Ammonia-to-Power: SOFC Integration and System Controls

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia-to-Power Technology Background and Objectives

Ammonia has emerged as a promising energy carrier in the global transition towards sustainable energy systems. The concept of Ammonia-to-Power represents a significant pathway for utilizing ammonia as an energy vector, with Solid Oxide Fuel Cell (SOFC) technology playing a pivotal role in this transformation. The historical development of this technology can be traced back to the early 2000s when researchers began exploring ammonia as an alternative fuel source due to its high energy density and zero-carbon emission potential when produced from renewable sources.

The evolution of Ammonia-to-Power technology has accelerated significantly in the past decade, driven by the urgent need for decarbonization across various sectors. The integration of SOFCs with ammonia fuel systems represents a convergence of two mature technologies to address contemporary energy challenges. SOFCs, known for their high electrical efficiency and fuel flexibility, have demonstrated capability to utilize ammonia directly or through cracking processes, making them ideal candidates for ammonia-based power generation.

The primary technical objective in this field is to develop efficient, reliable, and cost-effective systems that can convert ammonia into electrical power with minimal environmental impact. This involves optimizing the SOFC stack design for ammonia utilization, developing robust system controls to manage the complex thermochemical processes, and ensuring safe operation under various load conditions.

Another critical goal is to enhance system integration, addressing challenges related to ammonia cracking, thermal management, and balance of plant components. The technology aims to achieve electrical efficiencies exceeding 60%, significantly higher than conventional power generation methods, while maintaining operational stability over extended periods.

Research trends indicate a growing focus on developing advanced catalysts for ammonia decomposition at lower temperatures, innovative SOFC materials capable of direct ammonia oxidation, and sophisticated control algorithms to optimize system performance across varying operational scenarios. The field is also witnessing increased attention to hybrid systems that combine SOFCs with other technologies such as gas turbines to further enhance overall system efficiency.

The long-term vision for Ammonia-to-Power technology encompasses its deployment across multiple scales, from distributed generation systems for remote communities to large-scale power plants supporting grid stability. Additionally, there is significant interest in mobile applications, particularly in the maritime sector where ammonia is being considered as a potential fuel for long-distance shipping.

As global efforts to reduce carbon emissions intensify, Ammonia-to-Power systems with SOFC integration represent a technologically viable pathway to utilize green ammonia produced from renewable electricity, water, and air, thus completing a truly sustainable energy cycle.

The evolution of Ammonia-to-Power technology has accelerated significantly in the past decade, driven by the urgent need for decarbonization across various sectors. The integration of SOFCs with ammonia fuel systems represents a convergence of two mature technologies to address contemporary energy challenges. SOFCs, known for their high electrical efficiency and fuel flexibility, have demonstrated capability to utilize ammonia directly or through cracking processes, making them ideal candidates for ammonia-based power generation.

The primary technical objective in this field is to develop efficient, reliable, and cost-effective systems that can convert ammonia into electrical power with minimal environmental impact. This involves optimizing the SOFC stack design for ammonia utilization, developing robust system controls to manage the complex thermochemical processes, and ensuring safe operation under various load conditions.

Another critical goal is to enhance system integration, addressing challenges related to ammonia cracking, thermal management, and balance of plant components. The technology aims to achieve electrical efficiencies exceeding 60%, significantly higher than conventional power generation methods, while maintaining operational stability over extended periods.

Research trends indicate a growing focus on developing advanced catalysts for ammonia decomposition at lower temperatures, innovative SOFC materials capable of direct ammonia oxidation, and sophisticated control algorithms to optimize system performance across varying operational scenarios. The field is also witnessing increased attention to hybrid systems that combine SOFCs with other technologies such as gas turbines to further enhance overall system efficiency.

The long-term vision for Ammonia-to-Power technology encompasses its deployment across multiple scales, from distributed generation systems for remote communities to large-scale power plants supporting grid stability. Additionally, there is significant interest in mobile applications, particularly in the maritime sector where ammonia is being considered as a potential fuel for long-distance shipping.

As global efforts to reduce carbon emissions intensify, Ammonia-to-Power systems with SOFC integration represent a technologically viable pathway to utilize green ammonia produced from renewable electricity, water, and air, thus completing a truly sustainable energy cycle.

Market Analysis for Ammonia-Based Power Generation

The global market for ammonia-based power generation is experiencing significant growth, driven by the increasing focus on decarbonization and the search for sustainable energy alternatives. Current market valuations estimate the ammonia power generation sector to reach approximately $2.5 billion by 2030, with a compound annual growth rate of 12.7% from 2023 to 2030. This growth trajectory is supported by substantial investments in green ammonia production facilities worldwide, particularly in regions with abundant renewable energy resources.

The demand for ammonia as an energy carrier is primarily fueled by its potential as a hydrogen carrier and carbon-free fuel. Industrial sectors, particularly shipping and heavy industry, represent the largest market segments due to their need for high-density energy storage solutions that can enable long-duration operations. The maritime industry alone could consume up to 45 million tons of ammonia annually by 2035 if adoption rates follow projected patterns.

Regional analysis reveals varying market dynamics. Europe leads in terms of policy support and research funding, with countries like Germany, Denmark, and the Netherlands investing heavily in ammonia-based power systems. The Asia-Pacific region, particularly Japan, South Korea, and Australia, demonstrates the fastest growth rate due to strategic national hydrogen initiatives and limited domestic energy resources. North America shows strong research activity but more moderate commercial deployment compared to other regions.

Market barriers include the current high cost of green ammonia production, which remains 2-3 times more expensive than conventional methods. Infrastructure limitations present another significant challenge, as specialized storage, transportation, and handling facilities are required for ammonia's widespread adoption as an energy carrier.

Customer segmentation analysis indicates three primary market segments: utility-scale power generation, industrial power applications, and maritime propulsion systems. The utility segment values grid stability and dispatchable power capabilities, while industrial users prioritize reliability and compatibility with existing systems. Maritime applications focus on energy density and compliance with emerging emissions regulations.

Competitive analysis reveals that traditional power generation equipment manufacturers are increasingly entering this space, alongside specialized startups focused exclusively on ammonia-to-power technologies. Strategic partnerships between technology developers, ammonia producers, and end-users are becoming increasingly common, creating integrated value chains that address both supply and demand challenges.

The demand for ammonia as an energy carrier is primarily fueled by its potential as a hydrogen carrier and carbon-free fuel. Industrial sectors, particularly shipping and heavy industry, represent the largest market segments due to their need for high-density energy storage solutions that can enable long-duration operations. The maritime industry alone could consume up to 45 million tons of ammonia annually by 2035 if adoption rates follow projected patterns.

Regional analysis reveals varying market dynamics. Europe leads in terms of policy support and research funding, with countries like Germany, Denmark, and the Netherlands investing heavily in ammonia-based power systems. The Asia-Pacific region, particularly Japan, South Korea, and Australia, demonstrates the fastest growth rate due to strategic national hydrogen initiatives and limited domestic energy resources. North America shows strong research activity but more moderate commercial deployment compared to other regions.

Market barriers include the current high cost of green ammonia production, which remains 2-3 times more expensive than conventional methods. Infrastructure limitations present another significant challenge, as specialized storage, transportation, and handling facilities are required for ammonia's widespread adoption as an energy carrier.

Customer segmentation analysis indicates three primary market segments: utility-scale power generation, industrial power applications, and maritime propulsion systems. The utility segment values grid stability and dispatchable power capabilities, while industrial users prioritize reliability and compatibility with existing systems. Maritime applications focus on energy density and compliance with emerging emissions regulations.

Competitive analysis reveals that traditional power generation equipment manufacturers are increasingly entering this space, alongside specialized startups focused exclusively on ammonia-to-power technologies. Strategic partnerships between technology developers, ammonia producers, and end-users are becoming increasingly common, creating integrated value chains that address both supply and demand challenges.

SOFC Integration Technical Challenges and Constraints

The integration of Solid Oxide Fuel Cells (SOFCs) into ammonia-to-power systems presents significant technical challenges that must be addressed for successful implementation. One primary constraint is the high operating temperature requirement of SOFCs, typically between 600-1000°C, which necessitates specialized materials capable of withstanding thermal cycling and prolonged exposure to extreme temperatures without degradation or failure.

Material compatibility issues arise at these elevated temperatures, particularly at the interface between different components such as electrodes, electrolytes, and interconnects. The thermal expansion coefficient mismatch between these materials can lead to mechanical stress, cracking, and ultimately system failure over time. Additionally, the sealing technology must maintain gas-tight integrity across thermal cycles while preventing cross-contamination between fuel and oxidant streams.

Ammonia cracking for hydrogen production introduces another layer of complexity. The cracking process, which converts NH3 to N2 and H2, requires precise temperature control and effective catalysts. Integration of this process with the SOFC stack demands careful thermal management to utilize waste heat efficiently while preventing thermal runaway scenarios that could damage the system.

System control represents a significant technical hurdle, as SOFCs exhibit slow start-up and shutdown characteristics due to their high operating temperatures. This limits load-following capabilities and requires sophisticated control algorithms to manage transient operations. The control system must balance ammonia flow rates, cracking efficiency, and SOFC operating parameters to maintain optimal performance while preventing harmful conditions such as carbon deposition or catalyst poisoning.

Durability and longevity constraints are particularly challenging in ammonia-powered SOFCs. Trace impurities in ammonia feedstock can cause progressive degradation of electrodes and catalysts. Nitrogen compounds may interact with electrode materials, potentially causing performance losses over time. Current SOFC systems typically demonstrate degradation rates of 0.5-2% per 1000 hours, which must be improved for commercial viability.

Scale-up considerations present additional constraints, as laboratory-scale demonstrations often fail to translate directly to industrial applications. Heat management becomes increasingly complex at larger scales, requiring innovative approaches to maintain temperature uniformity across larger cell areas and stacks. The balance of plant components must be properly sized and integrated to support efficient operation while minimizing parasitic losses.

Cost remains a significant barrier to widespread adoption, with current SOFC systems costing approximately $3000-5000 per kilowatt. The integration with ammonia processing equipment adds further capital expenses. Reducing these costs while maintaining performance and reliability represents a critical challenge for commercial deployment of ammonia-to-power SOFC systems.

Material compatibility issues arise at these elevated temperatures, particularly at the interface between different components such as electrodes, electrolytes, and interconnects. The thermal expansion coefficient mismatch between these materials can lead to mechanical stress, cracking, and ultimately system failure over time. Additionally, the sealing technology must maintain gas-tight integrity across thermal cycles while preventing cross-contamination between fuel and oxidant streams.

Ammonia cracking for hydrogen production introduces another layer of complexity. The cracking process, which converts NH3 to N2 and H2, requires precise temperature control and effective catalysts. Integration of this process with the SOFC stack demands careful thermal management to utilize waste heat efficiently while preventing thermal runaway scenarios that could damage the system.

System control represents a significant technical hurdle, as SOFCs exhibit slow start-up and shutdown characteristics due to their high operating temperatures. This limits load-following capabilities and requires sophisticated control algorithms to manage transient operations. The control system must balance ammonia flow rates, cracking efficiency, and SOFC operating parameters to maintain optimal performance while preventing harmful conditions such as carbon deposition or catalyst poisoning.

Durability and longevity constraints are particularly challenging in ammonia-powered SOFCs. Trace impurities in ammonia feedstock can cause progressive degradation of electrodes and catalysts. Nitrogen compounds may interact with electrode materials, potentially causing performance losses over time. Current SOFC systems typically demonstrate degradation rates of 0.5-2% per 1000 hours, which must be improved for commercial viability.

Scale-up considerations present additional constraints, as laboratory-scale demonstrations often fail to translate directly to industrial applications. Heat management becomes increasingly complex at larger scales, requiring innovative approaches to maintain temperature uniformity across larger cell areas and stacks. The balance of plant components must be properly sized and integrated to support efficient operation while minimizing parasitic losses.

Cost remains a significant barrier to widespread adoption, with current SOFC systems costing approximately $3000-5000 per kilowatt. The integration with ammonia processing equipment adds further capital expenses. Reducing these costs while maintaining performance and reliability represents a critical challenge for commercial deployment of ammonia-to-power SOFC systems.

Current SOFC System Control Solutions

01 SOFC control systems for ammonia-to-power conversion

Control systems for Solid Oxide Fuel Cells (SOFCs) in ammonia-to-power applications focus on optimizing the electrochemical conversion process. These systems monitor and adjust operating parameters such as temperature, fuel flow rate, and electrical load to maintain stable operation and maximize efficiency. Advanced control algorithms can adapt to varying ammonia feed conditions while preventing degradation of cell components, ensuring reliable power generation from ammonia fuel.- SOFC system control for ammonia-to-power conversion: Control systems for Solid Oxide Fuel Cells (SOFCs) in ammonia-to-power applications focus on optimizing the electrochemical conversion of ammonia to electricity. These systems monitor and regulate key parameters such as temperature, fuel flow rates, and electrical output to maintain stable operation and maximize efficiency. Advanced control algorithms can adjust operating conditions in real-time to respond to load changes while preventing damage to the fuel cell stack.

- Thermal management and heat integration in ammonia SOFC systems: Thermal management is critical in ammonia-powered SOFC systems to maintain optimal operating temperatures (typically 600-900°C) required for efficient ammonia cracking and electrochemical reactions. Control systems regulate heat exchangers, insulation systems, and cooling mechanisms to balance heat generation and dissipation. Effective thermal integration recovers waste heat from the exhaust stream to preheat incoming ammonia fuel, significantly improving overall system efficiency and reducing startup times.

- Ammonia cracking and hydrogen feed control for SOFC: Control systems for ammonia cracking processes in SOFC applications regulate the conversion of ammonia to hydrogen and nitrogen before electrochemical utilization. These systems monitor catalyst temperatures, ammonia flow rates, and cracking efficiency to ensure optimal hydrogen production. Advanced sensors and feedback loops adjust process parameters to maintain stable hydrogen feed to the fuel cell stack while minimizing unconverted ammonia that could poison catalysts or reduce efficiency.

- Grid integration and load management for ammonia SOFC power systems: Control systems for grid-connected ammonia SOFC power systems manage the interface between the fuel cell and the electrical grid. These systems regulate power output, voltage, and frequency to meet grid requirements while optimizing fuel cell performance. Advanced power electronics and control algorithms enable dynamic response to changing load demands, grid conditions, and market signals, allowing ammonia-based SOFC systems to provide grid services such as frequency regulation and peak shaving.

- Safety and emissions control in ammonia-to-power SOFC systems: Safety control systems for ammonia-powered SOFCs monitor for ammonia leaks, manage nitrogen oxide emissions, and prevent hazardous operating conditions. These systems incorporate multiple safety layers including gas detection sensors, automatic shutdown protocols, and pressure relief mechanisms. Emissions control subsystems regulate the combustion process of any unconverted fuel to minimize environmental impact, while continuous monitoring ensures compliance with emissions standards and safe operation throughout the system's lifecycle.

02 Thermal management in ammonia-powered SOFC systems

Thermal management is critical in ammonia-powered SOFC systems to maintain optimal operating temperatures (typically 600-900°C) required for efficient ammonia cracking and electrochemical reactions. Control systems regulate heat distribution across the stack, manage startup/shutdown thermal cycles, and coordinate heat recovery from exhaust gases. Effective thermal management prevents thermal stress, extends cell lifetime, and improves overall system efficiency by utilizing waste heat for ammonia processing or additional power generation.Expand Specific Solutions03 Ammonia cracking and reforming control for SOFC integration

Control systems for ammonia cracking and reforming processes are essential for SOFC integration. These systems regulate catalytic decomposition of ammonia into hydrogen and nitrogen at appropriate temperatures and pressures before feeding to the fuel cell. Precise control of the cracking process prevents ammonia slip to the SOFC stack, optimizes hydrogen production rates, and manages potential catalyst poisoning. Advanced sensors and feedback loops ensure consistent fuel quality regardless of varying input conditions or system load demands.Expand Specific Solutions04 Grid integration and load management for ammonia-SOFC power systems

Control systems for grid integration enable ammonia-SOFC power systems to respond to varying electrical demands and interact with existing power infrastructure. These controls manage power conditioning, synchronization with grid frequency, and load following capabilities. The systems can optimize operation based on grid demand signals, electricity pricing, or renewable energy availability. Advanced control architectures allow for islanded operation, grid support services, and seamless transitions between different operating modes to maximize economic and technical performance.Expand Specific Solutions05 Safety and emissions control in ammonia-SOFC systems

Safety and emissions control systems are crucial for ammonia-SOFC power generation due to ammonia's toxicity and potential NOx formation. These control systems monitor for ammonia leaks, manage purge cycles, and ensure complete ammonia utilization or proper exhaust treatment. Automated safety protocols handle emergency shutdowns, system purging, and fault detection. Emissions control strategies focus on minimizing nitrogen oxide formation through precise temperature and air-fuel ratio management, ensuring environmentally compliant operation while maintaining system efficiency.Expand Specific Solutions

Leading Companies in Ammonia Fuel Cell Industry

The ammonia-to-power SOFC integration market is currently in an early growth phase, characterized by increasing commercial interest but limited widespread deployment. The global market size is projected to expand significantly as hydrogen economy initiatives gain momentum, with estimates suggesting a compound annual growth rate exceeding 25% through 2030. Technologically, solid oxide fuel cell integration with ammonia systems is advancing rapidly, with industry leaders like Bloom Energy Corp. demonstrating commercial-scale solutions with enhanced efficiency. Other key players including Toshiba Corp., Linde GmbH, and Nissan Motor Co. are making significant R&D investments, while academic institutions such as Fuzhou University and Huazhong University of Science & Technology are contributing breakthrough research in catalysis and system controls. The technology is approaching commercial maturity with remaining challenges in durability, cost reduction, and system integration.

Bloom Energy Corp.

Technical Solution: Bloom Energy has developed a proprietary solid oxide fuel cell (SOFC) technology that can directly utilize ammonia as a fuel source through their Energy Server platform. Their system incorporates an integrated ammonia cracker that thermally decomposes NH3 into nitrogen and hydrogen at temperatures above 650°C, which aligns perfectly with SOFC operating temperatures (700-900°C). The company's modular architecture allows for flexible scaling from 100kW to multi-megawatt installations while maintaining high electrical efficiency (>60% LHV). Their control system features advanced thermal management that utilizes waste heat from the SOFC stack to drive the endothermic ammonia cracking reaction, creating a thermally self-sustaining system once operational. Bloom's proprietary zirconia-based electrolyte formulation demonstrates enhanced tolerance to potential ammonia slip and nitrogen oxide formation compared to conventional SOFCs, extending stack lifetime to 5+ years even when operating with ammonia fuel.

Strengths: Industry-leading electrical efficiency when operating on ammonia (>60% LHV), modular design allowing for flexible deployment, and proprietary cell materials with enhanced durability when exposed to ammonia decomposition products. Weaknesses: Higher capital costs compared to conventional power generation, requires sophisticated control systems to manage thermal integration between ammonia cracking and SOFC operation, and potential performance degradation over time due to trace impurities in ammonia feedstock.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed an advanced ammonia-to-power SOFC system that leverages their expertise in catalysis and energy systems integration. Their approach centers on a novel dual-layer anode structure that facilitates direct internal ammonia decomposition while minimizing nitrogen oxide formation. The system incorporates Shell's proprietary ammonia purification technology that removes trace contaminants known to degrade SOFC performance over time. Their integrated control architecture features predictive maintenance capabilities through continuous electrochemical impedance spectroscopy monitoring, allowing real-time assessment of cell health and performance. Shell's system employs a modular design philosophy with standardized 50kW SOFC units that can be combined to create installations ranging from hundreds of kilowatts to multiple megawatts. The company has demonstrated stable operation exceeding 10,000 hours with degradation rates below 0.3% per 1000 hours when operating on industrial-grade ammonia, positioning their technology as particularly suitable for remote power applications and maritime installations where ammonia is increasingly considered as a carbon-free fuel option.

Strengths: Exceptional long-term stability with industry-leading low degradation rates, sophisticated real-time monitoring system for predictive maintenance, and extensive experience with ammonia purification technology. Weaknesses: Higher initial capital costs compared to conventional power generation, requires specialized technical expertise for maintenance and operation, and optimal performance depends on proprietary ammonia purification processes.

Key Patents in Ammonia-to-Power SOFC Integration

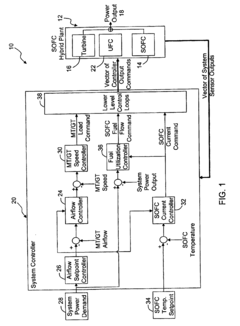

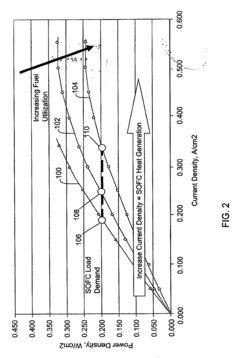

Methods and apparatus for controlled solid oxide fuel cell (SOFC)/turbine hybrid power generation

PatentActiveEP1713141B1

Innovation

- A system controller coordinates the operation of SOFC and turbine generators, regulating parameters like airflow, fuel flow, and temperature to maintain a predetermined SOFC temperature setpoint and ensure stable power output, using lower-level control loops and feedback structures to manage thermal and electrical outputs.

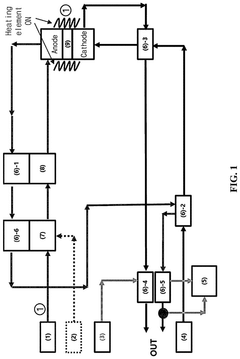

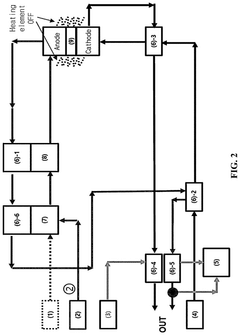

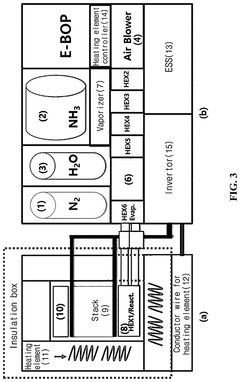

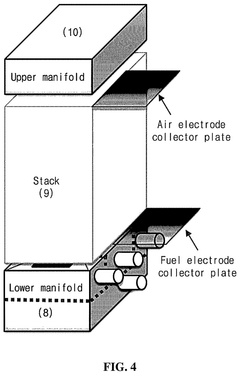

Ammonia-based solid oxide fuel cell (SOFC) system in which temperature rise using heating element is applied, and operation method therefor

PatentActiveUS20240332571A1

Innovation

- An ammonia-based SOFC system with an integrated stack-reformer configuration, where a heating element raises the temperature of the fuel cell stack and manifold, using a catalyst-filled fuel supply line for ammonia reforming, eliminating the need for a separate reformer and burner, and employing an electric heating element for environmentally friendly operation.

Environmental Impact Assessment of Ammonia Power Systems

The environmental impact assessment of ammonia power systems reveals a complex interplay between potential benefits and challenges. Ammonia (NH3) as a carbon-free hydrogen carrier offers significant advantages in reducing greenhouse gas emissions compared to conventional fossil fuel power generation. When utilized in Solid Oxide Fuel Cell (SOFC) systems, ammonia-to-power pathways can achieve theoretical efficiency rates of 60-70%, substantially higher than traditional combustion methods.

However, the environmental profile must be evaluated across the entire lifecycle. Ammonia production currently relies heavily on the Haber-Bosch process, which is energy-intensive and predominantly powered by natural gas, resulting in substantial CO2 emissions. Approximately 1.5-3 tons of CO2 are produced per ton of ammonia manufactured using conventional methods. The transition to green ammonia production using renewable electricity sources remains crucial for realizing the full environmental benefits.

SOFC integration with ammonia presents distinct environmental advantages over direct combustion alternatives. The electrochemical conversion process in SOFCs eliminates NOx formation during power generation, a significant concern with ammonia combustion. System controls in SOFC setups further optimize this benefit by precisely managing operating parameters such as temperature, fuel utilization, and air-fuel ratios.

Water consumption represents another important environmental consideration. SOFC systems typically require less cooling water than conventional thermal power plants, reducing water resource pressure. However, the production of green ammonia via electrolysis demands substantial water inputs, potentially creating resource competition in water-scarce regions.

Land use impacts vary significantly based on system configuration. Centralized ammonia-to-power facilities may have concentrated environmental footprints, while distributed generation models using ammonia fuel cells could minimize land disturbance. The transportation infrastructure for ammonia distribution must also be factored into comprehensive environmental assessments.

Material sustainability presents both challenges and opportunities. SOFCs utilize rare earth elements and specialized materials that raise resource depletion and supply chain concerns. Developing recycling pathways for these components will be essential for long-term sustainability. Conversely, ammonia's established global transportation infrastructure offers environmental advantages over developing new hydrogen transport systems.

Risk assessment studies indicate that while ammonia presents toxicity hazards, properly engineered SOFC systems with advanced controls can mitigate these risks through leak detection, automated shutdown protocols, and containment systems. These safety measures must be balanced against additional resource requirements for their implementation.

However, the environmental profile must be evaluated across the entire lifecycle. Ammonia production currently relies heavily on the Haber-Bosch process, which is energy-intensive and predominantly powered by natural gas, resulting in substantial CO2 emissions. Approximately 1.5-3 tons of CO2 are produced per ton of ammonia manufactured using conventional methods. The transition to green ammonia production using renewable electricity sources remains crucial for realizing the full environmental benefits.

SOFC integration with ammonia presents distinct environmental advantages over direct combustion alternatives. The electrochemical conversion process in SOFCs eliminates NOx formation during power generation, a significant concern with ammonia combustion. System controls in SOFC setups further optimize this benefit by precisely managing operating parameters such as temperature, fuel utilization, and air-fuel ratios.

Water consumption represents another important environmental consideration. SOFC systems typically require less cooling water than conventional thermal power plants, reducing water resource pressure. However, the production of green ammonia via electrolysis demands substantial water inputs, potentially creating resource competition in water-scarce regions.

Land use impacts vary significantly based on system configuration. Centralized ammonia-to-power facilities may have concentrated environmental footprints, while distributed generation models using ammonia fuel cells could minimize land disturbance. The transportation infrastructure for ammonia distribution must also be factored into comprehensive environmental assessments.

Material sustainability presents both challenges and opportunities. SOFCs utilize rare earth elements and specialized materials that raise resource depletion and supply chain concerns. Developing recycling pathways for these components will be essential for long-term sustainability. Conversely, ammonia's established global transportation infrastructure offers environmental advantages over developing new hydrogen transport systems.

Risk assessment studies indicate that while ammonia presents toxicity hazards, properly engineered SOFC systems with advanced controls can mitigate these risks through leak detection, automated shutdown protocols, and containment systems. These safety measures must be balanced against additional resource requirements for their implementation.

Scalability and Grid Integration Considerations

The scalability of ammonia-to-power systems utilizing Solid Oxide Fuel Cell (SOFC) technology represents a critical factor in their commercial viability and widespread adoption. Current SOFC systems for ammonia conversion typically operate at capacities ranging from 1kW to 250kW, with limited examples of larger installations. Scaling these systems to megawatt-level capacities necessary for grid-scale implementation requires modular approaches, where multiple SOFC stacks operate in parallel configurations with integrated control systems.

Grid integration of ammonia-based SOFC systems presents unique challenges compared to conventional power generation technologies. The electrochemical nature of SOFCs results in different response characteristics to load changes, with typical ramp rates of 2-5% per minute compared to 7-10% for natural gas turbines. This relatively slow response necessitates hybrid system designs incorporating energy storage solutions such as batteries or supercapacitors to manage transient loads and provide grid services.

Power quality considerations are paramount when connecting ammonia-SOFC systems to existing electrical infrastructure. The DC power generated by fuel cells requires sophisticated power conditioning systems including inverters with advanced control algorithms to ensure compliance with grid codes regarding frequency stability, voltage regulation, and harmonic distortion. Modern grid-connected SOFC systems achieve power quality metrics with total harmonic distortion below 3%, meeting IEEE 1547 standards.

Distributed generation models offer promising pathways for ammonia-SOFC deployment, particularly in microgrids and isolated power systems. These applications benefit from ammonia's storage capabilities, enabling seasonal energy storage that addresses intermittency challenges of renewable energy sources. Case studies from Japan's SIP Energy Carriers program demonstrate successful integration of 5-50kW ammonia-SOFC systems in microgrid environments, achieving system efficiencies of 45-55% with heat recovery.

Regulatory frameworks and grid interconnection standards vary significantly across regions, creating barriers to widespread implementation. Countries including Japan, Australia, and parts of the European Union have developed specific provisions for fuel cell grid integration, while many regions still lack clear regulatory pathways. Harmonization of these standards represents a critical step toward enabling large-scale ammonia-SOFC deployment.

Future grid architectures incorporating high penetrations of renewable energy will likely benefit from the dispatchable nature of ammonia-SOFC systems. Their ability to provide baseload power with low emissions complements variable renewable generation, potentially reducing overall system costs and improving reliability metrics such as Loss of Load Probability (LOLP) by 15-25% according to recent modeling studies.

Grid integration of ammonia-based SOFC systems presents unique challenges compared to conventional power generation technologies. The electrochemical nature of SOFCs results in different response characteristics to load changes, with typical ramp rates of 2-5% per minute compared to 7-10% for natural gas turbines. This relatively slow response necessitates hybrid system designs incorporating energy storage solutions such as batteries or supercapacitors to manage transient loads and provide grid services.

Power quality considerations are paramount when connecting ammonia-SOFC systems to existing electrical infrastructure. The DC power generated by fuel cells requires sophisticated power conditioning systems including inverters with advanced control algorithms to ensure compliance with grid codes regarding frequency stability, voltage regulation, and harmonic distortion. Modern grid-connected SOFC systems achieve power quality metrics with total harmonic distortion below 3%, meeting IEEE 1547 standards.

Distributed generation models offer promising pathways for ammonia-SOFC deployment, particularly in microgrids and isolated power systems. These applications benefit from ammonia's storage capabilities, enabling seasonal energy storage that addresses intermittency challenges of renewable energy sources. Case studies from Japan's SIP Energy Carriers program demonstrate successful integration of 5-50kW ammonia-SOFC systems in microgrid environments, achieving system efficiencies of 45-55% with heat recovery.

Regulatory frameworks and grid interconnection standards vary significantly across regions, creating barriers to widespread implementation. Countries including Japan, Australia, and parts of the European Union have developed specific provisions for fuel cell grid integration, while many regions still lack clear regulatory pathways. Harmonization of these standards represents a critical step toward enabling large-scale ammonia-SOFC deployment.

Future grid architectures incorporating high penetrations of renewable energy will likely benefit from the dispatchable nature of ammonia-SOFC systems. Their ability to provide baseload power with low emissions complements variable renewable generation, potentially reducing overall system costs and improving reliability metrics such as Loss of Load Probability (LOLP) by 15-25% according to recent modeling studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!