Reservoir Dynamics for Precision in 2JZ Fluid Systems

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Fluid System Background and Objectives

The 2JZ fluid system, renowned for its robustness and performance in automotive applications, has been a cornerstone of high-performance engine design since its introduction in the early 1990s. This system, originally developed by Toyota for their flagship sports cars, has become a benchmark for fluid dynamics in internal combustion engines. The evolution of the 2JZ system has been marked by continuous refinements in reservoir design, fluid flow optimization, and pressure management techniques.

The primary objective of researching reservoir dynamics in 2JZ fluid systems is to enhance precision and efficiency in fluid management, ultimately leading to improved engine performance and reliability. This research aims to address the increasing demands for power output, fuel efficiency, and environmental compliance in modern automotive applications. By focusing on the intricate interplay between fluid dynamics and reservoir design, researchers seek to unlock new potentials in engine performance while maintaining the legendary durability associated with the 2JZ platform.

Recent technological advancements in computational fluid dynamics (CFD) and materials science have opened new avenues for innovation in 2JZ fluid systems. These developments allow for more accurate modeling of fluid behavior under extreme conditions, enabling engineers to push the boundaries of design without compromising reliability. The integration of smart materials and adaptive control systems into reservoir design represents a promising frontier in this field, potentially leading to fluid systems that can dynamically adjust to varying operational demands.

The global trend towards electrification in the automotive industry has paradoxically intensified interest in advanced internal combustion engine technologies. This renewed focus on traditional powertrains has spurred investment in research aimed at extracting maximum efficiency and performance from proven platforms like the 2JZ. As such, the study of reservoir dynamics in these systems is not merely an exercise in incremental improvement but a critical path towards bridging current automotive technologies with future powertrain solutions.

Precision in 2JZ fluid systems is paramount, given the high-stress environments in which these engines often operate. Research objectives in this area include developing more accurate predictive models for fluid behavior under extreme temperatures and pressures, optimizing reservoir geometry to minimize turbulence and cavitation, and exploring novel materials that can enhance heat dissipation and fluid stability. These efforts are crucial for pushing the performance envelope while maintaining the reliability that has made the 2JZ system legendary among enthusiasts and engineers alike.

The primary objective of researching reservoir dynamics in 2JZ fluid systems is to enhance precision and efficiency in fluid management, ultimately leading to improved engine performance and reliability. This research aims to address the increasing demands for power output, fuel efficiency, and environmental compliance in modern automotive applications. By focusing on the intricate interplay between fluid dynamics and reservoir design, researchers seek to unlock new potentials in engine performance while maintaining the legendary durability associated with the 2JZ platform.

Recent technological advancements in computational fluid dynamics (CFD) and materials science have opened new avenues for innovation in 2JZ fluid systems. These developments allow for more accurate modeling of fluid behavior under extreme conditions, enabling engineers to push the boundaries of design without compromising reliability. The integration of smart materials and adaptive control systems into reservoir design represents a promising frontier in this field, potentially leading to fluid systems that can dynamically adjust to varying operational demands.

The global trend towards electrification in the automotive industry has paradoxically intensified interest in advanced internal combustion engine technologies. This renewed focus on traditional powertrains has spurred investment in research aimed at extracting maximum efficiency and performance from proven platforms like the 2JZ. As such, the study of reservoir dynamics in these systems is not merely an exercise in incremental improvement but a critical path towards bridging current automotive technologies with future powertrain solutions.

Precision in 2JZ fluid systems is paramount, given the high-stress environments in which these engines often operate. Research objectives in this area include developing more accurate predictive models for fluid behavior under extreme temperatures and pressures, optimizing reservoir geometry to minimize turbulence and cavitation, and exploring novel materials that can enhance heat dissipation and fluid stability. These efforts are crucial for pushing the performance envelope while maintaining the reliability that has made the 2JZ system legendary among enthusiasts and engineers alike.

Market Analysis for Precision Reservoir Dynamics

The market for precision reservoir dynamics in 2JZ fluid systems has shown significant growth potential in recent years. This technology, which focuses on enhancing the performance and efficiency of fluid management in high-performance engines, has garnered increasing attention from automotive manufacturers, racing teams, and aftermarket parts suppliers.

The global automotive fluid systems market, within which 2JZ systems represent a niche but high-value segment, is projected to expand at a steady rate. This growth is primarily driven by the increasing demand for high-performance vehicles and the continuous pursuit of engine efficiency improvements. The precision reservoir dynamics sector, in particular, is expected to outpace the overall market growth due to its critical role in optimizing engine performance.

Key market drivers include the rising popularity of motorsports, the growing trend of vehicle customization, and the increasing focus on fuel efficiency even in high-performance applications. Additionally, stringent emission regulations worldwide are pushing manufacturers to adopt more sophisticated fluid management systems, further boosting the demand for precision reservoir dynamics solutions.

The market for 2JZ fluid systems is geographically concentrated, with Japan, the United States, and Germany being the primary hubs. However, emerging markets in Asia and the Middle East are showing rapid growth, driven by increasing disposable incomes and a growing enthusiasm for high-performance vehicles.

In terms of market segmentation, the precision reservoir dynamics for 2JZ fluid systems cater to three main categories: OEM (Original Equipment Manufacturers), aftermarket performance parts, and professional racing teams. The OEM segment, while smaller in volume, offers stable and long-term contracts. The aftermarket segment shows the highest growth rate, fueled by enthusiasts seeking to enhance their vehicle's performance. The professional racing segment, although limited in size, drives innovation and serves as a testbed for new technologies.

Customer demand in this market is characterized by a strong emphasis on reliability, precision, and customization. End-users are willing to pay premium prices for systems that can demonstrably improve engine performance, fuel efficiency, and overall vehicle dynamics. This has led to a trend of continuous innovation and product development within the industry.

Despite the positive outlook, the market faces challenges such as high development costs, the need for specialized expertise, and the cyclical nature of the automotive industry. Additionally, the increasing shift towards electric vehicles poses a long-term threat to the traditional internal combustion engine market, including specialized systems like those for the 2JZ engine.

The global automotive fluid systems market, within which 2JZ systems represent a niche but high-value segment, is projected to expand at a steady rate. This growth is primarily driven by the increasing demand for high-performance vehicles and the continuous pursuit of engine efficiency improvements. The precision reservoir dynamics sector, in particular, is expected to outpace the overall market growth due to its critical role in optimizing engine performance.

Key market drivers include the rising popularity of motorsports, the growing trend of vehicle customization, and the increasing focus on fuel efficiency even in high-performance applications. Additionally, stringent emission regulations worldwide are pushing manufacturers to adopt more sophisticated fluid management systems, further boosting the demand for precision reservoir dynamics solutions.

The market for 2JZ fluid systems is geographically concentrated, with Japan, the United States, and Germany being the primary hubs. However, emerging markets in Asia and the Middle East are showing rapid growth, driven by increasing disposable incomes and a growing enthusiasm for high-performance vehicles.

In terms of market segmentation, the precision reservoir dynamics for 2JZ fluid systems cater to three main categories: OEM (Original Equipment Manufacturers), aftermarket performance parts, and professional racing teams. The OEM segment, while smaller in volume, offers stable and long-term contracts. The aftermarket segment shows the highest growth rate, fueled by enthusiasts seeking to enhance their vehicle's performance. The professional racing segment, although limited in size, drives innovation and serves as a testbed for new technologies.

Customer demand in this market is characterized by a strong emphasis on reliability, precision, and customization. End-users are willing to pay premium prices for systems that can demonstrably improve engine performance, fuel efficiency, and overall vehicle dynamics. This has led to a trend of continuous innovation and product development within the industry.

Despite the positive outlook, the market faces challenges such as high development costs, the need for specialized expertise, and the cyclical nature of the automotive industry. Additionally, the increasing shift towards electric vehicles poses a long-term threat to the traditional internal combustion engine market, including specialized systems like those for the 2JZ engine.

Current Challenges in 2JZ Fluid System Dynamics

The 2JZ fluid system, renowned for its robustness and performance in automotive applications, faces several challenges in achieving precise reservoir dynamics. One of the primary issues is the complexity of fluid behavior under varying operating conditions. The system's performance is highly sensitive to temperature fluctuations, which can significantly affect fluid viscosity and flow characteristics. This sensitivity makes it difficult to maintain consistent performance across a wide range of operating environments.

Another challenge lies in the accurate prediction and control of fluid pressure within the system. The 2JZ's high-performance nature often results in rapid pressure changes, which can lead to cavitation, especially during high-load scenarios. This phenomenon not only reduces system efficiency but also poses a risk of component damage over time. Engineers must develop advanced modeling techniques and control algorithms to mitigate these pressure-related issues effectively.

The integration of modern electronic control systems with the traditional mechanical components of the 2JZ fluid system presents another significant challenge. While electronic controls offer the potential for more precise management of fluid dynamics, they also introduce new complexities in system design and calibration. Achieving seamless communication between mechanical and electronic components is crucial for optimizing system performance and reliability.

Wear and degradation of system components over time also pose challenges to maintaining precise reservoir dynamics. The high-stress environment in which 2JZ fluid systems operate can lead to accelerated wear of seals, valves, and other critical components. This degradation can result in changes to fluid flow patterns and pressure distributions, making it difficult to maintain consistent performance without frequent maintenance and recalibration.

Furthermore, the pursuit of increased power output and efficiency in 2JZ systems often leads to modifications that can disrupt the carefully balanced fluid dynamics. Aftermarket upgrades and tuning practices, while potentially beneficial for performance, can introduce unforeseen complications in fluid behavior and system stability. Engineers must develop robust design strategies that can accommodate a range of modifications while maintaining precise control over reservoir dynamics.

Lastly, environmental concerns and regulatory pressures are driving the need for more efficient and cleaner fluid systems. This necessitates the development of new fluid formulations and system designs that can deliver high performance while meeting stringent emissions and efficiency standards. Balancing these requirements with the need for precise reservoir dynamics presents a complex engineering challenge that requires innovative solutions and advanced materials science.

Another challenge lies in the accurate prediction and control of fluid pressure within the system. The 2JZ's high-performance nature often results in rapid pressure changes, which can lead to cavitation, especially during high-load scenarios. This phenomenon not only reduces system efficiency but also poses a risk of component damage over time. Engineers must develop advanced modeling techniques and control algorithms to mitigate these pressure-related issues effectively.

The integration of modern electronic control systems with the traditional mechanical components of the 2JZ fluid system presents another significant challenge. While electronic controls offer the potential for more precise management of fluid dynamics, they also introduce new complexities in system design and calibration. Achieving seamless communication between mechanical and electronic components is crucial for optimizing system performance and reliability.

Wear and degradation of system components over time also pose challenges to maintaining precise reservoir dynamics. The high-stress environment in which 2JZ fluid systems operate can lead to accelerated wear of seals, valves, and other critical components. This degradation can result in changes to fluid flow patterns and pressure distributions, making it difficult to maintain consistent performance without frequent maintenance and recalibration.

Furthermore, the pursuit of increased power output and efficiency in 2JZ systems often leads to modifications that can disrupt the carefully balanced fluid dynamics. Aftermarket upgrades and tuning practices, while potentially beneficial for performance, can introduce unforeseen complications in fluid behavior and system stability. Engineers must develop robust design strategies that can accommodate a range of modifications while maintaining precise control over reservoir dynamics.

Lastly, environmental concerns and regulatory pressures are driving the need for more efficient and cleaner fluid systems. This necessitates the development of new fluid formulations and system designs that can deliver high performance while meeting stringent emissions and efficiency standards. Balancing these requirements with the need for precise reservoir dynamics presents a complex engineering challenge that requires innovative solutions and advanced materials science.

Existing Solutions for Precision Reservoir Dynamics

01 Precision fluid control systems for engines

Advanced fluid control systems designed specifically for 2JZ engines, focusing on precise management of fuel, oil, and coolant flow. These systems enhance engine performance, efficiency, and reliability through accurate metering and distribution of fluids throughout the engine.- Precision fluid control systems for 2JZ engines: Advanced fluid control systems designed specifically for 2JZ engines, focusing on precise management of various fluids including fuel, oil, and coolant. These systems incorporate high-precision components and sensors to optimize engine performance, efficiency, and reliability.

- Innovative pump designs for 2JZ fluid systems: Novel pump designs tailored for 2JZ engine fluid systems, featuring improved efficiency, durability, and flow control. These pumps utilize advanced materials and engineering techniques to enhance fluid circulation and pressure management within the engine.

- Integrated fluid monitoring and control systems: Comprehensive fluid monitoring and control systems for 2JZ engines, incorporating sensors, electronic control units, and actuators. These systems provide real-time data on fluid parameters and automatically adjust fluid flow and pressure to optimize engine performance under various operating conditions.

- Advanced filtration and purification technologies: Cutting-edge filtration and purification technologies designed for 2JZ fluid systems, ensuring the removal of contaminants and maintaining fluid quality. These technologies employ innovative filter designs and materials to extend engine life and maintain optimal performance.

- Precision fluid delivery and metering systems: High-precision fluid delivery and metering systems for 2JZ engines, focusing on accurate and consistent fluid distribution. These systems utilize advanced flow control mechanisms and precision-engineered components to ensure optimal fluid delivery across various engine operating conditions.

02 High-pressure fuel injection technology

Innovative high-pressure fuel injection systems tailored for 2JZ engines, enabling more efficient fuel atomization and combustion. These systems contribute to improved power output, reduced emissions, and better fuel economy through precise fuel delivery and spray patterns.Expand Specific Solutions03 Advanced cooling and lubrication systems

Specialized cooling and lubrication systems designed to optimize thermal management and reduce friction in 2JZ engines. These systems incorporate precision oil flow control, targeted cooling strategies, and advanced materials to enhance engine longevity and performance under high-stress conditions.Expand Specific Solutions04 Electronic fluid management and monitoring

Sophisticated electronic systems for real-time monitoring and management of fluid dynamics in 2JZ engines. These systems utilize sensors, actuators, and advanced algorithms to optimize fluid flow, pressure, and temperature across various engine operating conditions.Expand Specific Solutions05 Precision manufacturing techniques for fluid components

Cutting-edge manufacturing processes and quality control methods used in the production of high-precision fluid system components for 2JZ engines. These techniques ensure tight tolerances, superior surface finishes, and consistent performance of critical fluid system parts.Expand Specific Solutions

Key Players in 2JZ Fluid System Industry

The research on reservoir dynamics for precision in 2JZ fluid systems is currently in a developing stage, with the market showing significant growth potential. The technology's maturity is advancing, driven by collaborations between major oil companies and research institutions. Key players like PetroChina, Schlumberger, and Saudi Aramco are investing heavily in this field, leveraging their extensive industry experience and R&D capabilities. Universities such as China University of Petroleum and China University of Geosciences are contributing valuable academic insights. The competitive landscape is characterized by a mix of established energy giants and specialized technology providers, with companies like Siemens and Caliper Life Sciences bringing innovative approaches to fluid system analysis and control.

PetroChina Co., Ltd.

Technical Solution: PetroChina has developed a comprehensive approach to reservoir dynamics in 2JZ fluid systems, focusing on their vast and diverse portfolio of oil and gas fields. Their research combines advanced numerical simulation techniques with extensive field data to create highly accurate reservoir models. PetroChina's technology incorporates multi-scale modeling approaches, allowing for seamless integration of pore-scale physics with field-scale simulations[13]. The company has invested in developing artificial intelligence and machine learning algorithms to enhance history matching processes and improve production forecasting accuracy. PetroChina has also pioneered the use of smart well completions and intelligent production systems that adapt to changing reservoir conditions in real-time, optimizing production from 2JZ fluid systems[15].

Strengths: Extensive experience with diverse reservoir types, strong integration of AI/ML in reservoir modeling, and advanced smart well technologies. Weaknesses: Potential challenges in adapting technologies developed for domestic fields to international projects.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced reservoir dynamics modeling for 2JZ fluid systems, utilizing their proprietary INTERSECT reservoir simulation software. This technology enables high-resolution modeling of complex reservoirs, incorporating detailed geological and petrophysical data. The system employs adaptive mesh refinement techniques to focus computational resources on areas of interest, improving accuracy in predicting fluid flow and pressure changes[1]. Schlumberger's approach integrates real-time data from downhole sensors and surface measurements, allowing for continuous model updates and optimization of production strategies[3]. The company has also implemented machine learning algorithms to enhance history matching and future production forecasting, significantly reducing uncertainty in reservoir management decisions[5].

Strengths: Industry-leading simulation software, integration of real-time data, and advanced machine learning capabilities. Weaknesses: High computational requirements and potential complexity for smaller operators.

Core Innovations in 2JZ Fluid System Research

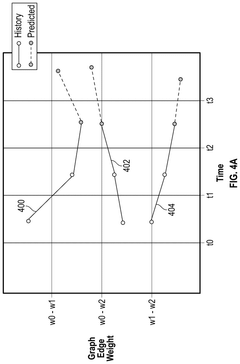

Method for optimal reservoir model adaptation based on spatiotemporal well connectivity analysis utilizing time dependent production data

PatentPendingUS20250225295A1

Innovation

- A machine learning-based approach that utilizes production time-series data and metadata to train a model, predict future production trends, determine well connectivity scores, and detect changes in reservoir dynamics using change point methods, allowing for adaptive well development plans.

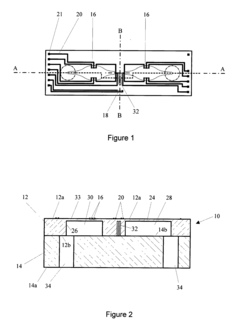

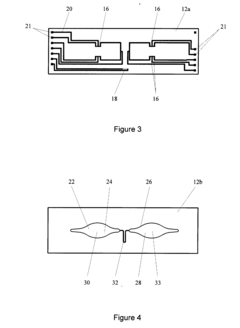

Apparatus for measuring a pressure at two points of a flowing fluid

PatentInactiveEP1236974A1

Innovation

- The device features spindle-shaped chambers with side walls perpendicular to their flat walls, equipped with elastically deformable membranes and piezoresistive transducers in a Wheatstone bridge configuration, along with a temperature sensor, to prevent bubble trapping and enhance measurement precision.

Environmental Impact of 2JZ Fluid Systems

The environmental impact of 2JZ fluid systems is a critical consideration in the context of reservoir dynamics research. These systems, while highly efficient in their primary function, can potentially have significant effects on the surrounding ecosystem if not properly managed. The primary environmental concerns stem from the potential for fluid leakage, which can contaminate soil and groundwater resources.

The 2JZ fluid systems typically utilize a combination of synthetic oils and additives, which, if released into the environment, can have long-lasting detrimental effects. These fluids are often resistant to natural degradation processes, persisting in the ecosystem for extended periods. This persistence can lead to bioaccumulation in local flora and fauna, potentially disrupting food chains and biodiversity.

Air quality is another environmental factor to consider. The operation of 2JZ fluid systems can result in the release of volatile organic compounds (VOCs) and other airborne particulates. These emissions, while generally minimal under normal operating conditions, can become more significant in the event of system malfunctions or during maintenance procedures. Long-term exposure to these emissions may contribute to local air pollution and potentially impact human health in surrounding communities.

Water resource management is a crucial aspect when assessing the environmental impact of 2JZ fluid systems. The systems often require substantial amounts of water for cooling and operational purposes. In water-stressed regions, this demand can put additional pressure on already limited water resources, potentially affecting local ecosystems and communities that rely on the same water sources.

Energy consumption is another environmental consideration. While 2JZ fluid systems are designed for efficiency, they still require significant energy input for operation. The source of this energy – whether from renewable or non-renewable sources – plays a role in the overall environmental footprint of the system. Efforts to integrate renewable energy sources or improve energy efficiency can help mitigate this aspect of environmental impact.

Waste management is an ongoing challenge in the operation and maintenance of 2JZ fluid systems. The disposal of used fluids, filters, and other system components must be carefully managed to prevent environmental contamination. Proper recycling and disposal protocols are essential to minimize the ecological footprint of these systems throughout their lifecycle.

In conclusion, while 2JZ fluid systems offer significant benefits in terms of performance and efficiency, their environmental impact must be carefully managed. Ongoing research and development efforts are focused on improving the environmental profile of these systems, including the development of more biodegradable fluids, enhanced leak detection technologies, and more efficient waste management practices. These advancements are crucial for ensuring the sustainable use of 2JZ fluid systems in reservoir dynamics applications.

The 2JZ fluid systems typically utilize a combination of synthetic oils and additives, which, if released into the environment, can have long-lasting detrimental effects. These fluids are often resistant to natural degradation processes, persisting in the ecosystem for extended periods. This persistence can lead to bioaccumulation in local flora and fauna, potentially disrupting food chains and biodiversity.

Air quality is another environmental factor to consider. The operation of 2JZ fluid systems can result in the release of volatile organic compounds (VOCs) and other airborne particulates. These emissions, while generally minimal under normal operating conditions, can become more significant in the event of system malfunctions or during maintenance procedures. Long-term exposure to these emissions may contribute to local air pollution and potentially impact human health in surrounding communities.

Water resource management is a crucial aspect when assessing the environmental impact of 2JZ fluid systems. The systems often require substantial amounts of water for cooling and operational purposes. In water-stressed regions, this demand can put additional pressure on already limited water resources, potentially affecting local ecosystems and communities that rely on the same water sources.

Energy consumption is another environmental consideration. While 2JZ fluid systems are designed for efficiency, they still require significant energy input for operation. The source of this energy – whether from renewable or non-renewable sources – plays a role in the overall environmental footprint of the system. Efforts to integrate renewable energy sources or improve energy efficiency can help mitigate this aspect of environmental impact.

Waste management is an ongoing challenge in the operation and maintenance of 2JZ fluid systems. The disposal of used fluids, filters, and other system components must be carefully managed to prevent environmental contamination. Proper recycling and disposal protocols are essential to minimize the ecological footprint of these systems throughout their lifecycle.

In conclusion, while 2JZ fluid systems offer significant benefits in terms of performance and efficiency, their environmental impact must be carefully managed. Ongoing research and development efforts are focused on improving the environmental profile of these systems, including the development of more biodegradable fluids, enhanced leak detection technologies, and more efficient waste management practices. These advancements are crucial for ensuring the sustainable use of 2JZ fluid systems in reservoir dynamics applications.

Regulatory Framework for Fluid System Technologies

The regulatory framework for fluid system technologies, particularly in the context of 2JZ fluid systems, is a complex and evolving landscape. Governments and industry bodies worldwide have established various regulations and standards to ensure the safety, efficiency, and environmental sustainability of these systems. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in setting guidelines for fluid systems, especially those used in automotive applications. The EPA's regulations focus on emissions control, fuel efficiency, and the use of environmentally friendly materials in fluid systems.

The European Union has implemented stringent regulations through the European Chemicals Agency (ECHA), which oversees the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This framework directly impacts the development and use of fluids in 2JZ systems, requiring manufacturers to assess and manage the risks associated with the substances they produce or import. Additionally, the EU's End-of-Life Vehicles Directive mandates the recycling and recovery of materials used in automotive fluid systems, promoting sustainability throughout the product lifecycle.

In Japan, the birthplace of the 2JZ engine, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has established comprehensive regulations for automotive fluid systems. These regulations cover aspects such as fuel efficiency standards, emissions control, and safety requirements for fluid containment and distribution within vehicles. The Japanese Industrial Standards (JIS) also provide detailed specifications for fluid system components, ensuring consistency and quality across the industry.

International organizations, such as the International Organization for Standardization (ISO), have developed global standards that influence the regulatory landscape for fluid system technologies. ISO 16232, for example, sets guidelines for the cleanliness of components in fluid circuits, which is critical for the precision and longevity of 2JZ fluid systems. These standards are often adopted or referenced by national regulatory bodies, creating a more harmonized global approach to fluid system regulation.

As research on reservoir dynamics for precision in 2JZ fluid systems progresses, regulatory frameworks are likely to evolve. Emerging technologies, such as advanced sensors and real-time monitoring systems, may lead to new regulations focused on predictive maintenance and performance optimization. Furthermore, the increasing emphasis on sustainability and circular economy principles is expected to drive regulations that promote the use of bio-based fluids and recyclable components in future fluid system designs.

The European Union has implemented stringent regulations through the European Chemicals Agency (ECHA), which oversees the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This framework directly impacts the development and use of fluids in 2JZ systems, requiring manufacturers to assess and manage the risks associated with the substances they produce or import. Additionally, the EU's End-of-Life Vehicles Directive mandates the recycling and recovery of materials used in automotive fluid systems, promoting sustainability throughout the product lifecycle.

In Japan, the birthplace of the 2JZ engine, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has established comprehensive regulations for automotive fluid systems. These regulations cover aspects such as fuel efficiency standards, emissions control, and safety requirements for fluid containment and distribution within vehicles. The Japanese Industrial Standards (JIS) also provide detailed specifications for fluid system components, ensuring consistency and quality across the industry.

International organizations, such as the International Organization for Standardization (ISO), have developed global standards that influence the regulatory landscape for fluid system technologies. ISO 16232, for example, sets guidelines for the cleanliness of components in fluid circuits, which is critical for the precision and longevity of 2JZ fluid systems. These standards are often adopted or referenced by national regulatory bodies, creating a more harmonized global approach to fluid system regulation.

As research on reservoir dynamics for precision in 2JZ fluid systems progresses, regulatory frameworks are likely to evolve. Emerging technologies, such as advanced sensors and real-time monitoring systems, may lead to new regulations focused on predictive maintenance and performance optimization. Furthermore, the increasing emphasis on sustainability and circular economy principles is expected to drive regulations that promote the use of bio-based fluids and recyclable components in future fluid system designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!