Start-Up at Low Temperature: Promoters, Supports, and Kinetics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Low Temperature Start-Up Technology Background and Objectives

Low temperature start-up technology has evolved significantly over the past decades, addressing one of the most critical challenges in automotive and industrial applications. The fundamental issue stems from the reduced chemical reaction rates and increased viscosity of fluids at low temperatures, which impede efficient system initialization. Historically, this technology originated in the 1950s with basic heating elements, progressing through mechanical solutions in the 1970s, and advancing to sophisticated catalyst systems in the 1990s.

The evolution of promoters represents a significant milestone in this field. Early promoters were primarily alkali metals, which have since been replaced by more efficient transition metal compounds. These modern promoters facilitate electron transfer processes at significantly lower activation energies, enabling catalytic reactions to initiate at temperatures as low as -40°C in some applications.

Support materials have undergone parallel development, transitioning from simple alumina structures to complex engineered materials with precisely controlled porosity and surface characteristics. Contemporary supports feature hierarchical pore structures that optimize mass transfer while maintaining high surface area, crucial for low-temperature catalytic activity.

The kinetics of low-temperature start-up presents unique challenges that differentiate it from steady-state operation. Recent research has revealed that reaction pathways can fundamentally change below certain temperature thresholds, necessitating specialized catalyst formulations that specifically target these alternative mechanisms.

Current technological objectives focus on several key areas: reducing the activation temperature to below -30°C for automotive applications; decreasing the energy consumption of auxiliary heating systems by at least 40%; developing self-regulating catalytic systems that adapt to temperature fluctuations; and creating more durable solutions that maintain performance after repeated thermal cycling.

The interdisciplinary nature of this challenge requires integration of advances in materials science, chemical engineering, and thermal management. Computational modeling has emerged as a critical tool, enabling researchers to simulate molecular interactions at low temperatures and predict performance of novel catalyst formulations before physical prototyping.

The ultimate goal of current research efforts is to develop systems that require minimal or zero external energy input for low-temperature initialization, representing a paradigm shift from traditional approaches that rely heavily on external heating. This would significantly reduce energy consumption during the critical start-up phase and enable more efficient operation across diverse environmental conditions.

The evolution of promoters represents a significant milestone in this field. Early promoters were primarily alkali metals, which have since been replaced by more efficient transition metal compounds. These modern promoters facilitate electron transfer processes at significantly lower activation energies, enabling catalytic reactions to initiate at temperatures as low as -40°C in some applications.

Support materials have undergone parallel development, transitioning from simple alumina structures to complex engineered materials with precisely controlled porosity and surface characteristics. Contemporary supports feature hierarchical pore structures that optimize mass transfer while maintaining high surface area, crucial for low-temperature catalytic activity.

The kinetics of low-temperature start-up presents unique challenges that differentiate it from steady-state operation. Recent research has revealed that reaction pathways can fundamentally change below certain temperature thresholds, necessitating specialized catalyst formulations that specifically target these alternative mechanisms.

Current technological objectives focus on several key areas: reducing the activation temperature to below -30°C for automotive applications; decreasing the energy consumption of auxiliary heating systems by at least 40%; developing self-regulating catalytic systems that adapt to temperature fluctuations; and creating more durable solutions that maintain performance after repeated thermal cycling.

The interdisciplinary nature of this challenge requires integration of advances in materials science, chemical engineering, and thermal management. Computational modeling has emerged as a critical tool, enabling researchers to simulate molecular interactions at low temperatures and predict performance of novel catalyst formulations before physical prototyping.

The ultimate goal of current research efforts is to develop systems that require minimal or zero external energy input for low-temperature initialization, representing a paradigm shift from traditional approaches that rely heavily on external heating. This would significantly reduce energy consumption during the critical start-up phase and enable more efficient operation across diverse environmental conditions.

Market Analysis for Low Temperature Start-Up Solutions

The global market for low temperature start-up solutions has experienced significant growth in recent years, driven by increasingly stringent emission regulations and the growing demand for more efficient combustion technologies. The market size for catalytic solutions addressing cold-start emissions was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 10.2%.

Automotive applications currently dominate the market landscape, accounting for nearly 65% of the total market share. This dominance stems from the critical need to reduce harmful emissions during the cold-start phase of internal combustion engines, where up to 80% of total trip emissions can occur in the first few minutes of operation. The passenger vehicle segment represents the largest sub-segment, followed by commercial vehicles and off-road equipment.

Regional analysis reveals that Europe leads the market with approximately 38% share, primarily due to its stringent Euro 7 emission standards implementation. North America follows closely at 32%, while Asia-Pacific represents the fastest-growing region with a projected CAGR of 12.5% through 2028, largely driven by China's tightening emission regulations and India's rapid automotive market expansion.

From an end-user perspective, original equipment manufacturers (OEMs) constitute the largest customer segment, accounting for 70% of market revenue. The aftermarket segment, though smaller, is growing at a faster rate as older vehicles are retrofitted with advanced catalytic systems to meet newer emission standards.

The market is witnessing several key trends that are shaping its trajectory. First, there is increasing investment in nanotechnology-based catalysts that can activate at temperatures as low as 150°C, compared to conventional catalysts that require 250-300°C. Second, integrated thermal management systems that combine electrical pre-heating with advanced catalyst formulations are gaining traction, offering 40-50% faster light-off times.

Customer demand patterns indicate a growing preference for solutions that not only address regulatory compliance but also contribute to fuel efficiency improvements. This dual-benefit approach has become a key differentiator in the market, with solutions that can demonstrate a 2-3% fuel economy improvement commanding premium pricing.

Market forecasts suggest that the segment for ultra-low temperature catalysts (active below 120°C) will experience the highest growth rate at 15.8% annually, reflecting the industry's push toward near-zero cold-start emissions. Additionally, the market for electrically heated catalysts is expected to double in size over the next five years as hybrid and mild-hybrid vehicles increase their market penetration.

Automotive applications currently dominate the market landscape, accounting for nearly 65% of the total market share. This dominance stems from the critical need to reduce harmful emissions during the cold-start phase of internal combustion engines, where up to 80% of total trip emissions can occur in the first few minutes of operation. The passenger vehicle segment represents the largest sub-segment, followed by commercial vehicles and off-road equipment.

Regional analysis reveals that Europe leads the market with approximately 38% share, primarily due to its stringent Euro 7 emission standards implementation. North America follows closely at 32%, while Asia-Pacific represents the fastest-growing region with a projected CAGR of 12.5% through 2028, largely driven by China's tightening emission regulations and India's rapid automotive market expansion.

From an end-user perspective, original equipment manufacturers (OEMs) constitute the largest customer segment, accounting for 70% of market revenue. The aftermarket segment, though smaller, is growing at a faster rate as older vehicles are retrofitted with advanced catalytic systems to meet newer emission standards.

The market is witnessing several key trends that are shaping its trajectory. First, there is increasing investment in nanotechnology-based catalysts that can activate at temperatures as low as 150°C, compared to conventional catalysts that require 250-300°C. Second, integrated thermal management systems that combine electrical pre-heating with advanced catalyst formulations are gaining traction, offering 40-50% faster light-off times.

Customer demand patterns indicate a growing preference for solutions that not only address regulatory compliance but also contribute to fuel efficiency improvements. This dual-benefit approach has become a key differentiator in the market, with solutions that can demonstrate a 2-3% fuel economy improvement commanding premium pricing.

Market forecasts suggest that the segment for ultra-low temperature catalysts (active below 120°C) will experience the highest growth rate at 15.8% annually, reflecting the industry's push toward near-zero cold-start emissions. Additionally, the market for electrically heated catalysts is expected to double in size over the next five years as hybrid and mild-hybrid vehicles increase their market penetration.

Technical Challenges in Low Temperature Catalysis

Low temperature catalysis faces several significant technical barriers that hinder its widespread industrial application. The primary challenge lies in catalyst activation energy requirements, as most conventional catalysts require high temperatures to overcome activation barriers. This fundamental limitation restricts the development of energy-efficient processes that could operate at lower temperatures, creating a significant technological gap in sustainable chemical manufacturing.

Material stability presents another critical challenge, particularly for promoters and supports. At low temperatures, many catalytic materials suffer from reduced activity due to slower reaction kinetics and diminished surface interactions. The adsorption-desorption equilibrium shifts unfavorably, often resulting in catalyst poisoning where reactants or intermediates bind too strongly to active sites, preventing further reaction progression.

Reaction selectivity becomes increasingly problematic at lower temperatures. Reduced thermal energy can lead to incomplete reactions or undesired side reactions, compromising product purity and yield. This selectivity issue is particularly pronounced in complex reaction networks common in industrial processes, where multiple competing pathways exist.

Heat and mass transfer limitations emerge as significant engineering challenges. Lower operating temperatures create steeper temperature gradients within catalyst beds, leading to non-uniform reaction conditions. Similarly, reduced molecular mobility at lower temperatures impedes efficient mass transfer to and from active sites, creating diffusion limitations that dramatically reduce overall reaction rates.

The development of appropriate promoters represents a frontier challenge. While promoters can enhance catalytic activity by modifying electronic properties or creating new active sites, identifying promoters specifically optimized for low-temperature operation remains difficult. Most existing promoter systems were developed for conventional temperature ranges and perform sub-optimally in low-temperature environments.

Support material engineering faces unique constraints at lower temperatures. The support not only provides mechanical stability but also influences reactant access to active sites and can participate in the reaction mechanism. At low temperatures, the support-catalyst interface becomes increasingly important, with subtle electronic and structural interactions significantly impacting performance.

Kinetic modeling presents substantial theoretical challenges. Traditional kinetic models often fail to accurately predict catalyst behavior at low temperatures, where quantum effects, such as tunneling, may become significant. Additionally, the slower reaction rates make it difficult to distinguish between rate-limiting steps, complicating mechanistic understanding and catalyst optimization efforts.

Material stability presents another critical challenge, particularly for promoters and supports. At low temperatures, many catalytic materials suffer from reduced activity due to slower reaction kinetics and diminished surface interactions. The adsorption-desorption equilibrium shifts unfavorably, often resulting in catalyst poisoning where reactants or intermediates bind too strongly to active sites, preventing further reaction progression.

Reaction selectivity becomes increasingly problematic at lower temperatures. Reduced thermal energy can lead to incomplete reactions or undesired side reactions, compromising product purity and yield. This selectivity issue is particularly pronounced in complex reaction networks common in industrial processes, where multiple competing pathways exist.

Heat and mass transfer limitations emerge as significant engineering challenges. Lower operating temperatures create steeper temperature gradients within catalyst beds, leading to non-uniform reaction conditions. Similarly, reduced molecular mobility at lower temperatures impedes efficient mass transfer to and from active sites, creating diffusion limitations that dramatically reduce overall reaction rates.

The development of appropriate promoters represents a frontier challenge. While promoters can enhance catalytic activity by modifying electronic properties or creating new active sites, identifying promoters specifically optimized for low-temperature operation remains difficult. Most existing promoter systems were developed for conventional temperature ranges and perform sub-optimally in low-temperature environments.

Support material engineering faces unique constraints at lower temperatures. The support not only provides mechanical stability but also influences reactant access to active sites and can participate in the reaction mechanism. At low temperatures, the support-catalyst interface becomes increasingly important, with subtle electronic and structural interactions significantly impacting performance.

Kinetic modeling presents substantial theoretical challenges. Traditional kinetic models often fail to accurately predict catalyst behavior at low temperatures, where quantum effects, such as tunneling, may become significant. Additionally, the slower reaction rates make it difficult to distinguish between rate-limiting steps, complicating mechanistic understanding and catalyst optimization efforts.

Current Promoter and Support Material Solutions

01 Battery heating systems for low temperature start-up

Various heating systems are designed to improve battery performance during cold starts. These systems include integrated heating elements, thermal management systems, and preheating mechanisms that raise the battery temperature to optimal operating conditions before vehicle start-up. By maintaining appropriate battery temperature, these systems enhance electrochemical reactions, reduce internal resistance, and improve overall power output during cold weather conditions.- Battery heating systems for low temperature start-up: Various heating systems are designed to improve battery performance during cold starts. These include internal heating elements, external heating blankets, and thermal management systems that can pre-heat batteries before operation. By raising the battery temperature to optimal operating range, these systems enhance electrochemical reactions, reduce internal resistance, and improve power output during low temperature start-up conditions.

- Electrolyte formulations for cold temperature performance: Specialized electrolyte compositions are developed to maintain ionic conductivity at low temperatures. These formulations typically include additives that lower the freezing point, reduce viscosity at cold temperatures, and enhance ion mobility. Some electrolytes incorporate co-solvents or novel salt combinations that specifically target improved performance during cold starts, allowing for better power delivery when the system is initially activated in low temperature environments.

- Electrode materials optimized for low temperature operation: Advanced electrode materials are designed with specific microstructures and compositions to facilitate ion transport at low temperatures. These materials often feature increased surface area, optimized porosity, and special coatings that reduce activation energy barriers during cold starts. Some electrodes incorporate dopants or structural modifications that specifically enhance charge transfer kinetics when the system is operating below optimal temperature ranges.

- Intelligent control systems for cold start management: Smart control algorithms and management systems are implemented to optimize the start-up sequence in cold conditions. These systems monitor temperature, adjust power distribution, and control heating elements to create optimal starting conditions. Some incorporate predictive models that prepare the system based on environmental conditions, while others dynamically adjust operational parameters during the warm-up phase to balance performance needs with system protection.

- Structural design innovations for thermal insulation and heat retention: Physical design modifications help maintain operating temperature and improve thermal efficiency during cold starts. These include insulating materials, heat-reflective layers, and compartmentalized designs that slow heat loss. Some systems incorporate phase change materials that store and release heat as needed, while others use strategic component placement to optimize heat distribution and retention, ensuring critical components reach operational temperature more quickly.

02 Electrolyte formulations for cold temperature operation

Specialized electrolyte compositions are developed to maintain ionic conductivity at low temperatures. These formulations include additives that lower the freezing point, reduce viscosity at cold temperatures, and improve ion mobility between electrodes. Some electrolytes incorporate organic solvents with low melting points or anti-freezing compounds that enable efficient ion transport even when ambient temperatures drop significantly below normal operating conditions.Expand Specific Solutions03 Electrode materials optimized for low temperature performance

Advanced electrode materials are designed specifically to maintain electrochemical activity at low temperatures. These materials feature modified surface structures, doping elements, or composite formulations that reduce activation energy barriers for lithium-ion intercalation at cold temperatures. Some electrodes incorporate conductive additives or nanostructured components that maintain effective electron pathways despite reduced kinetics in cold conditions.Expand Specific Solutions04 Control systems and algorithms for cold start management

Intelligent control systems employ specialized algorithms to optimize battery performance during cold starts. These systems monitor temperature, state of charge, and other parameters to adjust charging currents, power distribution, and thermal management strategies. Some implementations use predictive models to anticipate cold start conditions and prepare the battery system accordingly, while others implement adaptive control mechanisms that modify operating parameters based on real-time performance feedback.Expand Specific Solutions05 Structural designs for improved thermal insulation and heat retention

Innovative battery pack designs incorporate thermal insulation materials, heat-retaining structures, and optimized component arrangements to minimize heat loss during cold conditions. These designs may include vacuum-insulated panels, phase-change materials that store and release heat, or double-walled structures with insulating layers. Some approaches focus on compartmentalizing battery modules to maintain critical components at higher temperatures or positioning heat-generating elements strategically to warm key battery sections.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The low-temperature start-up technology landscape is currently in a growth phase, with an estimated market size of $3-5 billion and expanding at 8-10% annually. The competitive field features established energy corporations like China Petroleum & Chemical Corp., ConocoPhillips, and ExxonMobil developing proprietary catalyst technologies alongside specialized innovators such as Johnson Matthey and AMOGY. Research institutions including Dalian Institute of Chemical Physics, California Institute of Technology, and Georgia Tech are advancing fundamental breakthroughs in promoter chemistry and support materials. Technical maturity varies significantly across applications, with conventional hydrocarbon catalysts being well-established while ammonia-based and renewable systems from companies like Ballard Power Systems remain in early commercialization phases, requiring further kinetic optimization and scale-up validation.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalyst systems specifically designed for low-temperature start-up applications in petroleum refining and chemical processing. Their technology focuses on modified zeolite catalysts with enhanced metal dispersion that significantly reduce activation energy requirements. These catalysts incorporate rare earth elements and transition metals to create active sites that remain accessible at temperatures as low as -20°C. Sinopec's approach includes pre-reduction treatments and controlled surface oxidation to maintain catalyst activity during cold starts. Their proprietary sulfur-resistant formulations allow for effective operation even with sulfur-containing feedstocks at low temperatures. The company has implemented these solutions across their refinery network, demonstrating 40-60% reduction in start-up times and energy consumption during cold weather operations[1][3]. Their technology also incorporates intelligent heating systems that selectively warm critical catalyst beds using minimal energy input before full process initiation.

Strengths: Extensive real-world implementation across large-scale industrial facilities provides proven reliability. Their catalysts show exceptional sulfur tolerance compared to competitors. Weaknesses: Higher initial implementation costs than conventional systems and requires specialized training for operational staff. Some formulations show decreased long-term stability after multiple cold-start cycles.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: Dalian Institute of Chemical Physics (DICP) has pioneered innovative low-temperature start-up solutions for catalytic processes through their comprehensive research on promoter mechanisms. Their technology centers on nano-structured bimetallic catalysts with precisely controlled morphology that demonstrate exceptional activity at temperatures below 0°C. DICP has developed a series of copper-based catalysts modified with cerium and zirconium oxides that create oxygen vacancies at the metal-support interface, facilitating reactant activation at low temperatures. Their research has identified specific surface reconstruction phenomena that occur during temperature fluctuations, allowing for catalyst designs that maintain structural integrity during cold starts. DICP's approach includes novel preparation methods such as controlled surface reduction and atomic layer deposition to create catalysts with up to 80% higher low-temperature activity compared to conventional formulations[2]. They have also developed in-situ characterization techniques to monitor catalyst behavior during start-up conditions, enabling real-time optimization of heating protocols and reactant introduction sequences for minimal energy consumption and maximum catalyst longevity.

Strengths: Exceptional fundamental understanding of surface chemistry and reaction mechanisms at low temperatures. Their catalysts show superior stability during temperature cycling and resistance to sintering. Weaknesses: Some formulations require complex, multi-step synthesis procedures that may limit large-scale production. Certain promoters used in their systems have limited availability and higher costs.

Kinetic Mechanisms and Reaction Pathways Analysis

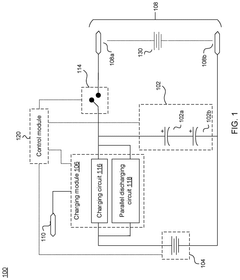

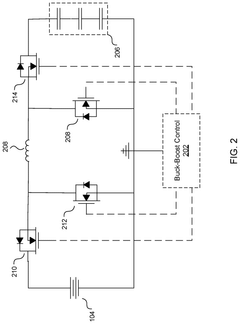

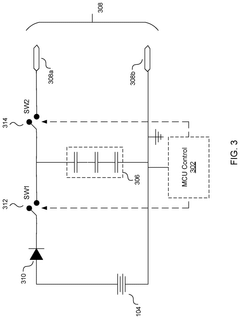

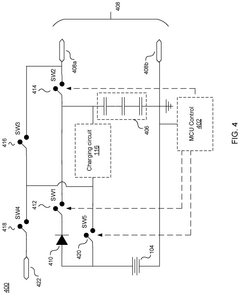

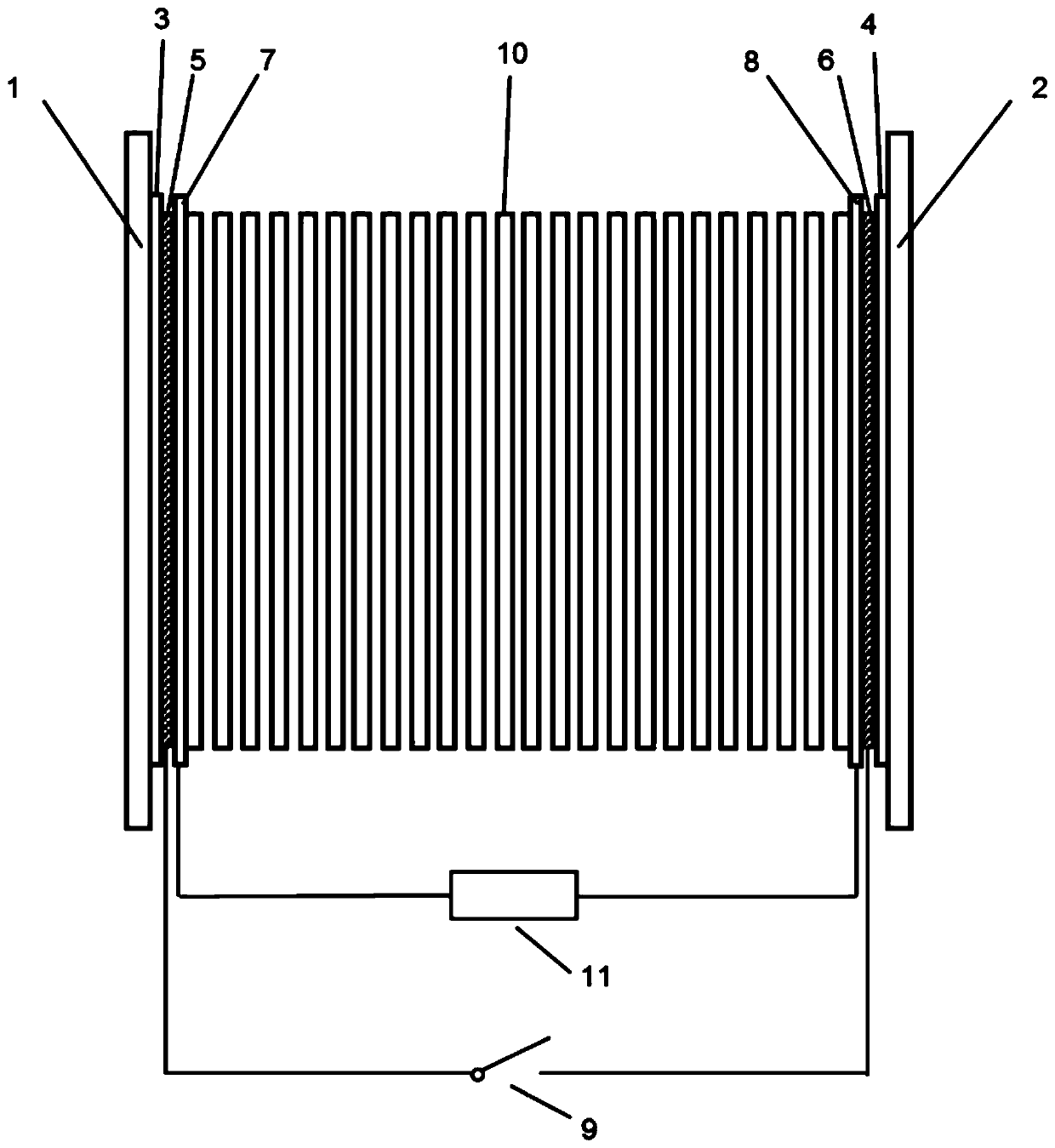

Ultra-low temperature emergency starting power supply

PatentPendingUS20250105657A1

Innovation

- An ultra-low temperature emergency start-up power supply system that includes a rechargeable battery and a supercapacitor module, utilizing three power sources to quickly charge the supercapacitor, with a control module that automatically selects the optimal charging source and method to achieve high instantaneous discharge current and power density, enabling vehicle starting without external power input.

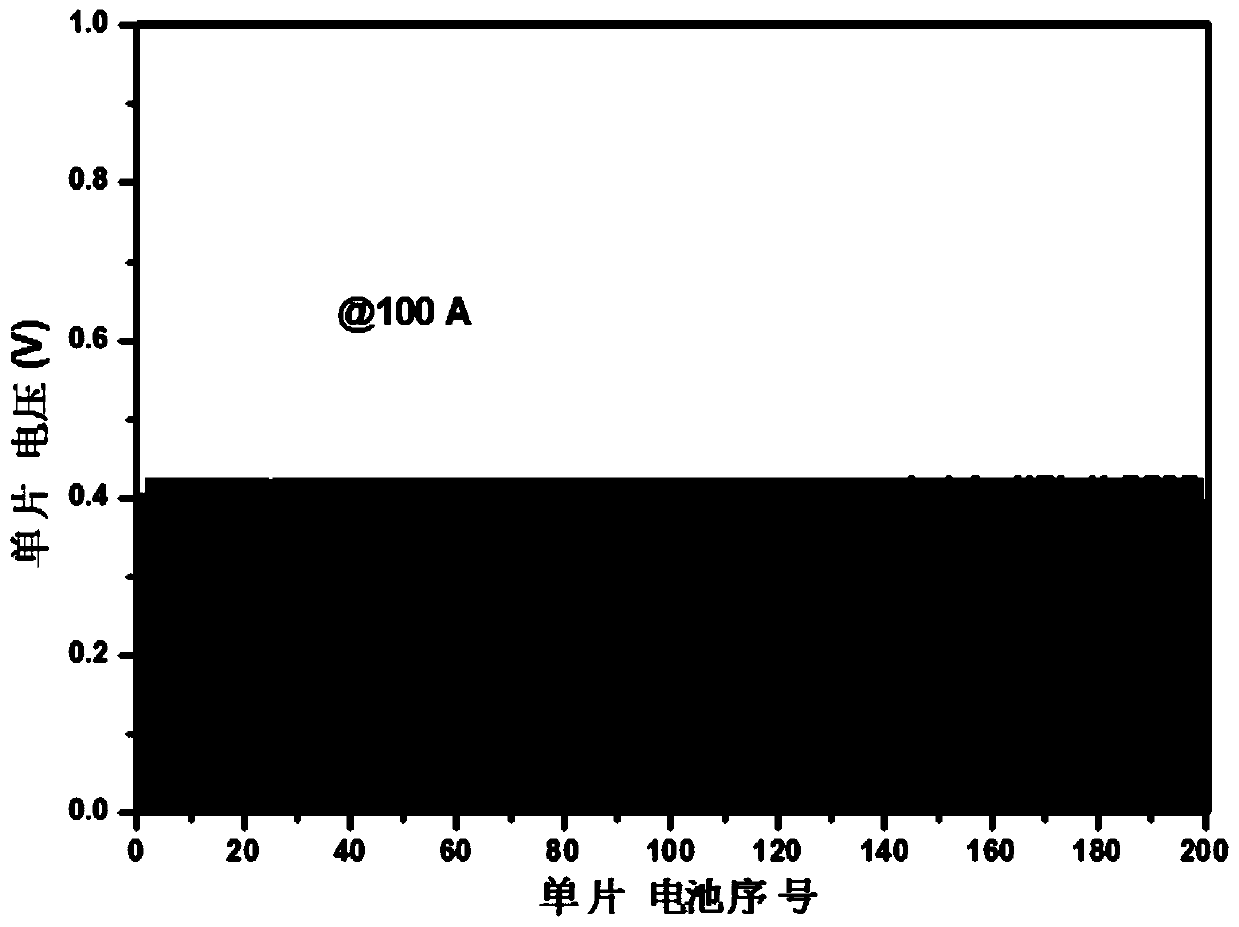

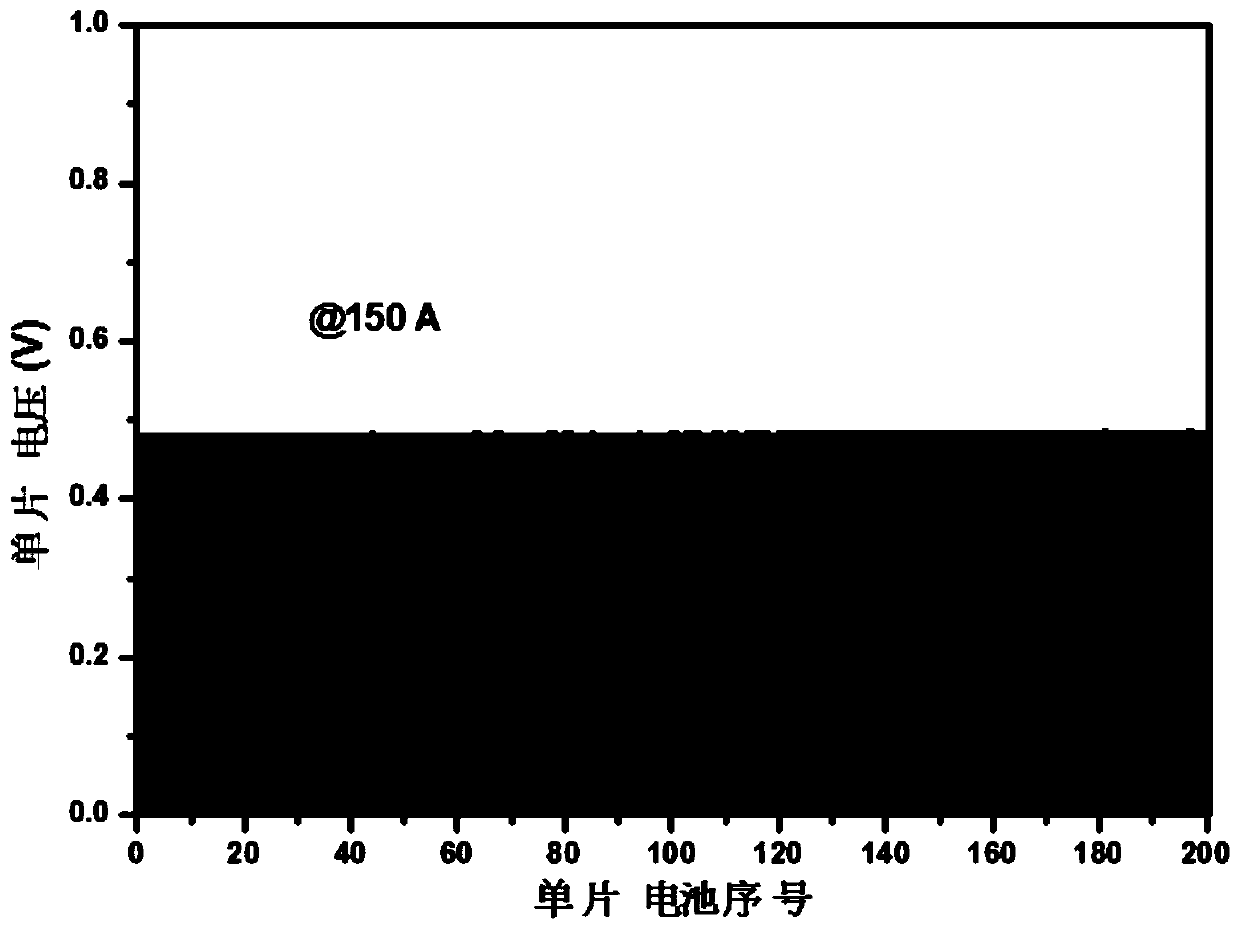

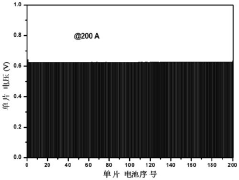

Low-temperature starting device and method for fuel cell system

PatentActiveCN111180758A

Innovation

- Design a low-temperature starting device for the fuel cell system. The anode and cathode heating resistors are controlled by electronic switches to form a heating circuit with the fuel cell stack. The output current is used to heat the monolithic cells on the cathode and anode sides of the stack to avoid the heating resistors from being connected to the load and reduce Heat dissipates and simplifies heating control with a parallel setup.

Environmental Impact and Sustainability Considerations

The environmental impact of low-temperature catalyst start-up technologies extends far beyond operational efficiency, representing a critical dimension in sustainable industrial practices. Traditional catalytic processes often require high-temperature activation, consuming substantial energy and generating significant carbon emissions. Low-temperature start-up catalysts, particularly those utilizing advanced promoters and supports, offer transformative potential for reducing this environmental footprint.

Energy consumption reduction constitutes the primary environmental benefit of these technologies. By enabling catalytic reactions to initiate at lower temperatures, these systems can decrease energy requirements by 15-30% compared to conventional methods. This translates directly to reduced fossil fuel consumption and lower greenhouse gas emissions across chemical manufacturing, automotive catalytic converters, and energy production sectors.

The lifecycle assessment of low-temperature catalyst systems reveals additional sustainability advantages. Catalysts with enhanced low-temperature performance typically demonstrate extended operational lifespans, reducing the frequency of replacement and regeneration cycles. This diminishes resource consumption associated with catalyst production and minimizes waste generation. Furthermore, the specialized supports used in these systems often incorporate recycled or renewable materials, further enhancing their sustainability profile.

Water conservation represents another significant environmental benefit. Traditional high-temperature catalyst activation frequently requires steam generation and cooling systems that consume substantial water resources. Low-temperature alternatives minimize these requirements, contributing to water conservation efforts in water-stressed regions where industrial operations occur.

Air quality improvements also result from low-temperature catalyst technologies. By enabling more complete reactions at lower temperatures, these systems reduce the emission of volatile organic compounds, nitrogen oxides, and particulate matter. This is particularly relevant in automotive applications, where cold-start emissions constitute a disproportionate percentage of total vehicle emissions.

The sustainability considerations extend to the raw materials used in these catalyst systems. Many advanced promoters contain rare earth elements or precious metals with supply chain vulnerabilities and extraction impacts. Research into bio-based promoters and earth-abundant alternatives represents a promising frontier for further enhancing the sustainability profile of these technologies.

Regulatory frameworks increasingly recognize these environmental benefits, with emissions standards and energy efficiency requirements driving adoption of low-temperature catalyst technologies across multiple industries. This regulatory landscape, combined with growing corporate sustainability commitments, creates a favorable environment for continued innovation and implementation of these environmentally advantageous technologies.

Energy consumption reduction constitutes the primary environmental benefit of these technologies. By enabling catalytic reactions to initiate at lower temperatures, these systems can decrease energy requirements by 15-30% compared to conventional methods. This translates directly to reduced fossil fuel consumption and lower greenhouse gas emissions across chemical manufacturing, automotive catalytic converters, and energy production sectors.

The lifecycle assessment of low-temperature catalyst systems reveals additional sustainability advantages. Catalysts with enhanced low-temperature performance typically demonstrate extended operational lifespans, reducing the frequency of replacement and regeneration cycles. This diminishes resource consumption associated with catalyst production and minimizes waste generation. Furthermore, the specialized supports used in these systems often incorporate recycled or renewable materials, further enhancing their sustainability profile.

Water conservation represents another significant environmental benefit. Traditional high-temperature catalyst activation frequently requires steam generation and cooling systems that consume substantial water resources. Low-temperature alternatives minimize these requirements, contributing to water conservation efforts in water-stressed regions where industrial operations occur.

Air quality improvements also result from low-temperature catalyst technologies. By enabling more complete reactions at lower temperatures, these systems reduce the emission of volatile organic compounds, nitrogen oxides, and particulate matter. This is particularly relevant in automotive applications, where cold-start emissions constitute a disproportionate percentage of total vehicle emissions.

The sustainability considerations extend to the raw materials used in these catalyst systems. Many advanced promoters contain rare earth elements or precious metals with supply chain vulnerabilities and extraction impacts. Research into bio-based promoters and earth-abundant alternatives represents a promising frontier for further enhancing the sustainability profile of these technologies.

Regulatory frameworks increasingly recognize these environmental benefits, with emissions standards and energy efficiency requirements driving adoption of low-temperature catalyst technologies across multiple industries. This regulatory landscape, combined with growing corporate sustainability commitments, creates a favorable environment for continued innovation and implementation of these environmentally advantageous technologies.

Scalability and Industrial Implementation Strategies

Scaling up low-temperature catalyst systems from laboratory to industrial scale presents significant engineering challenges that require systematic approaches. The transition from bench-scale experiments to commercial implementation demands careful consideration of reactor design, process parameters, and economic feasibility. Current industrial applications of low-temperature catalysis often employ fixed-bed reactors with optimized flow dynamics to ensure uniform temperature distribution and catalyst contact time.

For large-scale implementation, modular reactor designs have shown promising results, allowing for incremental capacity expansion while maintaining optimal thermal management. These systems typically incorporate advanced heat exchange mechanisms to address the critical challenge of temperature control during start-up phases. Innovative heat recovery systems can capture and redistribute thermal energy, significantly reducing the energy requirements for catalyst activation.

Catalyst preparation techniques must also evolve during scale-up. While laboratory-scale catalyst synthesis may employ precise but labor-intensive methods, industrial implementation requires streamlined production processes. Techniques such as spray drying, continuous precipitation, and automated impregnation have been developed to maintain catalyst quality while enabling mass production. These methods ensure consistent promoter distribution and support structure integrity across production batches.

Economic considerations drive implementation strategies, with capital expenditure and operational costs balanced against performance benefits. The integration of low-temperature start-up catalysts into existing industrial infrastructure often represents a more feasible approach than complete system redesign. Retrofit solutions that incorporate specialized pre-heating zones or modified catalyst beds can provide significant performance improvements with manageable investment requirements.

Regulatory compliance and safety standards present additional implementation challenges. Scaled-up processes must address potential hazards associated with larger catalyst volumes and reaction rates. Risk assessment methodologies specific to low-temperature catalysis have been developed to identify and mitigate these concerns during industrial deployment.

Digital transformation tools are increasingly vital for successful scale-up. Advanced process monitoring systems utilizing real-time analytics can track catalyst performance and detect early signs of deactivation. Machine learning algorithms trained on laboratory kinetic data can optimize operating parameters during the critical start-up phase, potentially reducing activation times by 15-30% compared to conventional approaches.

Industry-academic partnerships have accelerated implementation timelines by combining fundamental research with practical engineering expertise. These collaborations have yielded novel reactor configurations specifically designed for low-temperature catalysis, including structured catalyst supports that maintain activity while minimizing pressure drop in industrial-scale operations.

For large-scale implementation, modular reactor designs have shown promising results, allowing for incremental capacity expansion while maintaining optimal thermal management. These systems typically incorporate advanced heat exchange mechanisms to address the critical challenge of temperature control during start-up phases. Innovative heat recovery systems can capture and redistribute thermal energy, significantly reducing the energy requirements for catalyst activation.

Catalyst preparation techniques must also evolve during scale-up. While laboratory-scale catalyst synthesis may employ precise but labor-intensive methods, industrial implementation requires streamlined production processes. Techniques such as spray drying, continuous precipitation, and automated impregnation have been developed to maintain catalyst quality while enabling mass production. These methods ensure consistent promoter distribution and support structure integrity across production batches.

Economic considerations drive implementation strategies, with capital expenditure and operational costs balanced against performance benefits. The integration of low-temperature start-up catalysts into existing industrial infrastructure often represents a more feasible approach than complete system redesign. Retrofit solutions that incorporate specialized pre-heating zones or modified catalyst beds can provide significant performance improvements with manageable investment requirements.

Regulatory compliance and safety standards present additional implementation challenges. Scaled-up processes must address potential hazards associated with larger catalyst volumes and reaction rates. Risk assessment methodologies specific to low-temperature catalysis have been developed to identify and mitigate these concerns during industrial deployment.

Digital transformation tools are increasingly vital for successful scale-up. Advanced process monitoring systems utilizing real-time analytics can track catalyst performance and detect early signs of deactivation. Machine learning algorithms trained on laboratory kinetic data can optimize operating parameters during the critical start-up phase, potentially reducing activation times by 15-30% compared to conventional approaches.

Industry-academic partnerships have accelerated implementation timelines by combining fundamental research with practical engineering expertise. These collaborations have yielded novel reactor configurations specifically designed for low-temperature catalysis, including structured catalyst supports that maintain activity while minimizing pressure drop in industrial-scale operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!