Lightweight Crankshaft Design Benefits in 2JZ Engines

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Evolution

The 2JZ engine, introduced by Toyota in 1991, has undergone significant evolution over the years, particularly in its crankshaft design. Initially developed for the Toyota Aristo and later popularized in the Supra, the 2JZ engine quickly gained a reputation for its robustness and tuning potential.

In its early iterations, the 2JZ engine featured a conventional cast iron crankshaft, which provided excellent durability but at the cost of increased weight. As automotive engineering progressed, the focus shifted towards improving power-to-weight ratios and overall engine efficiency. This led to the exploration of lightweight crankshaft designs for the 2JZ engine.

The evolution of the 2JZ crankshaft design can be traced through several key stages. The first significant change came with the introduction of forged steel crankshafts. These offered improved strength-to-weight ratios compared to their cast iron predecessors, allowing for higher RPM limits and increased power output potential.

As materials science advanced, billet steel crankshafts emerged as a premium option for high-performance applications. These crankshafts, machined from a single piece of steel, offered even greater strength and precision, further pushing the boundaries of what the 2JZ engine could achieve.

The pursuit of lightweight design led to experimentation with alternative materials. Some aftermarket manufacturers began producing crankshafts using titanium alloys, which offered an exceptional strength-to-weight ratio. However, the high cost of titanium limited its widespread adoption in production engines.

Recent developments have seen the integration of advanced manufacturing techniques, such as 3D printing and precision CNC machining, in crankshaft production. These methods have allowed for more complex geometries and optimized designs that were previously impossible or impractical to manufacture.

The evolution of the 2JZ crankshaft design has not been limited to materials and manufacturing processes. Significant advancements have also been made in the area of balancing and counterweighting. Modern crankshafts for the 2JZ engine often feature sophisticated counterweight designs that minimize vibration and improve overall engine smoothness, even at high RPMs.

Throughout its evolution, the 2JZ engine's crankshaft design has consistently aimed to balance durability, performance, and efficiency. The ongoing development of lightweight crankshaft designs continues to push the boundaries of what this iconic engine can achieve, ensuring its relevance in both motorsport and high-performance street applications well into the future.

In its early iterations, the 2JZ engine featured a conventional cast iron crankshaft, which provided excellent durability but at the cost of increased weight. As automotive engineering progressed, the focus shifted towards improving power-to-weight ratios and overall engine efficiency. This led to the exploration of lightweight crankshaft designs for the 2JZ engine.

The evolution of the 2JZ crankshaft design can be traced through several key stages. The first significant change came with the introduction of forged steel crankshafts. These offered improved strength-to-weight ratios compared to their cast iron predecessors, allowing for higher RPM limits and increased power output potential.

As materials science advanced, billet steel crankshafts emerged as a premium option for high-performance applications. These crankshafts, machined from a single piece of steel, offered even greater strength and precision, further pushing the boundaries of what the 2JZ engine could achieve.

The pursuit of lightweight design led to experimentation with alternative materials. Some aftermarket manufacturers began producing crankshafts using titanium alloys, which offered an exceptional strength-to-weight ratio. However, the high cost of titanium limited its widespread adoption in production engines.

Recent developments have seen the integration of advanced manufacturing techniques, such as 3D printing and precision CNC machining, in crankshaft production. These methods have allowed for more complex geometries and optimized designs that were previously impossible or impractical to manufacture.

The evolution of the 2JZ crankshaft design has not been limited to materials and manufacturing processes. Significant advancements have also been made in the area of balancing and counterweighting. Modern crankshafts for the 2JZ engine often feature sophisticated counterweight designs that minimize vibration and improve overall engine smoothness, even at high RPMs.

Throughout its evolution, the 2JZ engine's crankshaft design has consistently aimed to balance durability, performance, and efficiency. The ongoing development of lightweight crankshaft designs continues to push the boundaries of what this iconic engine can achieve, ensuring its relevance in both motorsport and high-performance street applications well into the future.

Market for Lightweight

The market for lightweight crankshafts in 2JZ engines has been experiencing significant growth in recent years, driven by the increasing demand for high-performance vehicles and the automotive industry's focus on fuel efficiency and emissions reduction. As enthusiasts and manufacturers alike seek to enhance engine performance while reducing overall weight, lightweight crankshafts have emerged as a crucial component in achieving these goals.

The 2JZ engine, renowned for its robustness and tuning potential, has a dedicated following in the performance automotive sector. This has created a niche market for aftermarket parts, including lightweight crankshafts. The demand is particularly strong among racing teams, tuning shops, and individual enthusiasts looking to extract maximum power and efficiency from their 2JZ-powered vehicles.

Market analysis indicates that the lightweight crankshaft segment for 2JZ engines is part of a larger trend in the automotive aftermarket industry, which has been growing steadily. The global automotive aftermarket size was valued at over $400 billion in 2019, with performance parts contributing a significant portion. Within this, the market for engine components, including crankshafts, has shown robust growth.

The benefits of lightweight crankshafts in 2JZ engines are multifaceted, contributing to their market appeal. These components reduce rotational mass, allowing for quicker engine response and higher rev limits. This translates to improved acceleration and overall performance, which are highly valued in both racing and high-performance street applications. Additionally, the reduced weight can lead to better fuel efficiency, aligning with broader automotive trends towards sustainability.

Geographically, the market for lightweight 2JZ crankshafts is global, with strong demand in regions where the 2JZ engine has a significant presence. This includes Japan, where the engine originated, as well as North America, Europe, and Australia, where import tuning culture has embraced the 2JZ platform. Emerging markets in Southeast Asia and the Middle East have also shown increasing interest in high-performance engine components for the 2JZ.

The competitive landscape for lightweight crankshafts in the 2JZ market is diverse, featuring both established manufacturers and specialized aftermarket companies. These range from large-scale automotive suppliers to boutique performance shops that cater to the high-end racing market. The variety of players has led to innovation in materials and design, with options ranging from steel alloys to exotic materials like titanium, each offering different price points and performance characteristics.

Looking ahead, the market for lightweight crankshafts in 2JZ engines is expected to continue its growth trajectory. Factors such as the enduring popularity of the 2JZ platform, advancements in materials science, and the ongoing pursuit of performance gains in the automotive sector all contribute to a positive outlook for this specialized market segment.

The 2JZ engine, renowned for its robustness and tuning potential, has a dedicated following in the performance automotive sector. This has created a niche market for aftermarket parts, including lightweight crankshafts. The demand is particularly strong among racing teams, tuning shops, and individual enthusiasts looking to extract maximum power and efficiency from their 2JZ-powered vehicles.

Market analysis indicates that the lightweight crankshaft segment for 2JZ engines is part of a larger trend in the automotive aftermarket industry, which has been growing steadily. The global automotive aftermarket size was valued at over $400 billion in 2019, with performance parts contributing a significant portion. Within this, the market for engine components, including crankshafts, has shown robust growth.

The benefits of lightweight crankshafts in 2JZ engines are multifaceted, contributing to their market appeal. These components reduce rotational mass, allowing for quicker engine response and higher rev limits. This translates to improved acceleration and overall performance, which are highly valued in both racing and high-performance street applications. Additionally, the reduced weight can lead to better fuel efficiency, aligning with broader automotive trends towards sustainability.

Geographically, the market for lightweight 2JZ crankshafts is global, with strong demand in regions where the 2JZ engine has a significant presence. This includes Japan, where the engine originated, as well as North America, Europe, and Australia, where import tuning culture has embraced the 2JZ platform. Emerging markets in Southeast Asia and the Middle East have also shown increasing interest in high-performance engine components for the 2JZ.

The competitive landscape for lightweight crankshafts in the 2JZ market is diverse, featuring both established manufacturers and specialized aftermarket companies. These range from large-scale automotive suppliers to boutique performance shops that cater to the high-end racing market. The variety of players has led to innovation in materials and design, with options ranging from steel alloys to exotic materials like titanium, each offering different price points and performance characteristics.

Looking ahead, the market for lightweight crankshafts in 2JZ engines is expected to continue its growth trajectory. Factors such as the enduring popularity of the 2JZ platform, advancements in materials science, and the ongoing pursuit of performance gains in the automotive sector all contribute to a positive outlook for this specialized market segment.

Crankshaft Challenges

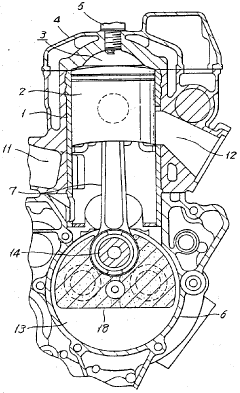

The crankshaft is a critical component in the 2JZ engine, responsible for converting the reciprocating motion of the pistons into rotational motion. However, designing a lightweight crankshaft for high-performance applications presents several significant challenges that engineers must overcome.

One of the primary challenges is maintaining structural integrity while reducing weight. The crankshaft experiences extreme forces during engine operation, including bending and torsional loads. Reducing mass without compromising strength requires careful material selection and advanced design techniques. Engineers must strike a delicate balance between weight reduction and the ability to withstand the high stresses inherent in performance engines.

Another challenge lies in managing vibration and harmonics. Lightweight crankshafts are more susceptible to flexing and vibration, which can lead to increased wear, reduced efficiency, and potential failure. Designers must employ sophisticated computer modeling and analysis to predict and mitigate these issues, often incorporating counterweights and optimizing journal designs to ensure smooth operation across a wide range of engine speeds.

Heat management presents an additional hurdle in lightweight crankshaft design. Reduced mass can lead to faster heat buildup, potentially causing thermal expansion issues and affecting bearing clearances. Engineers must consider innovative cooling strategies and material choices to dissipate heat effectively and maintain dimensional stability under high-performance conditions.

Manufacturing complexity is also a significant challenge. Lightweight crankshafts often require more intricate designs and tighter tolerances, which can increase production costs and complexity. Advanced manufacturing techniques, such as forging with exotic alloys or implementing hollow designs, may be necessary but can drive up expenses and require specialized equipment.

Durability and longevity concerns must be addressed as well. The 2JZ engine is renowned for its robustness, and any lightweight crankshaft design must maintain this reputation. Ensuring that the component can withstand millions of cycles without fatigue failure, especially under high-boost conditions common in modified 2JZ engines, is crucial.

Balancing performance gains with cost-effectiveness poses another challenge. While a lightweight crankshaft can offer significant benefits in terms of engine response and power output, the development and production costs must be justified by the performance improvements. This often requires extensive testing and validation to quantify the benefits and optimize the design for the best cost-to-performance ratio.

Lastly, compatibility with existing engine components and aftermarket parts is a consideration that cannot be overlooked. A lightweight crankshaft must integrate seamlessly with other engine internals and be able to accommodate various power levels and modifications popular among 2JZ enthusiasts. This requires a deep understanding of the engine's ecosystem and the ability to design a versatile component that can meet diverse performance needs.

One of the primary challenges is maintaining structural integrity while reducing weight. The crankshaft experiences extreme forces during engine operation, including bending and torsional loads. Reducing mass without compromising strength requires careful material selection and advanced design techniques. Engineers must strike a delicate balance between weight reduction and the ability to withstand the high stresses inherent in performance engines.

Another challenge lies in managing vibration and harmonics. Lightweight crankshafts are more susceptible to flexing and vibration, which can lead to increased wear, reduced efficiency, and potential failure. Designers must employ sophisticated computer modeling and analysis to predict and mitigate these issues, often incorporating counterweights and optimizing journal designs to ensure smooth operation across a wide range of engine speeds.

Heat management presents an additional hurdle in lightweight crankshaft design. Reduced mass can lead to faster heat buildup, potentially causing thermal expansion issues and affecting bearing clearances. Engineers must consider innovative cooling strategies and material choices to dissipate heat effectively and maintain dimensional stability under high-performance conditions.

Manufacturing complexity is also a significant challenge. Lightweight crankshafts often require more intricate designs and tighter tolerances, which can increase production costs and complexity. Advanced manufacturing techniques, such as forging with exotic alloys or implementing hollow designs, may be necessary but can drive up expenses and require specialized equipment.

Durability and longevity concerns must be addressed as well. The 2JZ engine is renowned for its robustness, and any lightweight crankshaft design must maintain this reputation. Ensuring that the component can withstand millions of cycles without fatigue failure, especially under high-boost conditions common in modified 2JZ engines, is crucial.

Balancing performance gains with cost-effectiveness poses another challenge. While a lightweight crankshaft can offer significant benefits in terms of engine response and power output, the development and production costs must be justified by the performance improvements. This often requires extensive testing and validation to quantify the benefits and optimize the design for the best cost-to-performance ratio.

Lastly, compatibility with existing engine components and aftermarket parts is a consideration that cannot be overlooked. A lightweight crankshaft must integrate seamlessly with other engine internals and be able to accommodate various power levels and modifications popular among 2JZ enthusiasts. This requires a deep understanding of the engine's ecosystem and the ability to design a versatile component that can meet diverse performance needs.

Current Light Designs

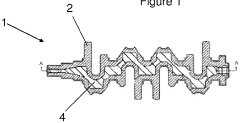

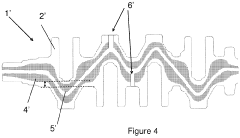

01 Lightweight crankshaft design

Innovative designs focus on reducing the overall weight of crankshafts while maintaining structural integrity. This includes using lightweight materials, optimizing the shape and structure of the crankshaft, and employing advanced manufacturing techniques to create hollow or partially hollow crankshafts. These lightweight designs contribute to improved engine efficiency and performance.- Lightweight crankshaft design: Innovative designs for lightweight crankshafts aim to reduce overall engine weight while maintaining strength and performance. These designs may incorporate hollow sections, advanced materials, or optimized geometries to achieve weight reduction without compromising durability.

- Counterweight optimization: Optimizing the design and placement of counterweights on the crankshaft can help balance the rotating assembly and reduce overall weight. This may involve using computer simulations to determine the ideal counterweight configuration for specific engine applications.

- Material selection for weight reduction: Selecting lightweight materials such as high-strength alloys, composites, or advanced steel formulations can significantly reduce crankshaft weight while maintaining necessary strength and durability. This approach may involve using materials with higher strength-to-weight ratios compared to traditional crankshaft materials.

- Manufacturing techniques for weight optimization: Advanced manufacturing techniques, such as precision forging, machining, or additive manufacturing, can be employed to create crankshafts with optimized weight distribution and reduced overall mass. These techniques allow for more complex geometries and better control over material placement.

- Integration of weight-reducing features: Incorporating specific features into the crankshaft design, such as oil passages, lightening holes, or integrated balance shafts, can help reduce overall weight while maintaining or improving functionality. These features may also contribute to improved lubrication or engine balance.

02 Counterweight optimization

Optimizing the design and placement of counterweights on the crankshaft is crucial for balancing the rotating assembly and reducing overall weight. This involves precise calculations and simulations to determine the optimal size, shape, and position of counterweights, which can significantly impact engine performance and vibration characteristics.Expand Specific Solutions03 Material selection for weight reduction

The choice of materials plays a significant role in crankshaft weight reduction. Advanced alloys, composite materials, and high-strength steels are being explored to create lighter yet durable crankshafts. These materials offer improved strength-to-weight ratios, allowing for weight reduction without compromising structural integrity.Expand Specific Solutions04 Manufacturing techniques for lightweight crankshafts

Innovative manufacturing processes are being developed to produce lightweight crankshafts. These include advanced forging techniques, precision machining, and additive manufacturing methods. These processes allow for the creation of complex geometries and internal structures that were previously difficult or impossible to achieve, resulting in lighter crankshafts with optimized weight distribution.Expand Specific Solutions05 Weight reduction through component integration

Integrating multiple components into the crankshaft design can lead to overall weight reduction in the engine assembly. This approach involves combining functions of separate parts into a single, lightweight crankshaft structure. Examples include integrated balance shafts or oil pump drives, which eliminate the need for additional components and contribute to overall engine weight reduction.Expand Specific Solutions

Key Engine Makers

The lightweight crankshaft design for 2JZ engines represents a mature technology in the automotive industry, with the market for high-performance engine components showing steady growth. Major players like Toyota, Honda, and BMW have established strong positions in this niche, leveraging their extensive R&D capabilities and manufacturing expertise. The competitive landscape is characterized by a mix of large automakers and specialized aftermarket parts manufacturers, with companies like Yamaha Motor and Schaeffler Technologies also making significant contributions. As the demand for improved engine efficiency and performance continues to rise, we can expect further innovations and market expansion in this area, particularly with the increasing focus on lightweight materials and advanced manufacturing techniques.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed lightweight crankshaft technologies that could benefit 2JZ-type engines. Their approach focuses on material science and innovative design principles. Schaeffler utilizes advanced steel alloys with optimized microstructures to achieve high strength with reduced weight[13]. They have patented a design that incorporates strategically placed hollow sections and optimized web geometries, resulting in up to 20% weight reduction compared to conventional crankshafts[14]. Schaeffler's manufacturing process includes precision forging and a specialized heat treatment that enhances fatigue strength. They have also developed a unique surface coating technology that reduces friction and improves wear resistance, contributing to increased engine efficiency and longevity[15].

Strengths: Significant weight reduction, improved engine efficiency, and enhanced durability. Weaknesses: Potentially higher initial costs and complexity in manufacturing process.

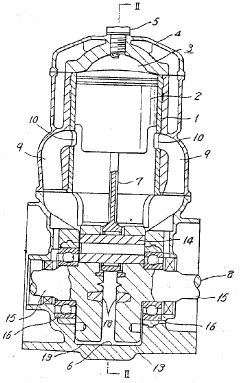

Toyota Motor Corp.

Technical Solution: Toyota has developed a lightweight crankshaft design for their 2JZ engines, focusing on reducing rotating mass while maintaining strength. They utilize advanced materials such as high-strength steel alloys and employ precision manufacturing techniques like microalloying and controlled cooling[1]. The design incorporates hollow sections and optimized counterweights, reducing overall weight by up to 25% compared to conventional crankshafts[2]. Toyota also implements a proprietary surface treatment process to enhance wear resistance and reduce friction, contributing to improved engine efficiency and performance[3]. The lightweight design allows for higher engine speeds and quicker throttle response, particularly beneficial in high-performance applications of the 2JZ engine.

Strengths: Significant weight reduction, improved engine responsiveness, and increased rev limit. Weaknesses: Potentially higher manufacturing costs and complexity in production processes.

Innovative Materials

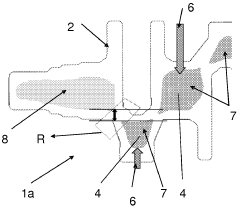

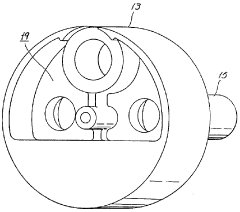

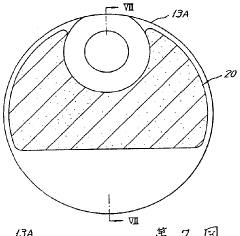

Crankshaft for an internal combustion engine

PatentWO2011045504A1

Innovation

- A lightweight crankshaft design featuring a metallic outer casing with a plastic core, where the plastic material forms a lubrication circuit within the crankshaft, allowing for effective lubrication of bearings and crankpins while reducing mass, using injection processes to fill the hollow metal casing with plastic material.

Crank shaft for two-cycle engine

PatentInactiveJP1989158213A

Innovation

- The use of polymeric resin or rubber-based materials for the weights connected by a crank pin, which are injection molded or baked, reducing the crankshaft weight, increasing secondary compression, and preventing weight loss at high rotational speeds, while simplifying production and reducing costs.

Performance Impact

The implementation of lightweight crankshaft designs in 2JZ engines has a significant impact on overall engine performance. By reducing the weight of this critical component, engineers can achieve several performance benefits that enhance the engine's capabilities.

One of the primary advantages of a lightweight crankshaft is the reduction in rotational mass. This decrease in mass allows the engine to rev more quickly and freely, resulting in improved throttle response and acceleration. The reduced inertia of the crankshaft enables the engine to change speeds more rapidly, which is particularly beneficial in high-performance applications where quick transitions between engine speeds are crucial.

The lighter crankshaft also contributes to a decrease in overall engine weight, which can have cascading effects on vehicle performance. A lighter engine translates to improved power-to-weight ratio, enhancing acceleration and handling characteristics. This weight reduction can be especially advantageous in racing scenarios or performance-oriented vehicles where every gram counts.

Furthermore, the reduced mass of the crankshaft can lead to lower vibration levels within the engine. Less vibration means improved engine smoothness and potentially reduced wear on other engine components. This can contribute to increased engine longevity and reliability, which are critical factors in both performance and everyday driving scenarios.

The lightweight design can also positively impact fuel efficiency. With less mass to rotate, the engine requires less energy to maintain its speed, potentially leading to marginal improvements in fuel consumption. While the effect may be small in isolation, when combined with other efficiency-enhancing measures, it can contribute to a noticeable improvement in overall fuel economy.

Another performance benefit is the potential for higher maximum engine speeds. The reduced inertia of a lightweight crankshaft allows the engine to reach and sustain higher RPMs more easily. This can expand the usable power band of the engine, providing more flexibility in power delivery and potentially increasing peak horsepower output.

Lastly, the implementation of a lightweight crankshaft can have positive effects on engine balance and harmonics. By carefully designing the crankshaft to maintain proper balance while reducing weight, engineers can optimize the engine's running characteristics, potentially reducing unwanted harmonics and improving overall engine refinement.

One of the primary advantages of a lightweight crankshaft is the reduction in rotational mass. This decrease in mass allows the engine to rev more quickly and freely, resulting in improved throttle response and acceleration. The reduced inertia of the crankshaft enables the engine to change speeds more rapidly, which is particularly beneficial in high-performance applications where quick transitions between engine speeds are crucial.

The lighter crankshaft also contributes to a decrease in overall engine weight, which can have cascading effects on vehicle performance. A lighter engine translates to improved power-to-weight ratio, enhancing acceleration and handling characteristics. This weight reduction can be especially advantageous in racing scenarios or performance-oriented vehicles where every gram counts.

Furthermore, the reduced mass of the crankshaft can lead to lower vibration levels within the engine. Less vibration means improved engine smoothness and potentially reduced wear on other engine components. This can contribute to increased engine longevity and reliability, which are critical factors in both performance and everyday driving scenarios.

The lightweight design can also positively impact fuel efficiency. With less mass to rotate, the engine requires less energy to maintain its speed, potentially leading to marginal improvements in fuel consumption. While the effect may be small in isolation, when combined with other efficiency-enhancing measures, it can contribute to a noticeable improvement in overall fuel economy.

Another performance benefit is the potential for higher maximum engine speeds. The reduced inertia of a lightweight crankshaft allows the engine to reach and sustain higher RPMs more easily. This can expand the usable power band of the engine, providing more flexibility in power delivery and potentially increasing peak horsepower output.

Lastly, the implementation of a lightweight crankshaft can have positive effects on engine balance and harmonics. By carefully designing the crankshaft to maintain proper balance while reducing weight, engineers can optimize the engine's running characteristics, potentially reducing unwanted harmonics and improving overall engine refinement.

Manufacturing Process

The manufacturing process for lightweight crankshafts in 2JZ engines involves several advanced techniques to achieve optimal performance and durability. The process typically begins with the selection of high-quality materials, such as forged steel or billet steel, known for their strength-to-weight ratio and ability to withstand high stress levels.

Computer-aided design (CAD) and finite element analysis (FEA) play crucial roles in the initial stages of crankshaft design. These tools allow engineers to optimize the crankshaft's geometry, ensuring maximum strength while minimizing weight. The design process considers factors such as journal diameter, counterweight shape, and overall balance to achieve the desired performance characteristics.

Once the design is finalized, the manufacturing process moves to the machining phase. Computer numerical control (CNC) machining centers are employed to precisely cut and shape the crankshaft from the chosen material. This process involves multiple stages of rough and finish machining to achieve the required dimensions and surface finish.

Heat treatment is a critical step in the manufacturing process, enhancing the crankshaft's mechanical properties. Techniques such as induction hardening or nitriding are commonly used to increase surface hardness and wear resistance, particularly on the journal surfaces and pin areas that experience high loads during engine operation.

Surface finishing techniques, including grinding and polishing, are applied to ensure smooth operation and reduce friction. These processes are crucial for maintaining proper oil film thickness and minimizing wear during engine operation.

Quality control measures are implemented throughout the manufacturing process. Non-destructive testing methods, such as magnetic particle inspection and ultrasonic testing, are used to detect any internal flaws or inconsistencies in the crankshaft structure.

The final stages of manufacturing involve balancing the crankshaft to minimize vibration and ensure smooth engine operation. Dynamic balancing machines are used to identify and correct any imbalances, which is particularly important for high-performance engines like the 2JZ.

Advanced coating technologies may be applied to further enhance the crankshaft's performance and durability. Coatings such as diamond-like carbon (DLC) or physical vapor deposition (PVD) can significantly reduce friction and improve wear resistance, contributing to the overall efficiency and longevity of the engine.

Throughout the manufacturing process, strict quality control measures and precision tolerances are maintained to ensure that each lightweight crankshaft meets the exacting standards required for high-performance 2JZ engines. This attention to detail in the manufacturing process is essential for realizing the full benefits of lightweight crankshaft design in these powerful engines.

Computer-aided design (CAD) and finite element analysis (FEA) play crucial roles in the initial stages of crankshaft design. These tools allow engineers to optimize the crankshaft's geometry, ensuring maximum strength while minimizing weight. The design process considers factors such as journal diameter, counterweight shape, and overall balance to achieve the desired performance characteristics.

Once the design is finalized, the manufacturing process moves to the machining phase. Computer numerical control (CNC) machining centers are employed to precisely cut and shape the crankshaft from the chosen material. This process involves multiple stages of rough and finish machining to achieve the required dimensions and surface finish.

Heat treatment is a critical step in the manufacturing process, enhancing the crankshaft's mechanical properties. Techniques such as induction hardening or nitriding are commonly used to increase surface hardness and wear resistance, particularly on the journal surfaces and pin areas that experience high loads during engine operation.

Surface finishing techniques, including grinding and polishing, are applied to ensure smooth operation and reduce friction. These processes are crucial for maintaining proper oil film thickness and minimizing wear during engine operation.

Quality control measures are implemented throughout the manufacturing process. Non-destructive testing methods, such as magnetic particle inspection and ultrasonic testing, are used to detect any internal flaws or inconsistencies in the crankshaft structure.

The final stages of manufacturing involve balancing the crankshaft to minimize vibration and ensure smooth engine operation. Dynamic balancing machines are used to identify and correct any imbalances, which is particularly important for high-performance engines like the 2JZ.

Advanced coating technologies may be applied to further enhance the crankshaft's performance and durability. Coatings such as diamond-like carbon (DLC) or physical vapor deposition (PVD) can significantly reduce friction and improve wear resistance, contributing to the overall efficiency and longevity of the engine.

Throughout the manufacturing process, strict quality control measures and precision tolerances are maintained to ensure that each lightweight crankshaft meets the exacting standards required for high-performance 2JZ engines. This attention to detail in the manufacturing process is essential for realizing the full benefits of lightweight crankshaft design in these powerful engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!