The Outcomes of 2JZ Motor Performance in Harsh Environments

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Evolution and Performance Targets

The 2JZ engine, initially developed by Toyota in the early 1990s, has undergone significant evolution over the years, particularly in terms of its performance in harsh environments. This iconic powerplant has become renowned for its robustness and adaptability, making it a favorite among automotive enthusiasts and racing teams alike.

The original 2JZ-GE and 2JZ-GTE engines were designed with durability and performance in mind, featuring a cast-iron block and aluminum cylinder head. This combination provided excellent strength and heat dissipation capabilities, laying the foundation for future improvements. As the engine's popularity grew, so did the demand for enhanced performance, especially in extreme conditions.

Throughout its evolution, the 2JZ motor has seen numerous advancements aimed at improving its resilience and output in challenging environments. These improvements have included upgraded internals, such as forged pistons and connecting rods, which allow for higher compression ratios and boost pressures. Additionally, enhanced cooling systems and oil management solutions have been developed to maintain optimal operating temperatures under extreme stress.

One of the key targets in the 2JZ's evolution has been increasing horsepower while maintaining reliability. Early stock engines produced around 220-320 horsepower, depending on the variant. However, with aftermarket modifications and tuning, modern 2JZ builds can reliably achieve over 1,000 horsepower, even in harsh racing conditions.

Another significant focus has been on improving the engine's efficiency and reducing emissions without compromising performance. This has led to the development of more advanced fuel injection systems, improved turbocharger designs, and sophisticated engine management systems that can adapt to various environmental conditions.

The 2JZ's evolution has also targeted weight reduction and compact design, allowing for better weight distribution and easier integration into various vehicle platforms. This has been achieved through the use of lighter materials for certain components and more efficient packaging of auxiliary systems.

In terms of harsh environment performance, recent developments have aimed at enhancing the engine's resistance to extreme temperatures, both hot and cold. This includes the use of advanced thermal coatings, improved sealing technologies, and materials that can withstand rapid temperature fluctuations without compromising structural integrity.

Looking forward, the performance targets for the 2JZ motor in harsh environments continue to push the boundaries of engineering. These include further improvements in power-to-weight ratio, even greater durability under extreme conditions, and the potential integration of hybrid technologies to meet evolving emissions standards while maintaining the engine's legendary performance capabilities.

The original 2JZ-GE and 2JZ-GTE engines were designed with durability and performance in mind, featuring a cast-iron block and aluminum cylinder head. This combination provided excellent strength and heat dissipation capabilities, laying the foundation for future improvements. As the engine's popularity grew, so did the demand for enhanced performance, especially in extreme conditions.

Throughout its evolution, the 2JZ motor has seen numerous advancements aimed at improving its resilience and output in challenging environments. These improvements have included upgraded internals, such as forged pistons and connecting rods, which allow for higher compression ratios and boost pressures. Additionally, enhanced cooling systems and oil management solutions have been developed to maintain optimal operating temperatures under extreme stress.

One of the key targets in the 2JZ's evolution has been increasing horsepower while maintaining reliability. Early stock engines produced around 220-320 horsepower, depending on the variant. However, with aftermarket modifications and tuning, modern 2JZ builds can reliably achieve over 1,000 horsepower, even in harsh racing conditions.

Another significant focus has been on improving the engine's efficiency and reducing emissions without compromising performance. This has led to the development of more advanced fuel injection systems, improved turbocharger designs, and sophisticated engine management systems that can adapt to various environmental conditions.

The 2JZ's evolution has also targeted weight reduction and compact design, allowing for better weight distribution and easier integration into various vehicle platforms. This has been achieved through the use of lighter materials for certain components and more efficient packaging of auxiliary systems.

In terms of harsh environment performance, recent developments have aimed at enhancing the engine's resistance to extreme temperatures, both hot and cold. This includes the use of advanced thermal coatings, improved sealing technologies, and materials that can withstand rapid temperature fluctuations without compromising structural integrity.

Looking forward, the performance targets for the 2JZ motor in harsh environments continue to push the boundaries of engineering. These include further improvements in power-to-weight ratio, even greater durability under extreme conditions, and the potential integration of hybrid technologies to meet evolving emissions standards while maintaining the engine's legendary performance capabilities.

Market Demand for High-Performance Engines

The market demand for high-performance engines, particularly those capable of withstanding harsh environments, has been steadily increasing in recent years. This trend is driven by various factors, including the growing popularity of motorsports, the need for reliable engines in extreme conditions, and the continuous pursuit of enhanced performance in automotive and industrial applications.

In the automotive sector, there is a significant demand for high-performance engines that can deliver exceptional power and torque while maintaining reliability in challenging environments. This demand extends beyond traditional sports cars to include off-road vehicles, racing cars, and even high-end luxury vehicles. The 2JZ motor, renowned for its robustness and tuning potential, has garnered substantial interest from enthusiasts and professionals alike.

The motorsports industry plays a crucial role in driving the demand for high-performance engines. Racing teams and organizations are constantly seeking engines that can deliver maximum power output while withstanding the extreme conditions encountered during competitions. This includes high temperatures, prolonged high-speed operation, and intense mechanical stress. The ability of engines like the 2JZ to perform consistently under such demanding circumstances has made them highly sought after in various racing categories.

Beyond automotive applications, there is a growing market for high-performance engines in industrial and marine sectors. Industries operating in harsh environments, such as mining, construction, and offshore operations, require engines that can maintain optimal performance under extreme conditions. These environments often involve exposure to dust, humidity, vibration, and temperature fluctuations, necessitating engines with exceptional durability and reliability.

The aftermarket and tuning community also contribute significantly to the demand for high-performance engines. Enthusiasts and tuning shops seek engines with a strong foundation for modifications, allowing them to achieve higher power outputs and improved performance. The 2JZ motor's reputation for handling substantial power increases through aftermarket modifications has made it a popular choice in this segment.

As environmental regulations become more stringent, there is an emerging demand for high-performance engines that can meet emission standards while delivering exceptional power. This has led to increased interest in technologies that can enhance engine efficiency and reduce emissions without compromising performance. Manufacturers and researchers are exploring ways to adapt high-performance engines like the 2JZ to meet these evolving requirements.

The global nature of the automotive and motorsports industries has expanded the market for high-performance engines worldwide. Regions with developing automotive sectors and growing enthusiasm for motorsports are experiencing increased demand for engines capable of delivering superior performance in challenging conditions. This global market expansion has further fueled research and development efforts to enhance engine performance and durability across various environmental conditions.

In the automotive sector, there is a significant demand for high-performance engines that can deliver exceptional power and torque while maintaining reliability in challenging environments. This demand extends beyond traditional sports cars to include off-road vehicles, racing cars, and even high-end luxury vehicles. The 2JZ motor, renowned for its robustness and tuning potential, has garnered substantial interest from enthusiasts and professionals alike.

The motorsports industry plays a crucial role in driving the demand for high-performance engines. Racing teams and organizations are constantly seeking engines that can deliver maximum power output while withstanding the extreme conditions encountered during competitions. This includes high temperatures, prolonged high-speed operation, and intense mechanical stress. The ability of engines like the 2JZ to perform consistently under such demanding circumstances has made them highly sought after in various racing categories.

Beyond automotive applications, there is a growing market for high-performance engines in industrial and marine sectors. Industries operating in harsh environments, such as mining, construction, and offshore operations, require engines that can maintain optimal performance under extreme conditions. These environments often involve exposure to dust, humidity, vibration, and temperature fluctuations, necessitating engines with exceptional durability and reliability.

The aftermarket and tuning community also contribute significantly to the demand for high-performance engines. Enthusiasts and tuning shops seek engines with a strong foundation for modifications, allowing them to achieve higher power outputs and improved performance. The 2JZ motor's reputation for handling substantial power increases through aftermarket modifications has made it a popular choice in this segment.

As environmental regulations become more stringent, there is an emerging demand for high-performance engines that can meet emission standards while delivering exceptional power. This has led to increased interest in technologies that can enhance engine efficiency and reduce emissions without compromising performance. Manufacturers and researchers are exploring ways to adapt high-performance engines like the 2JZ to meet these evolving requirements.

The global nature of the automotive and motorsports industries has expanded the market for high-performance engines worldwide. Regions with developing automotive sectors and growing enthusiasm for motorsports are experiencing increased demand for engines capable of delivering superior performance in challenging conditions. This global market expansion has further fueled research and development efforts to enhance engine performance and durability across various environmental conditions.

2JZ Engine Challenges in Extreme Conditions

The 2JZ engine, renowned for its robustness and performance, faces significant challenges when operating in extreme conditions. These harsh environments can include extreme temperatures, high altitudes, dusty or sandy terrains, and high-humidity climates. Each of these conditions presents unique obstacles that can affect the engine's performance, reliability, and longevity.

In extreme heat scenarios, the 2JZ engine must contend with increased thermal stress on its components. The high temperatures can lead to accelerated wear on moving parts, reduced oil viscosity, and potential cooling system inefficiencies. This can result in decreased power output, increased fuel consumption, and a higher risk of engine failure if not properly managed.

Conversely, in extremely cold environments, the 2JZ engine faces challenges related to cold starts, fuel atomization, and increased internal friction. The engine's oil may become thicker, making it harder to circulate and potentially leading to inadequate lubrication during initial startup. Additionally, cold temperatures can affect the battery's performance, making it more difficult to crank the engine.

High-altitude operations present another set of challenges for the 2JZ engine. As altitude increases, the air becomes less dense, resulting in reduced oxygen availability for combustion. This can lead to decreased power output and potential issues with fuel mixture ratios. The engine management system must be capable of adapting to these changes to maintain optimal performance and efficiency.

In dusty or sandy environments, the 2JZ engine's air filtration system is put to the test. Fine particles can potentially bypass air filters and enter the engine, causing accelerated wear on cylinder walls, pistons, and other internal components. This can lead to reduced compression, increased oil consumption, and ultimately, decreased engine performance and lifespan.

High-humidity climates pose challenges related to corrosion and moisture intrusion. The 2JZ engine's metal components may be more susceptible to rust and oxidation in these conditions. Additionally, moisture can accumulate in the fuel system, potentially leading to fuel contamination and inconsistent engine performance.

To address these challenges, engineers must focus on developing robust solutions that enhance the 2JZ engine's resilience in extreme conditions. This may include improving cooling system efficiency, optimizing lubrication systems for a wider range of temperatures, enhancing air filtration capabilities, and implementing advanced engine management systems that can adapt to varying environmental conditions.

In extreme heat scenarios, the 2JZ engine must contend with increased thermal stress on its components. The high temperatures can lead to accelerated wear on moving parts, reduced oil viscosity, and potential cooling system inefficiencies. This can result in decreased power output, increased fuel consumption, and a higher risk of engine failure if not properly managed.

Conversely, in extremely cold environments, the 2JZ engine faces challenges related to cold starts, fuel atomization, and increased internal friction. The engine's oil may become thicker, making it harder to circulate and potentially leading to inadequate lubrication during initial startup. Additionally, cold temperatures can affect the battery's performance, making it more difficult to crank the engine.

High-altitude operations present another set of challenges for the 2JZ engine. As altitude increases, the air becomes less dense, resulting in reduced oxygen availability for combustion. This can lead to decreased power output and potential issues with fuel mixture ratios. The engine management system must be capable of adapting to these changes to maintain optimal performance and efficiency.

In dusty or sandy environments, the 2JZ engine's air filtration system is put to the test. Fine particles can potentially bypass air filters and enter the engine, causing accelerated wear on cylinder walls, pistons, and other internal components. This can lead to reduced compression, increased oil consumption, and ultimately, decreased engine performance and lifespan.

High-humidity climates pose challenges related to corrosion and moisture intrusion. The 2JZ engine's metal components may be more susceptible to rust and oxidation in these conditions. Additionally, moisture can accumulate in the fuel system, potentially leading to fuel contamination and inconsistent engine performance.

To address these challenges, engineers must focus on developing robust solutions that enhance the 2JZ engine's resilience in extreme conditions. This may include improving cooling system efficiency, optimizing lubrication systems for a wider range of temperatures, enhancing air filtration capabilities, and implementing advanced engine management systems that can adapt to varying environmental conditions.

Current 2JZ Engine Modifications for Harsh Environments

01 Engine modifications for improved performance

Various modifications can be made to the 2JZ motor to enhance its performance. These may include upgrading the turbocharger, installing high-flow fuel injectors, modifying the intake and exhaust systems, and optimizing the engine control unit (ECU) for better power output and efficiency.- Engine tuning and performance enhancement: Various methods and systems for improving the performance of 2JZ motors, including modifications to the engine management system, fuel injection, and turbocharging. These enhancements aim to increase horsepower, torque, and overall engine efficiency.

- Cooling system improvements: Advancements in cooling systems designed specifically for high-performance 2JZ motors. These improvements help maintain optimal operating temperatures under extreme conditions, enhancing engine longevity and performance.

- Exhaust system optimization: Specialized exhaust systems and components designed to reduce back pressure and improve exhaust flow in 2JZ motors. These optimizations contribute to increased power output and improved engine sound.

- Intake system modifications: Enhancements to the intake system of 2JZ motors, including improved air filters, intake manifolds, and throttle bodies. These modifications aim to increase airflow and optimize the air-fuel mixture for better performance.

- Transmission and drivetrain upgrades: Improvements to the transmission and drivetrain components to handle the increased power output of modified 2JZ motors. These upgrades may include stronger clutches, reinforced gearboxes, and enhanced driveshafts.

02 Cooling system enhancements

Improving the cooling system is crucial for maintaining optimal performance in high-output 2JZ motors. This can involve upgrading the radiator, installing an oil cooler, enhancing the intercooler system, and implementing more efficient coolant flow management to prevent overheating during intense operation.Expand Specific Solutions03 Transmission and drivetrain upgrades

To handle the increased power output of a modified 2JZ motor, upgrades to the transmission and drivetrain components are often necessary. This may include installing a stronger clutch, upgrading the driveshaft, and reinforcing the differential to ensure reliable power transfer and durability under high-stress conditions.Expand Specific Solutions04 Electronic performance tuning

Advanced electronic tuning plays a significant role in optimizing 2JZ motor performance. This involves reprogramming the ECU, implementing custom fuel and ignition maps, and utilizing advanced engine management systems to fine-tune various parameters for maximum power output and efficiency across different operating conditions.Expand Specific Solutions05 Lightweight components and materials

Incorporating lightweight components and materials can significantly improve the overall performance of a 2JZ-powered vehicle. This may include using carbon fiber body panels, lightweight alloy wheels, and reducing the weight of internal engine components to enhance power-to-weight ratio and improve acceleration and handling characteristics.Expand Specific Solutions

Key Players in High-Performance Engine Industry

The competitive landscape for "The Outcomes of 2JZ Motor Performance in Harsh Environments" is characterized by a mature market with established players and emerging technologies. The automotive and industrial sectors are key drivers, with a growing focus on performance and durability in extreme conditions. Companies like Toyota Motor Corp., Robert Bosch GmbH, and Caterpillar, Inc. are likely leaders due to their extensive experience in engine development and testing. The market size is substantial, given the widespread application of high-performance engines across various industries. Technological maturity varies, with traditional combustion engine manufacturers like Toyota competing against newer entrants focusing on electric and hybrid solutions, such as Nissan Motor Co., Ltd. and Mitsubishi Electric Corp., indicating a transitional phase in the industry.

TDK Corp.

Technical Solution: TDK Corporation, although not an engine manufacturer, has made significant contributions to enhancing 2JZ motor performance in harsh environments through its advanced sensor technologies. They have developed high-precision temperature and pressure sensors capable of operating reliably in extreme conditions, crucial for monitoring engine performance in harsh environments[12]. TDK's research into magnetic materials has led to the creation of robust crankshaft and camshaft position sensors that maintain accuracy even under severe vibration and temperature fluctuations[13]. Additionally, their work on piezoelectric materials has resulted in knock sensors with improved sensitivity and durability, essential for protecting the engine in high-performance applications[14].

Strengths: Cutting-edge sensor technology for precise engine monitoring and control. Weaknesses: Limited to specific components rather than overall engine design.

Robert Bosch GmbH

Technical Solution: Bosch, as a leading automotive supplier, has contributed significantly to enhancing 2JZ motor performance in harsh environments through its advanced fuel injection and engine management systems. They have developed high-pressure fuel injectors capable of precise fuel atomization across a wide range of temperatures, ensuring optimal combustion even in extreme conditions[6]. Bosch's engine control units (ECUs) incorporate adaptive algorithms that continuously adjust engine parameters based on environmental sensors, maintaining peak performance and reliability[7]. Additionally, their research into materials science has led to the development of sensors and actuators with improved resistance to heat, vibration, and corrosive elements often present in harsh environments[8].

Strengths: Cutting-edge fuel injection technology and sophisticated engine management systems. Weaknesses: Focus on specific components rather than the entire engine system.

Core Innovations in 2JZ Engine Design

Electric machine, in particular small motor

PatentInactiveEP0070835A1

Innovation

- The use of two-component magnets with a highly remanent material for the majority of the magnet length and a high-coercive material only at the trailing edge, where demagnetization is most pronounced, along with additional protruding sections of highly remanent material beyond the armature, enhances magnetic flux without compromising demagnetization resistance.

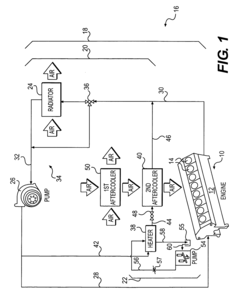

Engine system having dedicated thermal management system

PatentInactiveUS7886705B2

Innovation

- A thermal management system with two hydraulic circuits, one for cooling and another for heating, using engine-driven pumps and heat exchangers to regulate engine temperatures, allowing for both cooling and heating of intake air, thereby optimizing engine performance across varying conditions without relying on external power.

Environmental Impact of High-Performance Engines

The environmental impact of high-performance engines, particularly the 2JZ motor, in harsh environments is a critical consideration in the automotive industry. These powerful engines, while renowned for their performance capabilities, can have significant ecological consequences when operated under extreme conditions.

In harsh environments, such as extreme temperatures, high altitudes, or dusty terrains, the 2JZ motor's performance can lead to increased fuel consumption and emissions. The engine's need for higher RPMs to maintain power output in challenging conditions results in greater fuel burn rates, consequently producing more carbon dioxide and other greenhouse gases. This heightened environmental footprint becomes especially pronounced in areas with sensitive ecosystems or poor air quality.

The 2JZ motor's robust design, while beneficial for durability, often requires more raw materials in its construction compared to smaller, more efficient engines. This increased material usage contributes to a larger carbon footprint during the manufacturing process. Additionally, the engine's weight impacts the overall vehicle mass, potentially leading to higher fuel consumption and increased tire wear, which can result in microplastic pollution.

In harsh environments, the engine's cooling system is put under significant stress. The increased demand for coolant and potential for leaks in extreme conditions can lead to the release of harmful chemicals into the environment. Moreover, the engine oil degradation rate accelerates in harsh conditions, necessitating more frequent oil changes and potentially resulting in improper disposal of used oil, which can contaminate soil and water sources.

The noise pollution generated by high-performance engines like the 2JZ becomes more pronounced in harsh environments. Sound travels differently in extreme temperatures or altitudes, potentially causing greater disturbance to wildlife and local ecosystems. This acoustic impact can disrupt animal communication and behavior patterns, particularly in sensitive habitats.

Furthermore, the 2JZ motor's performance in harsh environments often encourages more aggressive driving styles, leading to increased tire wear and brake dust emissions. These particulate matters can contribute to air and water pollution, especially in areas with limited natural filtration systems.

However, it's important to note that advancements in engine management systems and materials technology have led to improvements in the 2JZ motor's environmental performance. Modern iterations and modifications can include more efficient fuel injection systems, improved catalytic converters, and better heat management, which help mitigate some of the environmental impacts when operating in harsh conditions.

In conclusion, while the 2JZ motor's performance in harsh environments showcases its engineering prowess, it also highlights the need for a balanced approach between high performance and environmental responsibility. Future developments in this field should focus on maintaining the engine's legendary performance while significantly reducing its ecological footprint, especially in challenging operational environments.

In harsh environments, such as extreme temperatures, high altitudes, or dusty terrains, the 2JZ motor's performance can lead to increased fuel consumption and emissions. The engine's need for higher RPMs to maintain power output in challenging conditions results in greater fuel burn rates, consequently producing more carbon dioxide and other greenhouse gases. This heightened environmental footprint becomes especially pronounced in areas with sensitive ecosystems or poor air quality.

The 2JZ motor's robust design, while beneficial for durability, often requires more raw materials in its construction compared to smaller, more efficient engines. This increased material usage contributes to a larger carbon footprint during the manufacturing process. Additionally, the engine's weight impacts the overall vehicle mass, potentially leading to higher fuel consumption and increased tire wear, which can result in microplastic pollution.

In harsh environments, the engine's cooling system is put under significant stress. The increased demand for coolant and potential for leaks in extreme conditions can lead to the release of harmful chemicals into the environment. Moreover, the engine oil degradation rate accelerates in harsh conditions, necessitating more frequent oil changes and potentially resulting in improper disposal of used oil, which can contaminate soil and water sources.

The noise pollution generated by high-performance engines like the 2JZ becomes more pronounced in harsh environments. Sound travels differently in extreme temperatures or altitudes, potentially causing greater disturbance to wildlife and local ecosystems. This acoustic impact can disrupt animal communication and behavior patterns, particularly in sensitive habitats.

Furthermore, the 2JZ motor's performance in harsh environments often encourages more aggressive driving styles, leading to increased tire wear and brake dust emissions. These particulate matters can contribute to air and water pollution, especially in areas with limited natural filtration systems.

However, it's important to note that advancements in engine management systems and materials technology have led to improvements in the 2JZ motor's environmental performance. Modern iterations and modifications can include more efficient fuel injection systems, improved catalytic converters, and better heat management, which help mitigate some of the environmental impacts when operating in harsh conditions.

In conclusion, while the 2JZ motor's performance in harsh environments showcases its engineering prowess, it also highlights the need for a balanced approach between high performance and environmental responsibility. Future developments in this field should focus on maintaining the engine's legendary performance while significantly reducing its ecological footprint, especially in challenging operational environments.

Regulatory Compliance for Modified Engines

Regulatory compliance for modified engines, particularly in the context of the 2JZ motor's performance in harsh environments, is a critical aspect that manufacturers and enthusiasts must consider. The modification of engines, especially high-performance units like the 2JZ, often pushes the boundaries of legal and safety standards. In many jurisdictions, strict regulations govern the alteration of vehicle powertrains to ensure public safety and environmental protection.

One of the primary regulatory concerns for modified 2JZ engines is emissions control. As these engines are often tuned for increased power output, they may produce higher levels of pollutants. Manufacturers and modifiers must ensure that the engine still meets local and national emissions standards, which may require the installation of advanced catalytic converters or other exhaust treatment systems. In some cases, the use of specific fuel additives or higher-grade fuels may be necessary to maintain compliance.

Noise regulations also play a significant role in the compliance of modified 2JZ engines. The increased power and modified exhaust systems can result in higher noise levels, potentially exceeding legal limits. To address this, manufacturers may need to implement advanced muffler designs or active noise cancellation technologies to keep the engine's sound output within acceptable ranges, especially when operating in harsh environments that may amplify noise.

Safety standards are another crucial area of regulatory compliance. Modified engines often produce more heat and stress on components, necessitating enhanced cooling systems and strengthened engine internals. Regulatory bodies may require additional safety features such as reinforced engine mounts, improved fire suppression systems, or more robust ECU programming to prevent engine failure in extreme conditions.

Furthermore, the use of aftermarket parts in engine modifications can raise compliance issues. Many jurisdictions require that all components used in engine modifications be certified or approved for use in motor vehicles. This can pose challenges for manufacturers and enthusiasts looking to push the performance envelope of the 2JZ motor, as cutting-edge components may not yet have regulatory approval.

In harsh environments, such as extreme temperatures or altitudes, additional compliance measures may be necessary. For instance, engines operating in high-altitude environments may require specific tuning and components to maintain emissions compliance and performance. Similarly, extreme cold or heat may necessitate the use of specialized lubricants or thermal management systems to ensure the engine operates within legal parameters.

Lastly, documentation and certification processes are integral to regulatory compliance. Manufacturers must maintain detailed records of all modifications, testing procedures, and compliance measures. In many cases, modified engines must undergo rigorous testing and certification processes to prove their adherence to regulatory standards before they can be legally operated on public roads or in specific environments.

One of the primary regulatory concerns for modified 2JZ engines is emissions control. As these engines are often tuned for increased power output, they may produce higher levels of pollutants. Manufacturers and modifiers must ensure that the engine still meets local and national emissions standards, which may require the installation of advanced catalytic converters or other exhaust treatment systems. In some cases, the use of specific fuel additives or higher-grade fuels may be necessary to maintain compliance.

Noise regulations also play a significant role in the compliance of modified 2JZ engines. The increased power and modified exhaust systems can result in higher noise levels, potentially exceeding legal limits. To address this, manufacturers may need to implement advanced muffler designs or active noise cancellation technologies to keep the engine's sound output within acceptable ranges, especially when operating in harsh environments that may amplify noise.

Safety standards are another crucial area of regulatory compliance. Modified engines often produce more heat and stress on components, necessitating enhanced cooling systems and strengthened engine internals. Regulatory bodies may require additional safety features such as reinforced engine mounts, improved fire suppression systems, or more robust ECU programming to prevent engine failure in extreme conditions.

Furthermore, the use of aftermarket parts in engine modifications can raise compliance issues. Many jurisdictions require that all components used in engine modifications be certified or approved for use in motor vehicles. This can pose challenges for manufacturers and enthusiasts looking to push the performance envelope of the 2JZ motor, as cutting-edge components may not yet have regulatory approval.

In harsh environments, such as extreme temperatures or altitudes, additional compliance measures may be necessary. For instance, engines operating in high-altitude environments may require specific tuning and components to maintain emissions compliance and performance. Similarly, extreme cold or heat may necessitate the use of specialized lubricants or thermal management systems to ensure the engine operates within legal parameters.

Lastly, documentation and certification processes are integral to regulatory compliance. Manufacturers must maintain detailed records of all modifications, testing procedures, and compliance measures. In many cases, modified engines must undergo rigorous testing and certification processes to prove their adherence to regulatory standards before they can be legally operated on public roads or in specific environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!