Decentralized Ammonia Cracking for Remote Microgrids: Techno-Economics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Cracking Technology Evolution and Objectives

Ammonia cracking technology has evolved significantly over the past century, transitioning from a laboratory curiosity to a potential cornerstone of renewable energy systems. The process, which involves breaking ammonia (NH3) into hydrogen (H2) and nitrogen (N2), was first developed in the early 20th century primarily for industrial applications. Early catalytic cracking methods required high temperatures (800-900°C) and expensive noble metal catalysts, making the process energy-intensive and economically prohibitive for small-scale applications.

The 1970s energy crisis sparked renewed interest in ammonia as an energy carrier, leading to advancements in catalyst technology that reduced operating temperatures to 500-700°C. By the 1990s, researchers began exploring ruthenium and nickel-based catalysts that offered improved efficiency, though still at relatively high temperatures. The early 2000s saw the emergence of structured catalysts and membrane reactor concepts that began to address scale and efficiency challenges.

Recent technological breakthroughs have dramatically transformed the landscape of ammonia cracking. Advanced catalyst formulations incorporating transition metals and novel support materials have reduced operating temperatures to 400-500°C while maintaining high conversion rates. Microreactor technologies have enabled more compact system designs with improved heat management capabilities, critical for decentralized applications. Additionally, plasma-assisted cracking methods have emerged as promising alternatives for lower temperature operation.

The primary objective of current ammonia cracking technology development is to create economically viable, small-scale systems suitable for remote microgrid applications. This requires achieving several key technical goals: reducing catalyst costs while maintaining performance, lowering operating temperatures to below 400°C to minimize energy requirements, developing compact and modular system designs for easy deployment, and ensuring reliable operation with minimal maintenance requirements in remote settings.

Another critical objective is improving overall system efficiency to maximize hydrogen yield while minimizing energy input. This includes optimizing heat recovery systems, reducing startup times, and developing intelligent control systems capable of adapting to variable renewable energy inputs. For remote microgrids specifically, the technology must achieve cost parity with diesel generators while offering superior environmental performance and leveraging locally produced renewable ammonia.

The evolution trajectory points toward fully integrated systems that combine ammonia storage, cracking, and hydrogen utilization in a single package optimized for microgrid applications. The ultimate goal is developing "plug-and-play" solutions that can be deployed in remote locations with minimal infrastructure requirements, providing a viable pathway for clean energy access in areas beyond the reach of conventional power grids.

The 1970s energy crisis sparked renewed interest in ammonia as an energy carrier, leading to advancements in catalyst technology that reduced operating temperatures to 500-700°C. By the 1990s, researchers began exploring ruthenium and nickel-based catalysts that offered improved efficiency, though still at relatively high temperatures. The early 2000s saw the emergence of structured catalysts and membrane reactor concepts that began to address scale and efficiency challenges.

Recent technological breakthroughs have dramatically transformed the landscape of ammonia cracking. Advanced catalyst formulations incorporating transition metals and novel support materials have reduced operating temperatures to 400-500°C while maintaining high conversion rates. Microreactor technologies have enabled more compact system designs with improved heat management capabilities, critical for decentralized applications. Additionally, plasma-assisted cracking methods have emerged as promising alternatives for lower temperature operation.

The primary objective of current ammonia cracking technology development is to create economically viable, small-scale systems suitable for remote microgrid applications. This requires achieving several key technical goals: reducing catalyst costs while maintaining performance, lowering operating temperatures to below 400°C to minimize energy requirements, developing compact and modular system designs for easy deployment, and ensuring reliable operation with minimal maintenance requirements in remote settings.

Another critical objective is improving overall system efficiency to maximize hydrogen yield while minimizing energy input. This includes optimizing heat recovery systems, reducing startup times, and developing intelligent control systems capable of adapting to variable renewable energy inputs. For remote microgrids specifically, the technology must achieve cost parity with diesel generators while offering superior environmental performance and leveraging locally produced renewable ammonia.

The evolution trajectory points toward fully integrated systems that combine ammonia storage, cracking, and hydrogen utilization in a single package optimized for microgrid applications. The ultimate goal is developing "plug-and-play" solutions that can be deployed in remote locations with minimal infrastructure requirements, providing a viable pathway for clean energy access in areas beyond the reach of conventional power grids.

Market Analysis for Decentralized Energy Solutions

The decentralized energy solutions market is experiencing significant growth globally, driven by increasing energy demands in remote areas, rising focus on renewable energy integration, and the need for energy independence. The market size for decentralized energy solutions was valued at approximately $142 billion in 2022 and is projected to reach $329 billion by 2030, growing at a CAGR of 11.2% during the forecast period.

Remote microgrids represent a substantial segment within this market, particularly in regions with limited access to centralized power infrastructure. These areas include remote communities, islands, mining operations, and military installations, which collectively account for over 1.2 billion people worldwide without reliable electricity access. The demand for innovative energy carriers like ammonia in these settings stems from the challenges of intermittent renewable generation and the need for long-duration energy storage solutions.

Ammonia as an energy carrier presents a compelling value proposition for remote microgrids due to its high energy density (18.6 MJ/kg) and established transportation infrastructure. The market for ammonia as an energy vector is expected to grow from $5.3 billion in 2023 to approximately $14.8 billion by 2028. This growth is particularly relevant for decentralized ammonia cracking technologies that enable on-site hydrogen production for power generation.

Regional analysis reveals varying market dynamics. Asia-Pacific leads the market with substantial investments in remote microgrid solutions, particularly in island nations like Indonesia and the Philippines, and in rural electrification projects across India and China. North America follows closely, with significant deployment in Alaska, northern Canada, and Native American reservations, where grid extension is economically prohibitive.

Customer segmentation within this market includes commercial entities (mining operations, telecommunications), public institutions (military bases, research stations), and community-based organizations (indigenous communities, island populations). Each segment presents distinct requirements regarding system scale, reliability standards, and economic constraints that influence technology adoption.

The economic drivers for decentralized ammonia cracking in microgrids include reduced diesel dependency (saving 40-60% in fuel costs), carbon emissions reduction (potentially 70-90% lower than diesel generators), and enhanced energy security. The total cost of ownership analysis indicates that while initial capital expenditure is 30-50% higher than conventional solutions, operational expenses over a 15-year lifecycle can be 25-35% lower, yielding positive returns for installations above certain capacity thresholds.

Market barriers include high upfront costs, technical complexity of ammonia handling systems, safety concerns, and regulatory uncertainties regarding ammonia use as an energy carrier. Additionally, competition from alternative energy storage technologies such as batteries, hydrogen, and synthetic fuels creates market fragmentation that challenges widespread adoption.

Remote microgrids represent a substantial segment within this market, particularly in regions with limited access to centralized power infrastructure. These areas include remote communities, islands, mining operations, and military installations, which collectively account for over 1.2 billion people worldwide without reliable electricity access. The demand for innovative energy carriers like ammonia in these settings stems from the challenges of intermittent renewable generation and the need for long-duration energy storage solutions.

Ammonia as an energy carrier presents a compelling value proposition for remote microgrids due to its high energy density (18.6 MJ/kg) and established transportation infrastructure. The market for ammonia as an energy vector is expected to grow from $5.3 billion in 2023 to approximately $14.8 billion by 2028. This growth is particularly relevant for decentralized ammonia cracking technologies that enable on-site hydrogen production for power generation.

Regional analysis reveals varying market dynamics. Asia-Pacific leads the market with substantial investments in remote microgrid solutions, particularly in island nations like Indonesia and the Philippines, and in rural electrification projects across India and China. North America follows closely, with significant deployment in Alaska, northern Canada, and Native American reservations, where grid extension is economically prohibitive.

Customer segmentation within this market includes commercial entities (mining operations, telecommunications), public institutions (military bases, research stations), and community-based organizations (indigenous communities, island populations). Each segment presents distinct requirements regarding system scale, reliability standards, and economic constraints that influence technology adoption.

The economic drivers for decentralized ammonia cracking in microgrids include reduced diesel dependency (saving 40-60% in fuel costs), carbon emissions reduction (potentially 70-90% lower than diesel generators), and enhanced energy security. The total cost of ownership analysis indicates that while initial capital expenditure is 30-50% higher than conventional solutions, operational expenses over a 15-year lifecycle can be 25-35% lower, yielding positive returns for installations above certain capacity thresholds.

Market barriers include high upfront costs, technical complexity of ammonia handling systems, safety concerns, and regulatory uncertainties regarding ammonia use as an energy carrier. Additionally, competition from alternative energy storage technologies such as batteries, hydrogen, and synthetic fuels creates market fragmentation that challenges widespread adoption.

Technical Barriers and Global Development Status

Decentralized ammonia cracking technology faces several significant technical barriers that currently limit its widespread implementation in remote microgrid applications. The primary challenge lies in achieving efficient catalytic conversion at lower temperatures. Traditional ammonia cracking requires temperatures of 800-900°C, which demands substantial energy input and creates thermal management challenges in small-scale systems. Catalyst degradation under these high-temperature conditions further complicates long-term operation, with most catalysts showing performance decline after 1000-2000 hours of operation.

Material constraints present another major barrier, as reactor components must withstand both high temperatures and the corrosive nature of ammonia and its decomposition products. Current materials that meet these requirements significantly increase system costs, making economic viability difficult to achieve in remote applications. Additionally, heat integration remains problematic, with inefficient heat recovery systems reducing overall system efficiency by 15-25% compared to theoretical maximums.

Scale-appropriate design represents a critical challenge for microgrid applications. Most existing ammonia cracking technologies were developed for industrial-scale operations and do not scale down efficiently to the kilowatt range needed for remote microgrids. This mismatch results in disproportionately high capital costs and reduced operational efficiency at smaller scales.

Globally, ammonia cracking technology development shows significant regional variation. Japan leads in small-scale applications through initiatives like the SIP Energy Carriers program, which has demonstrated integrated systems at the 10-50 kW scale with thermal efficiencies approaching 65%. European research, particularly in Germany and Denmark, focuses on catalyst development, with recent breakthroughs in ruthenium-based catalysts that can operate at temperatures as low as 450°C, though with reduced conversion rates.

North American development has concentrated on system integration and control strategies, with the U.S. Department of Energy supporting several projects targeting remote and island communities. These initiatives have achieved important advances in automation and load-following capabilities but still struggle with economic viability. Australian research emphasizes ruggedized designs for extreme environments, addressing dust protection and thermal cycling challenges specific to remote operations.

Emerging economies, particularly India and China, are rapidly expanding their research capabilities in this field, focusing on cost reduction through novel manufacturing approaches and alternative catalyst formulations. Recent developments in China have demonstrated nickel-based catalysts that, while less efficient than noble metal alternatives, offer significantly lower costs and acceptable performance for non-critical applications.

Material constraints present another major barrier, as reactor components must withstand both high temperatures and the corrosive nature of ammonia and its decomposition products. Current materials that meet these requirements significantly increase system costs, making economic viability difficult to achieve in remote applications. Additionally, heat integration remains problematic, with inefficient heat recovery systems reducing overall system efficiency by 15-25% compared to theoretical maximums.

Scale-appropriate design represents a critical challenge for microgrid applications. Most existing ammonia cracking technologies were developed for industrial-scale operations and do not scale down efficiently to the kilowatt range needed for remote microgrids. This mismatch results in disproportionately high capital costs and reduced operational efficiency at smaller scales.

Globally, ammonia cracking technology development shows significant regional variation. Japan leads in small-scale applications through initiatives like the SIP Energy Carriers program, which has demonstrated integrated systems at the 10-50 kW scale with thermal efficiencies approaching 65%. European research, particularly in Germany and Denmark, focuses on catalyst development, with recent breakthroughs in ruthenium-based catalysts that can operate at temperatures as low as 450°C, though with reduced conversion rates.

North American development has concentrated on system integration and control strategies, with the U.S. Department of Energy supporting several projects targeting remote and island communities. These initiatives have achieved important advances in automation and load-following capabilities but still struggle with economic viability. Australian research emphasizes ruggedized designs for extreme environments, addressing dust protection and thermal cycling challenges specific to remote operations.

Emerging economies, particularly India and China, are rapidly expanding their research capabilities in this field, focusing on cost reduction through novel manufacturing approaches and alternative catalyst formulations. Recent developments in China have demonstrated nickel-based catalysts that, while less efficient than noble metal alternatives, offer significantly lower costs and acceptable performance for non-critical applications.

Current Decentralized Ammonia Cracking Solutions

01 Decentralized ammonia cracking systems for hydrogen production

Decentralized ammonia cracking technologies enable on-site hydrogen production from ammonia, eliminating the need for centralized facilities. These systems typically include catalytic reactors that break down ammonia into hydrogen and nitrogen at specific temperatures and pressures. The economic advantages include reduced transportation costs, flexibility in deployment, and the ability to produce hydrogen at the point of use, which is particularly valuable for remote locations or distributed energy applications.- Decentralized ammonia cracking systems for hydrogen production: Decentralized ammonia cracking technologies enable on-site hydrogen production from ammonia, eliminating the need for centralized facilities. These systems typically include catalytic reactors that break down ammonia into hydrogen and nitrogen at specific temperatures and pressures. The economic advantages include reduced transportation costs, flexibility in deployment, and the ability to produce hydrogen at the point of use, which is particularly valuable for remote locations or distributed energy applications.

- Catalyst innovations for cost-effective ammonia decomposition: Advanced catalysts significantly impact the techno-economics of ammonia cracking by lowering the required reaction temperature and improving conversion efficiency. Recent innovations include ruthenium-based catalysts, nickel-based alternatives, and novel support materials that enhance catalyst longevity and performance. These developments reduce energy requirements and operational costs while increasing hydrogen yield, making decentralized ammonia cracking more economically viable for various applications including fuel cells and industrial processes.

- Integration with renewable energy sources: Coupling decentralized ammonia cracking systems with renewable energy sources creates economically advantageous hydrogen production pathways. Solar, wind, or other renewable power can drive the ammonia cracking process, reducing operational costs and carbon footprint. This integration enables energy storage in the form of ammonia, which can be transported and later cracked to produce hydrogen when needed, addressing intermittency issues associated with renewable energy generation and creating a more sustainable and economically viable hydrogen supply chain.

- Modular and scalable ammonia cracking units: Modular design approaches to ammonia cracking technology enable scalable deployment across various applications and locations. These systems can be sized appropriately for specific use cases, from small-scale distributed energy applications to larger industrial processes. The modular nature reduces capital expenditure risks by allowing incremental investment and expansion. Additionally, standardized manufacturing of these units can significantly reduce production costs through economies of scale, making the technology more accessible and economically viable for diverse markets.

- Heat management and energy efficiency improvements: Advanced heat management strategies significantly improve the techno-economics of ammonia cracking processes. Innovations include heat recovery systems that capture and reuse thermal energy from the exothermic portions of the reaction, reducing overall energy consumption. Process intensification techniques, such as membrane reactors and microreactor designs, enhance heat and mass transfer efficiency. These improvements lower operational costs and increase hydrogen production efficiency, making decentralized ammonia cracking more competitive with other hydrogen production methods.

02 Catalyst innovations for cost-effective ammonia decomposition

Advanced catalysts significantly impact the techno-economics of ammonia cracking by reducing the energy requirements and improving conversion efficiency. Recent innovations include ruthenium-based catalysts, nickel-based alternatives, and novel support materials that enhance catalyst performance while reducing precious metal content. These developments lower the activation energy required for ammonia decomposition, allowing for lower operating temperatures and pressures, which translates to reduced operational costs and improved economic viability of decentralized systems.Expand Specific Solutions03 Integration with renewable energy sources

The economic feasibility of decentralized ammonia cracking is enhanced when integrated with renewable energy sources. Systems that utilize solar, wind, or other renewable energy for the endothermic ammonia cracking process can significantly reduce operational costs and carbon footprint. This integration creates a sustainable pathway for green hydrogen production, where ammonia serves as both an energy carrier and hydrogen storage medium. The techno-economic analysis shows improved viability when considering the full lifecycle costs and environmental benefits.Expand Specific Solutions04 Modular and scalable system designs

Modular and scalable ammonia cracking systems offer economic advantages through standardization, mass production, and flexible deployment options. These systems can be sized appropriately for various applications, from small-scale industrial use to larger distributed energy networks. The modular approach reduces capital expenditure risks by allowing incremental investment and capacity expansion. Additionally, standardized components facilitate maintenance and reduce operational costs, improving the overall economic proposition of decentralized ammonia cracking technology.Expand Specific Solutions05 Heat management and energy efficiency improvements

Advanced heat management strategies significantly impact the techno-economics of ammonia cracking systems. Innovations include heat recovery systems that capture and reuse thermal energy from the exothermic portions of the process, reducing overall energy consumption. Membrane reactor technologies that combine reaction and separation steps also improve efficiency by shifting reaction equilibrium. These improvements in energy efficiency directly translate to lower operational costs and improved economic viability of decentralized ammonia cracking for hydrogen production.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The decentralized ammonia cracking market for remote microgrids is in an early growth phase, characterized by increasing interest due to its potential as a clean hydrogen carrier for energy storage. The global market size remains relatively small but is projected to expand significantly as renewable energy integration challenges drive demand for innovative storage solutions. Technologically, the field is still developing, with key players at different maturity levels. State Grid Corp. of China and China Petroleum & Chemical Corp. are leveraging their extensive infrastructure to pilot large-scale implementations, while research institutions like China Electric Power Research Institute and universities (Tianjin, Sichuan) are advancing fundamental technologies. Companies like Caterpillar and Uniper Technologies are developing commercial applications, focusing on system integration for remote power applications.

China Petroleum & Chemical Corp.

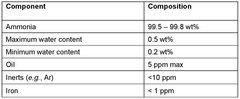

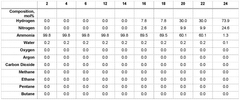

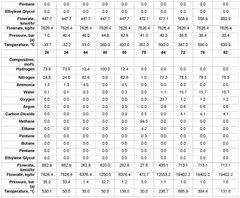

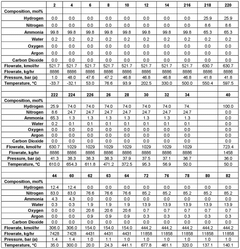

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative decentralized ammonia cracking system specifically designed for remote microgrids. Their technology utilizes a multi-stage catalytic process that enables efficient hydrogen release from ammonia at lower temperatures (350-400°C compared to traditional 500-600°C systems). The system incorporates ruthenium-based catalysts supported on modified alumina with promoters that enhance cracking efficiency while reducing catalyst degradation. Sinopec's approach integrates heat recovery mechanisms that capture and reuse thermal energy from the cracking process, improving overall system efficiency by approximately 15-20%. For remote microgrid applications, they've engineered modular units scalable from 5kW to 100kW that can be deployed in containerized solutions with minimal infrastructure requirements. The system includes advanced control algorithms that optimize cracking rates based on real-time power demand fluctuations, ensuring reliable hydrogen supply for fuel cells or generators.

Strengths: Superior catalyst technology reducing operating temperatures and energy requirements; highly modular design suitable for remote deployment; integrated heat recovery systems improving overall efficiency. Weaknesses: Higher initial capital costs compared to diesel generators; requires specialized maintenance expertise; catalyst performance degradation over time necessitating periodic replacement.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute (CEPRI) has developed a comprehensive decentralized ammonia cracking solution tailored for remote microgrid applications. Their system employs a novel dual-catalyst approach combining nickel-based primary catalysts with ruthenium-doped secondary catalysts, achieving cracking efficiencies of up to 99.5% at operating temperatures of 450-500°C. The technology features an innovative heat integration system that utilizes waste heat from associated power generation equipment to pre-heat ammonia, reducing the overall energy requirement by approximately 25% compared to conventional systems. CEPRI's solution incorporates advanced purification systems that remove trace ammonia from the hydrogen output stream to less than 1ppm, making it suitable for sensitive fuel cell applications. Their modular design allows for scalable implementation from 10kW to 1MW capacity, with each unit featuring intelligent load-following capabilities that adjust hydrogen production rates based on microgrid demand patterns. The system includes proprietary safety monitoring and automated shutdown protocols specifically designed for unmanned operation in remote locations.

Strengths: Exceptional hydrogen purity suitable for PEM fuel cells; advanced heat integration reducing operational costs; intelligent load-following capabilities optimizing ammonia usage; robust safety systems for remote operation. Weaknesses: Higher upfront capital costs compared to conventional generators; requires specialized technical expertise for maintenance; system performance degrades in extreme cold environments below -20°C.

Key Patents and Technical Innovations

Process and apparatus for cracking ammonia

PatentWO2024253893A1

Innovation

- A process and apparatus that splits the ammonia cracking duty between a fired reactor and an electrically heated reactor, utilizing a first catalyst in the fired reactor and a second catalyst in the electrically heated reactor, where the offgas from hydrogen recovery is used as fuel in the fired reactor, optimizing heat flux and energy usage.

Method and system for obtaining a hydrogen-containing product using ammonia

PatentWO2024032928A1

Innovation

- The method involves using at least partially electrically generated heat for catalytic ammonia cracking, followed by processing residual gases in an electrochemical unit, such as a fuel cell or electrochemical compressor, to produce electrical energy and heat, thereby enhancing efficiency and minimizing climate-relevant gas emissions.

Economic Feasibility and Cost Analysis

The economic feasibility of decentralized ammonia cracking systems for remote microgrids hinges on several critical factors. Initial capital expenditure represents a significant barrier, with current small-scale ammonia cracking units requiring investments of $2,000-5,000 per kW of hydrogen production capacity. This high upfront cost stems from specialized materials needed for high-temperature catalytic processes and safety systems required for handling ammonia.

Operational expenses present another economic consideration, primarily driven by energy requirements for the endothermic cracking process. Current systems demand 1.5-2.0 kWh of energy input per kg of hydrogen produced, representing approximately 15-20% of the energy contained in the resulting hydrogen. For remote microgrids with limited energy resources, this energy overhead significantly impacts overall system efficiency and economics.

Maintenance costs for these systems vary based on operational conditions but typically range from 3-7% of capital costs annually. Catalyst replacement represents a recurring expense, with current catalysts requiring replacement every 2-5 years depending on operating conditions and ammonia purity. These maintenance requirements necessitate skilled technicians, which may be scarce in remote locations.

When comparing with alternatives, decentralized ammonia cracking demonstrates competitive advantages in specific scenarios. While diesel generators remain less expensive initially ($500-1,000/kW), their lifetime fuel and maintenance costs exceed those of hydrogen-based systems when operating beyond 5-7 years. Battery storage systems offer lower operational costs but face limitations in energy density and discharge duration for extended microgrid operation.

Levelized cost of energy (LCOE) analysis indicates that ammonia cracking systems currently deliver hydrogen at $6-10/kg, translating to electricity costs of $0.20-0.35/kWh when used with fuel cells. This compares to diesel generation costs of $0.30-0.50/kWh in remote locations, suggesting economic viability in long-term deployments despite higher initial investments.

Economies of scale present significant opportunities for cost reduction. Analysis suggests that increasing system capacity from 10kW to 100kW can reduce per-unit costs by 30-40%, primarily through more efficient heat integration and control systems. Additionally, technological improvements in catalyst efficiency could potentially reduce energy requirements by 20-30% within the next five years, substantially improving economic feasibility.

Operational expenses present another economic consideration, primarily driven by energy requirements for the endothermic cracking process. Current systems demand 1.5-2.0 kWh of energy input per kg of hydrogen produced, representing approximately 15-20% of the energy contained in the resulting hydrogen. For remote microgrids with limited energy resources, this energy overhead significantly impacts overall system efficiency and economics.

Maintenance costs for these systems vary based on operational conditions but typically range from 3-7% of capital costs annually. Catalyst replacement represents a recurring expense, with current catalysts requiring replacement every 2-5 years depending on operating conditions and ammonia purity. These maintenance requirements necessitate skilled technicians, which may be scarce in remote locations.

When comparing with alternatives, decentralized ammonia cracking demonstrates competitive advantages in specific scenarios. While diesel generators remain less expensive initially ($500-1,000/kW), their lifetime fuel and maintenance costs exceed those of hydrogen-based systems when operating beyond 5-7 years. Battery storage systems offer lower operational costs but face limitations in energy density and discharge duration for extended microgrid operation.

Levelized cost of energy (LCOE) analysis indicates that ammonia cracking systems currently deliver hydrogen at $6-10/kg, translating to electricity costs of $0.20-0.35/kWh when used with fuel cells. This compares to diesel generation costs of $0.30-0.50/kWh in remote locations, suggesting economic viability in long-term deployments despite higher initial investments.

Economies of scale present significant opportunities for cost reduction. Analysis suggests that increasing system capacity from 10kW to 100kW can reduce per-unit costs by 30-40%, primarily through more efficient heat integration and control systems. Additionally, technological improvements in catalyst efficiency could potentially reduce energy requirements by 20-30% within the next five years, substantially improving economic feasibility.

Environmental Impact and Sustainability Metrics

Decentralized ammonia cracking systems for remote microgrids present significant environmental implications that must be thoroughly evaluated. The life cycle assessment (LCA) of these systems reveals a substantial reduction in greenhouse gas emissions compared to traditional diesel generators, with potential carbon footprint reductions of 60-85% depending on the ammonia production method. When green ammonia (produced using renewable electricity) is employed, the emissions advantage becomes even more pronounced, approaching carbon-neutral operation.

The water consumption metrics for ammonia cracking systems show mixed results. While the cracking process itself requires minimal water, the upstream ammonia production can be water-intensive, particularly for green ammonia produced via electrolysis. This creates a sustainability trade-off that must be considered in water-scarce regions. Recent technological improvements have reduced water requirements by approximately 30% compared to earlier systems, though this remains an area requiring further optimization.

Land use considerations reveal that decentralized ammonia cracking facilities require significantly less land area than equivalent solar or wind installations for remote power generation. A typical 100kW ammonia cracking system requires approximately 25-40 square meters, excluding storage facilities. This compact footprint makes these systems particularly valuable for remote communities with limited available land or challenging terrain.

Air quality impacts present another important sustainability dimension. While ammonia cracking produces negligible particulate matter compared to diesel generators, there are concerns regarding potential ammonia slip (unreacted ammonia release). Modern catalytic systems have reduced this risk substantially, with emissions typically below 5ppm, well within safety guidelines. NOx emissions from the cracking process are also minimal when proper temperature control and selective catalytic reduction are implemented.

The circular economy potential of these systems is noteworthy. The primary catalysts used in ammonia cracking (typically ruthenium, nickel, or iron-based) demonstrate excellent recyclability, with recovery rates exceeding 90% in industrial settings. Additionally, the heat generated during the cracking process can be captured and utilized for space heating or other thermal applications, improving overall system efficiency by 15-25%.

Biodiversity impact assessments indicate minimal direct ecological disruption from decentralized ammonia cracking facilities, particularly when compared to fossil fuel alternatives. However, ammonia spill risks must be mitigated through proper storage design and handling protocols to protect local ecosystems, especially in sensitive environments where remote microgrids are often deployed.

The water consumption metrics for ammonia cracking systems show mixed results. While the cracking process itself requires minimal water, the upstream ammonia production can be water-intensive, particularly for green ammonia produced via electrolysis. This creates a sustainability trade-off that must be considered in water-scarce regions. Recent technological improvements have reduced water requirements by approximately 30% compared to earlier systems, though this remains an area requiring further optimization.

Land use considerations reveal that decentralized ammonia cracking facilities require significantly less land area than equivalent solar or wind installations for remote power generation. A typical 100kW ammonia cracking system requires approximately 25-40 square meters, excluding storage facilities. This compact footprint makes these systems particularly valuable for remote communities with limited available land or challenging terrain.

Air quality impacts present another important sustainability dimension. While ammonia cracking produces negligible particulate matter compared to diesel generators, there are concerns regarding potential ammonia slip (unreacted ammonia release). Modern catalytic systems have reduced this risk substantially, with emissions typically below 5ppm, well within safety guidelines. NOx emissions from the cracking process are also minimal when proper temperature control and selective catalytic reduction are implemented.

The circular economy potential of these systems is noteworthy. The primary catalysts used in ammonia cracking (typically ruthenium, nickel, or iron-based) demonstrate excellent recyclability, with recovery rates exceeding 90% in industrial settings. Additionally, the heat generated during the cracking process can be captured and utilized for space heating or other thermal applications, improving overall system efficiency by 15-25%.

Biodiversity impact assessments indicate minimal direct ecological disruption from decentralized ammonia cracking facilities, particularly when compared to fossil fuel alternatives. However, ammonia spill risks must be mitigated through proper storage design and handling protocols to protect local ecosystems, especially in sensitive environments where remote microgrids are often deployed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!