Benefits of Self-Healing Polymers in 2JZ Component Repair

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Self-Healing Polymers: Background and Objectives

Self-healing polymers represent a groundbreaking advancement in materials science, offering significant potential for enhancing the durability and longevity of 2JZ engine components. These innovative materials possess the remarkable ability to autonomously repair damage, addressing a critical challenge in maintaining high-performance engines. The development of self-healing polymers stems from the need to extend the operational life of engine parts and reduce maintenance costs associated with frequent repairs or replacements.

The evolution of self-healing polymers can be traced back to the early 2000s, with initial research focusing on biomimetic approaches inspired by natural healing processes. Over the past two decades, significant strides have been made in improving the efficiency, speed, and versatility of self-healing mechanisms. The application of these advanced materials to 2JZ engine components represents a convergence of cutting-edge materials science and automotive engineering.

In the context of 2JZ component repair, self-healing polymers offer a promising solution to combat wear, fatigue, and micro-cracks that can compromise engine performance and longevity. The 2JZ engine, renowned for its robustness and tuning potential, stands to benefit greatly from the integration of self-healing materials. These polymers can potentially address common issues such as gasket failures, seal degradation, and surface wear on critical components.

The primary objective of implementing self-healing polymers in 2JZ component repair is to create a more resilient and self-maintaining engine system. This technology aims to extend the service intervals of engine parts, reduce downtime for repairs, and ultimately enhance the overall reliability of the 2JZ engine. Additionally, the incorporation of self-healing materials aligns with broader industry trends towards more sustainable and resource-efficient automotive technologies.

As we explore the potential benefits of self-healing polymers for 2JZ components, it is crucial to consider the specific requirements and operating conditions of high-performance engines. The extreme temperatures, pressures, and mechanical stresses encountered in a 2JZ engine present unique challenges for self-healing materials. Consequently, the development and application of these polymers must be tailored to withstand the demanding environment while maintaining their restorative properties.

The successful integration of self-healing polymers into 2JZ component repair could mark a significant milestone in engine technology. It promises not only to address current maintenance challenges but also to pave the way for more advanced, self-sustaining engine designs in the future. As research in this field progresses, we anticipate a new era of engine components that can actively respond to and mitigate damage, potentially revolutionizing the longevity and performance of high-output engines like the 2JZ.

The evolution of self-healing polymers can be traced back to the early 2000s, with initial research focusing on biomimetic approaches inspired by natural healing processes. Over the past two decades, significant strides have been made in improving the efficiency, speed, and versatility of self-healing mechanisms. The application of these advanced materials to 2JZ engine components represents a convergence of cutting-edge materials science and automotive engineering.

In the context of 2JZ component repair, self-healing polymers offer a promising solution to combat wear, fatigue, and micro-cracks that can compromise engine performance and longevity. The 2JZ engine, renowned for its robustness and tuning potential, stands to benefit greatly from the integration of self-healing materials. These polymers can potentially address common issues such as gasket failures, seal degradation, and surface wear on critical components.

The primary objective of implementing self-healing polymers in 2JZ component repair is to create a more resilient and self-maintaining engine system. This technology aims to extend the service intervals of engine parts, reduce downtime for repairs, and ultimately enhance the overall reliability of the 2JZ engine. Additionally, the incorporation of self-healing materials aligns with broader industry trends towards more sustainable and resource-efficient automotive technologies.

As we explore the potential benefits of self-healing polymers for 2JZ components, it is crucial to consider the specific requirements and operating conditions of high-performance engines. The extreme temperatures, pressures, and mechanical stresses encountered in a 2JZ engine present unique challenges for self-healing materials. Consequently, the development and application of these polymers must be tailored to withstand the demanding environment while maintaining their restorative properties.

The successful integration of self-healing polymers into 2JZ component repair could mark a significant milestone in engine technology. It promises not only to address current maintenance challenges but also to pave the way for more advanced, self-sustaining engine designs in the future. As research in this field progresses, we anticipate a new era of engine components that can actively respond to and mitigate damage, potentially revolutionizing the longevity and performance of high-output engines like the 2JZ.

Market Analysis for Self-Healing 2JZ Components

The market for self-healing 2JZ components is experiencing significant growth, driven by the increasing demand for more durable and efficient automotive parts. The 2JZ engine, renowned for its robustness and performance, has a dedicated following in the automotive enthusiast community. As these engines age, the need for reliable repair solutions becomes more pressing, creating a fertile ground for self-healing polymer technologies.

The potential market size for self-healing 2JZ components is substantial, considering the large number of vehicles still using this engine and the growing aftermarket sector. The global automotive repair and maintenance market, which includes specialized components like those for the 2JZ engine, is projected to expand steadily over the next few years. Within this broader market, the niche for advanced repair technologies such as self-healing polymers is gaining traction.

Consumer demand for longer-lasting engine components is a key driver in this market. Vehicle owners are increasingly seeking solutions that can extend the life of their engines and reduce maintenance costs. Self-healing polymers offer a compelling value proposition by potentially reducing the frequency of repairs and replacements, which is particularly attractive for high-performance engines like the 2JZ that are often pushed to their limits.

The automotive industry's shift towards more sustainable and environmentally friendly practices also contributes to the market potential of self-healing 2JZ components. These technologies align with the growing emphasis on reducing waste and improving resource efficiency in vehicle maintenance and repair processes. As environmental regulations become stricter, solutions that extend component lifespan and reduce the need for replacements are likely to see increased adoption.

Market trends indicate a growing interest in advanced materials across the automotive sector. This trend bodes well for self-healing polymers in 2JZ component repair, as it suggests a receptive market for innovative material solutions. The integration of smart materials in automotive applications is expected to accelerate, with self-healing technologies at the forefront of this movement.

However, the market also faces challenges. The relatively high initial cost of self-healing polymer components compared to traditional replacements may slow adoption rates, particularly in price-sensitive segments. Additionally, the specialized nature of 2JZ engine repairs means that the market, while potentially lucrative, remains niche compared to more mainstream automotive repair sectors.

Despite these challenges, the long-term market outlook for self-healing 2JZ components is positive. As the technology matures and production scales up, costs are expected to decrease, making these solutions more accessible to a broader range of consumers. The unique benefits offered by self-healing polymers, such as extended component life and reduced maintenance needs, position them as a premium solution in the automotive repair market, with significant growth potential in the coming years.

The potential market size for self-healing 2JZ components is substantial, considering the large number of vehicles still using this engine and the growing aftermarket sector. The global automotive repair and maintenance market, which includes specialized components like those for the 2JZ engine, is projected to expand steadily over the next few years. Within this broader market, the niche for advanced repair technologies such as self-healing polymers is gaining traction.

Consumer demand for longer-lasting engine components is a key driver in this market. Vehicle owners are increasingly seeking solutions that can extend the life of their engines and reduce maintenance costs. Self-healing polymers offer a compelling value proposition by potentially reducing the frequency of repairs and replacements, which is particularly attractive for high-performance engines like the 2JZ that are often pushed to their limits.

The automotive industry's shift towards more sustainable and environmentally friendly practices also contributes to the market potential of self-healing 2JZ components. These technologies align with the growing emphasis on reducing waste and improving resource efficiency in vehicle maintenance and repair processes. As environmental regulations become stricter, solutions that extend component lifespan and reduce the need for replacements are likely to see increased adoption.

Market trends indicate a growing interest in advanced materials across the automotive sector. This trend bodes well for self-healing polymers in 2JZ component repair, as it suggests a receptive market for innovative material solutions. The integration of smart materials in automotive applications is expected to accelerate, with self-healing technologies at the forefront of this movement.

However, the market also faces challenges. The relatively high initial cost of self-healing polymer components compared to traditional replacements may slow adoption rates, particularly in price-sensitive segments. Additionally, the specialized nature of 2JZ engine repairs means that the market, while potentially lucrative, remains niche compared to more mainstream automotive repair sectors.

Despite these challenges, the long-term market outlook for self-healing 2JZ components is positive. As the technology matures and production scales up, costs are expected to decrease, making these solutions more accessible to a broader range of consumers. The unique benefits offered by self-healing polymers, such as extended component life and reduced maintenance needs, position them as a premium solution in the automotive repair market, with significant growth potential in the coming years.

Current Challenges in 2JZ Repair Technologies

The 2JZ engine, renowned for its robustness and performance, still faces several challenges in repair and maintenance. One of the primary issues is the complexity of the engine's design, which makes repairs time-consuming and often requires specialized tools and expertise. This complexity can lead to increased downtime for vehicles and higher repair costs.

Another significant challenge is the wear and tear on critical components, particularly in high-performance applications. The 2JZ's ability to handle high boost pressures and produce substantial power output can accelerate the degradation of certain parts, such as gaskets, seals, and bearings. This necessitates more frequent replacements and meticulous maintenance schedules.

Corrosion and thermal stress pose additional challenges in 2JZ repair. The engine's high operating temperatures and exposure to various environmental conditions can lead to material fatigue and deterioration over time. This is particularly problematic for components like the head gasket and exhaust manifold, which are subjected to extreme temperature fluctuations.

The availability of genuine parts is becoming increasingly difficult as the engine ages. This scarcity can force mechanics and enthusiasts to rely on aftermarket components, which may not always meet the same quality standards as original equipment manufacturer (OEM) parts. This situation can potentially compromise the engine's performance and longevity.

Furthermore, the 2JZ's reputation for reliability has led to many engines being pushed to their limits through modifications and tuning. While this demonstrates the engine's capabilities, it also results in accelerated wear and more frequent need for repairs, especially in areas like the valve train and bottom end components.

Diagnostic challenges also persist, particularly with older 2JZ engines that may not have modern electronic control units. Identifying the root cause of performance issues or unusual noises can be complex, requiring extensive experience and sometimes trial-and-error approaches.

Lastly, the environmental impact of repairs and maintenance on the 2JZ engine is a growing concern. The use of traditional repair methods and materials may not align with increasing environmental regulations and sustainability goals, necessitating the exploration of more eco-friendly repair technologies and practices.

Another significant challenge is the wear and tear on critical components, particularly in high-performance applications. The 2JZ's ability to handle high boost pressures and produce substantial power output can accelerate the degradation of certain parts, such as gaskets, seals, and bearings. This necessitates more frequent replacements and meticulous maintenance schedules.

Corrosion and thermal stress pose additional challenges in 2JZ repair. The engine's high operating temperatures and exposure to various environmental conditions can lead to material fatigue and deterioration over time. This is particularly problematic for components like the head gasket and exhaust manifold, which are subjected to extreme temperature fluctuations.

The availability of genuine parts is becoming increasingly difficult as the engine ages. This scarcity can force mechanics and enthusiasts to rely on aftermarket components, which may not always meet the same quality standards as original equipment manufacturer (OEM) parts. This situation can potentially compromise the engine's performance and longevity.

Furthermore, the 2JZ's reputation for reliability has led to many engines being pushed to their limits through modifications and tuning. While this demonstrates the engine's capabilities, it also results in accelerated wear and more frequent need for repairs, especially in areas like the valve train and bottom end components.

Diagnostic challenges also persist, particularly with older 2JZ engines that may not have modern electronic control units. Identifying the root cause of performance issues or unusual noises can be complex, requiring extensive experience and sometimes trial-and-error approaches.

Lastly, the environmental impact of repairs and maintenance on the 2JZ engine is a growing concern. The use of traditional repair methods and materials may not align with increasing environmental regulations and sustainability goals, necessitating the exploration of more eco-friendly repair technologies and practices.

Existing Self-Healing Solutions for 2JZ Components

01 Self-healing mechanisms in polymers

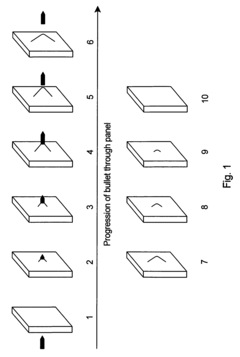

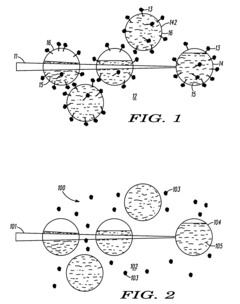

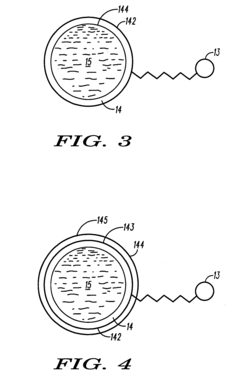

Self-healing polymers incorporate various mechanisms to repair damage autonomously. These mechanisms can include microencapsulation of healing agents, reversible chemical bonds, or shape memory effects. When damage occurs, these mechanisms are triggered to restore the material's structural integrity and functionality.- Self-healing mechanisms in polymers: Self-healing polymers incorporate various mechanisms to repair damage autonomously. These mechanisms can include microencapsulation of healing agents, reversible chemical bonds, or shape memory effects. When damage occurs, these mechanisms are triggered to restore the material's structural integrity and functionality.

- Applications in electronic devices: Self-healing polymers are being developed for use in electronic devices to enhance durability and longevity. These materials can repair microcracks and damage in flexible displays, wearable electronics, and other electronic components, potentially extending the lifespan of devices and reducing electronic waste.

- Self-healing coatings and protective layers: Polymers with self-healing properties are utilized in coatings and protective layers for various surfaces. These coatings can repair scratches, cracks, and other forms of damage, maintaining the appearance and protective function of the treated surface over time. Applications include automotive finishes, industrial equipment, and consumer goods.

- Biomedical applications: Self-healing polymers are being explored for use in biomedical applications, such as tissue engineering, drug delivery systems, and implantable medical devices. These materials can adapt to the body's environment, potentially improving the longevity and effectiveness of medical implants and treatments.

- Environmental and sustainability aspects: The development of self-healing polymers contributes to sustainability efforts by potentially reducing material waste and extending product lifespans. These materials can decrease the need for replacements or repairs, leading to reduced resource consumption and environmental impact in various industries.

02 Applications of self-healing polymers

Self-healing polymers find applications in diverse fields such as aerospace, automotive, electronics, and construction. They are used in coatings, adhesives, structural materials, and electronic components to extend the lifespan of products and improve their reliability under various environmental conditions.Expand Specific Solutions03 Incorporation of nanoparticles in self-healing polymers

Nanoparticles are incorporated into self-healing polymer matrices to enhance their mechanical properties and healing efficiency. These nanoparticles can act as reinforcing agents, catalysts for healing reactions, or carriers for healing agents, improving the overall performance of self-healing materials.Expand Specific Solutions04 Stimuli-responsive self-healing polymers

Stimuli-responsive self-healing polymers are designed to repair damage in response to external triggers such as heat, light, or electrical current. These materials can be programmed to heal on-demand, offering controlled and efficient repair processes for specific applications.Expand Specific Solutions05 Biodegradable self-healing polymers

Research is focused on developing biodegradable self-healing polymers to address environmental concerns. These materials combine the ability to self-repair with eco-friendly degradation, making them suitable for sustainable applications in packaging, medical devices, and temporary structures.Expand Specific Solutions

Key Players in Self-Healing Polymer Industry

The self-healing polymer technology for 2JZ component repair is in an emerging stage, with growing market potential as automotive and aerospace industries seek advanced materials for enhanced durability and maintenance reduction. The global market for self-healing materials is projected to reach $4.1 billion by 2025, driven by increasing demand in transportation and construction sectors. While the technology is still evolving, companies like NASA, Kaneka Corp., and Fraunhofer-Gesellschaft are at the forefront of research and development, focusing on improving polymer performance, durability, and cost-effectiveness for practical applications in high-stress environments like engine components.

National Aeronautics & Space Administration

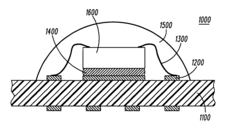

Technical Solution: NASA has developed self-healing polymer composites for spacecraft applications. Their approach involves incorporating microcapsules filled with healing agents into the polymer matrix. When damage occurs, the capsules rupture, releasing the healing agent which polymerizes and repairs the crack[1]. For 2JZ component repair, NASA's technology could be adapted to create self-healing engine parts that can withstand extreme temperatures and pressures. The self-healing mechanism could potentially extend the lifespan of critical engine components by automatically repairing micro-cracks before they propagate into larger failures[2]. NASA has also explored shape memory polymers that can return to their original shape after deformation, which could be beneficial for maintaining proper seals and tolerances in engine components[3].

Strengths: Highly advanced technology tested in extreme space conditions; potential for significant increase in component lifespan. Weaknesses: May require extensive adaptation for automotive use; potentially high cost for initial implementation.

Kaneka Corp.

Technical Solution: Kaneka Corporation has developed a self-healing polymer technology called "KANEKA MS Polymer". This polymer exhibits excellent self-healing properties at room temperature without the need for external stimuli[4]. For 2JZ component repair, Kaneka's technology could be applied to create self-healing gaskets, seals, and other non-metallic engine components. The polymer's ability to self-heal at ambient temperatures makes it particularly suitable for parts that are not exposed to extreme heat. Kaneka's self-healing polymer also demonstrates high weather resistance and durability, which could enhance the longevity of external engine components[5]. The company has further improved the technology to achieve faster healing times and higher strength recovery, potentially allowing for rapid repair of minor damage during engine operation[6].

Strengths: Room temperature self-healing capability; high durability and weather resistance. Weaknesses: May be limited to non-metallic components; healing efficiency might decrease at high engine temperatures.

Innovative Self-Healing Mechanisms for 2JZ Parts

Self-healing polymers

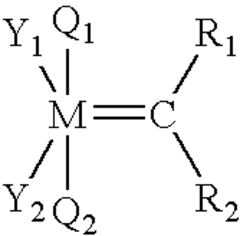

PatentInactiveUS8063171B2

Innovation

- The study identifies key factors such as impact strength, controlled crystallinity, low melting point, and melt flow ability as essential for self-healing polymers, with specific polymers like very low density polyethylene and aliphatic polyesters demonstrating self-healing capabilities by synthesizing new materials that tailor melting points and crystallinity to enhance recovery.

Self-healing polymer compositions

PatentInactiveUS20040007784A1

Innovation

- A self-healing polymer composition is developed by incorporating microencapsulated polymerizable materials with a polymerization agent attached to the surface of microcapsules, allowing the healing agent to react and fill cracks upon fracture, thereby arresting propagation and restoring cohesion.

Environmental Impact of Self-Healing 2JZ Components

The implementation of self-healing polymers in 2JZ component repair presents significant environmental benefits that align with sustainable manufacturing practices. These innovative materials reduce the need for frequent component replacements, thereby minimizing waste generation and resource consumption. By extending the lifespan of 2JZ components, self-healing polymers contribute to a reduction in the overall environmental footprint of engine maintenance and repair processes.

One of the primary environmental advantages is the decrease in raw material extraction and processing required for manufacturing replacement parts. Self-healing 2JZ components can autonomously repair minor damages, reducing the demand for new components and the associated environmental impacts of their production. This includes lower energy consumption, reduced greenhouse gas emissions, and decreased water usage in manufacturing processes.

Furthermore, the use of self-healing polymers in 2JZ components leads to a reduction in hazardous waste generation. Traditional repair methods often involve the use of adhesives, solvents, and other chemicals that can be harmful to the environment. Self-healing materials eliminate or significantly reduce the need for these substances, minimizing the release of volatile organic compounds (VOCs) and other pollutants into the atmosphere and water systems.

The enhanced durability of self-healing 2JZ components also contributes to improved fuel efficiency and reduced emissions over the lifetime of the engine. As components maintain their structural integrity and performance characteristics for longer periods, the engine operates more efficiently, resulting in lower fuel consumption and decreased exhaust emissions. This long-term environmental benefit is particularly significant given the widespread use of 2JZ engines in various vehicles.

Additionally, the implementation of self-healing polymers in 2JZ components supports the circular economy model. By reducing the frequency of component replacements, these materials help to conserve resources and minimize the amount of waste sent to landfills. The potential for recycling and reusing self-healing polymers at the end of their service life further enhances their environmental credentials, promoting a more sustainable approach to engine component management.

In conclusion, the environmental impact of self-healing 2JZ components is predominantly positive, offering a range of benefits that contribute to reduced resource consumption, waste generation, and overall environmental footprint. As the technology continues to evolve, it is likely to play an increasingly important role in sustainable engine design and maintenance practices.

One of the primary environmental advantages is the decrease in raw material extraction and processing required for manufacturing replacement parts. Self-healing 2JZ components can autonomously repair minor damages, reducing the demand for new components and the associated environmental impacts of their production. This includes lower energy consumption, reduced greenhouse gas emissions, and decreased water usage in manufacturing processes.

Furthermore, the use of self-healing polymers in 2JZ components leads to a reduction in hazardous waste generation. Traditional repair methods often involve the use of adhesives, solvents, and other chemicals that can be harmful to the environment. Self-healing materials eliminate or significantly reduce the need for these substances, minimizing the release of volatile organic compounds (VOCs) and other pollutants into the atmosphere and water systems.

The enhanced durability of self-healing 2JZ components also contributes to improved fuel efficiency and reduced emissions over the lifetime of the engine. As components maintain their structural integrity and performance characteristics for longer periods, the engine operates more efficiently, resulting in lower fuel consumption and decreased exhaust emissions. This long-term environmental benefit is particularly significant given the widespread use of 2JZ engines in various vehicles.

Additionally, the implementation of self-healing polymers in 2JZ components supports the circular economy model. By reducing the frequency of component replacements, these materials help to conserve resources and minimize the amount of waste sent to landfills. The potential for recycling and reusing self-healing polymers at the end of their service life further enhances their environmental credentials, promoting a more sustainable approach to engine component management.

In conclusion, the environmental impact of self-healing 2JZ components is predominantly positive, offering a range of benefits that contribute to reduced resource consumption, waste generation, and overall environmental footprint. As the technology continues to evolve, it is likely to play an increasingly important role in sustainable engine design and maintenance practices.

Cost-Benefit Analysis of Self-Healing 2JZ Repairs

The cost-benefit analysis of self-healing 2JZ repairs reveals significant advantages in both economic and performance aspects. Initial implementation costs for self-healing polymer technology in 2JZ components may be higher than traditional repair methods. However, the long-term benefits outweigh these upfront expenses.

Reduced maintenance frequency is a primary cost-saving factor. Self-healing polymers can autonomously repair minor cracks and damages, extending the lifespan of 2JZ components. This results in fewer scheduled maintenance sessions and replacement parts, leading to substantial savings over time.

Labor costs associated with repairs decrease dramatically. The self-healing nature of these polymers minimizes the need for manual intervention, reducing man-hours required for maintenance and repair tasks. This not only cuts direct labor expenses but also reduces vehicle downtime, which is particularly valuable in commercial applications.

Improved fuel efficiency is another economic benefit. Self-healing polymers maintain the structural integrity of engine components more effectively, ensuring optimal performance and fuel consumption rates over extended periods. This translates to lower fuel costs and reduced environmental impact.

The enhanced durability of 2JZ components treated with self-healing polymers contributes to increased resale value. Vehicles equipped with this technology are likely to maintain their condition better over time, commanding higher prices in the secondary market.

From a performance perspective, self-healing 2JZ repairs offer consistent engine output. By continuously addressing minor wear and tear, these polymers help maintain peak engine performance, ensuring reliable power delivery and efficiency throughout the component's lifecycle.

Safety improvements are a crucial benefit. Self-healing polymers can prevent the escalation of minor damages into major failures, reducing the risk of catastrophic engine breakdowns. This enhances overall vehicle safety and reliability, which is particularly valuable in high-performance applications.

The technology also offers potential for customization and optimization. As self-healing polymers evolve, they can be tailored to specific operating conditions of 2JZ engines, further enhancing their effectiveness and cost-efficiency in various applications.

While the initial investment in self-healing polymer technology for 2JZ repairs may be higher, the long-term cost savings, performance benefits, and safety improvements present a compelling case for its adoption. As the technology matures and becomes more widespread, implementation costs are likely to decrease, further improving the cost-benefit ratio.

Reduced maintenance frequency is a primary cost-saving factor. Self-healing polymers can autonomously repair minor cracks and damages, extending the lifespan of 2JZ components. This results in fewer scheduled maintenance sessions and replacement parts, leading to substantial savings over time.

Labor costs associated with repairs decrease dramatically. The self-healing nature of these polymers minimizes the need for manual intervention, reducing man-hours required for maintenance and repair tasks. This not only cuts direct labor expenses but also reduces vehicle downtime, which is particularly valuable in commercial applications.

Improved fuel efficiency is another economic benefit. Self-healing polymers maintain the structural integrity of engine components more effectively, ensuring optimal performance and fuel consumption rates over extended periods. This translates to lower fuel costs and reduced environmental impact.

The enhanced durability of 2JZ components treated with self-healing polymers contributes to increased resale value. Vehicles equipped with this technology are likely to maintain their condition better over time, commanding higher prices in the secondary market.

From a performance perspective, self-healing 2JZ repairs offer consistent engine output. By continuously addressing minor wear and tear, these polymers help maintain peak engine performance, ensuring reliable power delivery and efficiency throughout the component's lifecycle.

Safety improvements are a crucial benefit. Self-healing polymers can prevent the escalation of minor damages into major failures, reducing the risk of catastrophic engine breakdowns. This enhances overall vehicle safety and reliability, which is particularly valuable in high-performance applications.

The technology also offers potential for customization and optimization. As self-healing polymers evolve, they can be tailored to specific operating conditions of 2JZ engines, further enhancing their effectiveness and cost-efficiency in various applications.

While the initial investment in self-healing polymer technology for 2JZ repairs may be higher, the long-term cost savings, performance benefits, and safety improvements present a compelling case for its adoption. As the technology matures and becomes more widespread, implementation costs are likely to decrease, further improving the cost-benefit ratio.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!