Environmental Impact Assessment for Ammonia Cracking Deployments

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Cracking Technology Background and Objectives

Ammonia cracking technology has emerged as a promising pathway for clean hydrogen production, evolving significantly over the past decades. Initially developed in the early 20th century for industrial applications, ammonia cracking has recently gained renewed attention as a potential enabler for the hydrogen economy. The fundamental process involves the decomposition of ammonia (NH3) into nitrogen and hydrogen through catalytic reactions, typically at elevated temperatures between 400-900°C, depending on the catalyst system employed.

The evolution of this technology has been marked by several key developments, particularly in catalyst design. Early systems relied on nickel-based catalysts, while modern approaches incorporate ruthenium, iron, and other transition metals to improve efficiency and reduce energy requirements. Recent breakthroughs in nano-structured catalysts have shown promise in lowering the activation energy needed for the cracking process, potentially enabling lower temperature operation.

The primary technical objective for ammonia cracking deployments is to establish environmentally sustainable hydrogen production pathways that can support decarbonization efforts across multiple sectors. This includes developing systems with minimal carbon footprint throughout their lifecycle, from ammonia production to hydrogen utilization. Secondary objectives focus on improving energy efficiency, reducing catalyst costs, and enhancing system durability under various operating conditions.

Current research trends indicate a growing interest in integrating ammonia cracking with renewable energy sources to create truly carbon-neutral hydrogen production systems. This includes coupling with solar thermal energy for heat provision and utilizing green ammonia produced via renewable electricity. Additionally, there is significant momentum toward developing modular, scalable cracking systems that can be deployed in distributed energy networks.

The environmental implications of ammonia cracking technology are substantial, as it offers a potential alternative to fossil fuel-based hydrogen production methods that currently dominate the market. When paired with green ammonia production, this technology pathway could reduce greenhouse gas emissions by 60-90% compared to conventional hydrogen production methods, according to recent lifecycle assessments.

Looking forward, the technology trajectory suggests continued improvements in catalyst performance, system integration, and energy efficiency. The field is moving toward lower temperature operation, which would significantly reduce the energy intensity of the process while maintaining acceptable hydrogen production rates. These advancements are critical to achieving the long-term goal of establishing ammonia as a viable hydrogen carrier in a sustainable energy ecosystem.

The evolution of this technology has been marked by several key developments, particularly in catalyst design. Early systems relied on nickel-based catalysts, while modern approaches incorporate ruthenium, iron, and other transition metals to improve efficiency and reduce energy requirements. Recent breakthroughs in nano-structured catalysts have shown promise in lowering the activation energy needed for the cracking process, potentially enabling lower temperature operation.

The primary technical objective for ammonia cracking deployments is to establish environmentally sustainable hydrogen production pathways that can support decarbonization efforts across multiple sectors. This includes developing systems with minimal carbon footprint throughout their lifecycle, from ammonia production to hydrogen utilization. Secondary objectives focus on improving energy efficiency, reducing catalyst costs, and enhancing system durability under various operating conditions.

Current research trends indicate a growing interest in integrating ammonia cracking with renewable energy sources to create truly carbon-neutral hydrogen production systems. This includes coupling with solar thermal energy for heat provision and utilizing green ammonia produced via renewable electricity. Additionally, there is significant momentum toward developing modular, scalable cracking systems that can be deployed in distributed energy networks.

The environmental implications of ammonia cracking technology are substantial, as it offers a potential alternative to fossil fuel-based hydrogen production methods that currently dominate the market. When paired with green ammonia production, this technology pathway could reduce greenhouse gas emissions by 60-90% compared to conventional hydrogen production methods, according to recent lifecycle assessments.

Looking forward, the technology trajectory suggests continued improvements in catalyst performance, system integration, and energy efficiency. The field is moving toward lower temperature operation, which would significantly reduce the energy intensity of the process while maintaining acceptable hydrogen production rates. These advancements are critical to achieving the long-term goal of establishing ammonia as a viable hydrogen carrier in a sustainable energy ecosystem.

Market Demand Analysis for Hydrogen via Ammonia Cracking

The global hydrogen market is experiencing significant growth, with demand projected to reach 94 million tons by 2030, increasing from approximately 70 million tons in 2020. This growth trajectory is primarily driven by the urgent need for decarbonization across various industries, particularly in hard-to-abate sectors such as heavy transportation, steel production, and chemical manufacturing. Hydrogen derived from ammonia cracking represents a promising pathway to meet this escalating demand while addressing the challenges of hydrogen storage and transportation.

Ammonia (NH3) has emerged as an efficient hydrogen carrier due to its relatively high hydrogen content (17.6% by weight) and established global infrastructure for production, storage, and transportation. The market for hydrogen via ammonia cracking is expected to grow at a compound annual growth rate of 7.5% through 2030, with particularly strong demand in regions lacking robust hydrogen pipeline networks.

Industrial applications currently dominate the demand landscape, accounting for approximately 65% of potential hydrogen consumption from ammonia cracking. These applications include refineries, methanol production, and steel manufacturing, where hydrogen is used as a feedstock or reducing agent. The steel industry alone represents a substantial growth segment, as green hydrogen adoption could reduce carbon emissions by up to 95% compared to traditional blast furnace methods.

The transportation sector presents another significant market opportunity, particularly in maritime shipping where ammonia is being considered both as a direct fuel and as a hydrogen carrier for fuel cell applications. Major shipping companies have announced plans to deploy ammonia-powered vessels by 2025, creating additional demand for efficient ammonia cracking technologies at ports and maritime hubs.

Geographically, East Asia (particularly Japan and South Korea) leads in market readiness for hydrogen via ammonia cracking, having established national hydrogen strategies that specifically identify ammonia as a key vector. The European market is rapidly developing, driven by ambitious decarbonization targets and substantial investment in hydrogen infrastructure through initiatives like the European Clean Hydrogen Alliance.

Cost considerations remain critical to market adoption. Current hydrogen production via ammonia cracking costs between $4-6 per kilogram, compared to $1-3 for conventional gray hydrogen. However, this gap is expected to narrow significantly by 2030 as carbon pricing mechanisms mature and economies of scale are realized in green ammonia production and cracking technologies.

Energy security concerns following recent geopolitical developments have accelerated interest in ammonia as a hydrogen carrier, with several countries viewing it as a strategic pathway to reduce dependence on fossil fuel imports while advancing climate goals. This has translated into increased government support through subsidies, tax incentives, and research funding, further stimulating market growth potential.

Ammonia (NH3) has emerged as an efficient hydrogen carrier due to its relatively high hydrogen content (17.6% by weight) and established global infrastructure for production, storage, and transportation. The market for hydrogen via ammonia cracking is expected to grow at a compound annual growth rate of 7.5% through 2030, with particularly strong demand in regions lacking robust hydrogen pipeline networks.

Industrial applications currently dominate the demand landscape, accounting for approximately 65% of potential hydrogen consumption from ammonia cracking. These applications include refineries, methanol production, and steel manufacturing, where hydrogen is used as a feedstock or reducing agent. The steel industry alone represents a substantial growth segment, as green hydrogen adoption could reduce carbon emissions by up to 95% compared to traditional blast furnace methods.

The transportation sector presents another significant market opportunity, particularly in maritime shipping where ammonia is being considered both as a direct fuel and as a hydrogen carrier for fuel cell applications. Major shipping companies have announced plans to deploy ammonia-powered vessels by 2025, creating additional demand for efficient ammonia cracking technologies at ports and maritime hubs.

Geographically, East Asia (particularly Japan and South Korea) leads in market readiness for hydrogen via ammonia cracking, having established national hydrogen strategies that specifically identify ammonia as a key vector. The European market is rapidly developing, driven by ambitious decarbonization targets and substantial investment in hydrogen infrastructure through initiatives like the European Clean Hydrogen Alliance.

Cost considerations remain critical to market adoption. Current hydrogen production via ammonia cracking costs between $4-6 per kilogram, compared to $1-3 for conventional gray hydrogen. However, this gap is expected to narrow significantly by 2030 as carbon pricing mechanisms mature and economies of scale are realized in green ammonia production and cracking technologies.

Energy security concerns following recent geopolitical developments have accelerated interest in ammonia as a hydrogen carrier, with several countries viewing it as a strategic pathway to reduce dependence on fossil fuel imports while advancing climate goals. This has translated into increased government support through subsidies, tax incentives, and research funding, further stimulating market growth potential.

Current Technical Challenges in Ammonia Cracking Systems

Ammonia cracking systems face several significant technical challenges that currently limit their widespread deployment and efficiency. One of the primary obstacles is the high energy requirement for the endothermic ammonia decomposition reaction. The process typically requires temperatures between 400-900°C to achieve acceptable hydrogen yields, resulting in substantial energy consumption that impacts both operational costs and environmental footprint. This energy intensity presents a fundamental challenge to positioning ammonia cracking as a truly sustainable hydrogen carrier technology.

Catalyst performance remains another critical limitation. While ruthenium-based catalysts demonstrate superior activity, their high cost and limited availability restrict large-scale implementation. Alternative catalysts based on nickel, iron, or cobalt show promise but suffer from lower activity, requiring higher operating temperatures or larger reactor volumes to achieve comparable conversion rates. Additionally, catalyst deactivation through sintering, poisoning, or coking during extended operation periods necessitates frequent replacement or regeneration, further increasing operational complexity.

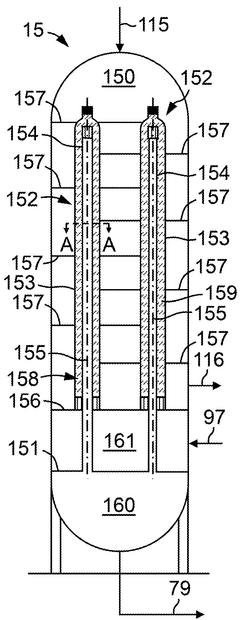

Heat management presents significant engineering challenges in ammonia cracking systems. The strongly endothermic reaction requires efficient heat transfer mechanisms to maintain optimal reaction temperatures throughout the catalyst bed. Current heat exchanger designs often struggle with thermal gradients that lead to uneven catalyst utilization and reduced overall system efficiency. The integration of heat recovery systems to capture and reuse thermal energy from the process stream remains technically challenging but essential for improving energy efficiency.

System control and response dynamics pose additional challenges, particularly for applications requiring variable hydrogen output. Ammonia cracking reactors typically exhibit slow thermal response times, making rapid adjustments to hydrogen production rates difficult. This limitation becomes particularly problematic in applications like transportation or grid balancing, where demand may fluctuate rapidly.

Material compatibility issues further complicate system design. The combination of high temperatures, hydrogen embrittlement risks, and potential ammonia slip requires specialized materials that can withstand these harsh conditions while maintaining structural integrity over extended operational periods. Current materials often represent compromises between performance, durability, and cost.

Ammonia slip—unreacted ammonia in the product stream—presents both technical and safety challenges. Even small concentrations of ammonia in hydrogen output can damage downstream equipment such as fuel cells or cause environmental concerns. Current purification technologies add complexity, cost, and energy penalties to the overall system.

Miniaturization and system integration remain significant hurdles for mobile or distributed applications. Developing compact, efficient cracking systems that can be safely operated in various environments requires innovative approaches to reactor design, thermal management, and system control that have not yet been fully realized in commercial systems.

Catalyst performance remains another critical limitation. While ruthenium-based catalysts demonstrate superior activity, their high cost and limited availability restrict large-scale implementation. Alternative catalysts based on nickel, iron, or cobalt show promise but suffer from lower activity, requiring higher operating temperatures or larger reactor volumes to achieve comparable conversion rates. Additionally, catalyst deactivation through sintering, poisoning, or coking during extended operation periods necessitates frequent replacement or regeneration, further increasing operational complexity.

Heat management presents significant engineering challenges in ammonia cracking systems. The strongly endothermic reaction requires efficient heat transfer mechanisms to maintain optimal reaction temperatures throughout the catalyst bed. Current heat exchanger designs often struggle with thermal gradients that lead to uneven catalyst utilization and reduced overall system efficiency. The integration of heat recovery systems to capture and reuse thermal energy from the process stream remains technically challenging but essential for improving energy efficiency.

System control and response dynamics pose additional challenges, particularly for applications requiring variable hydrogen output. Ammonia cracking reactors typically exhibit slow thermal response times, making rapid adjustments to hydrogen production rates difficult. This limitation becomes particularly problematic in applications like transportation or grid balancing, where demand may fluctuate rapidly.

Material compatibility issues further complicate system design. The combination of high temperatures, hydrogen embrittlement risks, and potential ammonia slip requires specialized materials that can withstand these harsh conditions while maintaining structural integrity over extended operational periods. Current materials often represent compromises between performance, durability, and cost.

Ammonia slip—unreacted ammonia in the product stream—presents both technical and safety challenges. Even small concentrations of ammonia in hydrogen output can damage downstream equipment such as fuel cells or cause environmental concerns. Current purification technologies add complexity, cost, and energy penalties to the overall system.

Miniaturization and system integration remain significant hurdles for mobile or distributed applications. Developing compact, efficient cracking systems that can be safely operated in various environments requires innovative approaches to reactor design, thermal management, and system control that have not yet been fully realized in commercial systems.

Current Ammonia Cracking Implementation Solutions

01 Environmental impact assessment of ammonia cracking processes

Ammonia cracking processes have various environmental impacts that need to be assessed. These processes involve the decomposition of ammonia into hydrogen and nitrogen, which can have both positive and negative environmental consequences. Environmental impact assessments help in understanding the overall ecological footprint of ammonia cracking technologies, including emissions, resource consumption, and potential hazards. These assessments are crucial for developing sustainable ammonia cracking solutions and meeting environmental regulations.- Emissions reduction in ammonia cracking processes: Ammonia cracking processes can be optimized to reduce harmful emissions to the environment. Various technologies have been developed to minimize the release of nitrogen oxides (NOx), carbon dioxide (CO2), and other greenhouse gases during the ammonia cracking process. These technologies include catalytic systems, advanced reactor designs, and process optimization techniques that can significantly lower the environmental footprint of hydrogen production from ammonia.

- Energy efficiency improvements in ammonia decomposition: Energy consumption is a major environmental concern in ammonia cracking operations. Innovations focus on improving energy efficiency through heat recovery systems, optimized reactor designs, and advanced catalysts that operate at lower temperatures. These improvements reduce the overall carbon footprint of the process by decreasing fossil fuel consumption required for heating. More efficient ammonia cracking processes contribute to more sustainable hydrogen production with reduced environmental impact.

- Life cycle assessment of ammonia as hydrogen carrier: Environmental impact evaluations of ammonia cracking consider the entire life cycle from production to end-use. These assessments analyze factors such as carbon intensity, water usage, land use changes, and potential for renewable integration. Comparative analyses between ammonia and other hydrogen carriers help identify the most environmentally sustainable pathways for hydrogen deployment in various applications. Understanding the complete environmental footprint enables better decision-making for sustainable energy systems.

- Catalyst innovations for environmentally friendly ammonia cracking: Development of novel catalysts plays a crucial role in reducing the environmental impact of ammonia cracking. Advanced catalytic materials enable more efficient conversion at lower temperatures, reducing energy requirements and associated emissions. Some catalysts also minimize the formation of byproducts and contaminants that could harm the environment. Research focuses on non-precious metal catalysts that are more sustainable and economically viable while maintaining high performance in ammonia decomposition reactions.

- Integration with renewable energy systems: Ammonia cracking processes can be integrated with renewable energy sources to minimize environmental impact. Systems that utilize solar, wind, or hydroelectric power for the energy-intensive cracking process significantly reduce greenhouse gas emissions compared to conventional methods. Green ammonia production and subsequent cracking represent a promising pathway for clean hydrogen production. These integrated systems can provide flexible energy storage solutions while addressing environmental concerns associated with traditional hydrogen production methods.

02 Emission reduction technologies in ammonia cracking

Various technologies have been developed to reduce emissions from ammonia cracking processes. These include catalytic systems that minimize the formation of nitrogen oxides (NOx), carbon capture technologies to manage CO2 emissions from the process, and advanced reactor designs that optimize energy efficiency. By implementing these emission reduction technologies, the environmental impact of ammonia cracking can be significantly decreased, making it a more sustainable option for hydrogen production.Expand Specific Solutions03 Energy efficiency improvements in ammonia decomposition

Improving energy efficiency in ammonia decomposition processes is essential for reducing their environmental impact. This involves developing more efficient catalysts, optimizing reactor designs, and implementing heat recovery systems. Energy-efficient ammonia cracking reduces the carbon footprint associated with the process by minimizing the energy input required. These improvements make ammonia a more viable carrier for hydrogen in clean energy applications.Expand Specific Solutions04 Life cycle assessment of ammonia as a hydrogen carrier

Life cycle assessments evaluate the environmental impacts of ammonia as a hydrogen carrier from production to end-use. These assessments consider factors such as raw material extraction, manufacturing processes, transportation, use phase, and disposal or recycling. By analyzing the entire life cycle, researchers can identify environmental hotspots and develop strategies to minimize the overall environmental impact of ammonia cracking technologies. This holistic approach helps in making informed decisions about the sustainability of ammonia-based hydrogen systems.Expand Specific Solutions05 Green ammonia production for sustainable hydrogen generation

Green ammonia production involves using renewable energy sources for ammonia synthesis, which can then be cracked to produce hydrogen with minimal environmental impact. This approach eliminates the carbon emissions associated with conventional ammonia production methods that rely on fossil fuels. Green ammonia serves as a carbon-neutral hydrogen carrier, offering a sustainable pathway for hydrogen generation. The development of green ammonia technologies is crucial for reducing the overall environmental footprint of hydrogen production through ammonia cracking.Expand Specific Solutions

Key Industry Players in Ammonia Cracking Sector

The environmental impact assessment for ammonia cracking deployments is currently in an early growth phase, with the market expanding rapidly due to increasing focus on hydrogen as a clean energy carrier. The global market size is projected to reach significant scale by 2030, driven by decarbonization initiatives. Technologically, the field shows varying maturity levels, with established industrial players like Air Products & Chemicals and China Petroleum & Chemical Corp leading commercial applications, while research institutions such as Fuzhou University, Tianjin University, and Peking University are advancing fundamental innovations. Companies like SK Innovation and Equinor Energy are developing integrated solutions, indicating the technology is transitioning from research to commercial deployment, though standardized environmental assessment frameworks remain under development.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed advanced ammonia cracking technology that utilizes structured catalysts and optimized reactor designs to efficiently convert ammonia to hydrogen with minimal environmental impact. Their system incorporates multi-stage heat recovery mechanisms that capture and reuse thermal energy from the cracking process, reducing overall energy consumption by up to 20% compared to conventional systems[1]. The company's environmental impact assessment framework specifically addresses emissions control through proprietary scrubbing technology that captures and neutralizes NOx compounds formed during the cracking process. Their integrated approach includes continuous emissions monitoring systems (CEMS) that provide real-time data on atmospheric releases, allowing for immediate operational adjustments to maintain compliance with environmental regulations[3]. Air Products has also pioneered water conservation measures in their ammonia cracking deployments, implementing closed-loop cooling systems that reduce freshwater consumption by approximately 40% compared to traditional open-loop systems.

Strengths: Industry-leading heat integration technology significantly reduces carbon footprint; proprietary catalyst formulations enable lower operating temperatures; comprehensive emissions monitoring capabilities ensure regulatory compliance. Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized maintenance expertise; performance efficiency may decrease in regions with extreme ambient temperature variations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an environmentally-optimized ammonia cracking technology that integrates carbon capture capabilities directly into the process design. Their system employs a dual-catalyst approach that operates at lower temperatures (450-550°C compared to traditional 850-900°C systems), significantly reducing energy requirements and associated greenhouse gas emissions[2]. Sinopec's environmental impact assessment methodology for ammonia cracking facilities incorporates comprehensive lifecycle analysis, accounting for upstream emissions from ammonia production through to end-use applications of the hydrogen produced. Their deployments feature advanced wastewater treatment systems specifically designed to handle the unique contaminant profile of ammonia cracking operations, including specialized filtration for catalyst particles and nitrogen compounds. The company has implemented real-time environmental monitoring networks around major installations that track air quality parameters including NOx, NH3, and particulate matter concentrations, with automated alert systems that trigger operational adjustments when measurements approach regulatory thresholds[4]. Sinopec has also pioneered the integration of renewable energy sources to power auxiliary systems in their ammonia cracking facilities, reducing the overall carbon intensity of hydrogen production.

Strengths: Comprehensive lifecycle approach to environmental assessment; innovative low-temperature catalyst technology reduces energy consumption; integrated carbon capture capabilities align with emerging carbon regulations. Weaknesses: Technology optimization still primarily focused on large-scale centralized facilities rather than distributed systems; higher catalyst replacement frequency compared to some competitors; performance data from long-term deployments still limited.

Core Patents and Technical Innovations in Ammonia Decomposition

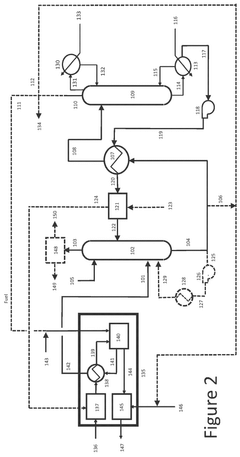

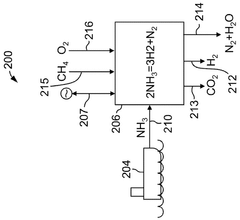

Ammonia capture and recycle in an ammonia cracker

PatentWO2024216054A1

Innovation

- A method involving a water wash column and stripper system where cracked ammonia gas is treated to produce a clean gas and recovered ammonia stream, with the recovered ammonia being recycled as fuel within the ammonia cracking unit, avoiding the need for compression and utilizing thermal integration for energy efficiency.

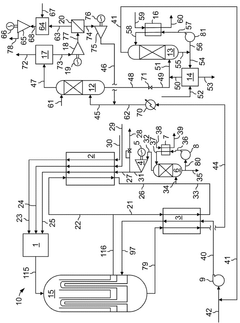

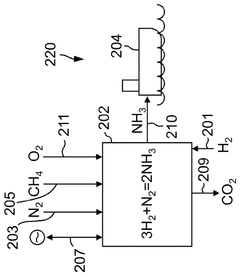

Ammonia cracking system and process

PatentWO2025114832A1

Innovation

- The development of a system and process for cracking ammonia (NH3) into its constituent components, hydrogen (H2) and nitrogen (N2), while capturing substantially all carbon dioxide produced, using a reactor with a catalyst and a carbon dioxide-based heating fluid stream.

Environmental Impact Assessment Methodologies

Environmental Impact Assessment (EIA) methodologies for ammonia cracking deployments require a systematic approach that considers the unique characteristics of this hydrogen carrier technology. The Life Cycle Assessment (LCA) framework stands as the cornerstone methodology, enabling comprehensive evaluation of environmental impacts from raw material extraction through production, transportation, cracking operations, and end-of-life management. This cradle-to-grave approach is particularly valuable for ammonia cracking systems as it captures both direct emissions during operation and indirect impacts throughout the supply chain.

Carbon footprint analysis represents another critical methodology, focusing specifically on greenhouse gas emissions associated with ammonia cracking facilities. This approach quantifies emissions in CO2-equivalent terms, allowing for standardized comparison with alternative hydrogen production and storage technologies. For ammonia cracking, this analysis must account for both the energy-intensive nature of the cracking process and the potential carbon benefits when green ammonia serves as the feedstock.

Water impact assessment methodologies are increasingly important for ammonia cracking deployments, particularly in water-stressed regions. These methodologies evaluate water consumption, potential contamination risks from ammonia leakage, and thermal impacts from cooling systems. Advanced water footprinting techniques can help quantify the total water requirements across the entire value chain, identifying opportunities for conservation and recycling.

Air quality impact methodologies focus on potential emissions of nitrogen oxides (NOx), ammonia slip, and particulate matter. These assessments typically employ dispersion modeling to predict the spatial distribution of pollutants under various meteorological conditions, helping to determine appropriate stack heights, emission controls, and buffer zones for ammonia cracking facilities.

Risk assessment methodologies constitute another essential component, addressing the potential for industrial accidents, ammonia releases, and associated consequences. These approaches typically combine quantitative risk assessment (QRA) techniques with hazard and operability studies (HAZOP) to identify potential failure modes and establish appropriate safety measures.

Biodiversity impact assessment methodologies evaluate potential effects on local ecosystems, particularly important when facilities are sited near sensitive habitats. These assessments consider both direct impacts from land use changes and indirect effects from emissions and water usage. For ammonia cracking deployments, particular attention must be paid to potential nitrogen deposition effects on surrounding vegetation.

Social impact assessment methodologies complement environmental evaluations by examining effects on local communities, including noise, visual impacts, and changes to local employment patterns. These approaches increasingly incorporate environmental justice considerations to ensure that impacts are not disproportionately borne by disadvantaged communities.

Carbon footprint analysis represents another critical methodology, focusing specifically on greenhouse gas emissions associated with ammonia cracking facilities. This approach quantifies emissions in CO2-equivalent terms, allowing for standardized comparison with alternative hydrogen production and storage technologies. For ammonia cracking, this analysis must account for both the energy-intensive nature of the cracking process and the potential carbon benefits when green ammonia serves as the feedstock.

Water impact assessment methodologies are increasingly important for ammonia cracking deployments, particularly in water-stressed regions. These methodologies evaluate water consumption, potential contamination risks from ammonia leakage, and thermal impacts from cooling systems. Advanced water footprinting techniques can help quantify the total water requirements across the entire value chain, identifying opportunities for conservation and recycling.

Air quality impact methodologies focus on potential emissions of nitrogen oxides (NOx), ammonia slip, and particulate matter. These assessments typically employ dispersion modeling to predict the spatial distribution of pollutants under various meteorological conditions, helping to determine appropriate stack heights, emission controls, and buffer zones for ammonia cracking facilities.

Risk assessment methodologies constitute another essential component, addressing the potential for industrial accidents, ammonia releases, and associated consequences. These approaches typically combine quantitative risk assessment (QRA) techniques with hazard and operability studies (HAZOP) to identify potential failure modes and establish appropriate safety measures.

Biodiversity impact assessment methodologies evaluate potential effects on local ecosystems, particularly important when facilities are sited near sensitive habitats. These assessments consider both direct impacts from land use changes and indirect effects from emissions and water usage. For ammonia cracking deployments, particular attention must be paid to potential nitrogen deposition effects on surrounding vegetation.

Social impact assessment methodologies complement environmental evaluations by examining effects on local communities, including noise, visual impacts, and changes to local employment patterns. These approaches increasingly incorporate environmental justice considerations to ensure that impacts are not disproportionately borne by disadvantaged communities.

Regulatory Compliance Framework for Ammonia Processing

The regulatory landscape for ammonia processing facilities encompasses a complex web of international, national, and local requirements that must be navigated for compliant operation. At the international level, the Paris Agreement and Montreal Protocol establish overarching frameworks for emissions control and environmental protection that directly impact ammonia cracking deployments. These agreements set baseline standards that are often incorporated into more specific regional regulations.

National regulatory frameworks vary significantly across jurisdictions, with the United States, European Union, and Asia-Pacific regions implementing distinct approaches. In the US, ammonia processing falls under the purview of multiple agencies including the Environmental Protection Agency (EPA) through the Clean Air Act and Clean Water Act, the Occupational Safety and Health Administration (OSHA) for worker safety standards, and the Department of Transportation (DOT) for transport regulations. The EPA's Risk Management Program specifically addresses facilities handling ammonia above threshold quantities.

European regulations are generally more stringent, with the Industrial Emissions Directive (IED) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) imposing comprehensive requirements for environmental protection and chemical management. The Seveso III Directive further addresses major accident hazards involving dangerous substances, including ammonia.

Permitting processes represent a critical compliance pathway for ammonia cracking facilities. These typically include environmental impact assessments, air quality permits, wastewater discharge permits, and hazardous materials handling authorizations. The permitting timeline can range from 6-24 months depending on jurisdiction and project complexity, representing a significant planning consideration for deployment schedules.

Emissions monitoring and reporting requirements constitute another key regulatory component. Most jurisdictions mandate continuous or periodic monitoring of NOx, NH3 slip, and other pollutants, with regular reporting to regulatory authorities. Best Available Techniques (BAT) standards, particularly prevalent in European contexts, establish technology benchmarks that facilities must meet or exceed.

Safety regulations specifically addressing ammonia's hazardous properties include requirements for leak detection systems, emergency response plans, and community notification protocols. These are often administered through programs like the US Chemical Facility Anti-Terrorism Standards (CFATS) or equivalent international frameworks.

Emerging regulatory trends indicate increasing stringency in emissions limits, greater emphasis on lifecycle assessment, and growing incorporation of environmental justice considerations into permitting decisions. Forward-looking compliance strategies must anticipate these developments while maintaining flexibility to adapt to jurisdiction-specific requirements.

National regulatory frameworks vary significantly across jurisdictions, with the United States, European Union, and Asia-Pacific regions implementing distinct approaches. In the US, ammonia processing falls under the purview of multiple agencies including the Environmental Protection Agency (EPA) through the Clean Air Act and Clean Water Act, the Occupational Safety and Health Administration (OSHA) for worker safety standards, and the Department of Transportation (DOT) for transport regulations. The EPA's Risk Management Program specifically addresses facilities handling ammonia above threshold quantities.

European regulations are generally more stringent, with the Industrial Emissions Directive (IED) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) imposing comprehensive requirements for environmental protection and chemical management. The Seveso III Directive further addresses major accident hazards involving dangerous substances, including ammonia.

Permitting processes represent a critical compliance pathway for ammonia cracking facilities. These typically include environmental impact assessments, air quality permits, wastewater discharge permits, and hazardous materials handling authorizations. The permitting timeline can range from 6-24 months depending on jurisdiction and project complexity, representing a significant planning consideration for deployment schedules.

Emissions monitoring and reporting requirements constitute another key regulatory component. Most jurisdictions mandate continuous or periodic monitoring of NOx, NH3 slip, and other pollutants, with regular reporting to regulatory authorities. Best Available Techniques (BAT) standards, particularly prevalent in European contexts, establish technology benchmarks that facilities must meet or exceed.

Safety regulations specifically addressing ammonia's hazardous properties include requirements for leak detection systems, emergency response plans, and community notification protocols. These are often administered through programs like the US Chemical Facility Anti-Terrorism Standards (CFATS) or equivalent international frameworks.

Emerging regulatory trends indicate increasing stringency in emissions limits, greater emphasis on lifecycle assessment, and growing incorporation of environmental justice considerations into permitting decisions. Forward-looking compliance strategies must anticipate these developments while maintaining flexibility to adapt to jurisdiction-specific requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!