Comparative Analysis: PSA vs Membrane vs Getter for H₂ Cleanup

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

H₂ Purification Technology Background and Objectives

Hydrogen purification technology has evolved significantly over the past decades, driven by the growing importance of hydrogen as a clean energy carrier in various industrial applications. The journey began in the early 20th century with basic filtration methods and has now advanced to sophisticated separation technologies including Pressure Swing Adsorption (PSA), membrane separation, and getter-based purification systems. Each technology represents a distinct approach to addressing the fundamental challenge of isolating high-purity hydrogen from gas mixtures containing contaminants such as CO, CO2, CH4, N2, and water vapor.

The evolution of hydrogen purification technologies has been closely linked to developments in the broader hydrogen economy, including production methods, storage solutions, and end-use applications. As hydrogen has gained prominence in sectors ranging from petroleum refining to semiconductor manufacturing, and more recently in fuel cell applications, the demands for higher purity levels and more efficient purification processes have intensified.

Current technological trends point toward more energy-efficient, cost-effective, and environmentally sustainable purification methods. There is a growing emphasis on developing systems that can operate at lower pressures, consume less energy, and maintain high recovery rates while achieving ultra-high purity levels (99.999%+) required for advanced applications such as PEM fuel cells.

The primary objective of this comparative analysis is to evaluate the three dominant hydrogen purification technologies—PSA, membrane separation, and getter-based systems—across multiple performance dimensions. These include purification efficiency, energy consumption, operational flexibility, scalability, capital and operational costs, and environmental impact. By systematically comparing these technologies, we aim to identify their respective strengths, limitations, and optimal application scenarios.

Additionally, this analysis seeks to explore the technological maturity of each method, current research frontiers, and potential innovation pathways. Understanding these aspects is crucial for stakeholders in the hydrogen value chain to make informed decisions about technology selection, investment priorities, and research directions.

The ultimate goal is to provide a comprehensive technological landscape that not only captures the current state of hydrogen purification but also anticipates future developments in this rapidly evolving field. This forward-looking perspective is essential as hydrogen continues to gain momentum as a key component of the global transition toward sustainable energy systems and decarbonized industrial processes.

The evolution of hydrogen purification technologies has been closely linked to developments in the broader hydrogen economy, including production methods, storage solutions, and end-use applications. As hydrogen has gained prominence in sectors ranging from petroleum refining to semiconductor manufacturing, and more recently in fuel cell applications, the demands for higher purity levels and more efficient purification processes have intensified.

Current technological trends point toward more energy-efficient, cost-effective, and environmentally sustainable purification methods. There is a growing emphasis on developing systems that can operate at lower pressures, consume less energy, and maintain high recovery rates while achieving ultra-high purity levels (99.999%+) required for advanced applications such as PEM fuel cells.

The primary objective of this comparative analysis is to evaluate the three dominant hydrogen purification technologies—PSA, membrane separation, and getter-based systems—across multiple performance dimensions. These include purification efficiency, energy consumption, operational flexibility, scalability, capital and operational costs, and environmental impact. By systematically comparing these technologies, we aim to identify their respective strengths, limitations, and optimal application scenarios.

Additionally, this analysis seeks to explore the technological maturity of each method, current research frontiers, and potential innovation pathways. Understanding these aspects is crucial for stakeholders in the hydrogen value chain to make informed decisions about technology selection, investment priorities, and research directions.

The ultimate goal is to provide a comprehensive technological landscape that not only captures the current state of hydrogen purification but also anticipates future developments in this rapidly evolving field. This forward-looking perspective is essential as hydrogen continues to gain momentum as a key component of the global transition toward sustainable energy systems and decarbonized industrial processes.

Market Demand Analysis for Hydrogen Cleanup Solutions

The global hydrogen cleanup solutions market is experiencing robust growth, driven primarily by the increasing adoption of hydrogen as a clean energy carrier across various industries. Current market valuations indicate that the hydrogen purification market reached approximately 5.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 6.8% through 2030. This growth trajectory is underpinned by the escalating demand for high-purity hydrogen in fuel cells, petroleum refining, and emerging green hydrogen applications.

Industrial sectors represent the largest market segment for hydrogen cleanup technologies, with petroleum refining accounting for nearly 45% of current demand. The semiconductor industry follows as the second-largest consumer, requiring ultra-high purity hydrogen for manufacturing processes. Additionally, the transportation sector is emerging as a significant growth driver, particularly with the accelerating deployment of hydrogen fuel cell vehicles in regions like Asia-Pacific and Europe.

Regional analysis reveals that Asia-Pacific currently dominates the market share at approximately 38%, led by China, Japan, and South Korea's aggressive investments in hydrogen infrastructure. North America and Europe follow closely, with Europe showing the fastest growth rate due to stringent environmental regulations and ambitious hydrogen strategy initiatives.

The demand for different hydrogen cleanup technologies varies significantly across applications. PSA (Pressure Swing Adsorption) systems currently hold the largest market share at approximately 42%, valued for their scalability and established presence in industrial applications. Membrane-based solutions are growing at the fastest rate, particularly in small to medium-scale applications where space constraints are critical. Getter technologies, while representing a smaller segment, are finding increasing applications in specialized high-purity requirements.

Customer requirements are increasingly focused on energy efficiency, with end-users seeking solutions that minimize the energy penalty associated with hydrogen purification. Market surveys indicate that over 70% of potential customers rank operational efficiency as their primary consideration, followed by capital expenditure and maintenance requirements.

The market is also witnessing a shift toward integrated solutions that combine multiple purification technologies to achieve optimal performance across varying operating conditions. This trend is particularly evident in green hydrogen production facilities, where fluctuating input purity levels necessitate adaptive purification approaches.

Regulatory drivers are significantly influencing market demand, with increasingly stringent emissions regulations in transportation and industry creating new opportunities for hydrogen cleanup technologies. The European Union's Hydrogen Strategy and similar initiatives worldwide are expected to further accelerate market growth by establishing clear frameworks for hydrogen quality standards and applications.

Industrial sectors represent the largest market segment for hydrogen cleanup technologies, with petroleum refining accounting for nearly 45% of current demand. The semiconductor industry follows as the second-largest consumer, requiring ultra-high purity hydrogen for manufacturing processes. Additionally, the transportation sector is emerging as a significant growth driver, particularly with the accelerating deployment of hydrogen fuel cell vehicles in regions like Asia-Pacific and Europe.

Regional analysis reveals that Asia-Pacific currently dominates the market share at approximately 38%, led by China, Japan, and South Korea's aggressive investments in hydrogen infrastructure. North America and Europe follow closely, with Europe showing the fastest growth rate due to stringent environmental regulations and ambitious hydrogen strategy initiatives.

The demand for different hydrogen cleanup technologies varies significantly across applications. PSA (Pressure Swing Adsorption) systems currently hold the largest market share at approximately 42%, valued for their scalability and established presence in industrial applications. Membrane-based solutions are growing at the fastest rate, particularly in small to medium-scale applications where space constraints are critical. Getter technologies, while representing a smaller segment, are finding increasing applications in specialized high-purity requirements.

Customer requirements are increasingly focused on energy efficiency, with end-users seeking solutions that minimize the energy penalty associated with hydrogen purification. Market surveys indicate that over 70% of potential customers rank operational efficiency as their primary consideration, followed by capital expenditure and maintenance requirements.

The market is also witnessing a shift toward integrated solutions that combine multiple purification technologies to achieve optimal performance across varying operating conditions. This trend is particularly evident in green hydrogen production facilities, where fluctuating input purity levels necessitate adaptive purification approaches.

Regulatory drivers are significantly influencing market demand, with increasingly stringent emissions regulations in transportation and industry creating new opportunities for hydrogen cleanup technologies. The European Union's Hydrogen Strategy and similar initiatives worldwide are expected to further accelerate market growth by establishing clear frameworks for hydrogen quality standards and applications.

Current Status and Challenges in H₂ Purification

Hydrogen purification technology has evolved significantly over the past decades, with three primary methods dominating the industrial landscape: Pressure Swing Adsorption (PSA), membrane separation, and getter-based purification. Each technology presents distinct advantages and limitations in achieving high-purity hydrogen for various applications including fuel cells, semiconductor manufacturing, and chemical processing.

PSA technology currently holds approximately 85% of the industrial hydrogen purification market due to its scalability and reliability. Modern PSA systems can achieve hydrogen purities exceeding 99.999% with recovery rates of 70-90%. However, these systems face challenges including high capital costs, significant energy consumption during pressurization cycles, and large physical footprints that limit their application in space-constrained environments.

Membrane separation technologies, particularly those utilizing palladium-based or polymeric membranes, have gained traction in medium-scale applications. Current commercial membranes can achieve purities of 99.99% with improving durability metrics. The primary technical challenges include membrane fouling, limited operational lifespans (typically 3-5 years), and performance degradation in the presence of certain contaminants such as hydrogen sulfide and carbon monoxide.

Getter-based purification, while less widespread in large-scale industrial applications, offers unique advantages for ultra-high purity requirements. Modern getter materials can achieve hydrogen purities exceeding 99.9999% by selectively removing oxygen, nitrogen, and other impurities. The technology faces challenges in scaling beyond niche applications due to limited throughput capacity and the need for periodic regeneration or replacement of getter materials.

Geographically, hydrogen purification technology development shows distinct patterns. North America and Europe lead in PSA technology advancement, with companies like Air Liquide and Air Products dominating patent portfolios. Asian markets, particularly Japan and South Korea, have made significant strides in membrane technology development, driven by their focus on hydrogen fuel cell vehicles and stationary power applications.

A critical challenge across all purification technologies is energy efficiency. Current purification processes typically consume 10-15% of the energy content of the hydrogen being purified. This represents a significant barrier to cost-effective green hydrogen production and distribution. Additionally, all technologies face durability challenges when processing hydrogen from diverse feedstocks with varying impurity profiles.

Emerging technical challenges include the need for purification systems capable of handling hydrogen derived from renewable sources, which often contains different impurity profiles compared to traditional fossil-derived hydrogen. Furthermore, the integration of purification technologies into decentralized hydrogen production systems remains technically challenging but commercially essential for the expansion of hydrogen as an energy carrier.

PSA technology currently holds approximately 85% of the industrial hydrogen purification market due to its scalability and reliability. Modern PSA systems can achieve hydrogen purities exceeding 99.999% with recovery rates of 70-90%. However, these systems face challenges including high capital costs, significant energy consumption during pressurization cycles, and large physical footprints that limit their application in space-constrained environments.

Membrane separation technologies, particularly those utilizing palladium-based or polymeric membranes, have gained traction in medium-scale applications. Current commercial membranes can achieve purities of 99.99% with improving durability metrics. The primary technical challenges include membrane fouling, limited operational lifespans (typically 3-5 years), and performance degradation in the presence of certain contaminants such as hydrogen sulfide and carbon monoxide.

Getter-based purification, while less widespread in large-scale industrial applications, offers unique advantages for ultra-high purity requirements. Modern getter materials can achieve hydrogen purities exceeding 99.9999% by selectively removing oxygen, nitrogen, and other impurities. The technology faces challenges in scaling beyond niche applications due to limited throughput capacity and the need for periodic regeneration or replacement of getter materials.

Geographically, hydrogen purification technology development shows distinct patterns. North America and Europe lead in PSA technology advancement, with companies like Air Liquide and Air Products dominating patent portfolios. Asian markets, particularly Japan and South Korea, have made significant strides in membrane technology development, driven by their focus on hydrogen fuel cell vehicles and stationary power applications.

A critical challenge across all purification technologies is energy efficiency. Current purification processes typically consume 10-15% of the energy content of the hydrogen being purified. This represents a significant barrier to cost-effective green hydrogen production and distribution. Additionally, all technologies face durability challenges when processing hydrogen from diverse feedstocks with varying impurity profiles.

Emerging technical challenges include the need for purification systems capable of handling hydrogen derived from renewable sources, which often contains different impurity profiles compared to traditional fossil-derived hydrogen. Furthermore, the integration of purification technologies into decentralized hydrogen production systems remains technically challenging but commercially essential for the expansion of hydrogen as an energy carrier.

Comparative Analysis of PSA, Membrane and Getter Methods

01 Pressure Swing Adsorption (PSA) Technology for H₂ Purification

Pressure Swing Adsorption (PSA) technology is widely used for hydrogen purification, utilizing adsorbent materials that selectively capture impurities under pressure while allowing hydrogen to pass through. The process involves cycles of pressurization and depressurization, where contaminants are adsorbed at high pressure and released during regeneration at low pressure. PSA systems can achieve high hydrogen purity levels (up to 99.9999%) and are particularly effective for removing carbon dioxide, carbon monoxide, methane, and nitrogen from hydrogen streams.- Pressure Swing Adsorption (PSA) Technology for H₂ Purification: Pressure Swing Adsorption (PSA) is a widely used technology for hydrogen purification that operates by selectively adsorbing impurities from hydrogen gas streams under pressure. The process involves multiple adsorption beds containing materials like zeolites, activated carbon, or molecular sieves that capture contaminants while allowing hydrogen to pass through. PSA systems can achieve high purification efficiencies, typically producing hydrogen with purity levels exceeding 99.9%. The technology is particularly effective for removing impurities such as CO, CO₂, CH₄, N₂, and water vapor from hydrogen streams.

- Membrane-Based Hydrogen Purification Systems: Membrane technology utilizes selective permeation to separate hydrogen from other gases. These systems typically employ palladium-based or polymer membranes that allow hydrogen molecules to pass through while blocking larger molecules. Membrane purification offers advantages including continuous operation, scalability, and lower energy consumption compared to some alternative methods. The purification efficiency depends on membrane material properties, operating temperature, pressure differential, and feed gas composition. Modern membrane systems can achieve hydrogen purities of 99.99% or higher, making them suitable for applications requiring ultra-pure hydrogen.

- Getter-Based Hydrogen Purification Methods: Getter purification technology uses reactive materials that chemically bind with impurities in hydrogen gas streams. These materials, often metal alloys or compounds, selectively react with contaminants such as oxygen, nitrogen, carbon monoxide, and water vapor. Getter systems are particularly effective for final polishing of hydrogen to achieve ultra-high purity levels. They can operate at various temperatures depending on the getter material used, with some systems functioning at room temperature while others require elevated temperatures to activate the getter material. This technology is especially valuable for applications requiring extremely pure hydrogen with impurity levels in the parts-per-billion range.

- Hybrid and Integrated Purification Systems: Hybrid hydrogen purification systems combine multiple technologies such as PSA, membrane, and getter methods to achieve optimal purification efficiency. These integrated approaches leverage the strengths of each technology while mitigating their individual limitations. For example, a PSA system might be used for bulk separation followed by membrane or getter technology for final polishing. Such combinations can achieve extremely high hydrogen purities (>99.9999%) while optimizing energy consumption, capital costs, and operational flexibility. Hybrid systems are particularly valuable for applications with varying feed gas compositions or fluctuating purity requirements.

- Monitoring and Control Systems for H₂ Purification: Advanced monitoring and control systems are essential for optimizing the efficiency of hydrogen purification technologies. These systems incorporate sensors, analyzers, and automated control algorithms to continuously monitor gas composition, pressure, temperature, and flow rates. Real-time monitoring enables precise control of operating parameters, detection of performance degradation, and predictive maintenance. Modern purification systems often include sophisticated control interfaces that allow operators to adjust parameters based on changing input conditions or purity requirements. These monitoring and control capabilities significantly enhance purification efficiency, reduce energy consumption, and extend the operational lifetime of purification equipment.

02 Membrane Separation Systems for Hydrogen Purification

Membrane separation technology utilizes selective permeation to purify hydrogen from gas mixtures. Hydrogen molecules, being smaller than most impurities, can pass through specialized membranes while larger molecules are retained. Common membrane materials include palladium alloys, polymers, and ceramics. These systems offer advantages such as continuous operation, lower energy consumption compared to some alternatives, and scalability. Membrane purification efficiency depends on factors including operating temperature, pressure differential, membrane material, and feed gas composition.Expand Specific Solutions03 Getter-Based Purification Methods

Getter purification technology involves materials that chemically react with and remove specific impurities from hydrogen gas. These materials, often metal alloys or compounds, irreversibly capture oxygen, nitrogen, water vapor, and other contaminants through chemical reactions. Getter systems are particularly effective for ultra-high purity applications where trace impurities must be eliminated. The purification efficiency depends on the getter material composition, operating temperature, and contact time. This method is often used as a final polishing step in multi-stage purification systems.Expand Specific Solutions04 Hybrid and Integrated Purification Systems

Hybrid purification systems combine multiple technologies (PSA, membrane, getter) to achieve optimal hydrogen purification efficiency. These integrated approaches leverage the strengths of each method while mitigating their individual limitations. For example, a membrane system might be used for bulk separation followed by PSA for intermediate purification and getter technology for final polishing. Such combinations can achieve ultra-high purity levels while optimizing energy consumption, recovery rates, and operational costs. These systems are particularly valuable for applications requiring both high purity and efficiency.Expand Specific Solutions05 Monitoring and Control Systems for Purification Efficiency

Advanced monitoring and control systems are essential for maintaining optimal hydrogen purification efficiency. These systems incorporate sensors, analyzers, and automated controls to continuously measure purity levels, detect breakthrough of contaminants, and adjust operating parameters accordingly. Real-time monitoring enables precise control of pressure, temperature, flow rates, and cycle times to maximize purification efficiency while minimizing energy consumption. Intelligent control algorithms can predict maintenance needs, prevent performance degradation, and optimize regeneration cycles based on feed gas composition and purity requirements.Expand Specific Solutions

Major Industry Players in H₂ Purification

The hydrogen cleanup technology market is currently in a growth phase, with increasing demand driven by clean energy initiatives and industrial applications. The market size is expanding rapidly, projected to reach significant value as hydrogen becomes central to decarbonization strategies. Among the three main technologies, PSA (Pressure Swing Adsorption) represents the most mature solution, with industry leaders like Air Liquide, Praxair Technology, and Air Products & Chemicals dominating implementation across various sectors. Membrane technology is gaining momentum with companies like Eltron Research and Sumitomo Seika advancing selective permeation solutions. Getter technology remains more specialized, with players like SICHUAN TECHAIRS and Haldor Topsøe developing innovative materials for specific applications. The competitive landscape shows established industrial gas companies expanding their technological portfolios while specialized firms focus on breakthrough innovations in specific purification methods.

Air Liquide SA

Technical Solution: Air Liquide has pioneered a comprehensive portfolio of hydrogen purification technologies, with particular expertise in membrane separation systems. Their MEDAL™ polymer membrane technology utilizes hollow fiber modules with proprietary polymer materials that allow hydrogen to permeate preferentially while rejecting larger molecules like CO, CO2, and hydrocarbons. These membranes operate on the principle of solution-diffusion, where hydrogen dissolves into the membrane material and diffuses through it at rates much higher than contaminant gases. Air Liquide's membrane systems operate continuously rather than cyclically, offering significant advantages in applications requiring steady hydrogen output. Their latest generation membranes feature enhanced selectivity and permeability characteristics, achieving hydrogen purities up to 99.5% in single-stage configurations and over 99.9% in multi-stage designs. The company has optimized membrane module configurations to maximize surface area while minimizing pressure drop, resulting in systems that can process hydrogen streams ranging from small-scale (100 Nm³/h) to large industrial applications (>50,000 Nm³/h). Air Liquide also offers hybrid purification solutions that combine membrane technology with PSA or cryogenic separation for optimized performance in challenging applications.

Strengths: Lower capital costs compared to PSA for small to medium applications, continuous operation without cycling, compact footprint requiring minimal space, and simple operation with few moving parts. Weaknesses: Generally lower hydrogen recovery rates than PSA systems, difficulty achieving ultra-high purity without multiple stages, and sensitivity to certain contaminants that can damage membrane materials.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed advanced PSA (Pressure Swing Adsorption) technology for hydrogen purification that utilizes proprietary adsorbent materials and optimized cycle configurations. Their PRISM® PSA systems employ multiple adsorption beds containing molecular sieves and activated carbon to selectively remove impurities like CO, CO2, CH4, and N2 from hydrogen streams. The process operates through pressure cycling, where impurities adsorb at high pressure and desorb during depressurization. Air Products has enhanced traditional PSA with rapid-cycle designs that reduce bed size and capital costs while maintaining high hydrogen recovery rates (up to 90%) and purities exceeding 99.999%. Their systems incorporate sophisticated valve sequencing and process control algorithms to optimize performance across varying feed compositions and flow rates. For large-scale applications, Air Products offers modular PSA units that can be scaled to process hydrogen flows from 1,000 to over 200,000 Nm³/h, making them suitable for refinery operations, chemical processing, and hydrogen production facilities.

Strengths: High hydrogen purity (>99.999%), excellent scalability for industrial applications, proven reliability with thousands of installations worldwide, and lower energy consumption compared to cryogenic methods. Weaknesses: Relatively high capital costs for smaller applications, complexity of operation requiring specialized expertise, and potential for reduced efficiency when handling feeds with highly variable compositions.

Key Technical Innovations in H₂ Cleanup

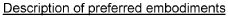

A pressure swing adsorption process for producing hydrogen and carbon dioxide

PatentWO2020221629A1

Innovation

- A PSA process that involves feeding an input gas through an adsorbent material under high pressure to separate H2 and CO2, followed by intermediate and sub-atmospheric pressure steps to release impurities and CO2, allowing for simultaneous high-purity H2 and CO2 recovery in a single PSA stage, with optional stream exchanges and pressurization methods across multiple vessels.

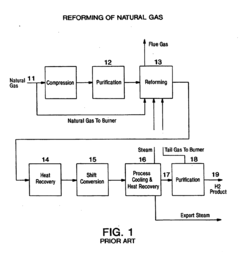

Pressure swing adsorption process for the production of hydrogen

PatentInactiveEP1076035B1

Innovation

- The process employs a PSA system with CaX zeolite adsorbent having a SiO2/Al2O3 mole ratio of 2.0-2.5, where additional adsorbent layers remove CO2 and H2O upstream, followed by a CaX zeolite layer to adsorb N2, enhancing hydrogen recovery and reducing zeolite quantity, thereby achieving high purity hydrogen production.

Economic Feasibility Assessment of H₂ Cleanup Technologies

The economic viability of hydrogen purification technologies represents a critical factor in their industrial adoption. PSA (Pressure Swing Adsorption) systems demonstrate favorable economics at medium to large scales, with capital costs ranging from $1-3 million for standard industrial installations. These systems benefit from economies of scale, with unit costs decreasing significantly as capacity increases. Operational expenses primarily involve electricity for compression, estimated at 0.2-0.4 kWh per kg of hydrogen processed, and periodic replacement of adsorbent materials every 3-5 years.

Membrane technologies present a different economic profile, with lower initial capital investment ($0.5-1.5 million for comparable capacity) but potentially higher operational costs. The primary economic consideration for membrane systems is the replacement frequency of the membrane modules, typically every 2-3 years, representing 15-25% of the initial capital cost. Energy requirements are generally lower than PSA, averaging 0.1-0.3 kWh per kg of hydrogen, creating potential long-term operational savings.

Getter-based purification systems show distinctive economic characteristics, with relatively high material costs but simplified system design. The economics are heavily dependent on the specific getter material employed, with newer alloys offering improved capacity-to-cost ratios. These systems excel in specialized applications where ultra-high purity is required, though their economic feasibility diminishes at larger scales due to the direct relationship between hydrogen volume and getter material requirements.

Lifecycle cost analysis reveals that PSA systems typically achieve payback periods of 3-5 years in continuous industrial applications, while membrane systems may reach breakeven in 2-4 years depending on operational parameters and hydrogen throughput. Getter systems generally show longer payback periods of 4-7 years but may be economically justified in high-value applications where purity requirements exceed 99.9999%.

Market sensitivity analysis indicates that PSA economics are most vulnerable to electricity price fluctuations, while membrane systems face greater exposure to raw material price volatility for specialized polymers. Getter systems demonstrate particular sensitivity to rare earth and specialty metal pricing, which can significantly impact their economic viability as these materials often constitute 40-60% of system costs.

Future economic trends suggest improving cost structures for all three technologies, with membrane systems potentially experiencing the most significant cost reductions (projected 30-40% over the next decade) due to ongoing materials science advancements and manufacturing scale improvements. PSA systems are expected to see more modest cost reductions of 15-25%, primarily through efficiency improvements and control system optimization.

Membrane technologies present a different economic profile, with lower initial capital investment ($0.5-1.5 million for comparable capacity) but potentially higher operational costs. The primary economic consideration for membrane systems is the replacement frequency of the membrane modules, typically every 2-3 years, representing 15-25% of the initial capital cost. Energy requirements are generally lower than PSA, averaging 0.1-0.3 kWh per kg of hydrogen, creating potential long-term operational savings.

Getter-based purification systems show distinctive economic characteristics, with relatively high material costs but simplified system design. The economics are heavily dependent on the specific getter material employed, with newer alloys offering improved capacity-to-cost ratios. These systems excel in specialized applications where ultra-high purity is required, though their economic feasibility diminishes at larger scales due to the direct relationship between hydrogen volume and getter material requirements.

Lifecycle cost analysis reveals that PSA systems typically achieve payback periods of 3-5 years in continuous industrial applications, while membrane systems may reach breakeven in 2-4 years depending on operational parameters and hydrogen throughput. Getter systems generally show longer payback periods of 4-7 years but may be economically justified in high-value applications where purity requirements exceed 99.9999%.

Market sensitivity analysis indicates that PSA economics are most vulnerable to electricity price fluctuations, while membrane systems face greater exposure to raw material price volatility for specialized polymers. Getter systems demonstrate particular sensitivity to rare earth and specialty metal pricing, which can significantly impact their economic viability as these materials often constitute 40-60% of system costs.

Future economic trends suggest improving cost structures for all three technologies, with membrane systems potentially experiencing the most significant cost reductions (projected 30-40% over the next decade) due to ongoing materials science advancements and manufacturing scale improvements. PSA systems are expected to see more modest cost reductions of 15-25%, primarily through efficiency improvements and control system optimization.

Environmental Impact and Sustainability Considerations

The environmental impact of hydrogen purification technologies is becoming increasingly important as the hydrogen economy expands. PSA (Pressure Swing Adsorption), membrane, and getter technologies each present distinct environmental footprints that must be carefully evaluated when selecting purification methods for industrial applications.

PSA systems generally require significant energy input for the compression and decompression cycles, contributing to indirect carbon emissions when powered by non-renewable sources. However, PSA offers advantages in resource efficiency as adsorbent materials can typically be regenerated multiple times before replacement, reducing waste generation. The primary environmental concern with PSA is its energy intensity, which can be mitigated through integration with renewable energy sources or waste heat recovery systems.

Membrane technologies demonstrate promising sustainability profiles with lower energy requirements compared to PSA systems. Modern polymeric and metallic membranes operate at moderate temperatures and pressures, reducing overall energy consumption. Additionally, membranes generally have smaller physical footprints, requiring less construction material and associated embodied carbon. The manufacturing process for advanced membranes, however, may involve specialized materials with their own environmental implications, particularly regarding end-of-life disposal or recycling challenges.

Getter technologies present unique environmental considerations. While they operate with minimal energy requirements during use, the production of getter materials often involves energy-intensive processes and rare or precious metals. The environmental impact of mining and processing these materials must be factored into sustainability assessments. Furthermore, spent getter materials may require specialized disposal procedures due to potential contamination with hydrogen sulfide or other impurities removed during purification.

Water consumption varies significantly across these technologies. PSA typically requires minimal water, while some membrane systems may need water for cooling or cleaning processes. Getter technologies generally have negligible water requirements during operation, though their manufacturing processes may be water-intensive.

Life cycle assessment (LCA) studies indicate that the environmental superiority of any given technology depends heavily on specific implementation factors, including scale, hydrogen source, energy mix, and operational parameters. For small-scale applications, getters may offer the lowest overall environmental impact despite higher material intensity. For large industrial applications, membrane technologies increasingly demonstrate favorable environmental profiles when considering the full life cycle impacts.

Carbon footprint reduction strategies for hydrogen purification include integration with renewable energy sources, heat integration with surrounding processes, material efficiency improvements, and development of bio-based or recyclable purification materials. As hydrogen gains prominence in decarbonization efforts, ensuring that purification processes themselves maintain minimal environmental footprints becomes essential for truly sustainable hydrogen deployment.

PSA systems generally require significant energy input for the compression and decompression cycles, contributing to indirect carbon emissions when powered by non-renewable sources. However, PSA offers advantages in resource efficiency as adsorbent materials can typically be regenerated multiple times before replacement, reducing waste generation. The primary environmental concern with PSA is its energy intensity, which can be mitigated through integration with renewable energy sources or waste heat recovery systems.

Membrane technologies demonstrate promising sustainability profiles with lower energy requirements compared to PSA systems. Modern polymeric and metallic membranes operate at moderate temperatures and pressures, reducing overall energy consumption. Additionally, membranes generally have smaller physical footprints, requiring less construction material and associated embodied carbon. The manufacturing process for advanced membranes, however, may involve specialized materials with their own environmental implications, particularly regarding end-of-life disposal or recycling challenges.

Getter technologies present unique environmental considerations. While they operate with minimal energy requirements during use, the production of getter materials often involves energy-intensive processes and rare or precious metals. The environmental impact of mining and processing these materials must be factored into sustainability assessments. Furthermore, spent getter materials may require specialized disposal procedures due to potential contamination with hydrogen sulfide or other impurities removed during purification.

Water consumption varies significantly across these technologies. PSA typically requires minimal water, while some membrane systems may need water for cooling or cleaning processes. Getter technologies generally have negligible water requirements during operation, though their manufacturing processes may be water-intensive.

Life cycle assessment (LCA) studies indicate that the environmental superiority of any given technology depends heavily on specific implementation factors, including scale, hydrogen source, energy mix, and operational parameters. For small-scale applications, getters may offer the lowest overall environmental impact despite higher material intensity. For large industrial applications, membrane technologies increasingly demonstrate favorable environmental profiles when considering the full life cycle impacts.

Carbon footprint reduction strategies for hydrogen purification include integration with renewable energy sources, heat integration with surrounding processes, material efficiency improvements, and development of bio-based or recyclable purification materials. As hydrogen gains prominence in decarbonization efforts, ensuring that purification processes themselves maintain minimal environmental footprints becomes essential for truly sustainable hydrogen deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!