Thermal Regulation Impact on 2JZ Climate Adaptive Engines

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Evolution

The 2JZ engine, initially introduced by Toyota in 1991, has undergone significant evolution over the years, particularly in response to thermal regulation challenges and the need for climate-adaptive engines. This iconic powerplant has demonstrated remarkable adaptability, transitioning from its origins as a high-performance engine to a more versatile and environmentally conscious design.

In its early iterations, the 2JZ engine was primarily focused on delivering raw power and performance. However, as global climate concerns grew and emissions regulations tightened, Toyota engineers began to shift their focus towards improving thermal efficiency and reducing environmental impact. This led to a series of innovations in thermal management systems, including advanced cooling technologies and heat recovery mechanisms.

One of the key developments in the 2JZ engine's evolution was the implementation of variable valve timing (VVT) technology. This innovation allowed for better control over engine temperature across a wide range of operating conditions, significantly improving fuel efficiency and reducing emissions without sacrificing performance. The VVT system's ability to optimize valve timing based on engine load and temperature proved crucial in adapting the 2JZ to varying climatic conditions.

Another significant milestone in the 2JZ's thermal regulation capabilities was the introduction of advanced electronic engine management systems. These sophisticated control units enabled real-time adjustments to fuel injection, ignition timing, and other parameters based on ambient temperature and engine thermal conditions. This adaptive approach ensured optimal performance and efficiency across diverse climate zones, from frigid arctic environments to scorching desert heat.

The evolution of materials science also played a crucial role in enhancing the 2JZ engine's thermal regulation. The incorporation of high-temperature alloys and ceramic coatings in critical components improved heat dissipation and thermal stability. These advancements allowed the engine to maintain peak performance even under extreme temperature conditions, further solidifying its reputation as a robust and versatile powerplant.

In recent years, the focus on climate adaptability has led to the integration of innovative cooling systems in the 2JZ platform. Advanced radiator designs, coupled with intelligent coolant flow management, have significantly improved the engine's ability to maintain optimal operating temperatures across a broad spectrum of environmental conditions. This has not only enhanced reliability but also contributed to improved fuel efficiency and reduced emissions.

The ongoing evolution of the 2JZ engine serves as a testament to Toyota's commitment to engineering excellence and environmental responsibility. As climate change continues to present new challenges, the adaptability and resilience of the 2JZ platform position it as a benchmark for future engine designs, particularly in the realm of thermal regulation and climate adaptivity.

In its early iterations, the 2JZ engine was primarily focused on delivering raw power and performance. However, as global climate concerns grew and emissions regulations tightened, Toyota engineers began to shift their focus towards improving thermal efficiency and reducing environmental impact. This led to a series of innovations in thermal management systems, including advanced cooling technologies and heat recovery mechanisms.

One of the key developments in the 2JZ engine's evolution was the implementation of variable valve timing (VVT) technology. This innovation allowed for better control over engine temperature across a wide range of operating conditions, significantly improving fuel efficiency and reducing emissions without sacrificing performance. The VVT system's ability to optimize valve timing based on engine load and temperature proved crucial in adapting the 2JZ to varying climatic conditions.

Another significant milestone in the 2JZ's thermal regulation capabilities was the introduction of advanced electronic engine management systems. These sophisticated control units enabled real-time adjustments to fuel injection, ignition timing, and other parameters based on ambient temperature and engine thermal conditions. This adaptive approach ensured optimal performance and efficiency across diverse climate zones, from frigid arctic environments to scorching desert heat.

The evolution of materials science also played a crucial role in enhancing the 2JZ engine's thermal regulation. The incorporation of high-temperature alloys and ceramic coatings in critical components improved heat dissipation and thermal stability. These advancements allowed the engine to maintain peak performance even under extreme temperature conditions, further solidifying its reputation as a robust and versatile powerplant.

In recent years, the focus on climate adaptability has led to the integration of innovative cooling systems in the 2JZ platform. Advanced radiator designs, coupled with intelligent coolant flow management, have significantly improved the engine's ability to maintain optimal operating temperatures across a broad spectrum of environmental conditions. This has not only enhanced reliability but also contributed to improved fuel efficiency and reduced emissions.

The ongoing evolution of the 2JZ engine serves as a testament to Toyota's commitment to engineering excellence and environmental responsibility. As climate change continues to present new challenges, the adaptability and resilience of the 2JZ platform position it as a benchmark for future engine designs, particularly in the realm of thermal regulation and climate adaptivity.

Market for Climate-Adaptive Engines

The market for climate-adaptive engines, particularly those incorporating advanced thermal regulation systems like those in the 2JZ engine, is experiencing significant growth and transformation. This surge is driven by increasing global awareness of climate change and the need for more efficient, environmentally friendly transportation solutions. The automotive industry, a key player in this market, is witnessing a shift towards engines that can maintain optimal performance across diverse climatic conditions.

Climate-adaptive engines are gaining traction in regions with extreme weather variations, where traditional engines often struggle to maintain efficiency. Countries with diverse climates, such as the United States, China, and India, are showing particular interest in these technologies. The market is not limited to passenger vehicles; commercial vehicles, including trucks and buses, are also adopting climate-adaptive engine technologies to improve fuel efficiency and reduce emissions across varying environmental conditions.

The demand for climate-adaptive engines is further bolstered by stringent environmental regulations worldwide. Governments are implementing stricter emission standards, pushing automakers to innovate and develop engines that can adapt to different climatic conditions while maintaining low emission levels. This regulatory pressure is creating a robust market for advanced thermal regulation technologies in engines.

In terms of market size, the global climate-adaptive engine market is showing promising growth. While exact figures are challenging to pinpoint due to the emerging nature of this technology, industry analysts project substantial growth over the next decade. This growth is attributed to increasing consumer demand for fuel-efficient vehicles and the automotive industry's push towards more sustainable technologies.

The market is also seeing a rise in research and development investments. Major automotive manufacturers and technology companies are allocating significant resources to develop and refine climate-adaptive engine technologies. This investment trend indicates a strong belief in the long-term potential of these engines in the automotive market.

Furthermore, the market for climate-adaptive engines is not isolated to new vehicle sales. There is a growing aftermarket segment for retrofitting existing engines with climate-adaptive technologies, particularly in regions with aging vehicle fleets. This aftermarket potential adds another dimension to the overall market size and growth prospects.

As the technology matures, we can expect to see a broader adoption across various vehicle segments, from economy cars to luxury vehicles and heavy-duty trucks. This widespread application will likely lead to economies of scale, potentially reducing the cost of climate-adaptive engine technologies and further driving market growth.

Climate-adaptive engines are gaining traction in regions with extreme weather variations, where traditional engines often struggle to maintain efficiency. Countries with diverse climates, such as the United States, China, and India, are showing particular interest in these technologies. The market is not limited to passenger vehicles; commercial vehicles, including trucks and buses, are also adopting climate-adaptive engine technologies to improve fuel efficiency and reduce emissions across varying environmental conditions.

The demand for climate-adaptive engines is further bolstered by stringent environmental regulations worldwide. Governments are implementing stricter emission standards, pushing automakers to innovate and develop engines that can adapt to different climatic conditions while maintaining low emission levels. This regulatory pressure is creating a robust market for advanced thermal regulation technologies in engines.

In terms of market size, the global climate-adaptive engine market is showing promising growth. While exact figures are challenging to pinpoint due to the emerging nature of this technology, industry analysts project substantial growth over the next decade. This growth is attributed to increasing consumer demand for fuel-efficient vehicles and the automotive industry's push towards more sustainable technologies.

The market is also seeing a rise in research and development investments. Major automotive manufacturers and technology companies are allocating significant resources to develop and refine climate-adaptive engine technologies. This investment trend indicates a strong belief in the long-term potential of these engines in the automotive market.

Furthermore, the market for climate-adaptive engines is not isolated to new vehicle sales. There is a growing aftermarket segment for retrofitting existing engines with climate-adaptive technologies, particularly in regions with aging vehicle fleets. This aftermarket potential adds another dimension to the overall market size and growth prospects.

As the technology matures, we can expect to see a broader adoption across various vehicle segments, from economy cars to luxury vehicles and heavy-duty trucks. This widespread application will likely lead to economies of scale, potentially reducing the cost of climate-adaptive engine technologies and further driving market growth.

Thermal Regulation Challenges

The thermal regulation of 2JZ climate adaptive engines presents significant challenges in the face of varying environmental conditions. These engines, designed to operate efficiently across a wide range of climates, must contend with extreme temperature fluctuations that can impact performance, fuel efficiency, and overall longevity.

One of the primary challenges is maintaining optimal engine temperature in diverse climatic conditions. In hot environments, the engine must dissipate excess heat effectively to prevent overheating, which can lead to reduced performance and potential damage. Conversely, in cold climates, the engine needs to reach and maintain its ideal operating temperature quickly to ensure efficient combustion and reduce emissions.

The thermal management system must also adapt to rapid temperature changes, such as those experienced during altitude changes or when transitioning between different climate zones. This requires sophisticated control algorithms and sensors capable of real-time adjustments to coolant flow, fan speeds, and other thermal regulation components.

Another significant challenge lies in the materials used in engine construction. Components must withstand thermal expansion and contraction without compromising structural integrity or sealing properties. This is particularly crucial for gaskets, seals, and other interface materials that maintain the engine's internal pressure and prevent fluid leaks.

The integration of turbochargers in 2JZ engines adds another layer of complexity to thermal regulation. Turbochargers generate significant heat during operation, which must be managed effectively to prevent damage and maintain efficiency. This often requires additional cooling systems, such as intercoolers, which must be integrated seamlessly into the overall thermal management strategy.

Fuel efficiency and emissions control are also closely tied to thermal regulation. Engines operating outside their optimal temperature range may experience incomplete combustion, leading to increased fuel consumption and higher emissions. Balancing these factors across various climate conditions while meeting stringent environmental regulations poses a substantial engineering challenge.

Furthermore, the electrical systems and electronic control units (ECUs) that manage engine operations are sensitive to temperature extremes. Ensuring these components remain within their operational temperature range is critical for maintaining engine performance and reliability in all climatic conditions.

As climate change leads to more extreme and unpredictable weather patterns, the demands on climate adaptive engines are likely to increase. This necessitates ongoing research and development to enhance the robustness and adaptability of thermal regulation systems in 2JZ engines, ensuring they can meet the challenges of an ever-changing global climate.

One of the primary challenges is maintaining optimal engine temperature in diverse climatic conditions. In hot environments, the engine must dissipate excess heat effectively to prevent overheating, which can lead to reduced performance and potential damage. Conversely, in cold climates, the engine needs to reach and maintain its ideal operating temperature quickly to ensure efficient combustion and reduce emissions.

The thermal management system must also adapt to rapid temperature changes, such as those experienced during altitude changes or when transitioning between different climate zones. This requires sophisticated control algorithms and sensors capable of real-time adjustments to coolant flow, fan speeds, and other thermal regulation components.

Another significant challenge lies in the materials used in engine construction. Components must withstand thermal expansion and contraction without compromising structural integrity or sealing properties. This is particularly crucial for gaskets, seals, and other interface materials that maintain the engine's internal pressure and prevent fluid leaks.

The integration of turbochargers in 2JZ engines adds another layer of complexity to thermal regulation. Turbochargers generate significant heat during operation, which must be managed effectively to prevent damage and maintain efficiency. This often requires additional cooling systems, such as intercoolers, which must be integrated seamlessly into the overall thermal management strategy.

Fuel efficiency and emissions control are also closely tied to thermal regulation. Engines operating outside their optimal temperature range may experience incomplete combustion, leading to increased fuel consumption and higher emissions. Balancing these factors across various climate conditions while meeting stringent environmental regulations poses a substantial engineering challenge.

Furthermore, the electrical systems and electronic control units (ECUs) that manage engine operations are sensitive to temperature extremes. Ensuring these components remain within their operational temperature range is critical for maintaining engine performance and reliability in all climatic conditions.

As climate change leads to more extreme and unpredictable weather patterns, the demands on climate adaptive engines are likely to increase. This necessitates ongoing research and development to enhance the robustness and adaptability of thermal regulation systems in 2JZ engines, ensuring they can meet the challenges of an ever-changing global climate.

Current Thermal Solutions

01 Adaptive thermal management systems for climate-responsive engines

Advanced thermal management systems are developed for engines to adapt to varying climate conditions. These systems utilize intelligent control algorithms and sensors to optimize engine performance and efficiency across different environmental temperatures. The adaptive systems can adjust cooling strategies, heat dissipation, and thermal regulation based on real-time climate data.- Adaptive thermal management systems for climate-responsive engines: Advanced thermal management systems are developed for engines to adapt to varying climate conditions. These systems utilize intelligent control algorithms and sensors to optimize engine performance and efficiency across different environmental temperatures. The adaptive systems can adjust cooling strategies, heat dissipation, and thermal regulation based on real-time climate data and engine operating conditions.

- Climate-specific engine cooling technologies: Specialized cooling technologies are designed for engines to address specific climate challenges. These may include enhanced radiator designs, advanced coolant formulations, and innovative heat exchanger configurations. The cooling systems are tailored to maintain optimal engine temperatures in extreme hot or cold environments, ensuring consistent performance and longevity of the engine components.

- Smart thermal regulation using AI and IoT integration: Integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies in engine thermal management systems enables predictive and adaptive temperature control. These smart systems can anticipate thermal loads based on route planning, weather forecasts, and historical data, adjusting engine parameters proactively to maintain optimal thermal conditions and improve overall efficiency.

- Multi-zone thermal management for climate-adaptive engines: Advanced engines employ multi-zone thermal management strategies to address varying thermal requirements across different engine components. This approach allows for targeted cooling or heating of specific areas, optimizing overall engine performance and efficiency. The system can dynamically adjust thermal management priorities based on climate conditions and engine load.

- Eco-friendly thermal regulation solutions for climate-adaptive engines: Development of environmentally friendly thermal regulation technologies for engines, focusing on reducing the carbon footprint of cooling systems. These solutions may include the use of natural refrigerants, waste heat recovery systems, and energy-efficient cooling methods. The eco-friendly approach aims to enhance engine performance while minimizing environmental impact across various climate conditions.

02 Climate-specific engine cooling technologies

Specialized cooling technologies are designed for engines to operate efficiently in specific climate zones. These may include advanced radiator designs, smart coolant flow control, and climate-optimized heat exchangers. The cooling systems are tailored to handle extreme temperatures, humidity levels, and altitude variations encountered in different geographical regions.Expand Specific Solutions03 Intelligent thermal regulation for hybrid and electric powertrains

Innovative thermal regulation strategies are developed for hybrid and electric powertrains to maintain optimal operating temperatures in various climates. These systems integrate battery thermal management, motor cooling, and power electronics temperature control to ensure consistent performance and longevity of electrified vehicle components across diverse environmental conditions.Expand Specific Solutions04 Climate-adaptive engine control and performance optimization

Advanced engine control systems are designed to adapt engine performance parameters based on climate conditions. These systems utilize real-time environmental data to adjust fuel injection, ignition timing, and air-fuel ratios, optimizing engine efficiency and emissions control across varying atmospheric conditions and altitudes.Expand Specific Solutions05 Innovative materials and coatings for climate-resilient engines

Development of new materials and coatings to enhance engine resilience in diverse climates. These innovations include heat-resistant alloys, thermal barrier coatings, and smart materials that adapt to temperature changes. The advanced materials improve engine durability, thermal efficiency, and performance stability across a wide range of environmental conditions.Expand Specific Solutions

Key 2JZ Engine Manufacturers

The thermal regulation impact on 2JZ climate adaptive engines represents an emerging field in automotive technology, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for fuel-efficient and environmentally friendly vehicles. The technology's maturity is still evolving, with major players like Toyota Motor Corp., Honda Motor Co., Ltd., and Volkswagen AG investing in research and development. Peugeot SA and Renault SA are also exploring this technology, while suppliers such as DENSO Corp. and Valeo Thermal Systems Japan Corp. are contributing to advancements in thermal management systems. As the industry progresses, collaboration between automakers and technology providers will be crucial for accelerating innovation and market adoption.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced thermal management system for their 2JZ climate adaptive engines, focusing on optimizing engine performance across diverse environmental conditions. The system utilizes a combination of intelligent coolant flow control and variable heat exchanger technology[1]. It incorporates a sophisticated electronic control unit that continuously monitors engine temperature, ambient conditions, and driving patterns to adjust coolant circulation and heat dissipation in real-time[3]. This adaptive approach allows for rapid warm-up in cold conditions and efficient cooling during high-load operations, contributing to improved fuel efficiency and reduced emissions[5]. Toyota has also integrated a heat recovery system that captures waste heat from the exhaust to warm the engine and cabin more quickly in cold weather, further enhancing overall thermal efficiency[7].

Strengths: Highly adaptive to various climates, improved fuel efficiency, and reduced emissions. Weaknesses: Increased system complexity and potential higher maintenance costs.

GM Global Technology Operations LLC

Technical Solution: GM has implemented a comprehensive thermal regulation strategy for climate adaptive engines, including those similar to the 2JZ. Their approach involves a dual-circuit cooling system with separate loops for the engine block and cylinder head[2]. This allows for more precise temperature control in different engine regions. GM's system also features an electric water pump that provides variable coolant flow based on engine load and ambient temperature[4]. Additionally, they have developed advanced thermal barrier coatings for engine components to reduce heat transfer to the coolant, allowing for higher combustion temperatures and improved efficiency[6]. The system is managed by a sophisticated thermal management module that uses predictive algorithms to anticipate cooling needs based on route information and historical data[8].

Strengths: Precise temperature control, improved thermal efficiency, and potential for increased power output. Weaknesses: Higher initial cost and increased complexity in the cooling system.

Innovative Cooling Technologies

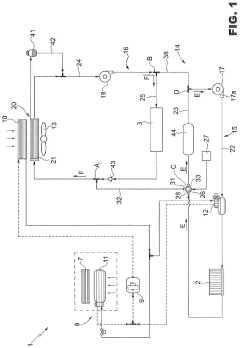

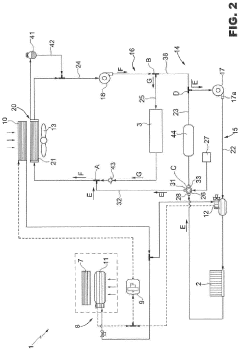

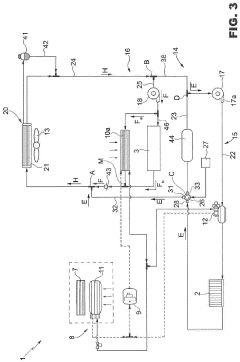

Improved device for thermally controlling the intake air of the internal combustion engine of a motor vehicle

PatentWO2003023216A1

Innovation

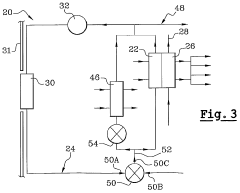

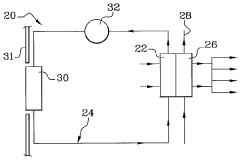

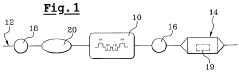

- A dual-stage thermal regulation system comprising a first intake air/coolant heat exchanger connected to a cold coolant circuit and a second intake air/heat transfer fluid heat exchanger connected to a very cold heat transfer fluid circuit, utilizing a heat pump and a recirculated exhaust gas/coolant heat exchanger to optimize intake air temperature regulation, with the second heat exchanger being arranged downstream of the first and utilizing a mixture of water and antifreeze as the heat transfer fluid.

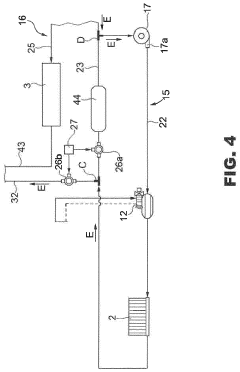

Thermal regulation system for electric drive vehicles and electric drive vehicle provided with this system

PatentPendingEP3650266A1

Innovation

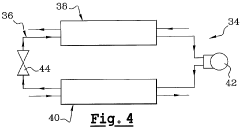

- A thermal regulation system with two loops that can operate in independent or coupled configurations, allowing for adjustable flow rates and fluid distribution between the battery and electric drive unit, utilizing valves and pumps to manage temperature thresholds and fluid flow, enabling flexible thermal management.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of climate-adaptive engines, particularly in the context of thermal regulation for the 2JZ engine. These regulations are designed to mitigate the environmental impact of vehicle emissions and promote sustainable transportation solutions.

The primary focus of environmental regulations affecting 2JZ climate-adaptive engines is the reduction of greenhouse gas emissions, particularly carbon dioxide (CO2). As global efforts to combat climate change intensify, stringent emission standards have been implemented across various jurisdictions. These standards typically set limits on the amount of CO2 and other pollutants that can be emitted per kilometer driven, pushing manufacturers to develop more efficient and environmentally friendly engine technologies.

In response to these regulations, thermal regulation systems in 2JZ climate-adaptive engines have become increasingly sophisticated. Advanced thermal management techniques are employed to optimize engine performance while minimizing emissions. This includes the use of intelligent cooling systems that can adapt to varying environmental conditions, ensuring optimal engine temperature and efficiency across a wide range of operating scenarios.

Another key aspect of environmental regulations impacting 2JZ climate-adaptive engines is the push for improved fuel efficiency. Many countries have implemented fuel economy standards that require vehicles to achieve specific miles-per-gallon targets. These standards indirectly influence thermal regulation strategies, as more efficient engines generally produce less waste heat and require less cooling.

The regulations also extend to the materials and manufacturing processes used in engine production. Restrictions on the use of certain materials, such as heavy metals or environmentally harmful substances, have led to innovations in thermal management components. For instance, the development of more environmentally friendly coolants and heat-dissipating materials has been driven by these regulatory requirements.

Furthermore, environmental regulations have spurred research into alternative powertrain technologies, which in turn influence the thermal regulation strategies employed in 2JZ climate-adaptive engines. As hybrid and electric vehicles gain prominence, thermal management systems must evolve to address the unique challenges posed by these new propulsion methods, while still meeting stringent environmental standards.

In conclusion, environmental regulations serve as a driving force for innovation in thermal regulation technologies for 2JZ climate-adaptive engines. These regulations not only set the standards for emissions and efficiency but also shape the direction of research and development in the automotive industry. As environmental concerns continue to grow, it is likely that these regulations will become even more stringent, further pushing the boundaries of thermal regulation technology in climate-adaptive engines.

The primary focus of environmental regulations affecting 2JZ climate-adaptive engines is the reduction of greenhouse gas emissions, particularly carbon dioxide (CO2). As global efforts to combat climate change intensify, stringent emission standards have been implemented across various jurisdictions. These standards typically set limits on the amount of CO2 and other pollutants that can be emitted per kilometer driven, pushing manufacturers to develop more efficient and environmentally friendly engine technologies.

In response to these regulations, thermal regulation systems in 2JZ climate-adaptive engines have become increasingly sophisticated. Advanced thermal management techniques are employed to optimize engine performance while minimizing emissions. This includes the use of intelligent cooling systems that can adapt to varying environmental conditions, ensuring optimal engine temperature and efficiency across a wide range of operating scenarios.

Another key aspect of environmental regulations impacting 2JZ climate-adaptive engines is the push for improved fuel efficiency. Many countries have implemented fuel economy standards that require vehicles to achieve specific miles-per-gallon targets. These standards indirectly influence thermal regulation strategies, as more efficient engines generally produce less waste heat and require less cooling.

The regulations also extend to the materials and manufacturing processes used in engine production. Restrictions on the use of certain materials, such as heavy metals or environmentally harmful substances, have led to innovations in thermal management components. For instance, the development of more environmentally friendly coolants and heat-dissipating materials has been driven by these regulatory requirements.

Furthermore, environmental regulations have spurred research into alternative powertrain technologies, which in turn influence the thermal regulation strategies employed in 2JZ climate-adaptive engines. As hybrid and electric vehicles gain prominence, thermal management systems must evolve to address the unique challenges posed by these new propulsion methods, while still meeting stringent environmental standards.

In conclusion, environmental regulations serve as a driving force for innovation in thermal regulation technologies for 2JZ climate-adaptive engines. These regulations not only set the standards for emissions and efficiency but also shape the direction of research and development in the automotive industry. As environmental concerns continue to grow, it is likely that these regulations will become even more stringent, further pushing the boundaries of thermal regulation technology in climate-adaptive engines.

Performance vs Efficiency

The 2JZ engine, renowned for its robustness and performance, faces new challenges in the era of climate-adaptive technologies. When considering the impact of thermal regulation on these engines, a critical balance between performance and efficiency emerges. The 2JZ's traditional strength lies in its ability to handle high boost pressures and generate substantial power outputs. However, as environmental concerns grow, the focus shifts towards optimizing efficiency without compromising performance.

Thermal regulation plays a pivotal role in this balance. Advanced cooling systems and heat management techniques can significantly improve the engine's efficiency by maintaining optimal operating temperatures across various climate conditions. This adaptability allows the engine to perform consistently, whether in scorching desert heat or frigid arctic environments. By precisely controlling thermal conditions, the engine can operate closer to its ideal temperature range, reducing energy losses and improving fuel economy.

However, the pursuit of efficiency through thermal regulation can potentially impact the engine's peak performance. Traditional performance enhancements often rely on pushing the engine beyond standard thermal limits, which may conflict with efficiency-focused thermal management strategies. The challenge lies in developing systems that can dynamically adjust thermal regulation based on driving conditions and performance demands.

Advanced materials and coatings play a crucial role in this performance-efficiency balance. Ceramic coatings and high-temperature alloys can improve heat retention where beneficial and enhance heat dissipation where necessary. This targeted approach to thermal management allows for more precise control over engine temperatures, potentially unlocking both performance gains and efficiency improvements.

Electronic control systems and adaptive algorithms represent another frontier in balancing performance and efficiency. These systems can continuously monitor and adjust engine parameters based on real-time thermal conditions, driver inputs, and environmental factors. By optimizing combustion timing, fuel injection, and boost pressure in response to thermal data, these systems can maximize both power output and fuel efficiency across a wide range of operating conditions.

The integration of hybrid technologies with the 2JZ platform presents intriguing possibilities for further enhancing this balance. Electric motors can provide instantaneous torque, allowing the combustion engine to operate in its most efficient range more frequently. Additionally, regenerative braking systems can capture and store energy that would otherwise be lost as heat, further improving overall system efficiency without compromising the engine's performance capabilities.

Thermal regulation plays a pivotal role in this balance. Advanced cooling systems and heat management techniques can significantly improve the engine's efficiency by maintaining optimal operating temperatures across various climate conditions. This adaptability allows the engine to perform consistently, whether in scorching desert heat or frigid arctic environments. By precisely controlling thermal conditions, the engine can operate closer to its ideal temperature range, reducing energy losses and improving fuel economy.

However, the pursuit of efficiency through thermal regulation can potentially impact the engine's peak performance. Traditional performance enhancements often rely on pushing the engine beyond standard thermal limits, which may conflict with efficiency-focused thermal management strategies. The challenge lies in developing systems that can dynamically adjust thermal regulation based on driving conditions and performance demands.

Advanced materials and coatings play a crucial role in this performance-efficiency balance. Ceramic coatings and high-temperature alloys can improve heat retention where beneficial and enhance heat dissipation where necessary. This targeted approach to thermal management allows for more precise control over engine temperatures, potentially unlocking both performance gains and efficiency improvements.

Electronic control systems and adaptive algorithms represent another frontier in balancing performance and efficiency. These systems can continuously monitor and adjust engine parameters based on real-time thermal conditions, driver inputs, and environmental factors. By optimizing combustion timing, fuel injection, and boost pressure in response to thermal data, these systems can maximize both power output and fuel efficiency across a wide range of operating conditions.

The integration of hybrid technologies with the 2JZ platform presents intriguing possibilities for further enhancing this balance. Electric motors can provide instantaneous torque, allowing the combustion engine to operate in its most efficient range more frequently. Additionally, regenerative braking systems can capture and store energy that would otherwise be lost as heat, further improving overall system efficiency without compromising the engine's performance capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!