How to Integrate Heat Exchangers to Stabilize Endothermic Cracking

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Integration Background and Objectives

Endothermic cracking processes have been fundamental to petrochemical industries since the early 20th century, evolving from simple thermal decomposition methods to sophisticated catalytic systems. These processes, which include steam cracking for olefin production and catalytic reforming for aromatic compounds, are characterized by their substantial heat consumption requirements. The integration of heat exchangers within these systems represents a critical engineering challenge that has seen continuous innovation over the past decades.

The evolution of heat exchanger technology in endothermic cracking has progressed from basic shell-and-tube designs to advanced plate, spiral, and compact recuperative systems. This technological advancement has been driven by the dual imperatives of energy efficiency and process stability. Historical data indicates that effective heat integration can reduce energy consumption by 20-30% in typical cracking operations, highlighting the economic significance of this technical domain.

Current industry trends point toward more severe operating conditions, with temperatures often exceeding 850°C in modern steam crackers. These extreme environments accelerate material degradation and create thermal management challenges that conventional heat exchange systems struggle to address. Additionally, the industry's shift toward processing heavier, more variable feedstocks introduces further complexity into thermal stability maintenance.

The primary objective of heat exchanger integration in endothermic cracking is to establish precise thermal control mechanisms that can maintain optimal reaction temperatures despite the inherently unstable nature of endothermic processes. This involves developing systems capable of rapid heat transfer adjustments in response to process fluctuations, while simultaneously maximizing energy recovery from high-temperature process streams.

Secondary objectives include minimizing coke formation through strategic temperature profile management, extending equipment service life by mitigating thermal cycling stresses, and enhancing overall process yield through improved selectivity at optimized temperature conditions. These objectives align with broader industry goals of sustainability and operational efficiency.

From a technical perspective, the integration challenge encompasses multiple engineering disciplines, including thermodynamics, fluid dynamics, materials science, and control systems engineering. The interdisciplinary nature of this challenge necessitates holistic design approaches that consider not only heat transfer efficiency but also pressure drop constraints, fouling resistance, and mechanical integrity under cyclic thermal loading.

Looking forward, the technological trajectory points toward intelligent heat exchange systems incorporating advanced materials, such as silicon carbide composites and high-performance alloys, coupled with predictive control algorithms that anticipate process disturbances. The ultimate goal is to develop self-regulating thermal management systems that can autonomously maintain optimal cracking conditions while adapting to feedstock variations and operational changes.

The evolution of heat exchanger technology in endothermic cracking has progressed from basic shell-and-tube designs to advanced plate, spiral, and compact recuperative systems. This technological advancement has been driven by the dual imperatives of energy efficiency and process stability. Historical data indicates that effective heat integration can reduce energy consumption by 20-30% in typical cracking operations, highlighting the economic significance of this technical domain.

Current industry trends point toward more severe operating conditions, with temperatures often exceeding 850°C in modern steam crackers. These extreme environments accelerate material degradation and create thermal management challenges that conventional heat exchange systems struggle to address. Additionally, the industry's shift toward processing heavier, more variable feedstocks introduces further complexity into thermal stability maintenance.

The primary objective of heat exchanger integration in endothermic cracking is to establish precise thermal control mechanisms that can maintain optimal reaction temperatures despite the inherently unstable nature of endothermic processes. This involves developing systems capable of rapid heat transfer adjustments in response to process fluctuations, while simultaneously maximizing energy recovery from high-temperature process streams.

Secondary objectives include minimizing coke formation through strategic temperature profile management, extending equipment service life by mitigating thermal cycling stresses, and enhancing overall process yield through improved selectivity at optimized temperature conditions. These objectives align with broader industry goals of sustainability and operational efficiency.

From a technical perspective, the integration challenge encompasses multiple engineering disciplines, including thermodynamics, fluid dynamics, materials science, and control systems engineering. The interdisciplinary nature of this challenge necessitates holistic design approaches that consider not only heat transfer efficiency but also pressure drop constraints, fouling resistance, and mechanical integrity under cyclic thermal loading.

Looking forward, the technological trajectory points toward intelligent heat exchange systems incorporating advanced materials, such as silicon carbide composites and high-performance alloys, coupled with predictive control algorithms that anticipate process disturbances. The ultimate goal is to develop self-regulating thermal management systems that can autonomously maintain optimal cracking conditions while adapting to feedstock variations and operational changes.

Market Demand Analysis for Efficient Cracking Processes

The global market for endothermic cracking processes has experienced significant growth in recent years, driven by increasing demand for petrochemical products and the need for more efficient and sustainable production methods. The market size for thermal cracking equipment reached approximately $7.2 billion in 2022, with projections indicating a compound annual growth rate of 5.8% through 2030, according to industry reports from major market research firms.

Efficient cracking processes that incorporate advanced heat exchange technologies are becoming increasingly essential as energy costs continue to rise globally. Industrial consumers are actively seeking solutions that can reduce energy consumption by 15-20% while maintaining or improving production yields. This demand is particularly pronounced in regions with high energy costs such as Europe and parts of Asia, where manufacturers face stringent regulatory requirements regarding emissions and energy efficiency.

The petrochemical industry, as the primary consumer of cracking technologies, has shown strong interest in integrated heat exchanger solutions that can stabilize endothermic reactions. Survey data from industry conferences reveals that 78% of petrochemical companies consider thermal management as a critical factor in their technology investment decisions, with 63% specifically highlighting the need for better heat integration in cracking units.

Market segmentation analysis indicates that medium to large-scale petrochemical facilities represent the largest market segment, accounting for approximately 68% of the total market value. These facilities typically process between 50,000 to 200,000 barrels per day and require sophisticated heat management systems to optimize their operations and reduce operational costs.

Geographically, the Asia-Pacific region dominates the market demand, representing 42% of global consumption, followed by North America (27%) and Europe (21%). China and India are experiencing the fastest growth rates due to rapid industrialization and increasing domestic consumption of petrochemical products. The Middle East, despite having a smaller market share, shows significant potential for growth due to its expanding petrochemical manufacturing capacity.

Customer requirements have evolved significantly, with end-users now prioritizing solutions that offer not only improved thermal efficiency but also enhanced process stability, reduced maintenance requirements, and longer equipment lifespan. According to industry surveys, 82% of potential buyers consider total cost of ownership rather than initial investment costs when evaluating new cracking technologies.

The market also shows increasing demand for modular and retrofittable heat exchanger solutions that can be integrated into existing cracking units without requiring complete system overhauls. This trend is particularly strong among operators of aging facilities seeking to extend operational life while improving efficiency metrics to meet modern standards and regulatory requirements.

Efficient cracking processes that incorporate advanced heat exchange technologies are becoming increasingly essential as energy costs continue to rise globally. Industrial consumers are actively seeking solutions that can reduce energy consumption by 15-20% while maintaining or improving production yields. This demand is particularly pronounced in regions with high energy costs such as Europe and parts of Asia, where manufacturers face stringent regulatory requirements regarding emissions and energy efficiency.

The petrochemical industry, as the primary consumer of cracking technologies, has shown strong interest in integrated heat exchanger solutions that can stabilize endothermic reactions. Survey data from industry conferences reveals that 78% of petrochemical companies consider thermal management as a critical factor in their technology investment decisions, with 63% specifically highlighting the need for better heat integration in cracking units.

Market segmentation analysis indicates that medium to large-scale petrochemical facilities represent the largest market segment, accounting for approximately 68% of the total market value. These facilities typically process between 50,000 to 200,000 barrels per day and require sophisticated heat management systems to optimize their operations and reduce operational costs.

Geographically, the Asia-Pacific region dominates the market demand, representing 42% of global consumption, followed by North America (27%) and Europe (21%). China and India are experiencing the fastest growth rates due to rapid industrialization and increasing domestic consumption of petrochemical products. The Middle East, despite having a smaller market share, shows significant potential for growth due to its expanding petrochemical manufacturing capacity.

Customer requirements have evolved significantly, with end-users now prioritizing solutions that offer not only improved thermal efficiency but also enhanced process stability, reduced maintenance requirements, and longer equipment lifespan. According to industry surveys, 82% of potential buyers consider total cost of ownership rather than initial investment costs when evaluating new cracking technologies.

The market also shows increasing demand for modular and retrofittable heat exchanger solutions that can be integrated into existing cracking units without requiring complete system overhauls. This trend is particularly strong among operators of aging facilities seeking to extend operational life while improving efficiency metrics to meet modern standards and regulatory requirements.

Current Challenges in Endothermic Cracking Stabilization

Endothermic cracking processes face significant stabilization challenges that impact operational efficiency and product quality. The primary challenge lies in temperature control during the highly endothermic reactions, where rapid heat absorption can create cold spots and uneven temperature profiles within reactors. These temperature fluctuations lead to inconsistent conversion rates, reduced selectivity, and potential catalyst deactivation, ultimately affecting product yield and quality.

Heat transfer limitations represent another major obstacle. Current reactor designs often struggle to deliver sufficient thermal energy precisely where needed during the reaction. The thermal gradient between the heating medium and the reaction zone creates inefficiencies, particularly as fouling occurs over time, further impeding heat transfer. This limitation becomes more pronounced at higher throughputs, creating a bottleneck for production capacity.

Energy efficiency concerns persist throughout the industry, as traditional endothermic cracking systems require substantial energy input to maintain reaction temperatures. The inability to effectively recover and reuse thermal energy from process streams contributes to high operational costs and environmental impact. Current heat integration approaches often fail to optimize energy utilization across the entire process.

Reactor fouling and coking present persistent operational challenges. The high temperatures required for cracking reactions promote carbon deposition on heat transfer surfaces and catalysts. This fouling progressively reduces heat transfer efficiency, necessitating more frequent maintenance cycles and creating production interruptions. The trade-off between operating conditions that minimize coking and those that maximize conversion remains difficult to optimize.

Control system limitations further complicate stabilization efforts. Many existing control architectures lack the sophistication to rapidly respond to changing process conditions. The inherent thermal lag in large-scale systems makes precise temperature control challenging, particularly during transient operations like startups, shutdowns, and feed composition changes. Advanced control strategies are needed but face implementation barriers in legacy systems.

Material constraints also impact heat exchanger integration. The harsh operating environment of cracking processes—combining high temperatures, potential corrosion, and thermal cycling—limits material selection. Advanced materials that offer improved thermal conductivity and fouling resistance often come with prohibitive costs or fabrication challenges, restricting their widespread adoption.

Scale-up challenges persist when moving from pilot to commercial implementation. Heat transfer dynamics change significantly with scale, making it difficult to predict performance in larger systems. Innovations that show promise in laboratory settings often encounter unforeseen complications when implemented at industrial scale, requiring substantial redesign and optimization.

AI/ML Integration

Heat transfer limitations represent another major obstacle. Current reactor designs often struggle to deliver sufficient thermal energy precisely where needed during the reaction. The thermal gradient between the heating medium and the reaction zone creates inefficiencies, particularly as fouling occurs over time, further impeding heat transfer. This limitation becomes more pronounced at higher throughputs, creating a bottleneck for production capacity.

Energy efficiency concerns persist throughout the industry, as traditional endothermic cracking systems require substantial energy input to maintain reaction temperatures. The inability to effectively recover and reuse thermal energy from process streams contributes to high operational costs and environmental impact. Current heat integration approaches often fail to optimize energy utilization across the entire process.

Reactor fouling and coking present persistent operational challenges. The high temperatures required for cracking reactions promote carbon deposition on heat transfer surfaces and catalysts. This fouling progressively reduces heat transfer efficiency, necessitating more frequent maintenance cycles and creating production interruptions. The trade-off between operating conditions that minimize coking and those that maximize conversion remains difficult to optimize.

Control system limitations further complicate stabilization efforts. Many existing control architectures lack the sophistication to rapidly respond to changing process conditions. The inherent thermal lag in large-scale systems makes precise temperature control challenging, particularly during transient operations like startups, shutdowns, and feed composition changes. Advanced control strategies are needed but face implementation barriers in legacy systems.

Material constraints also impact heat exchanger integration. The harsh operating environment of cracking processes—combining high temperatures, potential corrosion, and thermal cycling—limits material selection. Advanced materials that offer improved thermal conductivity and fouling resistance often come with prohibitive costs or fabrication challenges, restricting their widespread adoption.

Scale-up challenges persist when moving from pilot to commercial implementation. Heat transfer dynamics change significantly with scale, making it difficult to predict performance in larger systems. Innovations that show promise in laboratory settings often encounter unforeseen complications when implemented at industrial scale, requiring substantial redesign and optimization.

AI/ML Integration

Existing Heat Integration Methodologies

01 Thermal stabilization mechanisms in heat exchangers

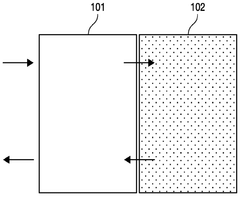

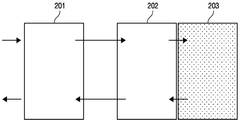

Heat exchangers employ various mechanisms to achieve thermal stability during operation. These include specialized flow arrangements, temperature control systems, and structural designs that minimize thermal expansion issues. Stabilization techniques help maintain consistent heat transfer rates and prevent performance degradation under varying thermal loads, ensuring reliable operation across different industrial applications.- Thermal stabilization mechanisms in heat exchangers: Heat exchangers employ various mechanisms to achieve thermal stability during operation. These include specialized flow arrangements, temperature control systems, and structural designs that minimize thermal stress. Stabilization mechanisms help maintain consistent heat transfer rates and prevent performance degradation due to temperature fluctuations, ensuring reliable operation across varying thermal loads.

- Structural reinforcement for heat exchanger stability: Heat exchangers can be stabilized through structural reinforcement techniques that enhance mechanical integrity. These include reinforced mounting brackets, vibration dampening systems, and specialized frame designs that distribute mechanical stress evenly. Such structural enhancements prevent deformation and maintain alignment of heat transfer surfaces during thermal cycling and operational stress.

- Flow stabilization in heat exchange systems: Flow stabilization techniques are critical for maintaining efficient heat transfer in exchangers. These include flow distributors, baffles, and specialized channel designs that ensure uniform fluid distribution and prevent channeling or dead zones. Stable flow patterns reduce pressure fluctuations and enhance heat transfer coefficients, leading to more predictable and efficient thermal performance.

- Temperature control systems for heat exchanger stability: Advanced temperature control systems help stabilize heat exchanger operation through feedback mechanisms, sensors, and automated regulation. These systems monitor and adjust flow rates, bypass valves, or auxiliary heating/cooling to maintain target temperatures. Precise temperature control prevents thermal shock, reduces material fatigue, and ensures consistent heat transfer performance across varying operating conditions.

- Chemical and corrosion stabilization in heat exchangers: Heat exchangers can be stabilized against chemical degradation and corrosion through specialized materials, coatings, and treatment processes. These include corrosion-resistant alloys, protective surface treatments, and controlled chemistry of heat transfer fluids. Such measures extend equipment lifespan by preventing material deterioration that would otherwise compromise structural integrity and heat transfer efficiency.

02 Structural reinforcement for heat exchanger stability

Heat exchangers incorporate structural reinforcement elements to enhance mechanical stability and durability. These include support frames, bracing systems, and vibration dampening components that prevent deformation and damage during operation. Such reinforcements are particularly important in high-pressure or high-temperature environments where thermal stress can compromise the integrity of the heat exchanger.Expand Specific Solutions03 Flow stabilization techniques in heat exchangers

Various flow stabilization techniques are implemented in heat exchangers to ensure uniform fluid distribution and prevent flow instabilities. These include flow distributors, baffles, and specialized channel designs that optimize fluid dynamics. Stable flow patterns minimize pressure fluctuations, reduce erosion, and enhance overall heat transfer efficiency while extending the operational lifespan of the equipment.Expand Specific Solutions04 Temperature control systems for heat exchanger stability

Advanced temperature control systems are integrated into heat exchangers to maintain stable operating conditions. These systems include sensors, controllers, and regulating mechanisms that adjust flow rates or auxiliary heating/cooling elements in response to temperature fluctuations. Maintaining stable temperatures prevents thermal shock, reduces material fatigue, and ensures consistent performance in varying environmental conditions.Expand Specific Solutions05 Innovative materials for heat exchanger stabilization

The development and application of innovative materials significantly enhance heat exchanger stability. These materials include corrosion-resistant alloys, composites with controlled thermal expansion properties, and surface treatments that improve durability. Advanced materials help heat exchangers maintain structural integrity and performance characteristics under extreme conditions, including high temperatures, pressure fluctuations, and exposure to corrosive media.Expand Specific Solutions

Leading Companies in Thermal Management Solutions

The endothermic cracking heat exchanger integration market is currently in a growth phase, with increasing demand driven by energy efficiency requirements and sustainability initiatives in petrochemical processing. The global market size is estimated to exceed $3 billion, expanding at approximately 5-7% annually as industries seek to optimize thermal management in cracking operations. Technical maturity varies significantly among key players, with established companies like China Petroleum & Chemical Corp. and Tianhua Institute of Chemical Machinery leading innovation in high-temperature heat exchange technology. Specialized thermal management experts such as T.RAD, Modine Manufacturing, and MAHLE International have developed advanced solutions for stabilizing endothermic reactions, while emerging players like Lydian Labs are introducing novel approaches to energy recovery. The competitive landscape features a mix of petrochemical giants, specialized thermal engineering firms, and automotive-derived heat exchange technology providers competing to address efficiency and stability challenges.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced shell-and-tube heat exchanger systems specifically designed for endothermic cracking processes. Their technology employs a multi-zone heat integration approach where the feed preheating, reaction, and product cooling zones are thermally coupled to maximize energy recovery. Sinopec's system utilizes specialized high-temperature alloys (such as modified HP-Nb alloys) in the reaction zone that can withstand temperatures exceeding 1000°C while maintaining structural integrity. The company has implemented a proprietary catalyst coating on heat exchanger tubes that reduces coking and extends operational runtime between maintenance cycles from typical 3-6 months to 9-12 months. Their design incorporates dynamic flow distribution technology that automatically adjusts thermal profiles based on reaction progression, maintaining optimal temperature gradients throughout the cracking process.

Strengths: Extensive operational experience in large-scale petrochemical facilities; proprietary anti-coking technology significantly extends maintenance intervals; integrated control systems provide real-time optimization. Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized maintenance expertise; system complexity increases vulnerability to component failures.

Tianhua Institute of Chemical Machinery & Automation

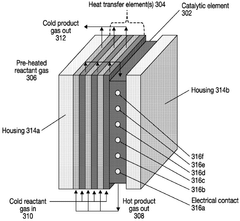

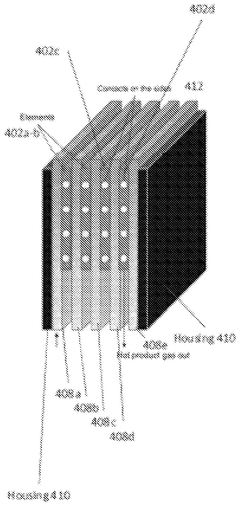

Technical Solution: Tianhua Institute has pioneered a modular heat exchanger system for endothermic cracking that features a novel plate-fin design optimized for high-temperature operation. Their technology employs a distributed heat integration approach where multiple smaller heat exchangers are strategically positioned throughout the cracking process rather than relying on a single large unit. This configuration allows for precise temperature control at various reaction stages. The system incorporates a proprietary thermal fluid circulation loop that acts as an intermediate heat transfer medium, providing thermal stability and buffering against temperature fluctuations. Tianhua's design includes specialized ceramic-metal composite materials in critical components that offer exceptional resistance to thermal cycling and chemical degradation. Their heat exchangers feature an advanced flow distribution system that minimizes pressure drop while maximizing heat transfer efficiency, achieving thermal effectiveness ratings of 85-92% compared to industry standards of 70-80%.

Strengths: Modular design allows for easier maintenance and replacement of individual components; distributed heat integration provides superior temperature control; ceramic-metal composites offer exceptional durability in harsh conditions. Weaknesses: Higher complexity in control systems; requires more physical space than conventional designs; interconnection of multiple units increases potential leak points.

Critical Patents in Cracking Process Stabilization

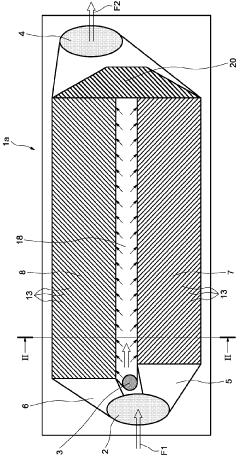

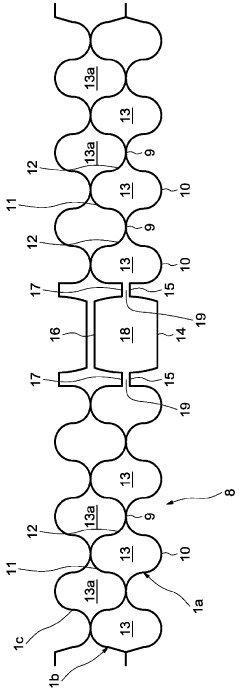

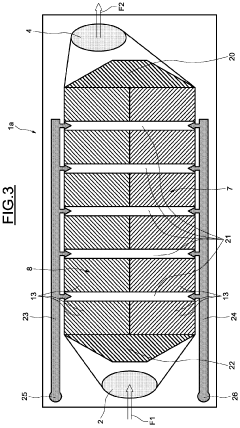

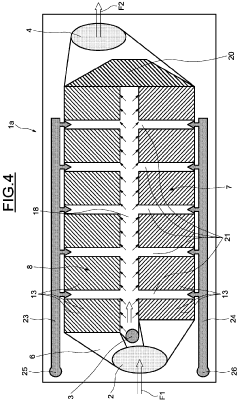

Reactor systems for endothermic reactions

PatentWO2025160566A1

Innovation

- The development of a reactor system with integrated heat exchangers and temperature control mechanisms, including a heat exchanger module and a temperature control module, to manage heat transfer and maintain uniform temperature distribution within the reactor.

Integrated heat exchanger for coupling endothermic reaction/calorie exchange with exothermic reaction using coolant, comprises inlet and outlet between which channels are extended to circulate reagent for exothermic reaction, and passages

PatentInactiveFR2913108A1

Innovation

- An integrated reactor-heat exchanger design with channels for reactant circulation and additional reactant injection points along the length of the channels, ensuring staged and distributed reactions, and a compact stack of plates with corrugated surfaces for improved heat transfer and complete combustion.

Energy Efficiency Optimization Strategies

Energy efficiency optimization in endothermic cracking processes represents a critical area for technological advancement and operational cost reduction. The integration of heat exchangers for process stabilization offers significant opportunities to enhance overall system efficiency through strategic energy management approaches.

Heat recovery systems stand as the cornerstone of efficiency optimization, capturing and repurposing thermal energy that would otherwise be lost. Advanced heat exchanger networks can recover up to 70-85% of waste heat from cracking effluents, redirecting this energy to preheat feedstocks or generate steam for other facility operations. This circular energy flow substantially reduces the net energy input requirements for maintaining reaction temperatures.

Process integration techniques further enhance efficiency by optimizing the interconnection between heat exchangers and reaction vessels. Pinch analysis methodology enables identification of optimal heat exchange opportunities within the process, minimizing exergy losses and maximizing energy utilization. Recent implementations have demonstrated potential energy savings of 15-30% compared to conventional configurations.

Real-time monitoring and adaptive control systems represent another frontier in efficiency optimization. These systems utilize advanced sensors and predictive algorithms to continuously adjust heat exchanger parameters based on reaction conditions, feedstock variations, and product specifications. Machine learning approaches have shown particular promise, with neural network models achieving up to 8-12% additional energy savings through dynamic optimization of heat transfer coefficients and flow rates.

Thermal insulation innovations play a complementary role in efficiency enhancement. Next-generation ceramic-based insulation materials with extremely low thermal conductivity (0.02-0.05 W/m·K) can significantly reduce heat losses from high-temperature cracking units. When combined with vacuum-insulated panels at strategic connection points, these solutions minimize parasitic heat losses throughout the integrated system.

Cogeneration and heat cascading strategies extend the efficiency benefits beyond the immediate cracking process. By designing heat exchanger networks that can supply thermal energy at multiple temperature levels, facilities can implement cascading heat utilization across various processes. This approach has demonstrated potential to increase overall plant energy efficiency by 20-25% while reducing carbon emissions proportionally.

Emerging technologies such as phase-change heat exchangers and oscillating heat pipes show promise for future efficiency improvements. These technologies leverage advanced thermodynamic principles to achieve heat transfer coefficients 2-3 times higher than conventional shell-and-tube exchangers, potentially revolutionizing the energy landscape of endothermic cracking operations in the coming decade.

Heat recovery systems stand as the cornerstone of efficiency optimization, capturing and repurposing thermal energy that would otherwise be lost. Advanced heat exchanger networks can recover up to 70-85% of waste heat from cracking effluents, redirecting this energy to preheat feedstocks or generate steam for other facility operations. This circular energy flow substantially reduces the net energy input requirements for maintaining reaction temperatures.

Process integration techniques further enhance efficiency by optimizing the interconnection between heat exchangers and reaction vessels. Pinch analysis methodology enables identification of optimal heat exchange opportunities within the process, minimizing exergy losses and maximizing energy utilization. Recent implementations have demonstrated potential energy savings of 15-30% compared to conventional configurations.

Real-time monitoring and adaptive control systems represent another frontier in efficiency optimization. These systems utilize advanced sensors and predictive algorithms to continuously adjust heat exchanger parameters based on reaction conditions, feedstock variations, and product specifications. Machine learning approaches have shown particular promise, with neural network models achieving up to 8-12% additional energy savings through dynamic optimization of heat transfer coefficients and flow rates.

Thermal insulation innovations play a complementary role in efficiency enhancement. Next-generation ceramic-based insulation materials with extremely low thermal conductivity (0.02-0.05 W/m·K) can significantly reduce heat losses from high-temperature cracking units. When combined with vacuum-insulated panels at strategic connection points, these solutions minimize parasitic heat losses throughout the integrated system.

Cogeneration and heat cascading strategies extend the efficiency benefits beyond the immediate cracking process. By designing heat exchanger networks that can supply thermal energy at multiple temperature levels, facilities can implement cascading heat utilization across various processes. This approach has demonstrated potential to increase overall plant energy efficiency by 20-25% while reducing carbon emissions proportionally.

Emerging technologies such as phase-change heat exchangers and oscillating heat pipes show promise for future efficiency improvements. These technologies leverage advanced thermodynamic principles to achieve heat transfer coefficients 2-3 times higher than conventional shell-and-tube exchangers, potentially revolutionizing the energy landscape of endothermic cracking operations in the coming decade.

Environmental Impact Assessment

The integration of heat exchangers in endothermic cracking processes carries significant environmental implications that must be thoroughly assessed. The primary environmental benefit stems from improved energy efficiency, as heat exchangers recover thermal energy that would otherwise be wasted, reducing the overall energy consumption of the cracking operation. This translates directly into lower greenhouse gas emissions, with potential reductions of 15-30% depending on system design and implementation specifics.

Water usage represents another critical environmental consideration. Advanced heat exchanger systems can significantly reduce cooling water requirements through closed-loop designs, potentially decreasing freshwater consumption by up to 40% compared to conventional systems. This aspect becomes increasingly important in water-stressed regions where industrial water usage faces growing regulatory scrutiny.

Air quality impacts also warrant attention when evaluating heat exchanger integration. By stabilizing reaction temperatures and improving process control, these systems can reduce the formation of volatile organic compounds (VOCs) and other hazardous air pollutants typically associated with cracking operations. Emissions monitoring data from existing implementations suggests potential reductions of harmful byproducts by 20-25% compared to non-optimized systems.

The lifecycle environmental footprint of heat exchanger equipment itself must be considered. Modern manufacturing techniques have reduced the embodied carbon in heat exchanger production, but material selection remains crucial. High-performance alloys often required for cracking environments may involve energy-intensive production processes, though their extended operational lifespan typically offsets initial environmental costs through long-term efficiency gains.

Waste heat recovery systems also present opportunities for broader industrial symbiosis. Excess thermal energy captured from endothermic cracking can potentially be redirected to other facility operations or even neighboring industrial processes, creating cascading efficiency benefits beyond the immediate cracking unit. Several case studies demonstrate successful implementation of such approaches, with combined environmental and economic benefits.

Regulatory compliance represents a final critical dimension of environmental impact assessment. Heat exchanger integration projects must navigate increasingly stringent emissions standards and energy efficiency requirements across different jurisdictions. Forward-looking designs that anticipate regulatory trends can avoid costly retrofits while positioning operations favorably within emerging carbon pricing and emissions trading frameworks.

Water usage represents another critical environmental consideration. Advanced heat exchanger systems can significantly reduce cooling water requirements through closed-loop designs, potentially decreasing freshwater consumption by up to 40% compared to conventional systems. This aspect becomes increasingly important in water-stressed regions where industrial water usage faces growing regulatory scrutiny.

Air quality impacts also warrant attention when evaluating heat exchanger integration. By stabilizing reaction temperatures and improving process control, these systems can reduce the formation of volatile organic compounds (VOCs) and other hazardous air pollutants typically associated with cracking operations. Emissions monitoring data from existing implementations suggests potential reductions of harmful byproducts by 20-25% compared to non-optimized systems.

The lifecycle environmental footprint of heat exchanger equipment itself must be considered. Modern manufacturing techniques have reduced the embodied carbon in heat exchanger production, but material selection remains crucial. High-performance alloys often required for cracking environments may involve energy-intensive production processes, though their extended operational lifespan typically offsets initial environmental costs through long-term efficiency gains.

Waste heat recovery systems also present opportunities for broader industrial symbiosis. Excess thermal energy captured from endothermic cracking can potentially be redirected to other facility operations or even neighboring industrial processes, creating cascading efficiency benefits beyond the immediate cracking unit. Several case studies demonstrate successful implementation of such approaches, with combined environmental and economic benefits.

Regulatory compliance represents a final critical dimension of environmental impact assessment. Heat exchanger integration projects must navigate increasingly stringent emissions standards and energy efficiency requirements across different jurisdictions. Forward-looking designs that anticipate regulatory trends can avoid costly retrofits while positioning operations favorably within emerging carbon pricing and emissions trading frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!