Materials Compatibility with Ammonia and Cracked Gas Streams

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Materials Compatibility Background & Objectives

Ammonia has emerged as a promising carbon-free energy carrier and fuel in the global transition towards sustainable energy systems. With its high energy density, established production infrastructure, and zero-carbon emissions when combusted, ammonia presents a viable solution for decarbonizing various sectors including power generation, maritime transportation, and industrial processes. The historical use of ammonia has primarily been confined to fertilizer production, which accounts for approximately 80% of global ammonia consumption. However, the paradigm is shifting as ammonia gains recognition for its potential as an energy vector.

The evolution of ammonia technology has progressed through several distinct phases. Initially, the Haber-Bosch process revolutionized ammonia production in the early 20th century, enabling industrial-scale synthesis. Recent technological advancements have focused on green ammonia production using renewable electricity, water electrolysis, and air separation to produce hydrogen and nitrogen feedstocks. This represents a significant departure from conventional production methods that rely heavily on natural gas and coal, which generate substantial carbon emissions.

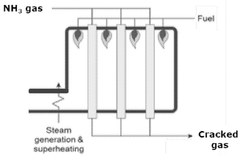

The primary objective of this technical research is to comprehensively evaluate materials compatibility with ammonia and cracked gas streams. Ammonia's corrosive nature presents significant challenges for containment, transportation, and utilization systems. When ammonia is "cracked" or decomposed into hydrogen and nitrogen at elevated temperatures, the resulting gas streams create additional materials compatibility concerns that must be addressed for safe and efficient operation.

Understanding the interaction between various materials and ammonia/cracked gas streams is crucial for developing robust infrastructure for the ammonia economy. This includes storage tanks, pipelines, valves, seals, and combustion equipment that can withstand prolonged exposure without degradation or failure. The research aims to identify optimal materials that offer resistance to ammonia-induced stress corrosion cracking, hydrogen embrittlement, and other degradation mechanisms.

Furthermore, this investigation seeks to establish standardized testing protocols and performance criteria for materials selection in ammonia applications. Current standards are primarily derived from the fertilizer industry and may not adequately address the requirements for energy applications, particularly those involving high temperatures, pressures, and cyclic loading conditions encountered in power generation and transportation sectors.

The outcomes of this research will directly inform engineering design decisions, material selection guidelines, and safety protocols for the expanding ammonia energy infrastructure. By addressing these fundamental materials compatibility challenges, we can accelerate the deployment of ammonia as a clean energy carrier and contribute significantly to global decarbonization efforts.

The evolution of ammonia technology has progressed through several distinct phases. Initially, the Haber-Bosch process revolutionized ammonia production in the early 20th century, enabling industrial-scale synthesis. Recent technological advancements have focused on green ammonia production using renewable electricity, water electrolysis, and air separation to produce hydrogen and nitrogen feedstocks. This represents a significant departure from conventional production methods that rely heavily on natural gas and coal, which generate substantial carbon emissions.

The primary objective of this technical research is to comprehensively evaluate materials compatibility with ammonia and cracked gas streams. Ammonia's corrosive nature presents significant challenges for containment, transportation, and utilization systems. When ammonia is "cracked" or decomposed into hydrogen and nitrogen at elevated temperatures, the resulting gas streams create additional materials compatibility concerns that must be addressed for safe and efficient operation.

Understanding the interaction between various materials and ammonia/cracked gas streams is crucial for developing robust infrastructure for the ammonia economy. This includes storage tanks, pipelines, valves, seals, and combustion equipment that can withstand prolonged exposure without degradation or failure. The research aims to identify optimal materials that offer resistance to ammonia-induced stress corrosion cracking, hydrogen embrittlement, and other degradation mechanisms.

Furthermore, this investigation seeks to establish standardized testing protocols and performance criteria for materials selection in ammonia applications. Current standards are primarily derived from the fertilizer industry and may not adequately address the requirements for energy applications, particularly those involving high temperatures, pressures, and cyclic loading conditions encountered in power generation and transportation sectors.

The outcomes of this research will directly inform engineering design decisions, material selection guidelines, and safety protocols for the expanding ammonia energy infrastructure. By addressing these fundamental materials compatibility challenges, we can accelerate the deployment of ammonia as a clean energy carrier and contribute significantly to global decarbonization efforts.

Market Analysis for Ammonia-Resistant Materials

The global market for ammonia-resistant materials is experiencing significant growth, driven by the expanding applications of ammonia as a carbon-free energy carrier and hydrogen storage medium. Current market valuations indicate that ammonia-resistant materials sector reached approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030. This growth trajectory is primarily fueled by increasing investments in ammonia infrastructure for clean energy applications.

The market segmentation reveals distinct categories based on material types. Specialty stainless steels dominate with roughly 40% market share, followed by nickel alloys at 25%, advanced polymers at 20%, and various other materials including ceramics and composites accounting for the remaining 15%. Geographically, Asia-Pacific represents the largest market region at 38%, followed by Europe (27%), North America (22%), and rest of the world (13%).

Key demand drivers include the hydrogen economy's development, with ammonia increasingly viewed as an efficient hydrogen carrier. The International Energy Agency reports that ammonia could transport approximately 30% of global hydrogen by 2050, creating substantial demand for compatible materials. Additionally, the maritime industry's decarbonization efforts are accelerating ammonia adoption as a marine fuel, with major shipping companies announcing ammonia-powered vessel projects.

Agricultural sector continues to provide baseline demand, with fertilizer production facilities requiring extensive ammonia-resistant infrastructure. This sector alone accounts for 65% of current material consumption, though energy applications are growing at triple the rate of traditional uses.

Market challenges include price volatility of high-performance alloys, with nickel and molybdenum price fluctuations creating uncertainty for manufacturers. Supply chain constraints, particularly for rare earth elements used in specialized coatings, present additional market barriers. Regulatory frameworks regarding ammonia handling are becoming more stringent globally, driving demand for materials with improved safety profiles.

Emerging opportunities exist in developing cost-effective alternatives to traditional materials, particularly in sealing technologies and gasket materials where current solutions face limitations in extreme conditions. The renewable energy sector's integration with ammonia systems presents another growth avenue, with green ammonia production facilities requiring specialized materials for electrolyzers and storage systems.

Customer segments show distinct requirements, with energy infrastructure developers prioritizing long-term durability, while agricultural applications focus more on cost-effectiveness and maintenance intervals. This market differentiation is creating specialized niches for material manufacturers who can address specific performance requirements.

The market segmentation reveals distinct categories based on material types. Specialty stainless steels dominate with roughly 40% market share, followed by nickel alloys at 25%, advanced polymers at 20%, and various other materials including ceramics and composites accounting for the remaining 15%. Geographically, Asia-Pacific represents the largest market region at 38%, followed by Europe (27%), North America (22%), and rest of the world (13%).

Key demand drivers include the hydrogen economy's development, with ammonia increasingly viewed as an efficient hydrogen carrier. The International Energy Agency reports that ammonia could transport approximately 30% of global hydrogen by 2050, creating substantial demand for compatible materials. Additionally, the maritime industry's decarbonization efforts are accelerating ammonia adoption as a marine fuel, with major shipping companies announcing ammonia-powered vessel projects.

Agricultural sector continues to provide baseline demand, with fertilizer production facilities requiring extensive ammonia-resistant infrastructure. This sector alone accounts for 65% of current material consumption, though energy applications are growing at triple the rate of traditional uses.

Market challenges include price volatility of high-performance alloys, with nickel and molybdenum price fluctuations creating uncertainty for manufacturers. Supply chain constraints, particularly for rare earth elements used in specialized coatings, present additional market barriers. Regulatory frameworks regarding ammonia handling are becoming more stringent globally, driving demand for materials with improved safety profiles.

Emerging opportunities exist in developing cost-effective alternatives to traditional materials, particularly in sealing technologies and gasket materials where current solutions face limitations in extreme conditions. The renewable energy sector's integration with ammonia systems presents another growth avenue, with green ammonia production facilities requiring specialized materials for electrolyzers and storage systems.

Customer segments show distinct requirements, with energy infrastructure developers prioritizing long-term durability, while agricultural applications focus more on cost-effectiveness and maintenance intervals. This market differentiation is creating specialized niches for material manufacturers who can address specific performance requirements.

Current Challenges in Materials for Ammonia Service

The ammonia industry faces significant materials challenges due to the corrosive nature of ammonia and its cracked gas derivatives. Carbon steel, traditionally used in ammonia service, experiences stress corrosion cracking (SCC) when exposed to oxygen-contaminated ammonia, particularly at operating pressures above 1.5 MPa. This phenomenon is exacerbated at ambient temperatures, creating a paradoxical situation where higher temperatures sometimes offer better material performance.

Stainless steels, while offering improved corrosion resistance, present their own challenges. Austenitic stainless steels (300 series) are susceptible to chloride-induced SCC, especially in heat-affected zones near welds. Duplex stainless steels show promise but require careful control of nitrogen content during welding to maintain their mechanical properties and corrosion resistance.

Nickel alloys, though highly resistant to ammonia corrosion, face economic constraints due to their high cost, limiting widespread adoption despite technical advantages. The industry continues to search for cost-effective alternatives that provide comparable performance.

Gasket and sealing materials present another critical challenge. Traditional materials like asbestos-based products have been phased out due to health concerns, while replacements such as PTFE and graphite composites often struggle to maintain integrity under the thermal cycling and pressure fluctuations common in ammonia processing equipment.

Hydrogen embrittlement emerges as a significant concern in cracked ammonia environments. The atomic hydrogen produced during ammonia cracking can penetrate metal lattices, causing reduced ductility and potentially catastrophic failure. This is particularly problematic for high-strength steels and certain non-ferrous alloys used in pressure-containing equipment.

Thermal cycling effects compound these challenges, as ammonia production and processing often involve temperature variations that induce mechanical stresses. The resulting expansion and contraction cycles accelerate fatigue mechanisms and can compromise material integrity over time, particularly at joints and transitions between different materials.

The industry also faces challenges with inspection and monitoring technologies. Non-destructive testing methods for detecting early-stage material degradation in ammonia service remain limited, often requiring equipment shutdown for thorough examination. This creates operational inefficiencies and increases the risk of unexpected failures between inspection intervals.

Emerging environmental regulations add another dimension to materials selection challenges, as lower-emission processes may introduce new operating conditions and chemical environments that existing materials are not fully qualified to handle.

Stainless steels, while offering improved corrosion resistance, present their own challenges. Austenitic stainless steels (300 series) are susceptible to chloride-induced SCC, especially in heat-affected zones near welds. Duplex stainless steels show promise but require careful control of nitrogen content during welding to maintain their mechanical properties and corrosion resistance.

Nickel alloys, though highly resistant to ammonia corrosion, face economic constraints due to their high cost, limiting widespread adoption despite technical advantages. The industry continues to search for cost-effective alternatives that provide comparable performance.

Gasket and sealing materials present another critical challenge. Traditional materials like asbestos-based products have been phased out due to health concerns, while replacements such as PTFE and graphite composites often struggle to maintain integrity under the thermal cycling and pressure fluctuations common in ammonia processing equipment.

Hydrogen embrittlement emerges as a significant concern in cracked ammonia environments. The atomic hydrogen produced during ammonia cracking can penetrate metal lattices, causing reduced ductility and potentially catastrophic failure. This is particularly problematic for high-strength steels and certain non-ferrous alloys used in pressure-containing equipment.

Thermal cycling effects compound these challenges, as ammonia production and processing often involve temperature variations that induce mechanical stresses. The resulting expansion and contraction cycles accelerate fatigue mechanisms and can compromise material integrity over time, particularly at joints and transitions between different materials.

The industry also faces challenges with inspection and monitoring technologies. Non-destructive testing methods for detecting early-stage material degradation in ammonia service remain limited, often requiring equipment shutdown for thorough examination. This creates operational inefficiencies and increases the risk of unexpected failures between inspection intervals.

Emerging environmental regulations add another dimension to materials selection challenges, as lower-emission processes may introduce new operating conditions and chemical environments that existing materials are not fully qualified to handle.

Existing Material Solutions for Ammonia and Cracked Gas Exposure

01 Polymer compatibility in composite materials

Various polymers can be combined to create composite materials with enhanced properties. The compatibility between different polymers is crucial for ensuring the stability and performance of the final product. Techniques such as surface modification and the use of compatibilizers can improve the interfacial adhesion between incompatible polymers, resulting in better mechanical properties and durability of the composite materials.- Polymer compatibility in composite materials: Polymer compatibility is crucial in developing composite materials with enhanced properties. Compatible polymers can form stable blends with improved mechanical strength, thermal stability, and chemical resistance. Techniques such as surface modification, addition of compatibilizers, and controlled processing conditions can improve the compatibility between different polymers, resulting in materials with superior performance characteristics for various industrial applications.

- Material compatibility in storage and containment systems: The compatibility between stored substances and containment materials is essential for safety and product integrity. Proper selection of materials that resist chemical degradation, corrosion, and permeation helps prevent contamination, leakage, and structural failure. Compatibility testing protocols and databases assist in identifying suitable material combinations for specific storage requirements, ensuring long-term stability and reducing the risk of hazardous interactions.

- Compatibility of materials in electronic and optical devices: Material compatibility in electronic and optical devices affects performance, reliability, and longevity. Thermal expansion coefficient matching, adhesion properties, and chemical stability between different materials are critical considerations. Advanced interface engineering techniques and novel material combinations help minimize stress, prevent delamination, and reduce signal interference in multilayer structures, leading to improved device functionality and extended operational lifetime.

- Biocompatibility of materials for medical applications: Biocompatibility is essential for materials used in medical devices and implants to prevent adverse biological responses. Materials must be non-toxic, non-immunogenic, and maintain their functional properties in biological environments. Surface modifications, coatings, and composite formulations can enhance biocompatibility while preserving mechanical and physical properties. Testing protocols evaluate cytotoxicity, inflammatory responses, and long-term tissue interactions to ensure safety and efficacy in clinical applications.

- Material compatibility in sustainable and recyclable products: Designing products with compatible materials facilitates recycling and supports sustainability goals. Material selection strategies focus on combinations that can be easily separated or recycled together without degradation. Compatibility considerations include similar melting points, chemical structures, and degradation pathways. Innovative design approaches incorporate bio-based materials, recyclable composites, and mono-material solutions to reduce environmental impact while maintaining product performance and durability.

02 Material compatibility in storage and packaging systems

The compatibility between stored materials and their packaging or container materials is essential for maintaining product integrity and safety. Incompatible materials can lead to degradation, contamination, or even hazardous reactions. Proper selection of packaging materials based on their chemical resistance, permeability, and interaction with the contained substances ensures longer shelf life and prevents potential safety issues.Expand Specific Solutions03 Compatibility testing methods and standards

Various testing methods and standards have been developed to evaluate the compatibility between different materials. These include accelerated aging tests, chemical resistance tests, and mechanical property evaluations after material contact. Standardized protocols ensure consistent and reliable assessment of material compatibility, which is crucial for quality control and regulatory compliance in industries such as medical devices, automotive, and electronics.Expand Specific Solutions04 Material compatibility in electronic and optical applications

In electronic and optical applications, the compatibility between different materials is critical for device performance and reliability. Issues such as thermal expansion mismatch, chemical interactions, and adhesion between layers can significantly impact functionality. Advanced material selection and interface engineering techniques are employed to ensure compatibility in multilayer structures used in semiconductors, displays, and optical components.Expand Specific Solutions05 Environmental and chemical resistance of materials

Materials used in various applications must be compatible with their operating environment, including exposure to chemicals, temperature fluctuations, and humidity. Enhancing the chemical resistance of materials through surface treatments, coatings, or material modifications can extend their service life and maintain performance under harsh conditions. This is particularly important in industrial equipment, outdoor applications, and chemical processing facilities.Expand Specific Solutions

Leading Suppliers and Manufacturers in Ammonia-Compatible Materials

The ammonia and cracked gas streams materials compatibility market is currently in a growth phase, with increasing demand driven by clean energy transitions and industrial applications. The market size is expanding significantly as ammonia gains prominence as a hydrogen carrier and carbon-free fuel. Technologically, the field shows varying maturity levels across different material solutions. Leading players like NIPPON STEEL, Baker Hughes, and Refratechnik Holding demonstrate advanced capabilities in high-temperature and corrosion-resistant materials. Research institutions such as Tianjin University and KIST are accelerating innovation in novel materials. Companies including Henkel, Saint-Gobain, and Clariant are developing specialized coatings and composites to address compatibility challenges. The competitive landscape features both established industrial materials providers and emerging specialized materials technology firms focusing on ammonia-specific applications.

Equinor Energy AS

Technical Solution: Equinor Energy AS has developed comprehensive materials compatibility solutions for ammonia and cracked gas streams in their energy transition projects. Their approach includes specialized stainless steel alloys with high nickel content (>25%) specifically engineered to resist ammonia stress corrosion cracking. The company employs a multi-layered protection system combining mechanical design considerations with material selection to manage the challenges of hydrogen embrittlement from cracked ammonia. Equinor has implemented advanced surface treatment technologies including specialized coatings with chromium-rich barriers that significantly reduce permeation and corrosion rates in ammonia environments. Their materials testing protocol includes accelerated aging tests under pressurized ammonia conditions (up to 20 MPa) and temperature cycling (from -33°C to 450°C) to simulate real-world operational stresses.

Strengths: Extensive experience with high-pressure gas handling systems from oil and gas operations provides transferable expertise to ammonia infrastructure. Their integrated approach combining materials science with system engineering creates comprehensive solutions. Weaknesses: Their solutions are primarily optimized for large-scale industrial applications and may be cost-prohibitive for smaller implementations.

Baker Hughes Co.

Technical Solution: Baker Hughes has pioneered advanced materials technology specifically designed for ammonia and cracked gas stream applications in their energy transition portfolio. Their proprietary ceramic-metallic (cermet) composites demonstrate exceptional resistance to both ammonia corrosion and hydrogen embrittlement. These materials incorporate nano-structured alumina and silicon carbide particles dispersed within a specialized nickel-chromium-molybdenum matrix, creating a barrier against ammonia penetration while maintaining structural integrity. Baker Hughes has developed specialized sealing technologies using fluoroelastomer compounds modified with specific fillers that maintain elasticity and sealing properties even after prolonged exposure to ammonia at varying pressures (0.1-30 MPa) and temperatures (-40°C to 200°C). Their materials undergo rigorous testing including cyclic pressure testing and thermal shock evaluation to ensure long-term reliability in ammonia service conditions.

Strengths: Their materials solutions benefit from decades of experience in extreme operating environments in oil and gas, providing proven reliability. The company's global supply chain and manufacturing capabilities ensure consistent quality and availability. Weaknesses: Higher initial investment costs compared to conventional materials, though potentially offset by longer service life and reduced maintenance requirements.

Critical Patents and Research in Ammonia-Resistant Alloys

Process for cracking ammonia

PatentWO2024218500A1

Innovation

- The process employs reaction vessels made from alloys resistant to nitriding and creep deformation, with compositions like nickel and cobalt-based alloys, optionally containing chromium, silicon, or aluminum, to maintain integrity at high pressures and temperatures for extended periods, and an oxide layer is formed to protect against nitriding.

Heat resistant alloy having nitriding resistance

PatentWO2024232408A1

Innovation

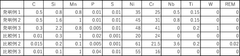

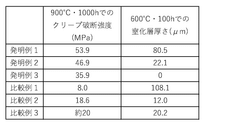

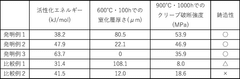

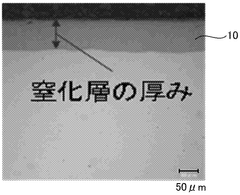

- A heat-resistant alloy composition with specific ranges of C, Si, Mn, P, S, Ni, Cr, and optional elements like Nb, Ti, and Mo, which enhances nitriding resistance and high-temperature creep rupture strength, is developed, featuring a high Ni content to inhibit nitrogen diffusion and form stable austenite phases, along with elements that suppress nitride layer growth.

Environmental Impact and Sustainability Considerations

The environmental impact of ammonia and cracked gas streams extends far beyond operational considerations, representing a critical dimension in the sustainable implementation of these technologies. Ammonia production traditionally relies on the Haber-Bosch process, which consumes approximately 1-2% of global energy and contributes significantly to greenhouse gas emissions. When considering materials compatibility with ammonia systems, environmental sustainability must be evaluated across the entire lifecycle of materials and processes.

Material selection directly influences environmental footprint through multiple pathways. Corrosion-resistant alloys often contain nickel, chromium, and other elements with energy-intensive mining and refining processes. The environmental cost of producing these specialized materials must be balanced against their longevity and reduced maintenance requirements. Materials that extend system lifespans ultimately reduce waste generation and resource consumption, creating a positive environmental impact despite potentially higher initial embodiment energy.

Leakage prevention represents another critical environmental consideration. Ammonia is highly toxic to aquatic organisms, with even small releases potentially causing significant ecological damage. Materials that maintain integrity under operational conditions minimize the risk of environmental contamination. This is particularly important as ammonia gains traction as a carbon-free energy carrier, where large-scale deployment could increase environmental exposure risks if material compatibility issues are not adequately addressed.

The recyclability and end-of-life management of materials used in ammonia systems further impact sustainability metrics. Materials designed for disassembly and recycling reduce waste and conserve resources. Composite materials, while offering excellent compatibility with ammonia, often present recycling challenges compared to homogeneous metal alloys. This creates tension between operational performance and circular economy principles that must be carefully navigated.

For cracked gas streams, which typically contain hydrogen and various carbon compounds, material selection influences both direct environmental impacts through potential leakage and indirect impacts through energy efficiency. Materials that minimize hydrogen embrittlement not only enhance safety but also prevent the escape of hydrogen—a potent indirect greenhouse gas that can extend the atmospheric lifetime of methane and other pollutants.

Emerging sustainable materials science offers promising alternatives to traditional solutions. Bio-based coatings, green corrosion inhibitors, and advanced ceramics derived from abundant materials may provide environmentally superior options for ammonia compatibility. These innovations align with broader sustainability goals while potentially offering comparable or superior performance to conventional materials.

Material selection directly influences environmental footprint through multiple pathways. Corrosion-resistant alloys often contain nickel, chromium, and other elements with energy-intensive mining and refining processes. The environmental cost of producing these specialized materials must be balanced against their longevity and reduced maintenance requirements. Materials that extend system lifespans ultimately reduce waste generation and resource consumption, creating a positive environmental impact despite potentially higher initial embodiment energy.

Leakage prevention represents another critical environmental consideration. Ammonia is highly toxic to aquatic organisms, with even small releases potentially causing significant ecological damage. Materials that maintain integrity under operational conditions minimize the risk of environmental contamination. This is particularly important as ammonia gains traction as a carbon-free energy carrier, where large-scale deployment could increase environmental exposure risks if material compatibility issues are not adequately addressed.

The recyclability and end-of-life management of materials used in ammonia systems further impact sustainability metrics. Materials designed for disassembly and recycling reduce waste and conserve resources. Composite materials, while offering excellent compatibility with ammonia, often present recycling challenges compared to homogeneous metal alloys. This creates tension between operational performance and circular economy principles that must be carefully navigated.

For cracked gas streams, which typically contain hydrogen and various carbon compounds, material selection influences both direct environmental impacts through potential leakage and indirect impacts through energy efficiency. Materials that minimize hydrogen embrittlement not only enhance safety but also prevent the escape of hydrogen—a potent indirect greenhouse gas that can extend the atmospheric lifetime of methane and other pollutants.

Emerging sustainable materials science offers promising alternatives to traditional solutions. Bio-based coatings, green corrosion inhibitors, and advanced ceramics derived from abundant materials may provide environmentally superior options for ammonia compatibility. These innovations align with broader sustainability goals while potentially offering comparable or superior performance to conventional materials.

Safety Standards and Risk Assessment Protocols

The comprehensive safety framework for ammonia and cracked gas streams requires adherence to multiple international standards, including ANSI/ASHRAE 15, ISO 5149, and EN 378 for refrigeration systems, as well as API 510 and ASME BPVC for pressure vessels. These standards establish critical parameters for material selection, inspection protocols, and operational safety limits when handling these potentially hazardous substances.

Risk assessment methodologies for ammonia systems typically follow the HAZOP (Hazard and Operability Study) approach, which systematically evaluates potential deviations from design intent. This process identifies critical failure points where material compatibility issues could lead to catastrophic outcomes. For cracked gas streams containing hydrogen, additional considerations under NFPA 2 and CGA G-5.5 standards become essential due to hydrogen embrittlement risks.

Material-specific risk protocols have evolved significantly since the 2019 International Institute of Ammonia Refrigeration (IIAR) guidelines update. These protocols now mandate comprehensive compatibility testing under simulated operational conditions, including pressure cycling and temperature extremes. The testing must account for both steady-state exposure and transient conditions that may occur during startup, shutdown, or emergency scenarios.

Detection and monitoring systems represent another critical safety component, with current standards requiring redundant ammonia detection systems with sensitivity thresholds of 25-35 ppm for early warning and 150-200 ppm for emergency response activation. Modern facilities increasingly implement IoT-enabled continuous monitoring systems that track material degradation indicators in real-time, allowing for predictive maintenance before critical failures occur.

Emergency response protocols specifically addressing material failure scenarios must be documented and regularly practiced. These protocols should include specific procedures for different types of material failures, such as stress corrosion cracking in stainless steel components or hydrogen-induced cracking in carbon steel elements. The OSHA Process Safety Management (PSM) standard requires these protocols to be updated whenever material changes are implemented in the system.

Periodic inspection requirements vary by material type and exposure conditions, with most standards now requiring non-destructive testing techniques such as ultrasonic thickness measurement, radiographic testing, and dye penetrant inspection at intervals determined by risk-based inspection methodologies. For critical components in ammonia service, inspection intervals typically range from 2-5 years, while hydrogen-exposed components may require more frequent assessment.

Risk assessment methodologies for ammonia systems typically follow the HAZOP (Hazard and Operability Study) approach, which systematically evaluates potential deviations from design intent. This process identifies critical failure points where material compatibility issues could lead to catastrophic outcomes. For cracked gas streams containing hydrogen, additional considerations under NFPA 2 and CGA G-5.5 standards become essential due to hydrogen embrittlement risks.

Material-specific risk protocols have evolved significantly since the 2019 International Institute of Ammonia Refrigeration (IIAR) guidelines update. These protocols now mandate comprehensive compatibility testing under simulated operational conditions, including pressure cycling and temperature extremes. The testing must account for both steady-state exposure and transient conditions that may occur during startup, shutdown, or emergency scenarios.

Detection and monitoring systems represent another critical safety component, with current standards requiring redundant ammonia detection systems with sensitivity thresholds of 25-35 ppm for early warning and 150-200 ppm for emergency response activation. Modern facilities increasingly implement IoT-enabled continuous monitoring systems that track material degradation indicators in real-time, allowing for predictive maintenance before critical failures occur.

Emergency response protocols specifically addressing material failure scenarios must be documented and regularly practiced. These protocols should include specific procedures for different types of material failures, such as stress corrosion cracking in stainless steel components or hydrogen-induced cracking in carbon steel elements. The OSHA Process Safety Management (PSM) standard requires these protocols to be updated whenever material changes are implemented in the system.

Periodic inspection requirements vary by material type and exposure conditions, with most standards now requiring non-destructive testing techniques such as ultrasonic thickness measurement, radiographic testing, and dye penetrant inspection at intervals determined by risk-based inspection methodologies. For critical components in ammonia service, inspection intervals typically range from 2-5 years, while hydrogen-exposed components may require more frequent assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!