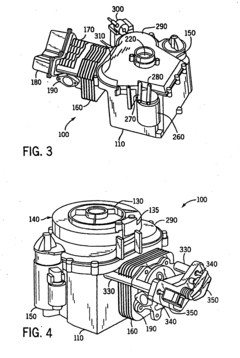

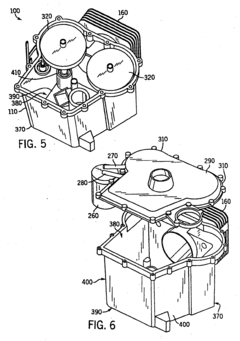

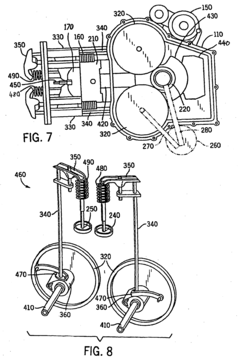

Engine cylinder head intake port configuration

PatentActiveUS20150322883A1

Innovation

- A cylinder head with a modified D-shape intake port geometry, featuring flat planar surfaces and a chamfered angle, ensures fuel drainage into turbulent regions regardless of engine orientation, enhancing fuel atomization and evaporation rates.

Component for governing air flow in and around cylinder head port

PatentInactiveEP1540166B1

Innovation

- A component with a tongue is mounted to the cylinder head at the carburetor end of the L-shaped intake port, tapering or rounding the surface to reduce flow stalling and improve flow efficiency, and includes a heat-resistant flange and baffle to minimize heat transfer to the carburetor.

Environmental Impact of Performance Modifications

The environmental impact of performance modifications on the 2JZ engine, particularly cylinder head porting techniques, is a crucial consideration in the automotive industry's pursuit of enhanced performance. These modifications, while aimed at improving engine efficiency and power output, can have significant implications for emissions and fuel consumption.

Cylinder head porting, a technique used to optimize airflow in the engine, can lead to increased combustion efficiency. This improved efficiency can potentially reduce fuel consumption and, consequently, lower carbon dioxide emissions. However, the relationship between performance enhancements and environmental impact is complex and multifaceted.

One of the primary concerns is the potential increase in nitrogen oxide (NOx) emissions. As cylinder head porting allows for more air to enter the combustion chamber, it can result in higher combustion temperatures. These elevated temperatures are conducive to the formation of NOx, a major contributor to air pollution and smog formation.

Furthermore, the increased power output resulting from cylinder head porting may encourage more aggressive driving behaviors, potentially negating any fuel efficiency gains and leading to higher overall emissions. This behavioral aspect is an important consideration when assessing the environmental impact of performance modifications.

The manufacturing process of performance parts, including ported cylinder heads, also contributes to the environmental footprint. The production of these specialized components often requires additional energy and resources compared to standard parts, potentially increasing the overall carbon footprint of the vehicle.

It's worth noting that the environmental impact can vary significantly depending on the specific porting techniques used and the overall engine management strategy. Advanced porting designs that focus on optimizing flow efficiency while maintaining proper fuel mixture and combustion characteristics may mitigate some of the negative environmental effects.

Regulatory compliance is another critical factor. Performance modifications must adhere to increasingly stringent emissions standards, which can limit the extent of modifications or require additional emissions control measures. This regulatory landscape plays a crucial role in shaping the development and implementation of performance enhancement techniques.

In conclusion, while cylinder head porting techniques for the 2JZ engine offer potential performance benefits, their environmental impact is a complex issue that requires careful consideration. Balancing performance gains with environmental responsibility remains a key challenge for automotive engineers and enthusiasts alike.

Cylinder head porting, a technique used to optimize airflow in the engine, can lead to increased combustion efficiency. This improved efficiency can potentially reduce fuel consumption and, consequently, lower carbon dioxide emissions. However, the relationship between performance enhancements and environmental impact is complex and multifaceted.

One of the primary concerns is the potential increase in nitrogen oxide (NOx) emissions. As cylinder head porting allows for more air to enter the combustion chamber, it can result in higher combustion temperatures. These elevated temperatures are conducive to the formation of NOx, a major contributor to air pollution and smog formation.

Furthermore, the increased power output resulting from cylinder head porting may encourage more aggressive driving behaviors, potentially negating any fuel efficiency gains and leading to higher overall emissions. This behavioral aspect is an important consideration when assessing the environmental impact of performance modifications.

The manufacturing process of performance parts, including ported cylinder heads, also contributes to the environmental footprint. The production of these specialized components often requires additional energy and resources compared to standard parts, potentially increasing the overall carbon footprint of the vehicle.

It's worth noting that the environmental impact can vary significantly depending on the specific porting techniques used and the overall engine management strategy. Advanced porting designs that focus on optimizing flow efficiency while maintaining proper fuel mixture and combustion characteristics may mitigate some of the negative environmental effects.

Regulatory compliance is another critical factor. Performance modifications must adhere to increasingly stringent emissions standards, which can limit the extent of modifications or require additional emissions control measures. This regulatory landscape plays a crucial role in shaping the development and implementation of performance enhancement techniques.

In conclusion, while cylinder head porting techniques for the 2JZ engine offer potential performance benefits, their environmental impact is a complex issue that requires careful consideration. Balancing performance gains with environmental responsibility remains a key challenge for automotive engineers and enthusiasts alike.

Cost-Benefit Analysis of 2JZ Porting Techniques

The cost-benefit analysis of 2JZ porting techniques reveals a complex interplay between performance gains and financial investment. Initial costs for cylinder head porting can range from $1,000 to $3,000, depending on the extent of modifications and the expertise of the technician. This investment typically yields horsepower increases of 20-50 HP, with some high-end ports achieving gains of up to 70 HP.

Labor costs constitute a significant portion of the expense, often accounting for 60-70% of the total. The remaining costs are attributed to specialized tools and materials required for the porting process. Time investment is also considerable, with professional porting jobs taking anywhere from 15 to 40 hours, depending on the complexity and desired outcome.

Performance benefits extend beyond raw horsepower gains. Improved airflow resulting from porting can enhance throttle response, increase torque across the RPM range, and potentially improve fuel efficiency at cruising speeds. These improvements can translate to faster acceleration times and better overall engine performance.

However, the cost-effectiveness of porting varies based on the engine's current state and intended use. For stock or mildly modified 2JZ engines, the performance gains may not justify the expense. Conversely, for heavily modified engines or those used in competitive racing, porting becomes increasingly beneficial as it complements other performance upgrades.

Longevity considerations must also be factored into the analysis. While properly executed porting can maintain or even improve engine reliability, aggressive porting techniques may reduce the engine's lifespan or require more frequent maintenance. This potential increase in long-term costs should be weighed against the performance benefits.

Alternative performance upgrades, such as forced induction or camshaft replacements, may offer more substantial power gains for a similar investment. However, porting can be an excellent complementary modification to these upgrades, often unlocking additional performance potential.

In conclusion, the cost-benefit ratio of 2JZ porting techniques is highly dependent on the specific application and goals of the engine build. For enthusiasts seeking moderate performance gains with a focus on naturally aspirated power, porting can offer a worthwhile return on investment. However, for those prioritizing maximum power output or operating on a limited budget, other modifications may provide better value.

Labor costs constitute a significant portion of the expense, often accounting for 60-70% of the total. The remaining costs are attributed to specialized tools and materials required for the porting process. Time investment is also considerable, with professional porting jobs taking anywhere from 15 to 40 hours, depending on the complexity and desired outcome.

Performance benefits extend beyond raw horsepower gains. Improved airflow resulting from porting can enhance throttle response, increase torque across the RPM range, and potentially improve fuel efficiency at cruising speeds. These improvements can translate to faster acceleration times and better overall engine performance.

However, the cost-effectiveness of porting varies based on the engine's current state and intended use. For stock or mildly modified 2JZ engines, the performance gains may not justify the expense. Conversely, for heavily modified engines or those used in competitive racing, porting becomes increasingly beneficial as it complements other performance upgrades.

Longevity considerations must also be factored into the analysis. While properly executed porting can maintain or even improve engine reliability, aggressive porting techniques may reduce the engine's lifespan or require more frequent maintenance. This potential increase in long-term costs should be weighed against the performance benefits.

Alternative performance upgrades, such as forced induction or camshaft replacements, may offer more substantial power gains for a similar investment. However, porting can be an excellent complementary modification to these upgrades, often unlocking additional performance potential.

In conclusion, the cost-benefit ratio of 2JZ porting techniques is highly dependent on the specific application and goals of the engine build. For enthusiasts seeking moderate performance gains with a focus on naturally aspirated power, porting can offer a worthwhile return on investment. However, for those prioritizing maximum power output or operating on a limited budget, other modifications may provide better value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!