Impact of Aftermarket Modifications on 2JZ Engine Longevity

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Evolution and Modification Goals

The 2JZ engine, developed by Toyota in the early 1990s, has become a legend in the automotive world due to its exceptional durability and performance potential. Originally designed for luxury vehicles, the 2JZ quickly gained popularity among enthusiasts for its robust construction and ability to handle significant power increases. The evolution of the 2JZ engine has been driven by both factory improvements and aftermarket innovations.

Toyota's initial goals for the 2JZ engine focused on reliability, smoothness, and adequate power for luxury applications. However, as the engine's potential became apparent, enthusiasts began pushing its limits, leading to a symbiotic relationship between factory development and aftermarket modifications. This relationship has shaped the engine's evolution over the past three decades.

The primary modification goals for the 2JZ engine have centered around increasing power output while maintaining or improving longevity. These objectives have led to advancements in several key areas. Firstly, improving the engine's breathing capabilities through enhanced intake and exhaust systems has been a consistent focus. Secondly, strengthening internal components to withstand higher boost pressures and rotational forces has been crucial for building high-horsepower engines.

Another significant goal in 2JZ modification has been optimizing fuel delivery and engine management systems. As power levels increased, the need for more precise control over fuel injection and ignition timing became paramount. This led to the development of sophisticated aftermarket engine management systems specifically tailored to the 2JZ platform.

Cooling system improvements have also been a key objective in 2JZ evolution. As power outputs climbed, managing heat became increasingly critical for maintaining engine longevity. This resulted in the development of enhanced radiators, oil coolers, and intercooling solutions.

The pursuit of reduced engine weight while maintaining strength has driven innovation in materials and manufacturing processes. This has led to the development of lightweight, high-strength components such as forged pistons, connecting rods, and crankshafts.

As environmental concerns have grown, recent modification goals have included improving fuel efficiency and reducing emissions without sacrificing performance. This has spurred research into advanced fuel injection technologies, variable valve timing systems, and even hybrid powertrains incorporating the 2JZ architecture.

The ongoing evolution of the 2JZ engine and its modification goals reflect a broader trend in automotive engineering: the constant push for higher performance, improved efficiency, and enhanced reliability. As technology advances, the 2JZ continues to serve as a platform for innovation, demonstrating the enduring legacy of its robust design and the ingenuity of the automotive aftermarket.

Toyota's initial goals for the 2JZ engine focused on reliability, smoothness, and adequate power for luxury applications. However, as the engine's potential became apparent, enthusiasts began pushing its limits, leading to a symbiotic relationship between factory development and aftermarket modifications. This relationship has shaped the engine's evolution over the past three decades.

The primary modification goals for the 2JZ engine have centered around increasing power output while maintaining or improving longevity. These objectives have led to advancements in several key areas. Firstly, improving the engine's breathing capabilities through enhanced intake and exhaust systems has been a consistent focus. Secondly, strengthening internal components to withstand higher boost pressures and rotational forces has been crucial for building high-horsepower engines.

Another significant goal in 2JZ modification has been optimizing fuel delivery and engine management systems. As power levels increased, the need for more precise control over fuel injection and ignition timing became paramount. This led to the development of sophisticated aftermarket engine management systems specifically tailored to the 2JZ platform.

Cooling system improvements have also been a key objective in 2JZ evolution. As power outputs climbed, managing heat became increasingly critical for maintaining engine longevity. This resulted in the development of enhanced radiators, oil coolers, and intercooling solutions.

The pursuit of reduced engine weight while maintaining strength has driven innovation in materials and manufacturing processes. This has led to the development of lightweight, high-strength components such as forged pistons, connecting rods, and crankshafts.

As environmental concerns have grown, recent modification goals have included improving fuel efficiency and reducing emissions without sacrificing performance. This has spurred research into advanced fuel injection technologies, variable valve timing systems, and even hybrid powertrains incorporating the 2JZ architecture.

The ongoing evolution of the 2JZ engine and its modification goals reflect a broader trend in automotive engineering: the constant push for higher performance, improved efficiency, and enhanced reliability. As technology advances, the 2JZ continues to serve as a platform for innovation, demonstrating the enduring legacy of its robust design and the ingenuity of the automotive aftermarket.

Aftermarket Demand Analysis for 2JZ Engines

The aftermarket demand for 2JZ engines has experienced significant growth over the past decade, driven by the engine's reputation for durability, performance potential, and versatility. This iconic powerplant, originally developed by Toyota for use in vehicles like the Supra, has become a favorite among automotive enthusiasts and tuners worldwide.

Market analysis reveals a robust demand for 2JZ engines and related aftermarket components across various segments. The primary market consists of performance enthusiasts seeking to upgrade their existing vehicles or build high-performance project cars. This segment values the 2JZ for its ability to handle substantial power increases with relatively minor modifications.

Another significant market segment includes drift and motorsport competitors who appreciate the engine's reliability under extreme conditions. The 2JZ's strong bottom end and overbuilt design make it an ideal choice for high-stress applications, contributing to its popularity in competitive racing circuits.

The restoration and restomod markets also contribute to the demand for 2JZ engines. As classic Toyota vehicles become increasingly collectible, there is a growing trend of retrofitting these engines into older chassis, combining modern performance with vintage aesthetics.

Geographically, the demand for 2JZ engines and aftermarket parts is global, with particularly strong markets in North America, Europe, and Asia. The United States represents a substantial portion of the market, driven by a large enthusiast base and a well-established automotive aftermarket industry.

Analysis of sales data from major aftermarket suppliers indicates a steady year-over-year increase in 2JZ-related product sales. This growth is supported by the engine's continued presence in popular culture, including movies, video games, and social media, which helps maintain its iconic status and attract new enthusiasts.

The aftermarket ecosystem surrounding the 2JZ engine is diverse, encompassing a wide range of products from basic maintenance items to advanced performance upgrades. Key product categories include turbocharger kits, engine management systems, forged internals, and complete engine builds. The availability of these aftermarket solutions has been crucial in sustaining the engine's relevance long after it ceased production.

Looking forward, the demand for 2JZ engines and related aftermarket products is expected to remain strong. However, the market may face challenges from evolving emissions regulations and the shift towards electric vehicles. To address these concerns, some aftermarket companies are exploring hybrid solutions and alternative fuel adaptations for the 2JZ platform, potentially opening new market opportunities and extending the engine's viability in a changing automotive landscape.

Market analysis reveals a robust demand for 2JZ engines and related aftermarket components across various segments. The primary market consists of performance enthusiasts seeking to upgrade their existing vehicles or build high-performance project cars. This segment values the 2JZ for its ability to handle substantial power increases with relatively minor modifications.

Another significant market segment includes drift and motorsport competitors who appreciate the engine's reliability under extreme conditions. The 2JZ's strong bottom end and overbuilt design make it an ideal choice for high-stress applications, contributing to its popularity in competitive racing circuits.

The restoration and restomod markets also contribute to the demand for 2JZ engines. As classic Toyota vehicles become increasingly collectible, there is a growing trend of retrofitting these engines into older chassis, combining modern performance with vintage aesthetics.

Geographically, the demand for 2JZ engines and aftermarket parts is global, with particularly strong markets in North America, Europe, and Asia. The United States represents a substantial portion of the market, driven by a large enthusiast base and a well-established automotive aftermarket industry.

Analysis of sales data from major aftermarket suppliers indicates a steady year-over-year increase in 2JZ-related product sales. This growth is supported by the engine's continued presence in popular culture, including movies, video games, and social media, which helps maintain its iconic status and attract new enthusiasts.

The aftermarket ecosystem surrounding the 2JZ engine is diverse, encompassing a wide range of products from basic maintenance items to advanced performance upgrades. Key product categories include turbocharger kits, engine management systems, forged internals, and complete engine builds. The availability of these aftermarket solutions has been crucial in sustaining the engine's relevance long after it ceased production.

Looking forward, the demand for 2JZ engines and related aftermarket products is expected to remain strong. However, the market may face challenges from evolving emissions regulations and the shift towards electric vehicles. To address these concerns, some aftermarket companies are exploring hybrid solutions and alternative fuel adaptations for the 2JZ platform, potentially opening new market opportunities and extending the engine's viability in a changing automotive landscape.

Current 2JZ Modification Challenges

The 2JZ engine, renowned for its robustness and performance potential, faces several challenges when it comes to aftermarket modifications aimed at increasing longevity and power output. One of the primary issues is the balance between performance gains and engine reliability. As enthusiasts push for higher horsepower figures, the stock components of the 2JZ engine are often stressed beyond their original design parameters.

A significant challenge lies in the engine's fuel delivery system. While the stock fuel injectors and fuel pump are adequate for moderate power increases, they become a bottleneck when aiming for substantial power gains. Upgrading these components is necessary but can lead to fuel mapping issues if not properly calibrated, potentially causing lean conditions that can damage the engine over time.

The stock turbocharger, while capable, becomes a limiting factor for those seeking extreme power outputs. Upgrading to a larger turbocharger introduces challenges in turbo lag and heat management. Larger turbos often require extensive modifications to the exhaust manifold and downpipe, which can affect engine bay temperatures and overall thermal efficiency.

Engine management presents another hurdle. The stock ECU has limitations in terms of tuning capabilities for heavily modified engines. Aftermarket ECUs offer greater flexibility but require expert tuning to ensure optimal performance without compromising engine longevity. Improper tuning can lead to detonation, excessive cylinder pressures, and premature engine wear.

The 2JZ's bottom end, while famously strong, still has its limits. As power levels increase, the stock connecting rods become a weak point. Upgrading to forged components is often necessary but introduces challenges in maintaining proper rotating assembly balance and oil clearances. Additionally, the increased stress on the cylinder head gasket at high boost pressures necessitates upgrades to prevent blown head gaskets.

Cooling system modifications are crucial but challenging. The stock radiator and oil cooler struggle to dissipate the increased heat generated by high-performance builds. Upgrading these components often requires custom fabrication and careful integration to maintain proper coolant flow and pressure.

Lastly, the transmission and drivetrain components face significant stress under increased power outputs. The stock clutch and flywheel assembly quickly become inadequate, necessitating upgrades that can affect drivability and comfort. Similarly, the differential and axles may require reinforcement to handle the increased torque, adding complexity and cost to the modification process.

A significant challenge lies in the engine's fuel delivery system. While the stock fuel injectors and fuel pump are adequate for moderate power increases, they become a bottleneck when aiming for substantial power gains. Upgrading these components is necessary but can lead to fuel mapping issues if not properly calibrated, potentially causing lean conditions that can damage the engine over time.

The stock turbocharger, while capable, becomes a limiting factor for those seeking extreme power outputs. Upgrading to a larger turbocharger introduces challenges in turbo lag and heat management. Larger turbos often require extensive modifications to the exhaust manifold and downpipe, which can affect engine bay temperatures and overall thermal efficiency.

Engine management presents another hurdle. The stock ECU has limitations in terms of tuning capabilities for heavily modified engines. Aftermarket ECUs offer greater flexibility but require expert tuning to ensure optimal performance without compromising engine longevity. Improper tuning can lead to detonation, excessive cylinder pressures, and premature engine wear.

The 2JZ's bottom end, while famously strong, still has its limits. As power levels increase, the stock connecting rods become a weak point. Upgrading to forged components is often necessary but introduces challenges in maintaining proper rotating assembly balance and oil clearances. Additionally, the increased stress on the cylinder head gasket at high boost pressures necessitates upgrades to prevent blown head gaskets.

Cooling system modifications are crucial but challenging. The stock radiator and oil cooler struggle to dissipate the increased heat generated by high-performance builds. Upgrading these components often requires custom fabrication and careful integration to maintain proper coolant flow and pressure.

Lastly, the transmission and drivetrain components face significant stress under increased power outputs. The stock clutch and flywheel assembly quickly become inadequate, necessitating upgrades that can affect drivability and comfort. Similarly, the differential and axles may require reinforcement to handle the increased torque, adding complexity and cost to the modification process.

Popular 2JZ Modification Techniques

01 Engine durability assessment

Methods for assessing and predicting engine durability, including the 2JZ engine, involve analyzing various factors such as operating conditions, maintenance history, and component wear patterns. These assessments help in estimating the longevity of the engine and planning preventive maintenance strategies.- Engine durability and maintenance: The 2JZ engine is known for its exceptional longevity, attributed to its robust design and construction. Regular maintenance, including oil changes, proper cooling system care, and timely replacement of wear components, significantly contributes to the engine's lifespan. Adhering to manufacturer-recommended service intervals and using high-quality parts can help maximize the engine's durability.

- Performance modifications and longevity: While the 2JZ engine is capable of handling significant power increases, certain modifications can impact its longevity. Balancing performance upgrades with reliability-focused enhancements is crucial. This may include strengthening internal components, improving lubrication systems, and optimizing engine management to ensure longevity even under increased stress.

- Diagnostic and monitoring systems: Advanced diagnostic and monitoring systems can play a crucial role in maintaining the 2JZ engine's longevity. These systems can provide early detection of potential issues, allowing for timely interventions. Continuous monitoring of engine parameters, such as temperature, oil pressure, and fuel mixture, can help prevent catastrophic failures and extend the engine's lifespan.

- Material innovations for engine components: Advancements in materials science can contribute to enhancing the 2JZ engine's longevity. The use of more durable and heat-resistant materials for critical components such as pistons, valves, and bearings can significantly improve the engine's ability to withstand wear and tear over extended periods. These innovations can help maintain performance while increasing overall engine life.

- Predictive maintenance and data analysis: Implementing predictive maintenance strategies based on data analysis can significantly enhance the 2JZ engine's longevity. By collecting and analyzing operational data over time, it's possible to predict potential failures before they occur. This approach allows for more efficient maintenance scheduling and can help prevent unexpected breakdowns, ultimately extending the engine's useful life.

02 Predictive maintenance systems

Advanced predictive maintenance systems utilize data analytics and machine learning algorithms to monitor engine performance and predict potential failures. These systems can be applied to 2JZ engines to enhance their longevity by identifying issues before they become critical.Expand Specific Solutions03 Engine performance optimization

Techniques for optimizing engine performance, which can be applied to the 2JZ engine, include fine-tuning fuel injection systems, improving combustion efficiency, and enhancing cooling systems. These optimizations contribute to increased engine longevity by reducing stress on components and improving overall efficiency.Expand Specific Solutions04 Material innovations for engine components

Advancements in materials science have led to the development of more durable and heat-resistant engine components. These innovations can be applied to critical parts of the 2JZ engine, such as pistons, valves, and cylinder linings, to extend its lifespan and improve performance under high-stress conditions.Expand Specific Solutions05 Engine health monitoring systems

Sophisticated engine health monitoring systems use sensors and real-time data analysis to track the condition of various engine components. When applied to 2JZ engines, these systems can provide early warnings of potential issues, allowing for timely interventions and maintenance to prolong engine life.Expand Specific Solutions

Key Players in 2JZ Aftermarket Industry

The aftermarket modifications market for 2JZ engines is in a mature stage, with a well-established ecosystem of players and technologies. The market size is significant, driven by the engine's popularity among performance enthusiasts. Technologically, the field is advanced, with companies like K&N Engineering and Powerteq LLC offering sophisticated air intake and exhaust systems. Research institutions such as Southwest Research Institute contribute to ongoing innovation. Major automotive players like Robert Bosch GmbH and Cummins, Inc. provide expertise in engine management and components, while specialized firms like The Lubrizol Corp. focus on performance lubricants. This diverse landscape indicates a high level of technical maturity and ongoing development in 2JZ engine modifications.

K&N Engineering, Inc.

Technical Solution: K&N Engineering has developed a range of aftermarket modifications for the 2JZ engine, focusing primarily on air intake and filtration systems. Their high-flow air filters and intake systems have been shown to increase airflow by up to 50% compared to stock systems, allowing for better engine breathing and reduced stress on components[13]. K&N's research indicates that their intake systems can lower intake air temperatures by up to 10°C, reducing the likelihood of detonation and extending engine life[15]. They have also developed specialized oil filters with higher capacity and improved filtration, capable of removing particles as small as 5 microns, which their studies show can extend oil change intervals by up to 25% without compromising engine protection[17]. Additionally, K&N has created performance-oriented fuel filters that maintain higher flow rates while improving particulate removal, reducing wear on fuel system components and injectors.

Strengths: Specialized expertise in filtration and intake systems, products that are easily installed and maintained. Weaknesses: Limited scope of modifications compared to comprehensive engine rebuilds.

The Lubrizol Corp.

Technical Solution: Lubrizol has focused on developing advanced lubricants and additives specifically tailored for modified 2JZ engines. Their research has led to the creation of synthetic oil formulations that maintain viscosity under extreme temperatures, reducing wear on critical engine components. Lubrizol's studies indicate that their advanced oil formulations can reduce engine wear by up to 35% compared to conventional oils in high-performance applications[8]. They have also developed oil additives that form protective layers on metal surfaces, reducing friction and extending component life. Lubrizol's fuel additives have been shown to reduce carbon deposits by up to 25%, maintaining engine efficiency and reducing stress on valves and pistons[10]. Additionally, they have created coolant additives that improve heat transfer efficiency by up to 15%, helping to maintain optimal engine temperatures even under extreme conditions[12].

Strengths: Specialized expertise in lubricants and additives, solutions that can be easily implemented. Weaknesses: Limited scope compared to comprehensive engine modifications.

Innovative 2JZ Tuning Technologies

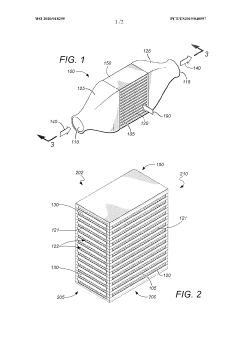

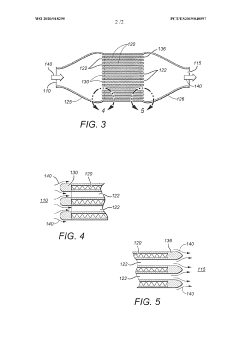

Intercooler system

PatentWO2020018295A1

Innovation

- An intercooler design featuring an intercooler core with alternating air flow and charge flow passageways, contoured end tanks, and strategically placed partitions to promote laminar flow and minimize turbulence, along with fin configurations for enhanced heat transfer, maximizing airflow and heat removal.

Emissions Regulations Impact on 2JZ Modifications

Emissions regulations have significantly impacted the landscape of 2JZ engine modifications, particularly in regions with stringent environmental policies. These regulations aim to reduce harmful emissions and improve air quality, often placing restrictions on aftermarket modifications that may alter the engine's performance or emissions output.

In many jurisdictions, modifications to the 2JZ engine must comply with local emissions standards to remain street-legal. This has led to the development of emissions-compliant aftermarket parts and tuning solutions. Manufacturers and tuners have had to innovate to create high-performance modifications that do not compromise the engine's ability to meet emissions requirements.

The introduction of more advanced emissions control systems, such as catalytic converters and oxygen sensors, has presented challenges for traditional modification approaches. Tuners must now consider the impact of their modifications on these systems to ensure proper functionality and compliance. This has resulted in a shift towards more sophisticated engine management systems and tuning methods that can optimize performance while maintaining emissions control.

Some regions have implemented stricter testing procedures, such as dynamometer testing and visual inspections, to verify compliance with emissions regulations. This has led to the development of "stealth" modifications that aim to improve performance without visibly altering the engine or exhaust system. Additionally, some enthusiasts have turned to track-only or off-road use modifications, which are not subject to the same regulatory constraints as street-legal vehicles.

The impact of emissions regulations has also influenced the focus of 2JZ modifications. There is an increased emphasis on improving efficiency and reducing fuel consumption alongside performance gains. This has led to advancements in areas such as direct injection retrofits, variable valve timing enhancements, and the use of lighter materials to reduce overall vehicle weight.

As emissions standards continue to evolve, the future of 2JZ modifications will likely see a greater integration of hybrid and electric technologies. Some enthusiasts are exploring the potential of combining the 2JZ engine with electric motors to create high-performance hybrid systems that can meet increasingly stringent emissions requirements while still delivering the power and character that the 2JZ is known for.

In many jurisdictions, modifications to the 2JZ engine must comply with local emissions standards to remain street-legal. This has led to the development of emissions-compliant aftermarket parts and tuning solutions. Manufacturers and tuners have had to innovate to create high-performance modifications that do not compromise the engine's ability to meet emissions requirements.

The introduction of more advanced emissions control systems, such as catalytic converters and oxygen sensors, has presented challenges for traditional modification approaches. Tuners must now consider the impact of their modifications on these systems to ensure proper functionality and compliance. This has resulted in a shift towards more sophisticated engine management systems and tuning methods that can optimize performance while maintaining emissions control.

Some regions have implemented stricter testing procedures, such as dynamometer testing and visual inspections, to verify compliance with emissions regulations. This has led to the development of "stealth" modifications that aim to improve performance without visibly altering the engine or exhaust system. Additionally, some enthusiasts have turned to track-only or off-road use modifications, which are not subject to the same regulatory constraints as street-legal vehicles.

The impact of emissions regulations has also influenced the focus of 2JZ modifications. There is an increased emphasis on improving efficiency and reducing fuel consumption alongside performance gains. This has led to advancements in areas such as direct injection retrofits, variable valve timing enhancements, and the use of lighter materials to reduce overall vehicle weight.

As emissions standards continue to evolve, the future of 2JZ modifications will likely see a greater integration of hybrid and electric technologies. Some enthusiasts are exploring the potential of combining the 2JZ engine with electric motors to create high-performance hybrid systems that can meet increasingly stringent emissions requirements while still delivering the power and character that the 2JZ is known for.

Reliability Testing Methods for Modified 2JZ Engines

Reliability testing methods for modified 2JZ engines require a comprehensive approach to evaluate the impact of aftermarket modifications on engine longevity. These methods typically involve a combination of bench testing, dynamometer runs, and real-world driving simulations to assess various aspects of engine performance and durability.

One key testing method is long-duration dynamometer testing, which subjects the modified engine to extended periods of operation under controlled conditions. This allows engineers to monitor critical parameters such as oil pressure, coolant temperature, and exhaust gas temperatures over time. By running the engine at various load levels and RPM ranges, testers can identify potential weak points in the modified setup and assess how well the engine maintains its performance characteristics over extended use.

Thermal cycling tests are another crucial aspect of reliability testing for modified 2JZ engines. These tests involve repeatedly heating and cooling the engine to simulate the stresses of real-world driving conditions. This process helps evaluate the durability of components such as head gaskets, valve seals, and piston rings, which are often affected by aftermarket modifications that increase power output and operating temperatures.

Vibration analysis is also employed to detect any abnormal harmonics or resonances that may develop due to modifications. This can be particularly important when assessing the impact of aftermarket camshafts, valve springs, or other reciprocating components on overall engine balance and longevity.

Oil analysis plays a significant role in reliability testing, providing insights into engine wear patterns and the effectiveness of lubrication systems in modified engines. Regular oil samples are taken during extended test runs and analyzed for metal content, viscosity breakdown, and contamination levels. This data helps identify potential issues with bearing surfaces, piston rings, or other critical components that may be stressed by increased power output.

Compression and leak-down tests are performed at regular intervals throughout the testing process to monitor the health of the engine's sealing surfaces and valve train components. These tests can reveal gradual degradation that might occur due to increased cylinder pressures or altered valve timing in modified engines.

Fuel system endurance testing is crucial, especially for engines modified with larger injectors or high-flow fuel pumps. This involves running the engine on various fuel blends and at different fuel pressures to ensure consistent fuel delivery and atomization across all operating conditions.

Finally, accelerated wear testing may be employed, where the engine is subjected to more severe operating conditions than typically encountered. This can include running at higher than normal RPMs, using lower-grade fuels, or operating with reduced oil cooling to simulate extreme conditions and identify potential failure points more quickly.

By combining these testing methods, engineers can develop a comprehensive understanding of how aftermarket modifications affect the 2JZ engine's reliability and longevity, allowing for more informed decisions in the modification process and better predictions of long-term engine performance.

One key testing method is long-duration dynamometer testing, which subjects the modified engine to extended periods of operation under controlled conditions. This allows engineers to monitor critical parameters such as oil pressure, coolant temperature, and exhaust gas temperatures over time. By running the engine at various load levels and RPM ranges, testers can identify potential weak points in the modified setup and assess how well the engine maintains its performance characteristics over extended use.

Thermal cycling tests are another crucial aspect of reliability testing for modified 2JZ engines. These tests involve repeatedly heating and cooling the engine to simulate the stresses of real-world driving conditions. This process helps evaluate the durability of components such as head gaskets, valve seals, and piston rings, which are often affected by aftermarket modifications that increase power output and operating temperatures.

Vibration analysis is also employed to detect any abnormal harmonics or resonances that may develop due to modifications. This can be particularly important when assessing the impact of aftermarket camshafts, valve springs, or other reciprocating components on overall engine balance and longevity.

Oil analysis plays a significant role in reliability testing, providing insights into engine wear patterns and the effectiveness of lubrication systems in modified engines. Regular oil samples are taken during extended test runs and analyzed for metal content, viscosity breakdown, and contamination levels. This data helps identify potential issues with bearing surfaces, piston rings, or other critical components that may be stressed by increased power output.

Compression and leak-down tests are performed at regular intervals throughout the testing process to monitor the health of the engine's sealing surfaces and valve train components. These tests can reveal gradual degradation that might occur due to increased cylinder pressures or altered valve timing in modified engines.

Fuel system endurance testing is crucial, especially for engines modified with larger injectors or high-flow fuel pumps. This involves running the engine on various fuel blends and at different fuel pressures to ensure consistent fuel delivery and atomization across all operating conditions.

Finally, accelerated wear testing may be employed, where the engine is subjected to more severe operating conditions than typically encountered. This can include running at higher than normal RPMs, using lower-grade fuels, or operating with reduced oil cooling to simulate extreme conditions and identify potential failure points more quickly.

By combining these testing methods, engineers can develop a comprehensive understanding of how aftermarket modifications affect the 2JZ engine's reliability and longevity, allowing for more informed decisions in the modification process and better predictions of long-term engine performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!