Influence of Camshaft Profiles on 2JZ Engine Torque Characteristics

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Camshaft Evolution

The evolution of camshaft profiles for the 2JZ engine represents a significant chapter in automotive engineering, showcasing the continuous pursuit of enhanced performance and efficiency. The 2JZ engine, renowned for its robustness and tuning potential, has undergone several iterations of camshaft design since its inception in the early 1990s.

Initially, the 2JZ engine was equipped with relatively conservative camshaft profiles, prioritizing reliability and smooth operation across a wide range of engine speeds. These early designs featured moderate lift and duration characteristics, balancing low-end torque with high-end power. As the engine gained popularity among enthusiasts and tuners, the demand for more aggressive camshaft profiles grew.

The mid-1990s saw the introduction of aftermarket camshafts with increased lift and duration, aimed at improving high-RPM performance. These modifications often came at the expense of low-end torque and idle quality, but they allowed the 2JZ to produce significantly more power in the upper rev range. This trend continued into the early 2000s, with even more extreme camshaft profiles being developed for racing applications.

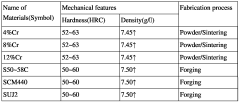

A pivotal moment in 2JZ camshaft evolution came with the advent of variable valve timing (VVT) technology. Toyota's implementation of VVT-i (Variable Valve Timing with intelligence) allowed for dynamic adjustment of camshaft timing, significantly improving the engine's versatility. This technology enabled the 2JZ to maintain strong low-end torque while still delivering impressive high-end power, effectively bridging the gap between street and race applications.

As materials science and manufacturing techniques advanced, so did the potential for more precise and durable camshaft designs. The introduction of roller lifters and improved valve spring technology allowed for even more aggressive camshaft profiles without sacrificing reliability. This led to a new generation of camshafts that could sustain higher engine speeds and produce more power across the entire RPM range.

Recent developments in camshaft technology for the 2JZ engine have focused on optimizing valve lift curves and timing for specific applications. Computer-aided design and simulation tools have enabled engineers to fine-tune camshaft profiles with unprecedented precision, tailoring them to meet specific performance goals while minimizing trade-offs in other areas of engine operation.

The latest trend in 2JZ camshaft evolution involves the integration of advanced materials such as titanium and ceramic coatings. These innovations have further reduced friction and wear, allowing for even more aggressive camshaft designs that can withstand the extreme conditions of high-performance applications. Additionally, the use of 3D printing technology has opened up new possibilities for rapid prototyping and testing of novel camshaft profiles, accelerating the pace of innovation in this field.

Initially, the 2JZ engine was equipped with relatively conservative camshaft profiles, prioritizing reliability and smooth operation across a wide range of engine speeds. These early designs featured moderate lift and duration characteristics, balancing low-end torque with high-end power. As the engine gained popularity among enthusiasts and tuners, the demand for more aggressive camshaft profiles grew.

The mid-1990s saw the introduction of aftermarket camshafts with increased lift and duration, aimed at improving high-RPM performance. These modifications often came at the expense of low-end torque and idle quality, but they allowed the 2JZ to produce significantly more power in the upper rev range. This trend continued into the early 2000s, with even more extreme camshaft profiles being developed for racing applications.

A pivotal moment in 2JZ camshaft evolution came with the advent of variable valve timing (VVT) technology. Toyota's implementation of VVT-i (Variable Valve Timing with intelligence) allowed for dynamic adjustment of camshaft timing, significantly improving the engine's versatility. This technology enabled the 2JZ to maintain strong low-end torque while still delivering impressive high-end power, effectively bridging the gap between street and race applications.

As materials science and manufacturing techniques advanced, so did the potential for more precise and durable camshaft designs. The introduction of roller lifters and improved valve spring technology allowed for even more aggressive camshaft profiles without sacrificing reliability. This led to a new generation of camshafts that could sustain higher engine speeds and produce more power across the entire RPM range.

Recent developments in camshaft technology for the 2JZ engine have focused on optimizing valve lift curves and timing for specific applications. Computer-aided design and simulation tools have enabled engineers to fine-tune camshaft profiles with unprecedented precision, tailoring them to meet specific performance goals while minimizing trade-offs in other areas of engine operation.

The latest trend in 2JZ camshaft evolution involves the integration of advanced materials such as titanium and ceramic coatings. These innovations have further reduced friction and wear, allowing for even more aggressive camshaft designs that can withstand the extreme conditions of high-performance applications. Additionally, the use of 3D printing technology has opened up new possibilities for rapid prototyping and testing of novel camshaft profiles, accelerating the pace of innovation in this field.

Market Demand for Enhanced Engine Performance

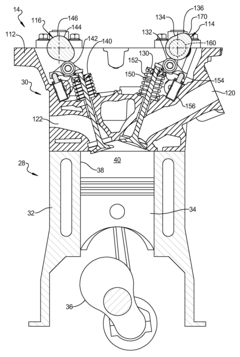

The market demand for enhanced engine performance, particularly in relation to the 2JZ engine and its camshaft profiles, has been steadily growing in recent years. This demand is driven by several factors, including the increasing popularity of motorsports, the rise of car enthusiast culture, and the continuous pursuit of improved fuel efficiency and power output in the automotive industry.

The 2JZ engine, originally developed by Toyota, has gained a cult following among car enthusiasts and tuners due to its robust design and high potential for modification. As a result, there is a significant market for aftermarket parts and performance upgrades, with camshaft profiles being a key area of interest for those seeking to optimize engine performance.

In the professional racing sector, teams and drivers are constantly seeking ways to extract maximum performance from their engines. The ability to fine-tune camshaft profiles offers a competitive edge, allowing for precise control over valve timing and duration. This level of customization can lead to improved torque characteristics, which is crucial for achieving better acceleration and overall performance on the track.

The aftermarket tuning industry has also seen a surge in demand for camshaft profile modifications. Enthusiasts and hobbyists are increasingly looking to enhance their vehicles' performance, with many focusing on the 2JZ engine due to its legendary status and potential for high-power outputs. This has led to a proliferation of specialized camshaft manufacturers and tuning shops offering custom profiles tailored to specific performance goals.

Furthermore, the growing trend of engine swaps, where enthusiasts install 2JZ engines into various vehicle platforms, has expanded the market for performance-enhancing components. As these engines find their way into a diverse range of vehicles, the demand for camshaft profiles that can optimize torque characteristics across different applications has increased.

The automotive industry's shift towards more efficient and powerful engines has also contributed to the market demand. While the 2JZ engine is no longer in production for new vehicles, the lessons learned from optimizing its performance continue to influence modern engine design. Manufacturers are investing in research and development to create camshaft profiles that can deliver improved torque characteristics while meeting stringent emissions standards.

As environmental concerns become more prominent, there is a growing interest in camshaft profiles that can enhance engine efficiency without sacrificing performance. This has led to increased demand for innovative solutions that can optimize the balance between power output and fuel consumption, particularly in the context of the 2JZ engine's legacy and its modern applications.

The 2JZ engine, originally developed by Toyota, has gained a cult following among car enthusiasts and tuners due to its robust design and high potential for modification. As a result, there is a significant market for aftermarket parts and performance upgrades, with camshaft profiles being a key area of interest for those seeking to optimize engine performance.

In the professional racing sector, teams and drivers are constantly seeking ways to extract maximum performance from their engines. The ability to fine-tune camshaft profiles offers a competitive edge, allowing for precise control over valve timing and duration. This level of customization can lead to improved torque characteristics, which is crucial for achieving better acceleration and overall performance on the track.

The aftermarket tuning industry has also seen a surge in demand for camshaft profile modifications. Enthusiasts and hobbyists are increasingly looking to enhance their vehicles' performance, with many focusing on the 2JZ engine due to its legendary status and potential for high-power outputs. This has led to a proliferation of specialized camshaft manufacturers and tuning shops offering custom profiles tailored to specific performance goals.

Furthermore, the growing trend of engine swaps, where enthusiasts install 2JZ engines into various vehicle platforms, has expanded the market for performance-enhancing components. As these engines find their way into a diverse range of vehicles, the demand for camshaft profiles that can optimize torque characteristics across different applications has increased.

The automotive industry's shift towards more efficient and powerful engines has also contributed to the market demand. While the 2JZ engine is no longer in production for new vehicles, the lessons learned from optimizing its performance continue to influence modern engine design. Manufacturers are investing in research and development to create camshaft profiles that can deliver improved torque characteristics while meeting stringent emissions standards.

As environmental concerns become more prominent, there is a growing interest in camshaft profiles that can enhance engine efficiency without sacrificing performance. This has led to increased demand for innovative solutions that can optimize the balance between power output and fuel consumption, particularly in the context of the 2JZ engine's legacy and its modern applications.

Current Camshaft Technology Limitations

The current limitations of camshaft technology in the context of the 2JZ engine's torque characteristics primarily revolve around the fixed nature of traditional camshaft designs. Conventional camshafts have a predetermined profile that remains constant throughout the engine's operation, which restricts the ability to optimize valve timing and lift across different engine speeds and load conditions.

One significant limitation is the trade-off between low-end torque and high-end power. Camshaft profiles designed for improved low-end torque typically feature less aggressive lobe profiles with shorter duration and lower lift. While this enhances low-rpm performance, it can limit the engine's ability to breathe efficiently at higher rpms, potentially sacrificing peak power output.

Conversely, camshafts optimized for high-end power often have more aggressive profiles with longer duration and higher lift. These designs can compromise low-end torque and idle stability, leading to a less versatile engine performance across the entire rpm range. This limitation is particularly relevant for the 2JZ engine, which is known for its broad powerband and adaptability to various applications.

Another constraint is the inability to adjust valve timing and lift in real-time based on engine operating conditions. This lack of adaptability means that the camshaft profile must be a compromise, balancing performance across various scenarios rather than optimizing for specific conditions on-the-fly.

The fixed overlap between the intake and exhaust valves also presents a challenge. While some overlap can improve cylinder scavenging at high rpms, excessive overlap at low rpms can lead to poor combustion efficiency and increased emissions. The inability to dynamically adjust this overlap limits the engine's potential for both performance and efficiency gains.

Furthermore, the mechanical nature of traditional camshafts introduces limitations in terms of precision and consistency. Manufacturing tolerances, wear over time, and the inherent flexibility of the valvetrain components can all contribute to deviations from the intended valve actuation profile, potentially impacting the engine's torque characteristics and overall performance.

Lastly, the physical constraints of the camshaft itself, including its mass and rotational inertia, can limit the maximum engine speed and the rate at which valve events can occur. This can restrict the potential for further increases in engine performance, particularly in high-performance applications where every fraction of a second in valve timing can make a significant difference.

One significant limitation is the trade-off between low-end torque and high-end power. Camshaft profiles designed for improved low-end torque typically feature less aggressive lobe profiles with shorter duration and lower lift. While this enhances low-rpm performance, it can limit the engine's ability to breathe efficiently at higher rpms, potentially sacrificing peak power output.

Conversely, camshafts optimized for high-end power often have more aggressive profiles with longer duration and higher lift. These designs can compromise low-end torque and idle stability, leading to a less versatile engine performance across the entire rpm range. This limitation is particularly relevant for the 2JZ engine, which is known for its broad powerband and adaptability to various applications.

Another constraint is the inability to adjust valve timing and lift in real-time based on engine operating conditions. This lack of adaptability means that the camshaft profile must be a compromise, balancing performance across various scenarios rather than optimizing for specific conditions on-the-fly.

The fixed overlap between the intake and exhaust valves also presents a challenge. While some overlap can improve cylinder scavenging at high rpms, excessive overlap at low rpms can lead to poor combustion efficiency and increased emissions. The inability to dynamically adjust this overlap limits the engine's potential for both performance and efficiency gains.

Furthermore, the mechanical nature of traditional camshafts introduces limitations in terms of precision and consistency. Manufacturing tolerances, wear over time, and the inherent flexibility of the valvetrain components can all contribute to deviations from the intended valve actuation profile, potentially impacting the engine's torque characteristics and overall performance.

Lastly, the physical constraints of the camshaft itself, including its mass and rotational inertia, can limit the maximum engine speed and the rate at which valve events can occur. This can restrict the potential for further increases in engine performance, particularly in high-performance applications where every fraction of a second in valve timing can make a significant difference.

Existing Camshaft Profile Solutions

01 Torque control and optimization

The 2JZ engine's torque characteristics can be controlled and optimized through various methods. These include adjusting fuel injection timing, modifying ignition timing, and implementing advanced engine management systems. Such optimizations can lead to improved engine performance, fuel efficiency, and overall drivability.- Engine torque control systems: Advanced control systems are employed to manage and optimize the torque characteristics of the 2JZ engine. These systems utilize various sensors and algorithms to adjust engine parameters in real-time, ensuring optimal performance across different operating conditions. The control systems can modulate factors such as fuel injection, ignition timing, and valve timing to achieve desired torque output and efficiency.

- Turbocharger integration for torque enhancement: The 2JZ engine's torque characteristics are significantly influenced by its turbocharger system. Turbocharging allows for increased air intake, resulting in higher combustion efficiency and torque output. Advanced turbocharger designs and control strategies are implemented to minimize turbo lag and provide a broader torque band across the engine's RPM range.

- Variable valve timing for torque optimization: Variable valve timing (VVT) technology is utilized in the 2JZ engine to optimize torque characteristics. By adjusting the timing of valve opening and closing based on engine speed and load, VVT systems can enhance low-end torque, improve high-end power, and increase overall engine efficiency. This technology contributes to the engine's reputation for smooth power delivery across a wide RPM range.

- Fuel injection and combustion optimization: The 2JZ engine's torque characteristics are further enhanced through advanced fuel injection and combustion optimization techniques. Precise control of fuel injection timing, duration, and pressure allows for improved fuel atomization and mixture formation. This results in more efficient combustion, leading to increased torque output and better fuel economy across various engine operating conditions.

- Engine mapping and calibration for torque management: Extensive engine mapping and calibration processes are employed to fine-tune the 2JZ engine's torque characteristics. These processes involve creating detailed performance maps that define optimal engine parameters for various operating conditions. Advanced calibration techniques are used to balance factors such as power output, fuel efficiency, and emissions, resulting in a well-rounded torque profile that suits different driving scenarios.

02 Turbocharger integration

The 2JZ engine's torque output can be significantly enhanced through the integration of turbochargers. Proper turbocharger sizing, boost control, and intercooling systems are crucial for maximizing torque across the engine's RPM range while maintaining reliability.Expand Specific Solutions03 Variable valve timing

Implementing variable valve timing (VVT) technology in the 2JZ engine can greatly influence its torque characteristics. VVT allows for optimized valve timing across different engine speeds and loads, resulting in improved low-end torque and high-end power output.Expand Specific Solutions04 Engine mapping and calibration

Precise engine mapping and calibration are essential for maximizing the 2JZ engine's torque output. This involves fine-tuning various parameters such as air-fuel ratios, ignition timing, and boost pressure across different operating conditions to achieve optimal torque characteristics.Expand Specific Solutions05 Torque measurement and analysis

Accurate measurement and analysis of the 2JZ engine's torque output are crucial for performance evaluation and optimization. Advanced dynamometer testing, real-time torque sensors, and data acquisition systems can be employed to gather detailed information about the engine's torque characteristics under various operating conditions.Expand Specific Solutions

Key Players in Performance Camshaft Industry

The competition landscape for "Influence of Camshaft Profiles on 2JZ Engine Torque Characteristics" is in a mature stage, with established players dominating the market. The global automotive camshaft market size is substantial, driven by increasing vehicle production and demand for high-performance engines. Technologically, the field is well-developed, with companies like GM Global Technology Operations, ThyssenKrupp Presta TecCenter, and Robert Bosch GmbH leading in innovation. Major automakers such as Mercedes-Benz, Ford, and Toyota are actively involved in camshaft profile optimization for their engines, including the 2JZ. Specialized firms like AVL List GmbH contribute advanced simulation and testing capabilities, while academic institutions like the University of Sussex provide research support.

Robert Bosch GmbH

Technical Solution: Bosch has developed a variable camshaft system called Valvetronic for optimizing engine torque characteristics. This system allows for continuous and precise adjustment of valve lift, effectively replacing the traditional throttle valve. By varying the camshaft profile dynamically, Bosch's technology can significantly influence the 2JZ engine's torque curve[4]. The system uses an eccentric shaft driven by an electric motor to adjust the valve lift, allowing for a range of 0.3 to 9.7 mm lift[5]. This precise control enables the engine to operate more efficiently across various load conditions, improving both performance and fuel economy. Bosch's camshaft profile design also incorporates advanced materials and coatings to reduce friction and wear, further enhancing the system's durability and efficiency[6].

Strengths: Highly precise valve control, improved fuel efficiency, and reduced pumping losses. Weaknesses: Increased system complexity and potential for higher production costs.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a sophisticated camshaft profile system for enhancing engine torque characteristics, which could be applied to engines like the 2JZ. Their CAMTRONIC system features two-stage switchable cam lobes, allowing for variable valve lift[7]. This technology enables the engine to switch between different camshaft profiles optimized for low and high engine speeds. The system uses electro-hydraulic actuators to shift between the two cam lobe profiles rapidly, providing optimal valve timing and lift for different operating conditions[8]. Mercedes-Benz has also implemented a continuous camshaft phaser system that works in conjunction with CAMTRONIC, allowing for even finer control over valve events. This combination results in improved torque delivery across the entire engine speed range, enhanced fuel efficiency, and reduced emissions[9].

Strengths: Flexible torque characteristics, improved fuel efficiency, and reduced emissions. Weaknesses: Increased mechanical complexity and potential for higher manufacturing costs.

Innovative Camshaft Design Patents

Lightweight aluminum camshaft and manufacturing method thereof

PatentWO2006041255A1

Innovation

- A lightweight aluminum camshaft is developed using separately fabricated cam pieces made from sintering metal or alloy, which are inserted into a mold and integrated with an aluminum shaft portion through die casting, enhancing durability and strength while allowing for optimal oil supply and reduced weight.

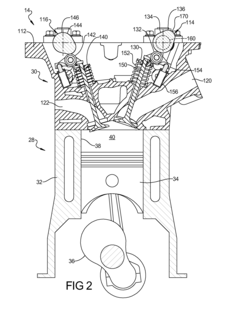

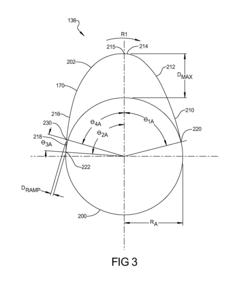

Camshaft profile for reducing cylinder pressures during engine cranking

PatentInactiveUS8333173B2

Innovation

- A camshaft assembly with a lobe member featuring a valve closing profile that includes a closing flank and a ramp with a radial extent less than 10% of the peak, engaged for at least 80 degrees of crankshaft rotation, allowing controlled intake valve closure and maintaining the valve open for 160 degrees, reducing cranking compression and torque loss.

Emissions Regulations Impact

The impact of emissions regulations on camshaft profiles and engine torque characteristics has become increasingly significant in recent years. As environmental concerns grow, governments worldwide have implemented stricter emissions standards, forcing automotive manufacturers to adapt their engine designs. These regulations have had a profound effect on the development of camshaft profiles for engines like the 2JZ, as engineers strive to balance performance with compliance.

Emissions regulations primarily target the reduction of harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. To meet these standards, manufacturers have had to optimize combustion processes, which directly influences camshaft design. The camshaft profile plays a crucial role in controlling valve timing and duration, affecting the engine's breathing characteristics and, consequently, its emissions output.

One of the most significant impacts of emissions regulations on camshaft profiles has been the shift towards variable valve timing (VVT) systems. These systems allow for dynamic adjustment of valve timing based on engine load and speed, optimizing both performance and emissions across a wide range of operating conditions. In the case of the 2JZ engine, the adoption of VVT technology has enabled engineers to design camshaft profiles that can provide high torque output while still meeting stringent emissions requirements.

Another key consideration is the reduction of overlap between intake and exhaust valve openings. Traditional high-performance camshaft profiles often featured significant overlap to improve cylinder scavenging at high engine speeds. However, this approach can lead to increased emissions, particularly at low engine speeds and idle. As a result, modern camshaft designs for engines like the 2JZ have had to strike a delicate balance, reducing overlap to minimize emissions while still maintaining adequate performance characteristics.

The push for improved fuel efficiency, driven in part by emissions regulations, has also influenced camshaft profile design. Engineers have focused on optimizing valve lift and duration to enhance combustion efficiency and reduce pumping losses. This has led to the development of more sophisticated camshaft profiles that can provide better low-end torque without sacrificing high-end power, aligning with the performance characteristics desired in engines like the 2JZ.

Furthermore, emissions regulations have spurred the development of advanced materials and manufacturing techniques for camshafts. These innovations allow for more precise and complex lobe profiles, enabling finer control over valve events and improving overall engine efficiency. The use of lightweight materials and improved surface treatments has also contributed to reduced friction and wear, further enhancing engine performance and longevity while meeting emissions standards.

Emissions regulations primarily target the reduction of harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. To meet these standards, manufacturers have had to optimize combustion processes, which directly influences camshaft design. The camshaft profile plays a crucial role in controlling valve timing and duration, affecting the engine's breathing characteristics and, consequently, its emissions output.

One of the most significant impacts of emissions regulations on camshaft profiles has been the shift towards variable valve timing (VVT) systems. These systems allow for dynamic adjustment of valve timing based on engine load and speed, optimizing both performance and emissions across a wide range of operating conditions. In the case of the 2JZ engine, the adoption of VVT technology has enabled engineers to design camshaft profiles that can provide high torque output while still meeting stringent emissions requirements.

Another key consideration is the reduction of overlap between intake and exhaust valve openings. Traditional high-performance camshaft profiles often featured significant overlap to improve cylinder scavenging at high engine speeds. However, this approach can lead to increased emissions, particularly at low engine speeds and idle. As a result, modern camshaft designs for engines like the 2JZ have had to strike a delicate balance, reducing overlap to minimize emissions while still maintaining adequate performance characteristics.

The push for improved fuel efficiency, driven in part by emissions regulations, has also influenced camshaft profile design. Engineers have focused on optimizing valve lift and duration to enhance combustion efficiency and reduce pumping losses. This has led to the development of more sophisticated camshaft profiles that can provide better low-end torque without sacrificing high-end power, aligning with the performance characteristics desired in engines like the 2JZ.

Furthermore, emissions regulations have spurred the development of advanced materials and manufacturing techniques for camshafts. These innovations allow for more precise and complex lobe profiles, enabling finer control over valve events and improving overall engine efficiency. The use of lightweight materials and improved surface treatments has also contributed to reduced friction and wear, further enhancing engine performance and longevity while meeting emissions standards.

Material Advancements in Camshaft Manufacturing

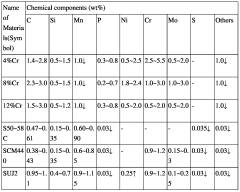

The advancements in camshaft manufacturing materials have played a crucial role in enhancing the performance and durability of engines, particularly in high-performance applications such as the 2JZ engine. Traditional camshafts were primarily made from cast iron or steel, but recent developments have introduced new materials and manufacturing techniques that significantly impact camshaft profiles and, consequently, engine torque characteristics.

One of the most notable advancements in camshaft materials is the use of billet steel. This high-grade steel allows for more precise machining and greater strength, enabling manufacturers to create more aggressive cam profiles without compromising durability. The improved material properties of billet steel camshafts contribute to reduced wear and increased longevity, even under high-stress conditions typical in performance engines like the 2JZ.

Another significant development is the introduction of composite materials in camshaft manufacturing. Carbon fiber-reinforced polymers (CFRP) have been explored for their potential to reduce weight while maintaining strength. Although not yet widely adopted in production engines, CFRP camshafts have shown promise in reducing rotational mass and improving engine response, which can directly influence torque characteristics.

Surface treatments and coatings have also evolved to enhance camshaft performance. Diamond-like carbon (DLC) coatings, for instance, provide exceptional hardness and low friction properties. When applied to camshafts, these coatings can significantly reduce wear on both the cam lobes and valve train components, allowing for more aggressive cam profiles that can optimize valve timing and lift for improved torque output.

The advent of powder metallurgy in camshaft production has opened new possibilities for material composition. This process allows for the creation of camshafts with tailored material properties, combining the strength of steel with the wear resistance of other alloys. Such camshafts can better withstand the high temperatures and pressures present in high-performance engines like the 2JZ, maintaining their profile integrity over extended periods of operation.

Lastly, the use of advanced alloys, such as those incorporating molybdenum and vanadium, has further pushed the boundaries of camshaft design. These alloys offer improved heat resistance and strength, allowing for even more aggressive cam profiles that can significantly alter valve lift and duration, directly impacting the engine's torque curve and overall performance characteristics.

One of the most notable advancements in camshaft materials is the use of billet steel. This high-grade steel allows for more precise machining and greater strength, enabling manufacturers to create more aggressive cam profiles without compromising durability. The improved material properties of billet steel camshafts contribute to reduced wear and increased longevity, even under high-stress conditions typical in performance engines like the 2JZ.

Another significant development is the introduction of composite materials in camshaft manufacturing. Carbon fiber-reinforced polymers (CFRP) have been explored for their potential to reduce weight while maintaining strength. Although not yet widely adopted in production engines, CFRP camshafts have shown promise in reducing rotational mass and improving engine response, which can directly influence torque characteristics.

Surface treatments and coatings have also evolved to enhance camshaft performance. Diamond-like carbon (DLC) coatings, for instance, provide exceptional hardness and low friction properties. When applied to camshafts, these coatings can significantly reduce wear on both the cam lobes and valve train components, allowing for more aggressive cam profiles that can optimize valve timing and lift for improved torque output.

The advent of powder metallurgy in camshaft production has opened new possibilities for material composition. This process allows for the creation of camshafts with tailored material properties, combining the strength of steel with the wear resistance of other alloys. Such camshafts can better withstand the high temperatures and pressures present in high-performance engines like the 2JZ, maintaining their profile integrity over extended periods of operation.

Lastly, the use of advanced alloys, such as those incorporating molybdenum and vanadium, has further pushed the boundaries of camshaft design. These alloys offer improved heat resistance and strength, allowing for even more aggressive cam profiles that can significantly alter valve lift and duration, directly impacting the engine's torque curve and overall performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!