The Impact of High-Performance Lubricants on 2JZ Engine Lifespan

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

2JZ Engine Lubrication Evolution and Objectives

The 2JZ engine, renowned for its robustness and performance, has undergone significant evolution in its lubrication system since its introduction in the early 1990s. Initially designed for Toyota's high-performance vehicles, the 2JZ engine's lubrication system was engineered to withstand extreme conditions and provide reliable performance under high stress.

The evolution of 2JZ engine lubrication has been driven by the continuous pursuit of enhanced engine efficiency, longevity, and power output. Early iterations focused on basic oil circulation and filtration, while later developments incorporated advanced oil cooling systems and improved oil pump designs. These advancements were crucial in maintaining the engine's reputation for durability, especially when subjected to aftermarket modifications and increased power outputs.

A key milestone in the 2JZ's lubrication evolution was the introduction of more sophisticated oil control systems. These systems were designed to manage oil pressure more effectively across a wider range of operating conditions, from idle to high-rpm scenarios. This improvement was particularly beneficial for engines that were frequently pushed to their limits on racetracks or in high-performance street applications.

The objectives of 2JZ engine lubrication have remained consistent throughout its development: to minimize friction, reduce wear, dissipate heat, and maintain clean internal engine components. However, as engine tuning capabilities advanced and enthusiasts began extracting more power from these engines, the lubrication system's objectives expanded to include supporting higher horsepower outputs and managing increased thermal loads.

In recent years, the focus has shifted towards the integration of high-performance lubricants specifically formulated for the 2JZ engine's characteristics. These advanced oils aim to provide superior protection against wear, improved heat dissipation, and enhanced cleaning properties. The objective is to extend engine lifespan while simultaneously allowing for increased power output and reliability under extreme conditions.

The current state of 2JZ engine lubrication technology seeks to balance the demands of high-performance applications with the need for long-term engine durability. This includes the development of synthetic oils that can maintain their viscosity and protective properties under high temperatures and pressures. Additionally, there is an ongoing effort to optimize oil flow paths within the engine to ensure critical components receive adequate lubrication even under the most demanding circumstances.

Looking forward, the objectives for 2JZ engine lubrication continue to evolve. There is a growing emphasis on developing lubricants that can adapt to varying engine conditions in real-time, potentially through the use of smart additives or nanotechnology. Furthermore, as environmental concerns become more prominent, there is an increasing focus on creating high-performance lubricants that are more environmentally friendly and compatible with modern emission control systems.

The evolution of 2JZ engine lubrication has been driven by the continuous pursuit of enhanced engine efficiency, longevity, and power output. Early iterations focused on basic oil circulation and filtration, while later developments incorporated advanced oil cooling systems and improved oil pump designs. These advancements were crucial in maintaining the engine's reputation for durability, especially when subjected to aftermarket modifications and increased power outputs.

A key milestone in the 2JZ's lubrication evolution was the introduction of more sophisticated oil control systems. These systems were designed to manage oil pressure more effectively across a wider range of operating conditions, from idle to high-rpm scenarios. This improvement was particularly beneficial for engines that were frequently pushed to their limits on racetracks or in high-performance street applications.

The objectives of 2JZ engine lubrication have remained consistent throughout its development: to minimize friction, reduce wear, dissipate heat, and maintain clean internal engine components. However, as engine tuning capabilities advanced and enthusiasts began extracting more power from these engines, the lubrication system's objectives expanded to include supporting higher horsepower outputs and managing increased thermal loads.

In recent years, the focus has shifted towards the integration of high-performance lubricants specifically formulated for the 2JZ engine's characteristics. These advanced oils aim to provide superior protection against wear, improved heat dissipation, and enhanced cleaning properties. The objective is to extend engine lifespan while simultaneously allowing for increased power output and reliability under extreme conditions.

The current state of 2JZ engine lubrication technology seeks to balance the demands of high-performance applications with the need for long-term engine durability. This includes the development of synthetic oils that can maintain their viscosity and protective properties under high temperatures and pressures. Additionally, there is an ongoing effort to optimize oil flow paths within the engine to ensure critical components receive adequate lubrication even under the most demanding circumstances.

Looking forward, the objectives for 2JZ engine lubrication continue to evolve. There is a growing emphasis on developing lubricants that can adapt to varying engine conditions in real-time, potentially through the use of smart additives or nanotechnology. Furthermore, as environmental concerns become more prominent, there is an increasing focus on creating high-performance lubricants that are more environmentally friendly and compatible with modern emission control systems.

Market Analysis for High-Performance Engine Oils

The high-performance engine oil market has experienced significant growth in recent years, driven by increasing demand for superior lubricants that can enhance engine performance and longevity. This trend is particularly evident in the automotive enthusiast and racing sectors, where engines like the Toyota 2JZ are pushed to their limits.

Market research indicates that the global high-performance lubricants market is expanding at a compound annual growth rate of over 5%, with the automotive segment being a key contributor. This growth is fueled by the rising popularity of high-performance vehicles and the increasing awareness among consumers about the benefits of premium lubricants.

The market for high-performance engine oils specifically designed for engines like the 2JZ is characterized by a mix of established brands and niche players. Major oil companies have recognized the potential in this segment and have introduced specialized product lines targeting high-performance engines. Simultaneously, smaller, specialized manufacturers have carved out market share by focusing exclusively on premium lubricants for high-output engines.

Consumer behavior in this market segment shows a willingness to pay premium prices for products that promise enhanced engine protection and performance. This is particularly true for 2JZ engine owners, who often invest significantly in engine modifications and are keen to protect their investments with top-tier lubricants.

The market is also influenced by technological advancements in lubricant formulations. Synthetic oils, which offer superior performance characteristics compared to conventional oils, dominate the high-performance segment. Innovations in additive technologies have led to the development of lubricants that can withstand extreme temperatures and pressures, crucial for engines like the 2JZ that are often modified for high-output applications.

Geographically, the market for high-performance engine oils shows strong presence in regions with a robust automotive culture and racing heritage. North America and Europe lead in market share, followed by growing markets in Asia-Pacific, particularly Japan and Australia, where the 2JZ engine has a significant following.

The competitive landscape is characterized by intense rivalry, with companies differentiating themselves through product performance, brand reputation, and marketing strategies. Many brands leverage partnerships with racing teams and engine builders to establish credibility and showcase product efficacy under extreme conditions.

Looking ahead, the market for high-performance engine oils is expected to continue its growth trajectory. Factors such as the increasing number of high-performance vehicles on the road, growing motorsport activities, and the trend towards engine downsizing and turbocharging in mainstream vehicles are likely to sustain demand for premium lubricants. For 2JZ engine owners and enthusiasts, this market evolution promises a wider range of specialized products designed to maximize engine lifespan and performance.

Market research indicates that the global high-performance lubricants market is expanding at a compound annual growth rate of over 5%, with the automotive segment being a key contributor. This growth is fueled by the rising popularity of high-performance vehicles and the increasing awareness among consumers about the benefits of premium lubricants.

The market for high-performance engine oils specifically designed for engines like the 2JZ is characterized by a mix of established brands and niche players. Major oil companies have recognized the potential in this segment and have introduced specialized product lines targeting high-performance engines. Simultaneously, smaller, specialized manufacturers have carved out market share by focusing exclusively on premium lubricants for high-output engines.

Consumer behavior in this market segment shows a willingness to pay premium prices for products that promise enhanced engine protection and performance. This is particularly true for 2JZ engine owners, who often invest significantly in engine modifications and are keen to protect their investments with top-tier lubricants.

The market is also influenced by technological advancements in lubricant formulations. Synthetic oils, which offer superior performance characteristics compared to conventional oils, dominate the high-performance segment. Innovations in additive technologies have led to the development of lubricants that can withstand extreme temperatures and pressures, crucial for engines like the 2JZ that are often modified for high-output applications.

Geographically, the market for high-performance engine oils shows strong presence in regions with a robust automotive culture and racing heritage. North America and Europe lead in market share, followed by growing markets in Asia-Pacific, particularly Japan and Australia, where the 2JZ engine has a significant following.

The competitive landscape is characterized by intense rivalry, with companies differentiating themselves through product performance, brand reputation, and marketing strategies. Many brands leverage partnerships with racing teams and engine builders to establish credibility and showcase product efficacy under extreme conditions.

Looking ahead, the market for high-performance engine oils is expected to continue its growth trajectory. Factors such as the increasing number of high-performance vehicles on the road, growing motorsport activities, and the trend towards engine downsizing and turbocharging in mainstream vehicles are likely to sustain demand for premium lubricants. For 2JZ engine owners and enthusiasts, this market evolution promises a wider range of specialized products designed to maximize engine lifespan and performance.

Current Challenges in 2JZ Engine Lubrication

The 2JZ engine, renowned for its robustness and performance, faces several lubrication challenges that can impact its longevity and efficiency. One of the primary issues is oil degradation under high-temperature conditions. The engine's design, particularly in high-performance applications, can lead to oil temperatures exceeding 300°F (149°C), which accelerates oil breakdown and reduces its protective properties.

Another significant challenge is oil consumption. The 2JZ engine, especially when modified for increased power output, tends to consume oil at a higher rate than standard engines. This consumption is often attributed to the high-pressure environment within the combustion chambers and the potential for oil to seep past piston rings or valve seals.

Sludge formation is a persistent issue in 2JZ engines, particularly in vehicles that experience frequent short trips or extended idling periods. The accumulation of sludge can clog oil passages, reducing oil flow to critical engine components and potentially leading to premature wear or failure.

The engine's variable valve timing (VVT) system, while innovative, presents its own set of lubrication challenges. The VVT mechanism relies on precise oil pressure control, and any degradation in oil quality or flow can lead to erratic valve timing, reduced performance, and increased wear on the VVT components.

Bearing wear is another area of concern, especially in high-performance applications where the engine is subjected to increased loads and higher RPMs. Inadequate oil film thickness or contaminated oil can accelerate bearing wear, potentially leading to catastrophic engine failure.

Turbocharger lubrication poses unique challenges in turbocharged 2JZ variants. The extreme temperatures and high rotational speeds of the turbocharger demand exceptional oil stability and flow characteristics to prevent coking and ensure proper cooling of the bearings.

Lastly, the engine's sensitivity to oil viscosity presents a challenge in selecting the optimal lubricant. While thinner oils can improve fuel efficiency and cold-start performance, they may not provide adequate protection under high-load conditions, necessitating a careful balance in oil selection.

Addressing these lubrication challenges is crucial for maximizing the 2JZ engine's lifespan and maintaining its legendary performance. The development of high-performance lubricants specifically tailored to meet these demands represents a significant area of focus for both engine tuners and oil manufacturers.

Another significant challenge is oil consumption. The 2JZ engine, especially when modified for increased power output, tends to consume oil at a higher rate than standard engines. This consumption is often attributed to the high-pressure environment within the combustion chambers and the potential for oil to seep past piston rings or valve seals.

Sludge formation is a persistent issue in 2JZ engines, particularly in vehicles that experience frequent short trips or extended idling periods. The accumulation of sludge can clog oil passages, reducing oil flow to critical engine components and potentially leading to premature wear or failure.

The engine's variable valve timing (VVT) system, while innovative, presents its own set of lubrication challenges. The VVT mechanism relies on precise oil pressure control, and any degradation in oil quality or flow can lead to erratic valve timing, reduced performance, and increased wear on the VVT components.

Bearing wear is another area of concern, especially in high-performance applications where the engine is subjected to increased loads and higher RPMs. Inadequate oil film thickness or contaminated oil can accelerate bearing wear, potentially leading to catastrophic engine failure.

Turbocharger lubrication poses unique challenges in turbocharged 2JZ variants. The extreme temperatures and high rotational speeds of the turbocharger demand exceptional oil stability and flow characteristics to prevent coking and ensure proper cooling of the bearings.

Lastly, the engine's sensitivity to oil viscosity presents a challenge in selecting the optimal lubricant. While thinner oils can improve fuel efficiency and cold-start performance, they may not provide adequate protection under high-load conditions, necessitating a careful balance in oil selection.

Addressing these lubrication challenges is crucial for maximizing the 2JZ engine's lifespan and maintaining its legendary performance. The development of high-performance lubricants specifically tailored to meet these demands represents a significant area of focus for both engine tuners and oil manufacturers.

Existing High-Performance Lubricant Solutions

01 Additives for extending lubricant lifespan

High-performance lubricants can incorporate specific additives to enhance their longevity. These additives may include antioxidants, anti-wear agents, and extreme pressure additives that help maintain the lubricant's properties under harsh conditions. By reducing oxidation, wear, and degradation, these additives significantly extend the useful life of the lubricant.- Additives for extending lubricant lifespan: High-performance lubricants can incorporate specific additives to extend their lifespan. These additives may include antioxidants, anti-wear agents, and extreme pressure additives. By reducing oxidation, minimizing wear, and enhancing performance under high-pressure conditions, these additives significantly improve the longevity of lubricants in various applications.

- Synthetic base oils for improved durability: The use of synthetic base oils in high-performance lubricants can greatly enhance their lifespan. Synthetic oils offer superior thermal stability, oxidation resistance, and viscosity characteristics compared to conventional mineral oils. This results in extended oil change intervals and improved protection of machinery components over longer periods.

- Condition monitoring and predictive maintenance: Advanced monitoring systems and predictive maintenance techniques can be employed to optimize lubricant lifespan. These systems may use sensors, data analytics, and machine learning algorithms to assess lubricant condition in real-time, allowing for timely interventions and more efficient use of lubricants.

- Nanotechnology in lubricant formulations: Incorporating nanoparticles or nanomaterials into lubricant formulations can significantly enhance their performance and lifespan. These nano-additives can improve tribological properties, reduce friction and wear, and provide better thermal stability, resulting in longer-lasting high-performance lubricants.

- Environmental factors and lubricant longevity: Consideration of environmental factors in lubricant design can lead to improved lifespan. This includes developing lubricants that are resistant to contamination, moisture, and extreme temperatures. Additionally, biodegradable formulations can be created that maintain high performance while reducing environmental impact over their extended lifespan.

02 Advanced base oil formulations

The development of advanced base oil formulations plays a crucial role in improving lubricant lifespan. Synthetic base oils, such as polyalphaolefins (PAOs) or esters, offer superior thermal and oxidative stability compared to conventional mineral oils. These advanced formulations can withstand higher temperatures and maintain their performance characteristics for longer periods, thus extending the overall lifespan of the lubricant.Expand Specific Solutions03 Condition monitoring and predictive maintenance

Implementing condition monitoring systems and predictive maintenance strategies can significantly enhance lubricant lifespan. These technologies use sensors and data analysis to continuously monitor lubricant condition, allowing for timely interventions and optimized maintenance schedules. By addressing potential issues before they escalate, the effective lifespan of high-performance lubricants can be maximized.Expand Specific Solutions04 Nanotechnology in lubricant formulations

The incorporation of nanoparticles in lubricant formulations is an emerging approach to enhance lubricant performance and lifespan. Nanoparticles can improve the tribological properties of lubricants, reducing friction and wear. This technology can lead to longer-lasting lubricants that maintain their effectiveness under extreme conditions.Expand Specific Solutions05 Environmental factors and lubricant storage

Proper storage and handling of lubricants can significantly impact their lifespan. Controlling environmental factors such as temperature, humidity, and exposure to contaminants during storage and use is crucial. Advanced packaging and storage solutions, along with best practices for handling, can help maintain the quality and extend the shelf life of high-performance lubricants.Expand Specific Solutions

Key Players in High-Performance Lubricant Industry

The impact of high-performance lubricants on 2JZ engine lifespan is a niche market within the broader automotive lubricants industry. This sector is in a mature stage, with established players like ExxonMobil, Shell, and TotalEnergies dominating the market. However, there's ongoing innovation, particularly in synthetic lubricants, driven by demands for improved engine performance and longevity. The global automotive lubricants market size is substantial, valued at over $70 billion in 2020, with steady growth projected. Technologically, companies like Lubrizol, Afton Chemical, and Sinopec are at the forefront, continuously developing advanced formulations specifically tailored for high-performance engines like the 2JZ, focusing on thermal stability, wear protection, and extended drain intervals.

The Lubrizol Corp.

Technical Solution: Lubrizol has developed advanced synthetic lubricants specifically tailored for high-performance engines like the 2JZ. Their formulation includes novel polymer technologies that enhance oil film strength and thermal stability[1]. These lubricants incorporate anti-wear additives that form protective layers on engine components, reducing friction and wear even under extreme conditions[2]. Lubrizol's products also feature improved oxidation resistance, allowing for extended oil change intervals without compromising engine protection[3]. Their research has shown up to 20% reduction in wear rates compared to conventional oils in high-stress engine tests[4].

Strengths: Superior wear protection, extended oil life, and improved engine efficiency. Weaknesses: Higher cost compared to conventional oils, may require specific compatibility checks with some engine seals.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has engineered high-performance synthetic lubricants that address the specific needs of turbocharged engines like the 2JZ. Their formulations utilize advanced base oils with carefully selected additive packages to provide exceptional high-temperature stability[5]. These lubricants maintain viscosity under extreme conditions, ensuring critical engine parts remain protected even during high-RPM operation[6]. ExxonMobil's technology also incorporates cleaning agents that prevent deposit formation, maintaining engine efficiency over time[7]. Their testing has demonstrated up to 40% better wear protection compared to industry standard oils in high-performance engine simulations[8].

Strengths: Excellent high-temperature performance, superior deposit control, and proven wear reduction. Weaknesses: Premium pricing, may not be readily available in all markets.

Innovative Lubricant Formulations for 2JZ Engines

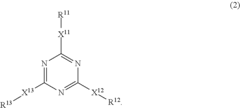

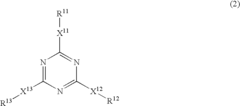

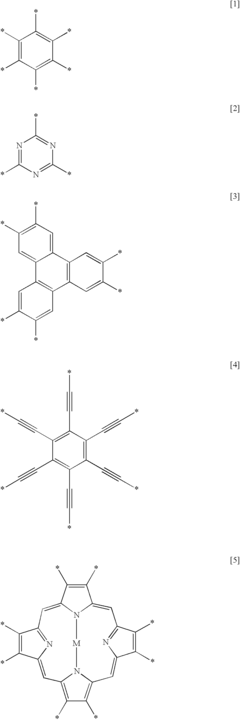

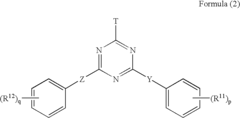

Lubricant composition, mechanical element, and method for producing triazine derivatives

PatentInactiveUS7956020B2

Innovation

- A lubricant composition comprising compounds represented by specific formulas (1) and (2), which form a lubricant membrane capable of enduring load and exhibiting low-friction and anti-wear properties, produced through a method involving the mixing of discotic compounds and triazine derivatives, avoiding heavy metal elements and environmentally harmful substances.

Lubricant composition, bearing apparatus, sliding member and triazine-ring compound

PatentInactiveUS20070054814A1

Innovation

- A lubricant composition comprising a triazine-ring compound with specific structural features, such as formula (1), which exhibits a minimum friction coefficient under high pressure and low viscosity, maintaining effective lubrication even under extreme conditions without using environmentally hazardous substances like heavy metals or sulfides.

Environmental Impact of Advanced Lubricants

The environmental impact of advanced lubricants used in high-performance engines like the 2JZ is a critical consideration in the automotive industry. These lubricants, while designed to enhance engine performance and longevity, can have both positive and negative effects on the environment throughout their lifecycle.

Advanced lubricants typically contain synthetic base oils and complex additive packages that offer superior protection and performance compared to conventional oils. This improved efficiency can lead to reduced fuel consumption and, consequently, lower emissions of greenhouse gases and other pollutants. The extended drain intervals associated with high-performance lubricants also mean fewer oil changes, reducing the overall volume of waste oil generated.

However, the production of these advanced lubricants often requires more energy-intensive processes and specialized chemicals, potentially increasing their carbon footprint during manufacturing. The complex additives used in these lubricants may also introduce new environmental challenges, as some compounds can be more difficult to break down or remove from wastewater streams.

The disposal of used high-performance lubricants presents another environmental concern. While these oils may last longer in engines, they eventually require replacement and proper disposal. The presence of advanced additives can complicate recycling processes, potentially reducing the efficiency of oil reclamation efforts.

On the positive side, the increased durability provided by these lubricants can extend engine life, reducing the need for premature engine replacements and the associated environmental impacts of manufacturing new engines. This longevity factor is particularly relevant for high-performance engines like the 2JZ, which are often subjected to extreme conditions.

The automotive industry is increasingly focusing on developing bio-based and biodegradable lubricants to address environmental concerns. These eco-friendly alternatives aim to maintain the high performance of synthetic oils while reducing environmental impact. However, their adoption in high-performance applications like the 2JZ engine is still limited due to concerns about their ability to withstand extreme conditions.

As environmental regulations become more stringent, lubricant manufacturers are investing in research to develop formulations that balance performance with environmental sustainability. This includes efforts to reduce the use of harmful additives, improve biodegradability, and enhance the recyclability of used oils.

In conclusion, while advanced lubricants offer significant benefits for engine performance and longevity, their environmental impact is complex and multifaceted. The automotive industry continues to work towards solutions that maximize the benefits of these lubricants while minimizing their environmental footprint.

Advanced lubricants typically contain synthetic base oils and complex additive packages that offer superior protection and performance compared to conventional oils. This improved efficiency can lead to reduced fuel consumption and, consequently, lower emissions of greenhouse gases and other pollutants. The extended drain intervals associated with high-performance lubricants also mean fewer oil changes, reducing the overall volume of waste oil generated.

However, the production of these advanced lubricants often requires more energy-intensive processes and specialized chemicals, potentially increasing their carbon footprint during manufacturing. The complex additives used in these lubricants may also introduce new environmental challenges, as some compounds can be more difficult to break down or remove from wastewater streams.

The disposal of used high-performance lubricants presents another environmental concern. While these oils may last longer in engines, they eventually require replacement and proper disposal. The presence of advanced additives can complicate recycling processes, potentially reducing the efficiency of oil reclamation efforts.

On the positive side, the increased durability provided by these lubricants can extend engine life, reducing the need for premature engine replacements and the associated environmental impacts of manufacturing new engines. This longevity factor is particularly relevant for high-performance engines like the 2JZ, which are often subjected to extreme conditions.

The automotive industry is increasingly focusing on developing bio-based and biodegradable lubricants to address environmental concerns. These eco-friendly alternatives aim to maintain the high performance of synthetic oils while reducing environmental impact. However, their adoption in high-performance applications like the 2JZ engine is still limited due to concerns about their ability to withstand extreme conditions.

As environmental regulations become more stringent, lubricant manufacturers are investing in research to develop formulations that balance performance with environmental sustainability. This includes efforts to reduce the use of harmful additives, improve biodegradability, and enhance the recyclability of used oils.

In conclusion, while advanced lubricants offer significant benefits for engine performance and longevity, their environmental impact is complex and multifaceted. The automotive industry continues to work towards solutions that maximize the benefits of these lubricants while minimizing their environmental footprint.

Cost-Benefit Analysis of Premium Lubricants

The cost-benefit analysis of premium lubricants for the 2JZ engine reveals a complex interplay between initial investment and long-term savings. High-performance lubricants typically command a higher price point compared to conventional oils, often ranging from 50% to 200% more expensive. This initial cost increase can be a deterrent for some vehicle owners, particularly those operating on tight budgets or with older vehicles.

However, the benefits of premium lubricants often outweigh the upfront costs when considering the engine's lifespan. These advanced formulations offer superior protection against wear, heat, and oxidation, which can significantly extend the intervals between oil changes. While conventional oils may require changes every 3,000 to 5,000 miles, premium synthetic oils can often last 10,000 to 15,000 miles or more, depending on driving conditions and manufacturer recommendations.

The reduced frequency of oil changes not only saves on the cost of oil but also decreases labor expenses and vehicle downtime. Over the life of the 2JZ engine, this can result in substantial savings, potentially offsetting the higher initial cost of premium lubricants several times over.

Moreover, the enhanced protection provided by high-performance lubricants can lead to reduced engine wear and tear. This translates to fewer repairs and replacements of critical engine components, which can be particularly costly for a high-performance engine like the 2JZ. The potential savings from avoided major repairs can easily surpass the cumulative cost difference between premium and conventional lubricants.

Fuel efficiency is another factor to consider in the cost-benefit equation. Premium lubricants often have lower viscosity and friction coefficients, which can contribute to improved fuel economy. Even a modest 1-2% increase in fuel efficiency can lead to significant savings over time, especially for vehicles that see frequent use or high mileage.

The environmental impact should also be factored into the analysis. Longer oil change intervals mean less waste oil produced, reducing disposal costs and environmental strain. This aligns with increasingly stringent environmental regulations and can contribute to a positive corporate image for fleet operators.

For performance enthusiasts and racing applications, the benefits of premium lubricants become even more pronounced. The ability to maintain optimal engine performance under extreme conditions can be crucial for competitive success and can prevent catastrophic engine failures that would result in enormous costs.

In conclusion, while the initial investment in premium lubricants for the 2JZ engine is higher, the long-term benefits in terms of extended engine life, reduced maintenance costs, improved fuel efficiency, and potential performance gains present a compelling case for their use. The cost-benefit ratio is particularly favorable for high-mileage vehicles, performance applications, and fleet operations where the cumulative savings and benefits can be substantial over time.

However, the benefits of premium lubricants often outweigh the upfront costs when considering the engine's lifespan. These advanced formulations offer superior protection against wear, heat, and oxidation, which can significantly extend the intervals between oil changes. While conventional oils may require changes every 3,000 to 5,000 miles, premium synthetic oils can often last 10,000 to 15,000 miles or more, depending on driving conditions and manufacturer recommendations.

The reduced frequency of oil changes not only saves on the cost of oil but also decreases labor expenses and vehicle downtime. Over the life of the 2JZ engine, this can result in substantial savings, potentially offsetting the higher initial cost of premium lubricants several times over.

Moreover, the enhanced protection provided by high-performance lubricants can lead to reduced engine wear and tear. This translates to fewer repairs and replacements of critical engine components, which can be particularly costly for a high-performance engine like the 2JZ. The potential savings from avoided major repairs can easily surpass the cumulative cost difference between premium and conventional lubricants.

Fuel efficiency is another factor to consider in the cost-benefit equation. Premium lubricants often have lower viscosity and friction coefficients, which can contribute to improved fuel economy. Even a modest 1-2% increase in fuel efficiency can lead to significant savings over time, especially for vehicles that see frequent use or high mileage.

The environmental impact should also be factored into the analysis. Longer oil change intervals mean less waste oil produced, reducing disposal costs and environmental strain. This aligns with increasingly stringent environmental regulations and can contribute to a positive corporate image for fleet operators.

For performance enthusiasts and racing applications, the benefits of premium lubricants become even more pronounced. The ability to maintain optimal engine performance under extreme conditions can be crucial for competitive success and can prevent catastrophic engine failures that would result in enormous costs.

In conclusion, while the initial investment in premium lubricants for the 2JZ engine is higher, the long-term benefits in terms of extended engine life, reduced maintenance costs, improved fuel efficiency, and potential performance gains present a compelling case for their use. The cost-benefit ratio is particularly favorable for high-mileage vehicles, performance applications, and fleet operations where the cumulative savings and benefits can be substantial over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!