Safety Cases and Standards for Onboard Ammonia Cracking Modules

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Cracking Technology Background and Objectives

Ammonia has emerged as a promising hydrogen carrier in the global transition toward decarbonized energy systems. The concept of ammonia cracking - the process of decomposing ammonia (NH3) into hydrogen (H2) and nitrogen (N2) - has evolved significantly since its initial development in the early 20th century. This technology has gained renewed attention in recent years as the maritime industry seeks viable pathways to reduce greenhouse gas emissions and meet increasingly stringent environmental regulations.

The evolution of ammonia cracking technology has been marked by several key developments. Initially utilized primarily in industrial applications for hydrogen production, the technology has undergone substantial refinement to address efficiency, catalyst performance, and reaction kinetics. Early systems operated at high temperatures (800-900°C) with relatively low conversion rates, whereas modern systems can achieve higher conversion efficiencies at lower temperatures through advanced catalyst formulations.

Onboard ammonia cracking represents a paradigm shift in maritime propulsion technology, enabling vessels to utilize ammonia as a fuel while leveraging existing hydrogen-compatible power systems such as fuel cells or hydrogen-modified internal combustion engines. This approach addresses the significant challenges associated with direct ammonia combustion, including NOx emissions, low flame speed, and narrow flammability limits.

The primary technical objectives for onboard ammonia cracking modules center on several critical parameters. First, achieving high conversion efficiency (>99%) at operational temperatures compatible with maritime applications is essential. Second, developing compact, vibration-resistant systems that can withstand the harsh marine environment presents a significant engineering challenge. Third, ensuring rapid response to load changes is crucial for maintaining propulsion reliability under varying operational conditions.

Safety considerations form the cornerstone of ammonia cracking technology development for maritime applications. The toxicity of ammonia, potential for hydrogen leakage, and thermal management of the highly endothermic cracking reaction all present unique safety challenges that must be addressed through robust engineering solutions and comprehensive safety protocols.

Current research trajectories focus on catalyst development to lower reaction temperatures, system integration to optimize heat recovery, and modular designs that facilitate maintenance while minimizing footprint. Additionally, efforts are underway to develop advanced sensors and control systems capable of monitoring reaction parameters and detecting potential safety issues before they escalate into hazardous situations.

The ultimate goal of this technology development is to establish ammonia cracking as a viable, safe, and efficient method for onboard hydrogen generation, thereby enabling the maritime industry to leverage ammonia's advantages as an energy carrier while mitigating its limitations as a direct fuel.

The evolution of ammonia cracking technology has been marked by several key developments. Initially utilized primarily in industrial applications for hydrogen production, the technology has undergone substantial refinement to address efficiency, catalyst performance, and reaction kinetics. Early systems operated at high temperatures (800-900°C) with relatively low conversion rates, whereas modern systems can achieve higher conversion efficiencies at lower temperatures through advanced catalyst formulations.

Onboard ammonia cracking represents a paradigm shift in maritime propulsion technology, enabling vessels to utilize ammonia as a fuel while leveraging existing hydrogen-compatible power systems such as fuel cells or hydrogen-modified internal combustion engines. This approach addresses the significant challenges associated with direct ammonia combustion, including NOx emissions, low flame speed, and narrow flammability limits.

The primary technical objectives for onboard ammonia cracking modules center on several critical parameters. First, achieving high conversion efficiency (>99%) at operational temperatures compatible with maritime applications is essential. Second, developing compact, vibration-resistant systems that can withstand the harsh marine environment presents a significant engineering challenge. Third, ensuring rapid response to load changes is crucial for maintaining propulsion reliability under varying operational conditions.

Safety considerations form the cornerstone of ammonia cracking technology development for maritime applications. The toxicity of ammonia, potential for hydrogen leakage, and thermal management of the highly endothermic cracking reaction all present unique safety challenges that must be addressed through robust engineering solutions and comprehensive safety protocols.

Current research trajectories focus on catalyst development to lower reaction temperatures, system integration to optimize heat recovery, and modular designs that facilitate maintenance while minimizing footprint. Additionally, efforts are underway to develop advanced sensors and control systems capable of monitoring reaction parameters and detecting potential safety issues before they escalate into hazardous situations.

The ultimate goal of this technology development is to establish ammonia cracking as a viable, safe, and efficient method for onboard hydrogen generation, thereby enabling the maritime industry to leverage ammonia's advantages as an energy carrier while mitigating its limitations as a direct fuel.

Market Analysis for Onboard Ammonia Cracking Systems

The global market for onboard ammonia cracking systems is experiencing significant growth driven by the maritime industry's urgent need to reduce carbon emissions. Current market size estimates indicate a valuation of approximately 450 million USD in 2023, with projections suggesting a compound annual growth rate of 28% through 2030. This rapid expansion is primarily fueled by increasingly stringent international maritime emission regulations, particularly the International Maritime Organization's target to reduce greenhouse gas emissions by at least 50% by 2050 compared to 2008 levels.

Maritime transportation represents the largest market segment for onboard ammonia cracking technology, accounting for roughly 65% of current demand. The commercial shipping sector, particularly container vessels and bulk carriers, demonstrates the highest adoption potential due to their long-range operational requirements and significant fuel consumption. Cruise ships represent another promising segment due to their high visibility and commitment to environmental sustainability as part of their brand positioning.

Regional market analysis reveals that Europe currently leads adoption with approximately 40% market share, driven by aggressive emission reduction policies and substantial government support for green shipping initiatives. Asia-Pacific follows closely at 35%, with Japan and South Korea emerging as technology development hubs due to their strong shipbuilding industries. North America accounts for about 20% of the market, with growth accelerating as regulatory frameworks evolve.

Customer segmentation shows three primary buyer categories: shipbuilding companies integrating systems into new vessel designs, retrofit solution providers targeting existing fleets, and shipping operators directly investing in emission reduction technologies. The retrofit market segment is particularly promising, representing a substantial opportunity as over 50,000 commercial vessels currently in operation will require emission reduction solutions to remain compliant with evolving regulations.

Key market drivers include regulatory pressure, fuel cost volatility, corporate sustainability commitments, and increasing pressure from cargo owners demanding greener transportation options. The total addressable market is expanding as technology costs decrease, with early adopters primarily consisting of large shipping conglomerates with substantial research and development budgets.

Market barriers include high initial capital expenditure requirements, technical integration challenges with existing vessel systems, and concerns regarding ammonia safety. Additionally, the lack of standardized safety protocols specifically addressing onboard ammonia cracking represents a significant market constraint that requires urgent attention from industry stakeholders and regulatory bodies to facilitate broader market penetration.

Maritime transportation represents the largest market segment for onboard ammonia cracking technology, accounting for roughly 65% of current demand. The commercial shipping sector, particularly container vessels and bulk carriers, demonstrates the highest adoption potential due to their long-range operational requirements and significant fuel consumption. Cruise ships represent another promising segment due to their high visibility and commitment to environmental sustainability as part of their brand positioning.

Regional market analysis reveals that Europe currently leads adoption with approximately 40% market share, driven by aggressive emission reduction policies and substantial government support for green shipping initiatives. Asia-Pacific follows closely at 35%, with Japan and South Korea emerging as technology development hubs due to their strong shipbuilding industries. North America accounts for about 20% of the market, with growth accelerating as regulatory frameworks evolve.

Customer segmentation shows three primary buyer categories: shipbuilding companies integrating systems into new vessel designs, retrofit solution providers targeting existing fleets, and shipping operators directly investing in emission reduction technologies. The retrofit market segment is particularly promising, representing a substantial opportunity as over 50,000 commercial vessels currently in operation will require emission reduction solutions to remain compliant with evolving regulations.

Key market drivers include regulatory pressure, fuel cost volatility, corporate sustainability commitments, and increasing pressure from cargo owners demanding greener transportation options. The total addressable market is expanding as technology costs decrease, with early adopters primarily consisting of large shipping conglomerates with substantial research and development budgets.

Market barriers include high initial capital expenditure requirements, technical integration challenges with existing vessel systems, and concerns regarding ammonia safety. Additionally, the lack of standardized safety protocols specifically addressing onboard ammonia cracking represents a significant market constraint that requires urgent attention from industry stakeholders and regulatory bodies to facilitate broader market penetration.

Technical Challenges and Safety Barriers

The implementation of onboard ammonia cracking modules faces significant technical challenges and safety barriers that must be addressed before widespread maritime adoption. The toxicity of ammonia presents a primary concern, as exposure to concentrations as low as 25-50 ppm can cause respiratory irritation, while higher concentrations above 300 ppm pose immediate danger to life. Any leakage in confined shipboard spaces could rapidly create hazardous conditions for crew members, necessitating robust detection systems and emergency protocols.

The high operating temperatures required for efficient ammonia cracking (typically 650-900°C) introduce substantial thermal management challenges. These extreme temperatures create material stress and potential failure points, particularly at connection interfaces and sealing components. Additionally, the thermal cycling during system startup and shutdown accelerates material fatigue, requiring specialized high-temperature alloys and advanced thermal insulation systems that can withstand maritime conditions.

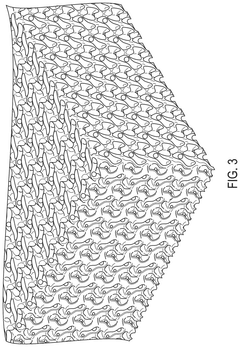

Catalyst degradation represents another significant technical barrier. Current catalysts, primarily based on nickel or ruthenium, suffer performance losses due to sulfur poisoning, carbon deposition, and sintering under prolonged operation. This degradation not only reduces hydrogen yield but may also increase the risk of ammonia slip—unconverted ammonia passing through the system—which presents both safety and environmental concerns.

The hydrogen produced during cracking introduces additional safety considerations. As a highly flammable gas with wide explosive limits (4-75% in air) and low ignition energy, hydrogen requires specialized containment systems. The potential for hydrogen embrittlement of metallic components further complicates material selection and system design, particularly in the high-pressure sections of the fuel system.

Vibration and motion in maritime environments pose unique challenges not present in stationary applications. The constant movement and occasional severe conditions can stress mechanical connections, accelerate component wear, and potentially create leak points. System designs must incorporate flexible connections and vibration dampening while maintaining absolute gas-tightness.

Regulatory frameworks present a significant non-technical barrier, as current maritime safety standards were not developed with ammonia fuel systems in mind. The International Maritime Organization (IMO) and classification societies are still developing comprehensive guidelines for ammonia as a marine fuel. This regulatory uncertainty complicates design decisions and certification processes, potentially delaying implementation timelines and increasing development costs.

Integration with existing ship systems presents additional challenges, particularly regarding space constraints, weight distribution, and compatibility with electrical and control systems. The additional safety equipment required—including gas detection, ventilation, and emergency shutdown systems—further increases system complexity and spatial requirements.

The high operating temperatures required for efficient ammonia cracking (typically 650-900°C) introduce substantial thermal management challenges. These extreme temperatures create material stress and potential failure points, particularly at connection interfaces and sealing components. Additionally, the thermal cycling during system startup and shutdown accelerates material fatigue, requiring specialized high-temperature alloys and advanced thermal insulation systems that can withstand maritime conditions.

Catalyst degradation represents another significant technical barrier. Current catalysts, primarily based on nickel or ruthenium, suffer performance losses due to sulfur poisoning, carbon deposition, and sintering under prolonged operation. This degradation not only reduces hydrogen yield but may also increase the risk of ammonia slip—unconverted ammonia passing through the system—which presents both safety and environmental concerns.

The hydrogen produced during cracking introduces additional safety considerations. As a highly flammable gas with wide explosive limits (4-75% in air) and low ignition energy, hydrogen requires specialized containment systems. The potential for hydrogen embrittlement of metallic components further complicates material selection and system design, particularly in the high-pressure sections of the fuel system.

Vibration and motion in maritime environments pose unique challenges not present in stationary applications. The constant movement and occasional severe conditions can stress mechanical connections, accelerate component wear, and potentially create leak points. System designs must incorporate flexible connections and vibration dampening while maintaining absolute gas-tightness.

Regulatory frameworks present a significant non-technical barrier, as current maritime safety standards were not developed with ammonia fuel systems in mind. The International Maritime Organization (IMO) and classification societies are still developing comprehensive guidelines for ammonia as a marine fuel. This regulatory uncertainty complicates design decisions and certification processes, potentially delaying implementation timelines and increasing development costs.

Integration with existing ship systems presents additional challenges, particularly regarding space constraints, weight distribution, and compatibility with electrical and control systems. The additional safety equipment required—including gas detection, ventilation, and emergency shutdown systems—further increases system complexity and spatial requirements.

Current Safety Solutions and Standards

01 Safety systems for ammonia cracking modules

Safety systems are essential components in ammonia cracking modules to prevent accidents and ensure operational safety. These systems include emergency shutdown mechanisms, pressure relief devices, gas detection systems, and containment measures. Advanced monitoring systems continuously track operating parameters such as temperature, pressure, and gas concentrations to detect abnormal conditions and trigger appropriate safety responses before hazardous situations develop.- Safety systems for ammonia cracking modules: Ammonia cracking modules require robust safety systems to prevent hazardous situations. These systems include gas detection sensors, emergency shutdown mechanisms, pressure relief devices, and containment systems. Advanced monitoring systems continuously track operating parameters such as temperature, pressure, and gas concentrations to detect anomalies before they become dangerous. Implementing these safety systems helps minimize risks associated with ammonia handling and hydrogen production.

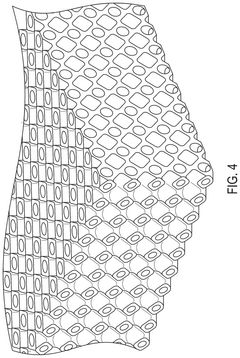

- Temperature and pressure control in ammonia cracking processes: Maintaining optimal temperature and pressure conditions is critical for safe operation of ammonia cracking modules. The process typically operates at high temperatures (400-900°C) and requires precise control systems to prevent thermal runaway scenarios. Pressure management systems including relief valves, rupture discs, and automated pressure control loops help prevent equipment failure. Thermal insulation and cooling systems are implemented to manage heat distribution and prevent hotspots that could compromise structural integrity.

- Material selection and corrosion prevention for ammonia crackers: The selection of appropriate materials is essential for safe ammonia cracking operations. Materials must withstand high temperatures, pressure fluctuations, and the corrosive nature of ammonia and its byproducts. Specialized alloys containing nickel, chromium, and molybdenum are commonly used for reactor vessels and piping. Protective coatings and linings help extend equipment life and prevent stress corrosion cracking. Regular inspection protocols are implemented to detect material degradation before failure occurs.

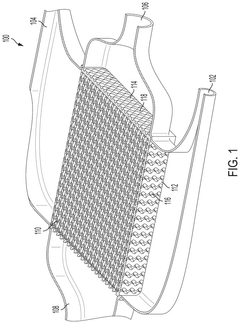

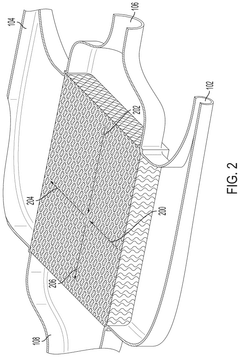

- Modular design and containment strategies: Modern ammonia cracking modules employ modular designs with integrated safety features. These include secondary containment systems to capture potential leaks, physical separation of critical components, and blast-resistant structures. The modular approach allows for easier maintenance, replacement of components, and isolation of hazardous areas. Some designs incorporate double-walled construction and interstitial monitoring to detect leaks before they become dangerous. This approach minimizes the impact of potential failures and contains hazardous materials.

- Automated control systems and emergency response protocols: Advanced control systems play a crucial role in maintaining safe operation of ammonia cracking modules. These systems include programmable logic controllers, distributed control systems, and safety instrumented systems that can automatically respond to abnormal conditions. Emergency response protocols include automated shutdown sequences, purging systems, and firefighting equipment specifically designed for ammonia-related incidents. Operator training programs and detailed emergency response plans are essential components of the overall safety strategy.

02 Thermal management and heat control safety

Effective thermal management is crucial for the safe operation of ammonia cracking modules. The cracking process involves high temperatures that must be carefully controlled to prevent overheating, thermal runaway, and potential structural failures. Safety features include temperature monitoring systems, cooling mechanisms, thermal insulation, and heat distribution technologies that maintain optimal operating temperatures while preventing hotspots that could compromise module integrity.Expand Specific Solutions03 Hydrogen handling safety protocols

Since ammonia cracking produces hydrogen, specialized safety protocols are implemented to manage this highly flammable gas. These include hydrogen-specific leak detection systems, specialized materials resistant to hydrogen embrittlement, proper ventilation systems, and flame arrestors. Safety measures also address the prevention of explosive hydrogen-air mixtures through purging procedures, controlled release mechanisms, and proper storage solutions designed to handle hydrogen's unique properties.Expand Specific Solutions04 Modular design and containment safety features

Modern ammonia cracking modules incorporate safety through modular design principles that isolate critical components and contain potential failures. Double-walled containment structures, blast-resistant enclosures, and strategic component placement minimize risk propagation. These designs include segregated control systems, redundant safety features, and quick-disconnect capabilities that allow for rapid isolation of compromised sections while maintaining overall system integrity during emergency situations.Expand Specific Solutions05 Monitoring and control systems for operational safety

Advanced monitoring and control systems are implemented to ensure the safe operation of ammonia cracking modules. These include real-time process monitoring, automated control systems with safety interlocks, predictive maintenance capabilities, and remote monitoring options. Sophisticated sensors track critical parameters while integrated control systems can automatically adjust operating conditions or initiate shutdown procedures when safety thresholds are approached, providing multiple layers of protection against potential hazards.Expand Specific Solutions

Key Industry Players and Stakeholders

The ammonia cracking module safety standards market is in an early growth phase, characterized by increasing demand driven by maritime decarbonization initiatives. The market size is expanding as shipping companies seek alternative fuels, with projected significant growth as ammonia gains traction as a marine fuel. Technologically, the field remains developing with varying maturity levels across players. Leading shipbuilders like Jiangnan Shipyard and Dalian Shipbuilding are advancing vessel integration capabilities, while chemical specialists such as Air Products & Chemicals and ExxonMobil Technology & Engineering focus on cracking process optimization. Maritime operators like NYK Line are contributing operational safety perspectives, with academic institutions including Shanghai Jiao Tong University and Dalian Maritime University providing research foundations for emerging safety protocols and standards development.

Dalian Shipbuilding Industry Co., Ltd.

Technical Solution: Dalian Shipbuilding has pioneered an integrated ammonia cracking module specifically designed for newbuild vessel integration. Their system features a dual-containment design where the ammonia cracking unit is housed within a gas-tight compartment with dedicated ventilation and fire suppression systems. The company has developed specialized high-temperature alloys for reactor vessels that resist ammonia-induced stress corrosion cracking while maintaining structural integrity at operating temperatures exceeding 850°C. Their approach incorporates continuous monitoring systems with distributed sensors for temperature, pressure, and ammonia concentration throughout the module. Dalian's design includes automated emergency shutdown protocols that interface directly with the vessel's safety management systems. The company has worked closely with classification societies to develop and implement safety standards specifically for ammonia fuel systems, including risk assessment methodologies for HAZOP and HAZID analyses tailored to ammonia cracking operations in marine environments.

Strengths: Deep integration with shipbuilding processes allowing for optimized vessel design around ammonia systems; extensive experience with marine regulatory compliance; strong relationships with classification societies. Weaknesses: Limited experience with the long-term operation of ammonia cracking technology; solutions primarily focused on newbuilds rather than retrofits; higher implementation costs compared to conventional propulsion systems.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed advanced ammonia cracking technology specifically designed for maritime applications. Their system utilizes structured catalysts with enhanced thermal stability that can withstand the harsh marine environment while maintaining high conversion efficiency. The company's onboard ammonia cracking modules feature a proprietary heat integration system that recovers thermal energy from the cracking process to improve overall efficiency. Their design incorporates multiple redundant safety systems including automated pressure relief, emergency shutdown capabilities, and advanced leak detection using infrared and electrochemical sensors. Air Products has also developed specialized materials for ammonia-resistant piping and components that minimize the risk of stress corrosion cracking. Their modular design allows for scalability across different vessel sizes while maintaining compliance with IMO regulations and classification society requirements for hazardous materials handling onboard ships.

Strengths: Industry-leading catalyst technology with proven durability in marine environments; comprehensive safety systems integration; extensive experience with industrial gas handling. Weaknesses: Higher initial capital costs compared to conventional systems; requires specialized maintenance protocols; system footprint may be challenging for retrofit applications on smaller vessels.

Critical Patents and Technical Literature Review

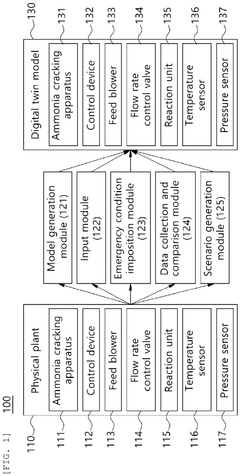

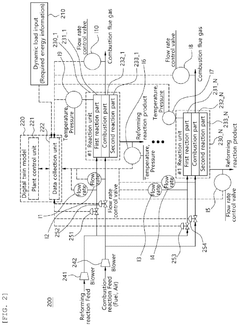

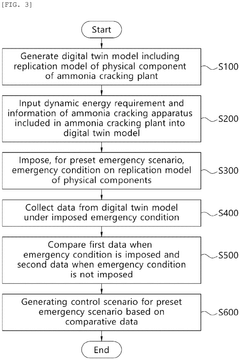

System and method for managing ammonia cracking plant, and computer-readable medium

PatentPendingEP4530778A1

Innovation

- A system and method utilizing a digital twin model to simulate and analyze emergency scenarios, incorporating real-time data to predict adjustments, identify vulnerabilities, and generate control scenarios for stable operation.

Systems and methods for engine-mounted catalytic production of hydrogen from ammonia for use as a combustion fuel

PatentActiveUS12162754B2

Innovation

- A system comprising an internal combustion engine, heat exchange catalyst units, electric catalyst units, and plate heat exchange units that work in series to crack ammonia into hydrogen, utilizing exhaust gas heat and electrical heating to facilitate ammonia cracking, and manage hydrogen storage and fueling efficiently.

Regulatory Framework and Compliance Requirements

The regulatory landscape for onboard ammonia cracking modules is complex and evolving, with significant variations across different jurisdictions and maritime authorities. Currently, the International Maritime Organization (IMO) has not established comprehensive standards specifically for ammonia cracking technology on vessels, creating a regulatory gap that stakeholders must navigate carefully. The IMO's International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) provides some applicable guidelines, though these were not designed with ammonia as a fuel in mind.

Classification societies such as DNV GL, Lloyd's Register, and American Bureau of Shipping have begun developing interim guidelines and notations for ammonia-fueled vessels, which partially address cracking modules. These guidelines typically incorporate risk assessment methodologies like HAZID (Hazard Identification) and HAZOP (Hazard and Operability Study) as mandatory components of the approval process for novel technologies.

National maritime authorities have varying approaches to regulating ammonia systems on vessels. The European Union's Alternative Fuels Infrastructure Directive (AFID) and the United States Coast Guard's regulations on alternative fuels provide frameworks that can be adapted to ammonia cracking systems, though specific provisions are still under development.

Compliance requirements generally focus on several key areas: material compatibility standards to prevent ammonia-induced stress corrosion cracking; leak detection and monitoring systems with specific sensitivity thresholds; ventilation requirements for enclosed spaces containing ammonia equipment; and emergency shutdown procedures tailored to ammonia's hazard profile.

Risk-based approval processes are becoming the norm for novel marine technologies like ammonia cracking modules. These typically require quantitative risk assessments demonstrating that risks have been reduced to As Low As Reasonably Practicable (ALARP) levels, with particular emphasis on preventing ammonia release scenarios.

Safety management systems must incorporate ammonia-specific elements, including crew training requirements, maintenance protocols, and emergency response procedures. Documentation requirements are substantial, typically including detailed technical specifications, risk assessments, operational manuals, and maintenance procedures.

The regulatory framework is expected to evolve significantly over the next 3-5 years as experience with ammonia as a marine fuel grows. Industry stakeholders should anticipate more prescriptive standards emerging as the technology matures, potentially including standardized design requirements for cracking modules and their integration with vessel systems.

Classification societies such as DNV GL, Lloyd's Register, and American Bureau of Shipping have begun developing interim guidelines and notations for ammonia-fueled vessels, which partially address cracking modules. These guidelines typically incorporate risk assessment methodologies like HAZID (Hazard Identification) and HAZOP (Hazard and Operability Study) as mandatory components of the approval process for novel technologies.

National maritime authorities have varying approaches to regulating ammonia systems on vessels. The European Union's Alternative Fuels Infrastructure Directive (AFID) and the United States Coast Guard's regulations on alternative fuels provide frameworks that can be adapted to ammonia cracking systems, though specific provisions are still under development.

Compliance requirements generally focus on several key areas: material compatibility standards to prevent ammonia-induced stress corrosion cracking; leak detection and monitoring systems with specific sensitivity thresholds; ventilation requirements for enclosed spaces containing ammonia equipment; and emergency shutdown procedures tailored to ammonia's hazard profile.

Risk-based approval processes are becoming the norm for novel marine technologies like ammonia cracking modules. These typically require quantitative risk assessments demonstrating that risks have been reduced to As Low As Reasonably Practicable (ALARP) levels, with particular emphasis on preventing ammonia release scenarios.

Safety management systems must incorporate ammonia-specific elements, including crew training requirements, maintenance protocols, and emergency response procedures. Documentation requirements are substantial, typically including detailed technical specifications, risk assessments, operational manuals, and maintenance procedures.

The regulatory framework is expected to evolve significantly over the next 3-5 years as experience with ammonia as a marine fuel grows. Industry stakeholders should anticipate more prescriptive standards emerging as the technology matures, potentially including standardized design requirements for cracking modules and their integration with vessel systems.

Risk Assessment Methodologies for Ammonia Systems

Risk assessment for ammonia systems requires specialized methodologies due to ammonia's unique properties as both a toxic substance and potential fuel. Traditional risk assessment frameworks like HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and QRA (Quantitative Risk Assessment) must be adapted to address the specific challenges of ammonia cracking modules in marine environments.

The HAZOP methodology, when applied to ammonia systems, focuses on identifying deviations from design intent that could lead to hazardous releases. For onboard ammonia cracking modules, this includes examining parameters such as temperature, pressure, flow rate, and catalyst activity, with particular attention to potential failure modes that could result in ammonia leakage or hydrogen release.

FMEA approaches for ammonia systems prioritize component-level analysis, evaluating failure probabilities and consequences for critical equipment such as heat exchangers, catalytic reactors, and containment systems. Maritime applications require additional consideration of vibration, corrosion from saltwater exposure, and ship motion effects on system integrity.

Quantitative Risk Assessment methodologies incorporate event tree and fault tree analyses to model complex accident scenarios. For ammonia cracking modules, these must account for the probability of ammonia release, potential ignition sources, dispersion patterns in confined shipboard spaces, and exposure risks to crew members. Consequence modeling typically includes toxic dispersion calculations using specialized software that accounts for the unique behavior of ammonia in marine atmospheres.

Bow-tie analysis has emerged as a particularly valuable tool for ammonia systems, providing visual representation of preventive and mitigative barriers. This approach helps identify critical safety functions and evaluate the independence and effectiveness of multiple protection layers required by maritime safety standards.

Dynamic risk assessment methodologies are increasingly important for ammonia cracking modules, as they can account for changing operational conditions during voyages. These approaches incorporate real-time monitoring data to continuously update risk profiles and trigger appropriate safety responses when risk thresholds are approached.

Industry-specific guidelines from organizations such as the American Bureau of Shipping (ABS) and DNV GL provide tailored risk assessment frameworks for ammonia as a marine fuel, emphasizing the need for comprehensive safety case development that demonstrates risks have been reduced to As Low As Reasonably Practicable (ALARP) levels before deployment on vessels.

The HAZOP methodology, when applied to ammonia systems, focuses on identifying deviations from design intent that could lead to hazardous releases. For onboard ammonia cracking modules, this includes examining parameters such as temperature, pressure, flow rate, and catalyst activity, with particular attention to potential failure modes that could result in ammonia leakage or hydrogen release.

FMEA approaches for ammonia systems prioritize component-level analysis, evaluating failure probabilities and consequences for critical equipment such as heat exchangers, catalytic reactors, and containment systems. Maritime applications require additional consideration of vibration, corrosion from saltwater exposure, and ship motion effects on system integrity.

Quantitative Risk Assessment methodologies incorporate event tree and fault tree analyses to model complex accident scenarios. For ammonia cracking modules, these must account for the probability of ammonia release, potential ignition sources, dispersion patterns in confined shipboard spaces, and exposure risks to crew members. Consequence modeling typically includes toxic dispersion calculations using specialized software that accounts for the unique behavior of ammonia in marine atmospheres.

Bow-tie analysis has emerged as a particularly valuable tool for ammonia systems, providing visual representation of preventive and mitigative barriers. This approach helps identify critical safety functions and evaluate the independence and effectiveness of multiple protection layers required by maritime safety standards.

Dynamic risk assessment methodologies are increasingly important for ammonia cracking modules, as they can account for changing operational conditions during voyages. These approaches incorporate real-time monitoring data to continuously update risk profiles and trigger appropriate safety responses when risk thresholds are approached.

Industry-specific guidelines from organizations such as the American Bureau of Shipping (ABS) and DNV GL provide tailored risk assessment frameworks for ammonia as a marine fuel, emphasizing the need for comprehensive safety case development that demonstrates risks have been reduced to As Low As Reasonably Practicable (ALARP) levels before deployment on vessels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!