Ammonia Slip Detection and Monitoring Strategies in Plants

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Slip Detection Background and Objectives

Ammonia slip, the unintended release of unreacted ammonia from selective catalytic reduction (SCR) systems, has emerged as a critical concern in industrial plants, power generation facilities, and automotive applications. The phenomenon gained significant attention in the 1970s when SCR technology was first implemented for NOx reduction in power plants. Since then, the evolution of environmental regulations has progressively lowered acceptable emission limits, making ammonia slip detection increasingly important for operational compliance and efficiency.

The technical trajectory of ammonia slip detection has evolved from basic periodic sampling methods to sophisticated continuous monitoring systems. Early detection relied primarily on wet chemistry techniques and colorimetric analysis, which provided only intermittent snapshots of emission levels. The 1990s saw the introduction of the first generation of continuous emission monitoring systems (CEMS), which represented a significant advancement but still suffered from reliability issues and maintenance challenges.

Recent technological developments have focused on real-time monitoring capabilities, with innovations in sensor technology, spectroscopic methods, and data analytics creating more robust detection frameworks. The integration of machine learning algorithms has further enhanced the predictive capabilities of these systems, allowing for proactive management of potential slip events before they reach critical levels.

The primary objective of ammonia slip detection and monitoring is to maintain emissions within increasingly stringent regulatory limits while optimizing the ammonia injection rate for maximum NOx reduction efficiency. This delicate balance presents a significant technical challenge, as over-injection leads to ammonia slip while under-injection results in insufficient NOx reduction.

Secondary objectives include minimizing operational costs associated with excessive ammonia consumption, preventing catalyst poisoning and deactivation, avoiding downstream equipment corrosion, and reducing the formation of ammonium bisulfate and other harmful byproducts. These objectives align with broader industry goals of sustainable operation and reduced environmental impact.

The technical goals for next-generation ammonia slip detection systems include achieving sub-ppm detection accuracy, reducing response time to near real-time, enhancing system durability in harsh industrial environments, and developing more cost-effective solutions that can be widely deployed across various industrial settings. Additionally, there is growing interest in developing integrated systems that simultaneously monitor multiple emission parameters to provide a comprehensive view of SCR performance.

As environmental regulations continue to tighten globally, the development of more advanced ammonia slip detection technologies represents a critical area for technical innovation and investment, with significant implications for industrial compliance, operational efficiency, and environmental protection.

The technical trajectory of ammonia slip detection has evolved from basic periodic sampling methods to sophisticated continuous monitoring systems. Early detection relied primarily on wet chemistry techniques and colorimetric analysis, which provided only intermittent snapshots of emission levels. The 1990s saw the introduction of the first generation of continuous emission monitoring systems (CEMS), which represented a significant advancement but still suffered from reliability issues and maintenance challenges.

Recent technological developments have focused on real-time monitoring capabilities, with innovations in sensor technology, spectroscopic methods, and data analytics creating more robust detection frameworks. The integration of machine learning algorithms has further enhanced the predictive capabilities of these systems, allowing for proactive management of potential slip events before they reach critical levels.

The primary objective of ammonia slip detection and monitoring is to maintain emissions within increasingly stringent regulatory limits while optimizing the ammonia injection rate for maximum NOx reduction efficiency. This delicate balance presents a significant technical challenge, as over-injection leads to ammonia slip while under-injection results in insufficient NOx reduction.

Secondary objectives include minimizing operational costs associated with excessive ammonia consumption, preventing catalyst poisoning and deactivation, avoiding downstream equipment corrosion, and reducing the formation of ammonium bisulfate and other harmful byproducts. These objectives align with broader industry goals of sustainable operation and reduced environmental impact.

The technical goals for next-generation ammonia slip detection systems include achieving sub-ppm detection accuracy, reducing response time to near real-time, enhancing system durability in harsh industrial environments, and developing more cost-effective solutions that can be widely deployed across various industrial settings. Additionally, there is growing interest in developing integrated systems that simultaneously monitor multiple emission parameters to provide a comprehensive view of SCR performance.

As environmental regulations continue to tighten globally, the development of more advanced ammonia slip detection technologies represents a critical area for technical innovation and investment, with significant implications for industrial compliance, operational efficiency, and environmental protection.

Industrial Market Demand for Ammonia Monitoring

The global market for ammonia monitoring solutions has witnessed substantial growth in recent years, driven primarily by stringent environmental regulations and increasing industrial awareness of operational efficiency. The industrial demand for ammonia monitoring systems is particularly pronounced in sectors such as power generation, chemical manufacturing, agriculture, and wastewater treatment, where ammonia emissions and leakage pose significant environmental and safety concerns.

In the power generation sector, particularly in plants utilizing Selective Catalytic Reduction (SCR) systems for NOx control, the demand for accurate ammonia slip detection has grown exponentially. This growth is attributed to the dual benefits of regulatory compliance and operational cost optimization. The market value for ammonia monitoring in this sector alone reached several hundred million dollars in 2022, with projected annual growth rates exceeding 7% through 2028.

Chemical manufacturing facilities represent another significant market segment, where ammonia monitoring is critical not only for environmental compliance but also for process optimization and worker safety. The refrigeration industry, which extensively uses ammonia as a cooling agent, has similarly increased its investment in monitoring technologies following several high-profile ammonia leak incidents that resulted in fatalities and substantial financial penalties.

Agriculture and fertilizer production facilities constitute a rapidly expanding market for ammonia monitoring solutions. With the global push toward sustainable farming practices and reduced environmental footprints, the demand for precise ammonia monitoring in fertilizer application and storage has intensified. Market analysts estimate that this segment will experience the fastest growth rate among all industrial applications over the next five years.

Wastewater treatment plants have emerged as another key market driver, as municipalities worldwide implement more stringent discharge regulations. The need to monitor ammonia levels throughout the treatment process has created a steady demand for both continuous and portable monitoring systems. This sector's market demand is characterized by a preference for integrated solutions that offer real-time data and predictive maintenance capabilities.

Geographically, North America and Europe currently dominate the ammonia monitoring market due to their advanced regulatory frameworks and industrial infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization in countries like China and India, coupled with increasingly stringent environmental regulations in these emerging economies.

The market demand is further shaped by technological preferences, with a clear shift toward continuous monitoring systems that offer real-time data and remote access capabilities. End-users increasingly seek solutions that integrate with existing industrial control systems and provide predictive analytics to prevent ammonia slip events before they occur.

In the power generation sector, particularly in plants utilizing Selective Catalytic Reduction (SCR) systems for NOx control, the demand for accurate ammonia slip detection has grown exponentially. This growth is attributed to the dual benefits of regulatory compliance and operational cost optimization. The market value for ammonia monitoring in this sector alone reached several hundred million dollars in 2022, with projected annual growth rates exceeding 7% through 2028.

Chemical manufacturing facilities represent another significant market segment, where ammonia monitoring is critical not only for environmental compliance but also for process optimization and worker safety. The refrigeration industry, which extensively uses ammonia as a cooling agent, has similarly increased its investment in monitoring technologies following several high-profile ammonia leak incidents that resulted in fatalities and substantial financial penalties.

Agriculture and fertilizer production facilities constitute a rapidly expanding market for ammonia monitoring solutions. With the global push toward sustainable farming practices and reduced environmental footprints, the demand for precise ammonia monitoring in fertilizer application and storage has intensified. Market analysts estimate that this segment will experience the fastest growth rate among all industrial applications over the next five years.

Wastewater treatment plants have emerged as another key market driver, as municipalities worldwide implement more stringent discharge regulations. The need to monitor ammonia levels throughout the treatment process has created a steady demand for both continuous and portable monitoring systems. This sector's market demand is characterized by a preference for integrated solutions that offer real-time data and predictive maintenance capabilities.

Geographically, North America and Europe currently dominate the ammonia monitoring market due to their advanced regulatory frameworks and industrial infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization in countries like China and India, coupled with increasingly stringent environmental regulations in these emerging economies.

The market demand is further shaped by technological preferences, with a clear shift toward continuous monitoring systems that offer real-time data and remote access capabilities. End-users increasingly seek solutions that integrate with existing industrial control systems and provide predictive analytics to prevent ammonia slip events before they occur.

Current Detection Technologies and Limitations

Ammonia slip detection in industrial plants currently relies on several established technologies, each with specific capabilities and limitations. Chemiluminescence analyzers represent one of the most widely deployed solutions, offering high sensitivity with detection limits as low as 0.1 ppm. These systems operate by measuring the light emitted during the reaction between ammonia and specific reagents. While providing accurate measurements, these analyzers require frequent calibration, regular maintenance of optical components, and face challenges with cross-sensitivity to other nitrogen-containing compounds.

Fourier Transform Infrared (FTIR) spectroscopy offers multi-component analysis capabilities by identifying ammonia's characteristic absorption patterns in the infrared spectrum. This technology provides real-time monitoring with minimal sample preparation, but its effectiveness diminishes in high-humidity environments due to water vapor interference. Additionally, FTIR systems represent significant capital investments and require specialized expertise for data interpretation and system maintenance.

Electrochemical sensors present a more cost-effective alternative with reasonable sensitivity ranges (1-100 ppm) and compact form factors suitable for distributed monitoring networks. However, these sensors suffer from limited lifespans (typically 1-2 years), cross-sensitivity issues with other gases, and performance degradation in fluctuating temperature and humidity conditions. Their response times also tend to be slower than optical methods, potentially delaying critical alerts in rapid leak scenarios.

Photoacoustic spectroscopy (PAS) has emerged as a promising detection method, utilizing the photoacoustic effect where absorbed light generates acoustic waves proportional to gas concentration. PAS offers excellent selectivity and sensitivity with minimal interference from other gases. Nevertheless, these systems remain vulnerable to ambient noise interference and vibration effects, requiring sophisticated signal processing algorithms and vibration isolation mechanisms that increase system complexity and cost.

Tunable diode laser absorption spectroscopy (TDLAS) represents the cutting edge in ammonia monitoring, providing highly selective, interference-free measurements with sub-ppm detection limits and rapid response times. Despite these advantages, TDLAS systems demand precise alignment, temperature control, and protection from optical path contamination. Their high acquisition costs and complexity have limited widespread adoption outside critical monitoring points.

A significant limitation across all current technologies is the challenge of continuous, reliable operation in harsh industrial environments characterized by high temperatures, dust, vibration, and corrosive atmospheres. Most systems require climate-controlled sampling systems or extensive sample conditioning that introduces maintenance requirements and potential failure points. Furthermore, existing technologies struggle with spatial resolution, typically providing point measurements rather than comprehensive coverage across large industrial facilities.

Fourier Transform Infrared (FTIR) spectroscopy offers multi-component analysis capabilities by identifying ammonia's characteristic absorption patterns in the infrared spectrum. This technology provides real-time monitoring with minimal sample preparation, but its effectiveness diminishes in high-humidity environments due to water vapor interference. Additionally, FTIR systems represent significant capital investments and require specialized expertise for data interpretation and system maintenance.

Electrochemical sensors present a more cost-effective alternative with reasonable sensitivity ranges (1-100 ppm) and compact form factors suitable for distributed monitoring networks. However, these sensors suffer from limited lifespans (typically 1-2 years), cross-sensitivity issues with other gases, and performance degradation in fluctuating temperature and humidity conditions. Their response times also tend to be slower than optical methods, potentially delaying critical alerts in rapid leak scenarios.

Photoacoustic spectroscopy (PAS) has emerged as a promising detection method, utilizing the photoacoustic effect where absorbed light generates acoustic waves proportional to gas concentration. PAS offers excellent selectivity and sensitivity with minimal interference from other gases. Nevertheless, these systems remain vulnerable to ambient noise interference and vibration effects, requiring sophisticated signal processing algorithms and vibration isolation mechanisms that increase system complexity and cost.

Tunable diode laser absorption spectroscopy (TDLAS) represents the cutting edge in ammonia monitoring, providing highly selective, interference-free measurements with sub-ppm detection limits and rapid response times. Despite these advantages, TDLAS systems demand precise alignment, temperature control, and protection from optical path contamination. Their high acquisition costs and complexity have limited widespread adoption outside critical monitoring points.

A significant limitation across all current technologies is the challenge of continuous, reliable operation in harsh industrial environments characterized by high temperatures, dust, vibration, and corrosive atmospheres. Most systems require climate-controlled sampling systems or extensive sample conditioning that introduces maintenance requirements and potential failure points. Furthermore, existing technologies struggle with spatial resolution, typically providing point measurements rather than comprehensive coverage across large industrial facilities.

Existing Ammonia Detection Implementation Methods

01 Sensor-based ammonia slip detection systems

Various sensor technologies are employed for detecting ammonia slip in exhaust systems. These sensors can directly measure ammonia concentrations in real-time, providing immediate feedback for control systems. Advanced sensor designs include cross-sensitivity compensation, temperature control, and signal processing algorithms to improve accuracy and reliability in harsh exhaust environments. These detection systems are crucial for monitoring SCR (Selective Catalytic Reduction) system performance and ensuring compliance with emissions regulations.- Optical ammonia slip detection systems: Optical detection systems use spectroscopic techniques to monitor ammonia slip in exhaust gases. These systems employ infrared, ultraviolet, or laser-based sensors to detect ammonia concentrations without direct contact with the exhaust stream. The optical methods provide real-time monitoring capabilities and can detect low concentrations of ammonia with high accuracy, making them suitable for emissions control systems in various applications including automotive and industrial settings.

- Electrochemical ammonia sensors for slip monitoring: Electrochemical sensors detect ammonia slip by measuring changes in electrical properties when ammonia molecules interact with sensing elements. These systems typically use semiconductor materials or chemical reactions that generate electrical signals proportional to ammonia concentration. The sensors can be integrated into control systems that provide continuous monitoring and can trigger alerts when ammonia levels exceed predetermined thresholds, helping to maintain compliance with emissions regulations.

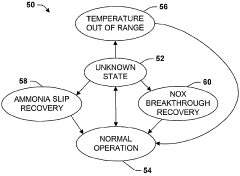

- Integrated ammonia slip control systems: These systems combine detection capabilities with feedback control mechanisms to actively manage ammonia injection in selective catalytic reduction (SCR) systems. By continuously monitoring ammonia levels and adjusting dosing rates, these integrated systems minimize slip while maintaining optimal NOx reduction efficiency. The control algorithms typically incorporate multiple parameters such as temperature, flow rate, and catalyst condition to optimize the ammonia injection strategy and prevent breakthrough emissions.

- Model-based ammonia slip prediction and detection: Model-based systems use computational algorithms and mathematical models to predict ammonia slip based on operating conditions and system parameters. These approaches often incorporate machine learning techniques or physics-based models to estimate ammonia concentrations without direct measurement. By analyzing patterns in exhaust gas composition, temperature profiles, and catalyst performance, these systems can provide early warning of potential ammonia slip events and recommend corrective actions to prevent emissions exceedances.

- Network-connected ammonia monitoring systems: These advanced monitoring solutions integrate ammonia slip detection with networked communication capabilities for remote monitoring and data analysis. The systems transmit real-time ammonia concentration data to central monitoring stations or cloud platforms, enabling trend analysis and compliance reporting. Features often include wireless connectivity, data logging, automated alerts, and integration with broader emissions management systems, allowing operators to monitor multiple sites simultaneously and implement predictive maintenance strategies.

02 Control systems for ammonia dosing optimization

Intelligent control systems are implemented to optimize ammonia dosing in SCR systems based on detection data. These systems use feedback loops from ammonia slip monitors to adjust urea injection rates, preventing excess ammonia emissions while maintaining NOx reduction efficiency. Advanced algorithms incorporate multiple parameters including engine load, exhaust temperature, and catalyst conditions to predict and prevent ammonia slip before it occurs. These control strategies help balance the trade-off between NOx conversion efficiency and ammonia slip.Expand Specific Solutions03 Integration of ammonia monitoring with vehicle diagnostics

Ammonia slip detection systems are integrated with broader vehicle diagnostic frameworks to provide comprehensive emissions control monitoring. These integrated systems can identify patterns indicating SCR system degradation or failure, triggering maintenance alerts before emissions exceed regulatory limits. The monitoring data is used for predictive maintenance, performance optimization, and regulatory compliance reporting. This integration enables fleet managers and operators to track emissions performance across multiple vehicles and identify systemic issues.Expand Specific Solutions04 Novel detection methodologies for ammonia measurement

Innovative approaches to ammonia detection include spectroscopic techniques, chemical reaction monitoring, and multi-parameter sensing arrays. These methodologies offer advantages in terms of sensitivity, selectivity, and durability compared to conventional sensors. Some systems employ indirect measurement techniques that infer ammonia concentrations from related parameters, providing redundancy and verification. Advanced signal processing techniques help filter noise and interference, improving detection accuracy in variable operating conditions.Expand Specific Solutions05 Remote monitoring and data analysis systems

Cloud-connected ammonia monitoring systems enable remote tracking and analysis of emissions data across multiple locations or vehicles. These systems incorporate data analytics to identify trends, anomalies, and optimization opportunities that might not be apparent in isolated measurements. Machine learning algorithms can be applied to historical data to improve prediction accuracy and system performance over time. Remote monitoring facilitates regulatory compliance reporting and enables centralized management of distributed SCR systems.Expand Specific Solutions

Leading Manufacturers and Technology Providers

Ammonia slip detection and monitoring in plants is currently in a growth phase, with increasing market demand driven by stringent environmental regulations. The global market is expanding as industries seek to reduce harmful emissions, with an estimated size of $300-400 million and projected annual growth of 6-8%. Technologically, the field shows varying maturity levels across different solutions. Leading players include Siemens AG and Robert Bosch GmbH, who offer advanced sensor-based systems, while specialized environmental engineering firms like Haldor Topsøe and FEV Europe GmbH focus on catalytic reduction technologies. Chinese companies such as State Grid Corp. and Jiangnan Environmental Protection Group are rapidly advancing in this space, particularly for large-scale industrial applications.

Xi'an Xire Boiler Environmental Protection Engineering Co., Ltd.

Technical Solution: Xi'an Xire has developed an integrated ammonia slip detection and monitoring system specifically designed for coal-fired power plants utilizing selective catalytic reduction (SCR) technology. Their solution employs a multi-point sampling network with tunable diode laser absorption spectroscopy (TDLAS) sensors strategically positioned at various locations within the flue gas pathway. The system features real-time continuous monitoring capabilities with detection limits as low as 1 ppm, allowing for immediate identification of ammonia breakthrough events. Their proprietary algorithm incorporates temperature and flow rate parameters to compensate for measurement variations across different operating conditions. The company has implemented a predictive maintenance approach that uses historical data patterns to anticipate potential ammonia slip events before they reach critical levels. Additionally, their system integrates with plant control systems to enable automated adjustments to ammonia injection rates, creating a closed-loop control mechanism that optimizes NOx reduction while minimizing ammonia slip.

Strengths: Specialized expertise in coal-fired power plant environments; system integration capabilities with existing plant control systems; predictive analytics for early warning. Weaknesses: Limited application outside of coal-fired power plants; requires significant initial calibration; system performance may degrade in extremely dusty conditions requiring more frequent maintenance.

Beijing Guodian Longyuan Environmental Engineering Co., Ltd.

Technical Solution: Beijing Guodian Longyuan has pioneered a comprehensive ammonia slip monitoring strategy specifically tailored for large-scale power generation facilities. Their approach combines traditional extractive sampling methods with advanced optical sensing technologies to create a redundant monitoring system. The primary component utilizes Fourier Transform Infrared (FTIR) spectroscopy with heated sampling lines to prevent ammonia adsorption, achieving measurement accuracy within ±0.5 ppm. This is complemented by a network of electrochemical sensors positioned at critical points in the flue gas path for cross-validation. The company's proprietary data integration platform correlates ammonia slip measurements with operational parameters such as load variations, catalyst condition, and ammonia injection rates to identify root causes of elevated ammonia levels. Their system incorporates automated calibration routines that use certified reference gases to maintain measurement accuracy over extended periods. Additionally, they've developed a catalyst activity monitoring module that tracks deactivation trends to predict when increased ammonia injection might lead to breakthrough events.

Strengths: Dual-technology approach provides redundancy and higher reliability; sophisticated data integration with plant operational parameters; automated calibration ensures long-term measurement accuracy. Weaknesses: Higher implementation and maintenance costs due to complex system architecture; requires specialized technical expertise for optimal operation; heated sampling lines consume additional energy.

Key Patents and Innovations in Slip Detection

SCR ammonia slip detection

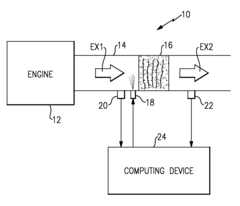

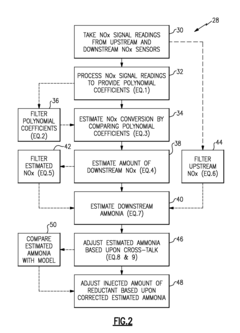

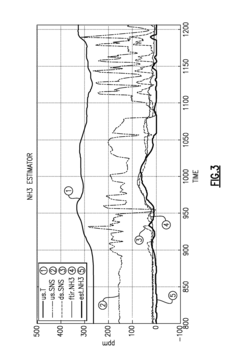

PatentActiveUS8607548B2

Innovation

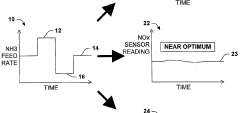

- A method using upstream and downstream NOx sensor signals to estimate NOx conversion and ammonia slip through a polynomial algorithm, which compares polynomial coefficients to distinguish between NOx and ammonia emissions, allowing for adjusted reductant injection to optimize SCR system performance.

Strategy for controlling NOX emissions and ammonia slip in an SCR system using a nonselective NOX/NH3 sensor

PatentWO2006000877A2

Innovation

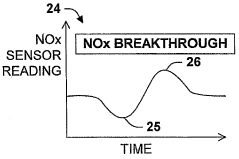

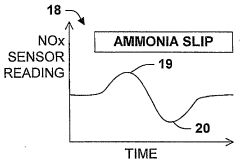

- A control system utilizing a nonselective NOx/NH3 sensor that introduces pulses in the ammonia feed rate to differentiate between ammonia slip and NOx breakthrough, employing a combination of feed-forward and feedback control with learning probabilistic models to adjust the ammonia feed rate and restore the SCR reactor's buffering capacity.

Environmental Compliance and Regulatory Standards

Ammonia slip in industrial plants is subject to increasingly stringent environmental regulations worldwide. The U.S. Environmental Protection Agency (EPA) has established National Ambient Air Quality Standards (NAAQS) that limit ammonia emissions due to their contribution to particulate matter formation and potential health impacts. Under the Clean Air Act, facilities must comply with specific emission limits, which vary depending on the industry sector and facility size.

In the European Union, the Industrial Emissions Directive (IED) sets strict requirements for ammonia emissions from industrial installations. The Best Available Techniques Reference Documents (BREFs) provide industry-specific emission limit values that operators must adhere to. For power plants and industrial boilers using Selective Catalytic Reduction (SCR) systems, ammonia slip is typically limited to 2-5 ppm to prevent secondary pollution.

China has recently strengthened its environmental protection framework through the revised Air Pollution Prevention and Control Law, imposing more stringent controls on ammonia emissions from industrial sources. Similar regulatory trends are observed in other major economies, reflecting growing global concern about air quality and environmental protection.

Compliance monitoring requirements typically mandate continuous emission monitoring systems (CEMS) for larger facilities, with specific requirements for data collection frequency, accuracy, and reporting protocols. Many jurisdictions require quarterly or annual compliance reports, with some moving toward real-time data submission to regulatory authorities.

Penalties for non-compliance can be severe, including substantial fines, mandatory facility upgrades, production restrictions, or even facility closure in cases of persistent violations. In the United States, the EPA can impose civil penalties up to $37,500 per violation per day under current regulations.

Industry standards such as those developed by the International Organization for Standardization (ISO) and ASTM International provide standardized methods for ammonia measurement and monitoring. These standards ensure consistency in measurement approaches and facilitate compliance verification across different jurisdictions.

Regulatory trends indicate a move toward more comprehensive monitoring requirements, lower emission thresholds, and increased transparency in environmental reporting. Many jurisdictions are implementing environmental justice considerations into permitting and enforcement actions, particularly for facilities located near vulnerable communities.

Companies implementing robust ammonia slip detection and monitoring strategies not only ensure regulatory compliance but may also benefit from reduced liability exposure, improved community relations, and potential marketing advantages in environmentally conscious markets.

In the European Union, the Industrial Emissions Directive (IED) sets strict requirements for ammonia emissions from industrial installations. The Best Available Techniques Reference Documents (BREFs) provide industry-specific emission limit values that operators must adhere to. For power plants and industrial boilers using Selective Catalytic Reduction (SCR) systems, ammonia slip is typically limited to 2-5 ppm to prevent secondary pollution.

China has recently strengthened its environmental protection framework through the revised Air Pollution Prevention and Control Law, imposing more stringent controls on ammonia emissions from industrial sources. Similar regulatory trends are observed in other major economies, reflecting growing global concern about air quality and environmental protection.

Compliance monitoring requirements typically mandate continuous emission monitoring systems (CEMS) for larger facilities, with specific requirements for data collection frequency, accuracy, and reporting protocols. Many jurisdictions require quarterly or annual compliance reports, with some moving toward real-time data submission to regulatory authorities.

Penalties for non-compliance can be severe, including substantial fines, mandatory facility upgrades, production restrictions, or even facility closure in cases of persistent violations. In the United States, the EPA can impose civil penalties up to $37,500 per violation per day under current regulations.

Industry standards such as those developed by the International Organization for Standardization (ISO) and ASTM International provide standardized methods for ammonia measurement and monitoring. These standards ensure consistency in measurement approaches and facilitate compliance verification across different jurisdictions.

Regulatory trends indicate a move toward more comprehensive monitoring requirements, lower emission thresholds, and increased transparency in environmental reporting. Many jurisdictions are implementing environmental justice considerations into permitting and enforcement actions, particularly for facilities located near vulnerable communities.

Companies implementing robust ammonia slip detection and monitoring strategies not only ensure regulatory compliance but may also benefit from reduced liability exposure, improved community relations, and potential marketing advantages in environmentally conscious markets.

Cost-Benefit Analysis of Detection Technologies

When evaluating ammonia slip detection technologies for industrial plants, a comprehensive cost-benefit analysis reveals significant economic implications across different implementation scenarios. Initial capital expenditure varies considerably among available technologies, with traditional extractive analyzers typically requiring investments of $50,000-$100,000 per installation point, while newer laser-based systems may demand $75,000-$150,000 initially but offer enhanced detection capabilities.

Operational expenses present another critical dimension, where electrochemical sensors demonstrate lower maintenance costs ($2,000-$5,000 annually) but require more frequent calibration and replacement. In contrast, FTIR and NDIR systems entail higher maintenance costs ($8,000-$15,000 annually) yet deliver superior longevity and measurement stability, potentially offsetting the higher initial investment through extended service intervals.

Detection accuracy directly impacts compliance costs, with high-precision systems (±1-2 ppm accuracy) potentially preventing regulatory penalties that can exceed $100,000 per violation in stringent jurisdictions. The economic value of precision increases proportionally with plant size and emission volume, making premium detection systems particularly cost-effective for large-scale operations.

Implementation timeframes also factor significantly into the cost-benefit equation. Rapid deployment solutions like electrochemical sensors can be operational within 1-2 weeks, minimizing production disruptions valued at $10,000-$50,000 per day in typical chemical processing facilities. Conversely, integrated continuous emission monitoring systems may require 1-3 months for full implementation but provide comprehensive data integration capabilities that enhance long-term operational efficiency.

Return on investment calculations indicate that advanced ammonia slip detection systems typically achieve payback within 12-36 months through a combination of reduced ammonia consumption (5-15% improvement), avoided compliance penalties, and process optimization benefits. Plants operating in regions with stringent emission regulations or carbon pricing mechanisms often experience accelerated ROI timeframes of 8-18 months.

The total cost of ownership analysis reveals that while initial acquisition costs represent only 20-30% of lifetime expenses, maintenance and calibration requirements constitute 40-60% of the long-term financial commitment. Therefore, technologies offering remote diagnostics and predictive maintenance capabilities deliver superior economic value despite potentially higher acquisition costs, particularly in facilities with limited technical personnel or remote locations.

Operational expenses present another critical dimension, where electrochemical sensors demonstrate lower maintenance costs ($2,000-$5,000 annually) but require more frequent calibration and replacement. In contrast, FTIR and NDIR systems entail higher maintenance costs ($8,000-$15,000 annually) yet deliver superior longevity and measurement stability, potentially offsetting the higher initial investment through extended service intervals.

Detection accuracy directly impacts compliance costs, with high-precision systems (±1-2 ppm accuracy) potentially preventing regulatory penalties that can exceed $100,000 per violation in stringent jurisdictions. The economic value of precision increases proportionally with plant size and emission volume, making premium detection systems particularly cost-effective for large-scale operations.

Implementation timeframes also factor significantly into the cost-benefit equation. Rapid deployment solutions like electrochemical sensors can be operational within 1-2 weeks, minimizing production disruptions valued at $10,000-$50,000 per day in typical chemical processing facilities. Conversely, integrated continuous emission monitoring systems may require 1-3 months for full implementation but provide comprehensive data integration capabilities that enhance long-term operational efficiency.

Return on investment calculations indicate that advanced ammonia slip detection systems typically achieve payback within 12-36 months through a combination of reduced ammonia consumption (5-15% improvement), avoided compliance penalties, and process optimization benefits. Plants operating in regions with stringent emission regulations or carbon pricing mechanisms often experience accelerated ROI timeframes of 8-18 months.

The total cost of ownership analysis reveals that while initial acquisition costs represent only 20-30% of lifetime expenses, maintenance and calibration requirements constitute 40-60% of the long-term financial commitment. Therefore, technologies offering remote diagnostics and predictive maintenance capabilities deliver superior economic value despite potentially higher acquisition costs, particularly in facilities with limited technical personnel or remote locations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!