How to Size Ammonia Cracking for H₂ Refueling Stations

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Cracking Technology Background and Objectives

Ammonia cracking technology has emerged as a promising pathway for hydrogen production, particularly in the context of refueling stations. The technology leverages ammonia (NH₃) as a hydrogen carrier, offering significant advantages in terms of energy density and existing infrastructure compatibility. Historically, ammonia cracking has been primarily utilized in industrial applications, but recent technological advancements have expanded its potential for decentralized hydrogen production.

The evolution of ammonia cracking technology can be traced back to the early 20th century with the development of the Haber-Bosch process for ammonia synthesis. However, the reverse process—efficiently decomposing ammonia into hydrogen—has gained substantial attention only in the past two decades as hydrogen fuel cell vehicles have emerged as a viable transportation option.

Current technological trends indicate a shift toward more efficient catalysts, reduced operating temperatures, and compact reactor designs specifically tailored for distributed applications such as hydrogen refueling stations. These developments aim to address the inherent challenges of ammonia decomposition, which traditionally requires high temperatures (>500°C) and specialized catalysts to achieve acceptable conversion rates.

The primary technical objective for ammonia cracking in refueling stations is to develop appropriately sized systems that can deliver hydrogen at the required purity (>99.97% for fuel cell applications), pressure, and flow rate to meet variable demand patterns. This necessitates precise sizing methodologies that balance capital expenditure, operational efficiency, and spatial constraints inherent to refueling infrastructure.

Secondary objectives include minimizing energy consumption during the cracking process, reducing catalyst degradation rates, managing heat integration, and ensuring safe operation in public-facing environments. The technology must also address the challenge of nitrogen separation from the produced hydrogen stream, as nitrogen is a byproduct of the ammonia decomposition reaction.

From a sustainability perspective, ammonia cracking technology aims to enable a carbon-free hydrogen supply chain when the ammonia is produced using renewable energy sources. This aligns with global decarbonization efforts and positions ammonia as a potential key enabler of the hydrogen economy, serving as both an energy carrier and storage medium.

The sizing of ammonia cracking systems for refueling stations represents a critical technical challenge that bridges fundamental chemical engineering principles with practical implementation requirements. Optimal sizing methodologies must account for daily and seasonal demand fluctuations, startup/shutdown cycles, and integration with downstream compression, storage, and dispensing systems.

The evolution of ammonia cracking technology can be traced back to the early 20th century with the development of the Haber-Bosch process for ammonia synthesis. However, the reverse process—efficiently decomposing ammonia into hydrogen—has gained substantial attention only in the past two decades as hydrogen fuel cell vehicles have emerged as a viable transportation option.

Current technological trends indicate a shift toward more efficient catalysts, reduced operating temperatures, and compact reactor designs specifically tailored for distributed applications such as hydrogen refueling stations. These developments aim to address the inherent challenges of ammonia decomposition, which traditionally requires high temperatures (>500°C) and specialized catalysts to achieve acceptable conversion rates.

The primary technical objective for ammonia cracking in refueling stations is to develop appropriately sized systems that can deliver hydrogen at the required purity (>99.97% for fuel cell applications), pressure, and flow rate to meet variable demand patterns. This necessitates precise sizing methodologies that balance capital expenditure, operational efficiency, and spatial constraints inherent to refueling infrastructure.

Secondary objectives include minimizing energy consumption during the cracking process, reducing catalyst degradation rates, managing heat integration, and ensuring safe operation in public-facing environments. The technology must also address the challenge of nitrogen separation from the produced hydrogen stream, as nitrogen is a byproduct of the ammonia decomposition reaction.

From a sustainability perspective, ammonia cracking technology aims to enable a carbon-free hydrogen supply chain when the ammonia is produced using renewable energy sources. This aligns with global decarbonization efforts and positions ammonia as a potential key enabler of the hydrogen economy, serving as both an energy carrier and storage medium.

The sizing of ammonia cracking systems for refueling stations represents a critical technical challenge that bridges fundamental chemical engineering principles with practical implementation requirements. Optimal sizing methodologies must account for daily and seasonal demand fluctuations, startup/shutdown cycles, and integration with downstream compression, storage, and dispensing systems.

Hydrogen Refueling Station Market Analysis

The global hydrogen refueling station market is experiencing significant growth, driven by increasing adoption of hydrogen fuel cell vehicles and governmental push towards cleaner energy alternatives. As of 2023, there are approximately 870 hydrogen refueling stations operational worldwide, with concentrated development in Asia-Pacific, Europe, and North America. Japan leads with over 160 stations, followed by Germany with about 100 stations, and the United States with roughly 70 stations primarily in California.

Market projections indicate substantial expansion, with the hydrogen refueling infrastructure market expected to grow at a CAGR of 25-30% through 2030. This growth is supported by major automotive manufacturers' commitments to hydrogen fuel cell vehicle production, including Toyota, Hyundai, and Honda, who have established commercial models in select markets.

The demand for hydrogen as a transportation fuel is closely tied to the deployment of fuel cell electric vehicles (FCEVs). Currently, the global FCEV fleet stands at approximately 50,000 vehicles, with projections suggesting this could reach 1-1.5 million units by 2030. Each hydrogen refueling station typically serves between 200-400 FCEVs, indicating a need for substantial infrastructure expansion to support projected vehicle adoption.

Investment patterns reveal increasing private-public partnerships funding hydrogen infrastructure. The European Clean Hydrogen Alliance has mobilized over €30 billion for hydrogen projects, while similar initiatives exist in Japan, South Korea, and China. In the United States, the Infrastructure Investment and Jobs Act allocated $8 billion for regional clean hydrogen hubs.

Consumer adoption faces challenges including high infrastructure costs, with a typical hydrogen refueling station costing between $1-3 million depending on capacity and location. The average cost of hydrogen fuel remains relatively high at $10-16 per kilogram, compared to conventional fuels, though economies of scale are expected to drive costs down to $4-6 per kilogram by 2030.

Regulatory frameworks are evolving to support market growth. The European Union's Hydrogen Strategy targets 1,000 hydrogen refueling stations by 2030, while California's Low Carbon Fuel Standard provides financial incentives for hydrogen infrastructure development. Japan's Strategic Roadmap for Hydrogen and Fuel Cells aims for 900 stations by 2030, demonstrating strong governmental commitment to hydrogen mobility solutions.

The integration of ammonia cracking technology into this market presents a significant opportunity to address hydrogen storage and transportation challenges, potentially reducing infrastructure costs and improving the economic viability of hydrogen as a transportation fuel.

Market projections indicate substantial expansion, with the hydrogen refueling infrastructure market expected to grow at a CAGR of 25-30% through 2030. This growth is supported by major automotive manufacturers' commitments to hydrogen fuel cell vehicle production, including Toyota, Hyundai, and Honda, who have established commercial models in select markets.

The demand for hydrogen as a transportation fuel is closely tied to the deployment of fuel cell electric vehicles (FCEVs). Currently, the global FCEV fleet stands at approximately 50,000 vehicles, with projections suggesting this could reach 1-1.5 million units by 2030. Each hydrogen refueling station typically serves between 200-400 FCEVs, indicating a need for substantial infrastructure expansion to support projected vehicle adoption.

Investment patterns reveal increasing private-public partnerships funding hydrogen infrastructure. The European Clean Hydrogen Alliance has mobilized over €30 billion for hydrogen projects, while similar initiatives exist in Japan, South Korea, and China. In the United States, the Infrastructure Investment and Jobs Act allocated $8 billion for regional clean hydrogen hubs.

Consumer adoption faces challenges including high infrastructure costs, with a typical hydrogen refueling station costing between $1-3 million depending on capacity and location. The average cost of hydrogen fuel remains relatively high at $10-16 per kilogram, compared to conventional fuels, though economies of scale are expected to drive costs down to $4-6 per kilogram by 2030.

Regulatory frameworks are evolving to support market growth. The European Union's Hydrogen Strategy targets 1,000 hydrogen refueling stations by 2030, while California's Low Carbon Fuel Standard provides financial incentives for hydrogen infrastructure development. Japan's Strategic Roadmap for Hydrogen and Fuel Cells aims for 900 stations by 2030, demonstrating strong governmental commitment to hydrogen mobility solutions.

The integration of ammonia cracking technology into this market presents a significant opportunity to address hydrogen storage and transportation challenges, potentially reducing infrastructure costs and improving the economic viability of hydrogen as a transportation fuel.

Current Ammonia Cracking Technologies and Challenges

Ammonia cracking technology has evolved significantly over the past decades, with several established methods now available for hydrogen production. The most prevalent approach involves thermal catalytic cracking, which operates at temperatures between 650-900°C using catalysts typically composed of nickel, ruthenium, or iron-based materials. This process achieves ammonia conversion rates of 95-99% but requires substantial energy input to maintain high temperatures.

Plasma-assisted cracking represents an emerging alternative that operates at lower temperatures (400-600°C) by using electrical discharge to generate reactive species that facilitate ammonia decomposition. While this method reduces thermal energy requirements, it introduces electrical energy demands and faces challenges with scaling to industrial capacities needed for refueling stations.

Membrane reactor technology combines reaction and separation processes by employing palladium or palladium-alloy membranes that selectively allow hydrogen to permeate while retaining nitrogen. This integration enhances conversion efficiency through equilibrium shifting but struggles with membrane durability under operating conditions and high manufacturing costs.

The sizing of ammonia crackers for hydrogen refueling stations encounters several technical challenges. Heat management represents a critical issue as the endothermic cracking reaction requires precise temperature control to maintain optimal conversion rates while preventing catalyst sintering or deactivation. Current systems employ various heat exchange mechanisms, but efficiency losses during thermal cycling remain problematic.

Catalyst degradation presents another significant challenge, with sulfur poisoning, carbon deposition, and thermal sintering reducing operational lifetimes. Advanced catalyst formulations with improved resistance to these degradation mechanisms are under development but often involve costly precious metals.

System response dynamics pose difficulties for refueling applications that require variable hydrogen output rates. Most existing crackers are designed for steady-state operation and exhibit suboptimal performance during rapid load changes, necessitating buffer storage systems that increase overall station complexity and cost.

Miniaturization and modularization efforts face constraints related to heat transfer limitations and catalyst bed configurations. Compact designs must balance pressure drop considerations with sufficient catalyst contact time, often resulting in complex geometries that complicate manufacturing and maintenance procedures.

Purification requirements add another layer of complexity, as hydrogen produced through ammonia cracking contains residual ammonia and nitrogen that must be removed to meet fuel cell vehicle standards (99.97% purity). Current purification systems typically employ pressure swing adsorption or membrane separation technologies that add significant footprint and capital requirements to station designs.

Plasma-assisted cracking represents an emerging alternative that operates at lower temperatures (400-600°C) by using electrical discharge to generate reactive species that facilitate ammonia decomposition. While this method reduces thermal energy requirements, it introduces electrical energy demands and faces challenges with scaling to industrial capacities needed for refueling stations.

Membrane reactor technology combines reaction and separation processes by employing palladium or palladium-alloy membranes that selectively allow hydrogen to permeate while retaining nitrogen. This integration enhances conversion efficiency through equilibrium shifting but struggles with membrane durability under operating conditions and high manufacturing costs.

The sizing of ammonia crackers for hydrogen refueling stations encounters several technical challenges. Heat management represents a critical issue as the endothermic cracking reaction requires precise temperature control to maintain optimal conversion rates while preventing catalyst sintering or deactivation. Current systems employ various heat exchange mechanisms, but efficiency losses during thermal cycling remain problematic.

Catalyst degradation presents another significant challenge, with sulfur poisoning, carbon deposition, and thermal sintering reducing operational lifetimes. Advanced catalyst formulations with improved resistance to these degradation mechanisms are under development but often involve costly precious metals.

System response dynamics pose difficulties for refueling applications that require variable hydrogen output rates. Most existing crackers are designed for steady-state operation and exhibit suboptimal performance during rapid load changes, necessitating buffer storage systems that increase overall station complexity and cost.

Miniaturization and modularization efforts face constraints related to heat transfer limitations and catalyst bed configurations. Compact designs must balance pressure drop considerations with sufficient catalyst contact time, often resulting in complex geometries that complicate manufacturing and maintenance procedures.

Purification requirements add another layer of complexity, as hydrogen produced through ammonia cracking contains residual ammonia and nitrogen that must be removed to meet fuel cell vehicle standards (99.97% purity). Current purification systems typically employ pressure swing adsorption or membrane separation technologies that add significant footprint and capital requirements to station designs.

Current Sizing Methodologies for Ammonia Crackers

01 Ammonia cracking reactor design and sizing

Ammonia cracking reactors require specific sizing considerations to efficiently convert ammonia into hydrogen and nitrogen. The design factors include reactor volume, catalyst bed dimensions, heat transfer surfaces, and flow distribution systems. Proper sizing ensures optimal residence time for complete ammonia decomposition while managing thermal profiles and pressure drops across the system. Advanced reactor designs incorporate features to handle varying throughput requirements and maintain consistent conversion rates.- Ammonia cracking reactor sizing and design: The design and sizing of ammonia cracking reactors involves specific considerations for optimal hydrogen production. These reactors must be properly dimensioned to ensure efficient thermal decomposition of ammonia into hydrogen and nitrogen. Key design factors include heat transfer surfaces, catalyst bed dimensions, and internal flow dynamics to maximize conversion rates while minimizing energy consumption. Proper sizing ensures adequate residence time and temperature distribution throughout the reactor volume.

- Catalyst systems for ammonia decomposition: Specialized catalyst systems play a crucial role in ammonia cracking efficiency and reactor sizing. These catalysts, often containing transition metals like ruthenium, nickel or iron, are designed with specific surface areas and porosity to enhance ammonia decomposition kinetics. The catalyst configuration, loading density, and distribution within the reactor directly impact the required reactor dimensions and operating parameters. Advanced catalyst formulations can reduce the overall reactor size needed for complete ammonia conversion.

- Thermal management systems for ammonia crackers: Effective thermal management is essential for properly sized ammonia cracking systems. These systems incorporate heat exchangers, insulation materials, and temperature control mechanisms to maintain optimal operating conditions. The sizing of thermal components must account for heat flux requirements, temperature gradients, and energy recovery opportunities. Proper thermal design ensures efficient heat distribution throughout the reactor while minimizing energy losses and preventing catalyst degradation due to hotspots.

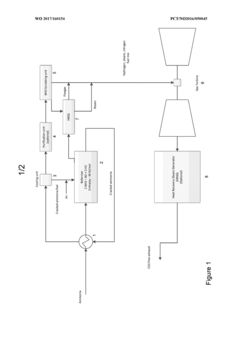

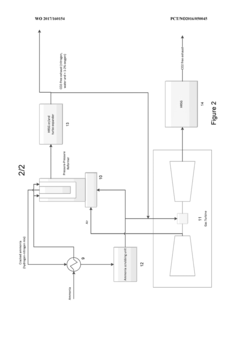

- Integration of ammonia crackers in hydrogen production systems: The integration of ammonia cracking units within larger hydrogen production and utilization systems affects their sizing requirements. System-level considerations include feed gas conditioning, product purification, pressure management, and downstream application requirements. The cracker sizing must account for fluctuating demand patterns, startup/shutdown cycles, and integration with renewable energy sources. Properly sized integrated systems optimize space utilization while ensuring reliable hydrogen supply for various applications.

- Novel materials and manufacturing methods for ammonia cracking components: Advanced materials and manufacturing techniques enable optimized sizing of ammonia cracking components. These innovations include high-temperature alloys, ceramic composites, and specialized coatings that enhance durability and performance. Additive manufacturing and precision fabrication methods allow for complex geometries that maximize surface area while minimizing volume. Material selection impacts heat transfer characteristics, mechanical integrity, and corrosion resistance, all of which influence the optimal sizing of reactor components.

02 Catalyst systems for ammonia cracking

Specialized catalysts are essential for efficient ammonia cracking processes. These catalysts typically contain transition metals such as nickel, ruthenium, or iron supported on various substrates. The sizing of catalyst particles and their distribution within the reactor significantly impacts conversion efficiency and system longevity. Catalyst bed dimensions must be carefully calculated to balance reaction kinetics with pressure drop considerations. Innovations in catalyst formulations focus on improving activity at lower temperatures and extending operational lifetimes.Expand Specific Solutions03 Heat management systems for ammonia cracking

Ammonia cracking is a highly endothermic process requiring substantial heat input to maintain reaction temperatures. Sizing of heat exchangers, thermal insulation, and heat recovery systems is critical for energy efficiency. The thermal management system must be designed to provide uniform temperature distribution across the catalyst bed while preventing hotspots that could damage components. Advanced systems incorporate staged heating zones and recuperative heat exchangers to optimize energy consumption and process stability.Expand Specific Solutions04 Integration of ammonia cracking units in hydrogen production systems

Ammonia crackers must be appropriately sized to integrate with upstream and downstream processes in hydrogen production facilities. System integration considerations include feed purification requirements, product gas handling, and compatibility with end-use applications. The sizing of interconnecting piping, control systems, and safety equipment must accommodate the full operational range of the integrated system. Modern designs focus on modular approaches that allow for scalability and flexible deployment across various applications.Expand Specific Solutions05 Ammonia cracking for portable and distributed hydrogen applications

Compact ammonia cracking systems require specialized sizing approaches to balance performance with portability. These systems must achieve high conversion efficiency while minimizing weight and volume. Design considerations include miniaturized heat exchangers, optimized catalyst configurations, and integrated control systems. The sizing methodology focuses on power density metrics and rapid start-up capabilities. Recent innovations address challenges in thermal management and catalyst utilization for small-scale applications, enabling distributed hydrogen production from ammonia carriers.Expand Specific Solutions

Key Industry Players in Ammonia Cracking Systems

The ammonia cracking for H₂ refueling stations market is in an early growth phase, characterized by increasing commercial interest as hydrogen gains traction as a clean energy carrier. The global market size is projected to expand significantly, driven by decarbonization initiatives and hydrogen mobility adoption. Technologically, the field is advancing from pilot to commercial scale, with varying levels of maturity. Leading players include Air Products & Chemicals, which has extensive hydrogen infrastructure experience, and Johnson Matthey, known for catalyst technologies. Energy majors like TotalEnergies, Saudi Aramco, and Sinopec are investing in hydrogen infrastructure development. Academic institutions such as Tianjin University and Colorado School of Mines are contributing research advancements, while specialized companies like Casale SA are developing process optimization technologies for ammonia cracking systems.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed a comprehensive ammonia cracking technology for hydrogen refueling stations that utilizes a multi-stage catalytic process. Their system employs ruthenium-based catalysts supported on structured carriers to achieve ammonia conversion rates exceeding 99.5% at temperatures around 650-700°C. The technology incorporates heat integration systems that recover thermal energy from the cracking process to preheat incoming ammonia, improving overall energy efficiency by approximately 15-20%. For sizing considerations, Air Products employs a modular approach with standardized units capable of producing 50-500 kg/day of hydrogen, allowing for scalable implementation based on station demand profiles. Their systems include advanced purification stages using pressure swing adsorption (PSA) technology to remove residual ammonia and nitrogen to meet fuel cell vehicle requirements (<0.1 ppm NH3).

Strengths: Industry-leading conversion efficiency with proven commercial deployments; modular design allows for demand-based scaling; comprehensive heat integration reduces operational costs. Weaknesses: Higher capital costs compared to conventional hydrogen production methods; requires specialized maintenance expertise; system footprint may be challenging for urban refueling stations with limited space.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated ammonia cracking system for hydrogen refueling stations that utilizes proprietary nickel-based catalysts with rare earth element promoters. Their technology operates at moderate temperatures (550-600°C) and achieves ammonia conversion rates of approximately 98%. Sinopec's approach focuses on optimizing the sizing of ammonia crackers based on a dynamic demand model that accounts for daily and seasonal fluctuations in hydrogen demand. Their system architecture incorporates a two-stage cracking process with intermediate cooling and purification steps to enhance overall efficiency. For hydrogen refueling stations, Sinopec has standardized three capacity tiers: small (100-200 kg H2/day), medium (300-500 kg H2/day), and large (>500 kg H2/day), with corresponding ammonia storage and cracking units sized accordingly. The system includes advanced process control algorithms that adjust operating parameters in real-time to optimize energy consumption and catalyst performance based on demand patterns.

Strengths: Extensive distribution network and infrastructure expertise; cost-effective catalyst formulation with good durability; comprehensive sizing methodology based on real-world operational data. Weaknesses: Slightly lower conversion efficiency compared to precious metal catalysts; larger physical footprint required for equivalent hydrogen output; higher energy consumption per unit of hydrogen produced.

Critical Patents and Research in Ammonia Cracking Efficiency

Process

PatentPendingGB2625908A

Innovation

- Supplying a hydrogen-containing recycle gas from downstream of the ammonia cracking reactor to the catalyst-containing reaction tubes reduces nitriding rates and maintains high hydrogen recovery, allowing for a smaller reactor design and reduced capital costs.

Ammonia cracking

PatentWO2017160154A1

Innovation

- The ammonia cracking process is integrated with a gas turbine to produce a mixture of hydrogen and nitrogen from ammonia, which is then combusted to generate power, avoiding the need for hydrogen storage and transportation and minimizing nitrogen oxide emissions, using a catalytic ammonia-cracking device to decompose ammonia into hydrogen and nitrogen at elevated temperatures.

Environmental Impact and Sustainability Assessment

The environmental impact of ammonia cracking systems for hydrogen refueling stations represents a critical consideration in the broader transition to hydrogen-based transportation. When evaluating these systems, lifecycle greenhouse gas emissions must be comprehensively assessed, comparing the carbon footprint of ammonia-based hydrogen production against conventional fossil fuel-based methods. Research indicates that ammonia cracking pathways can potentially reduce carbon emissions by 60-90% compared to steam methane reforming when the ammonia is produced using renewable energy sources.

Water consumption presents another significant environmental factor, as ammonia cracking processes require water for cooling systems and potentially for hydrogen purification. In water-stressed regions, this demand necessitates careful management strategies, including closed-loop cooling systems and water recycling technologies that can reduce freshwater requirements by up to 75%.

Air quality impacts from ammonia cracking operations primarily stem from potential ammonia leakage and NOx emissions during the thermal decomposition process. Modern cracking systems incorporate advanced catalysts that operate at lower temperatures (450-550°C rather than traditional 850°C systems), substantially reducing NOx formation. Additionally, state-of-the-art monitoring systems can detect ammonia leaks at concentrations as low as 5ppm, well below hazardous levels.

From a sustainability perspective, ammonia cracking systems offer significant advantages through their integration potential with renewable energy infrastructure. The ability to use green ammonia (produced with renewable electricity) creates a fully sustainable hydrogen pathway with near-zero lifecycle emissions. This approach addresses the intermittency challenges of renewable energy by utilizing ammonia as an energy carrier that can be transported and stored using existing infrastructure.

Land use requirements for ammonia cracking facilities at refueling stations are relatively modest compared to other hydrogen production methods. A typical 500 kg/day hydrogen capacity system requires approximately 25-40 square meters of space, making it feasible for integration into existing fueling infrastructure with minimal additional land disturbance.

Material sustainability represents another important dimension, with catalyst materials often containing precious metals like ruthenium or nickel. Recent innovations have focused on developing catalysts with reduced rare metal content while maintaining efficiency, and implementing recovery systems that can reclaim up to 90% of catalyst materials at end-of-life, significantly improving the resource sustainability profile of these systems.

Water consumption presents another significant environmental factor, as ammonia cracking processes require water for cooling systems and potentially for hydrogen purification. In water-stressed regions, this demand necessitates careful management strategies, including closed-loop cooling systems and water recycling technologies that can reduce freshwater requirements by up to 75%.

Air quality impacts from ammonia cracking operations primarily stem from potential ammonia leakage and NOx emissions during the thermal decomposition process. Modern cracking systems incorporate advanced catalysts that operate at lower temperatures (450-550°C rather than traditional 850°C systems), substantially reducing NOx formation. Additionally, state-of-the-art monitoring systems can detect ammonia leaks at concentrations as low as 5ppm, well below hazardous levels.

From a sustainability perspective, ammonia cracking systems offer significant advantages through their integration potential with renewable energy infrastructure. The ability to use green ammonia (produced with renewable electricity) creates a fully sustainable hydrogen pathway with near-zero lifecycle emissions. This approach addresses the intermittency challenges of renewable energy by utilizing ammonia as an energy carrier that can be transported and stored using existing infrastructure.

Land use requirements for ammonia cracking facilities at refueling stations are relatively modest compared to other hydrogen production methods. A typical 500 kg/day hydrogen capacity system requires approximately 25-40 square meters of space, making it feasible for integration into existing fueling infrastructure with minimal additional land disturbance.

Material sustainability represents another important dimension, with catalyst materials often containing precious metals like ruthenium or nickel. Recent innovations have focused on developing catalysts with reduced rare metal content while maintaining efficiency, and implementing recovery systems that can reclaim up to 90% of catalyst materials at end-of-life, significantly improving the resource sustainability profile of these systems.

Economic Feasibility and ROI Analysis

The economic viability of ammonia cracking systems for hydrogen refueling stations represents a critical factor in their widespread adoption. Initial capital expenditure for ammonia cracking infrastructure ranges from $1.5-3 million USD for medium-sized stations capable of producing 200-500 kg of hydrogen daily. This investment encompasses the cracker unit, purification systems, storage facilities, and safety equipment.

Operational expenses primarily consist of ammonia feedstock costs, energy consumption for the cracking process, maintenance, and labor. Current market analysis indicates ammonia prices fluctuate between $400-700 per ton, translating to approximately $2.20-3.90 per kg of hydrogen produced. Energy requirements for the endothermic cracking process add $0.50-1.20 per kg of hydrogen, depending on local electricity rates and system efficiency.

Return on investment calculations suggest payback periods of 5-8 years for stations in high-demand areas, with shorter periods possible in regions with favorable renewable energy policies or carbon pricing mechanisms. Sensitivity analysis reveals that ammonia procurement costs represent the most significant variable affecting profitability, followed by electricity prices and station utilization rates.

Economies of scale play a substantial role in economic feasibility. Small stations producing less than 100 kg/day face challenging economics with current technology, while facilities exceeding 500 kg/day demonstrate more favorable unit economics. The optimal sizing appears to correlate with local market demand density, with urban centers supporting larger installations than rural deployments.

Government incentives significantly impact the ROI timeline. Jurisdictions offering carbon credits, renewable fuel standards, or direct subsidies for clean hydrogen infrastructure can reduce payback periods by 30-50%. The European Union's hydrogen strategy and Japan's hydrogen roadmap provide particularly favorable economic environments, while the United States offers regionally variable support through state-level initiatives.

Financing models are evolving to address the capital-intensive nature of these installations. Public-private partnerships, equipment leasing arrangements, and hydrogen-as-a-service business models are emerging to distribute initial investment burdens and accelerate deployment. These innovative approaches can improve project IRR by 3-5 percentage points compared to traditional financing structures.

Long-term economic projections indicate improving feasibility as technology matures and scales. Current levelized cost of hydrogen from ammonia cracking ranges from $4-7 per kg, with projections suggesting potential reduction to $2.50-4.00 per kg by 2030 as catalyst efficiency improves and equipment costs decline through manufacturing scale.

Operational expenses primarily consist of ammonia feedstock costs, energy consumption for the cracking process, maintenance, and labor. Current market analysis indicates ammonia prices fluctuate between $400-700 per ton, translating to approximately $2.20-3.90 per kg of hydrogen produced. Energy requirements for the endothermic cracking process add $0.50-1.20 per kg of hydrogen, depending on local electricity rates and system efficiency.

Return on investment calculations suggest payback periods of 5-8 years for stations in high-demand areas, with shorter periods possible in regions with favorable renewable energy policies or carbon pricing mechanisms. Sensitivity analysis reveals that ammonia procurement costs represent the most significant variable affecting profitability, followed by electricity prices and station utilization rates.

Economies of scale play a substantial role in economic feasibility. Small stations producing less than 100 kg/day face challenging economics with current technology, while facilities exceeding 500 kg/day demonstrate more favorable unit economics. The optimal sizing appears to correlate with local market demand density, with urban centers supporting larger installations than rural deployments.

Government incentives significantly impact the ROI timeline. Jurisdictions offering carbon credits, renewable fuel standards, or direct subsidies for clean hydrogen infrastructure can reduce payback periods by 30-50%. The European Union's hydrogen strategy and Japan's hydrogen roadmap provide particularly favorable economic environments, while the United States offers regionally variable support through state-level initiatives.

Financing models are evolving to address the capital-intensive nature of these installations. Public-private partnerships, equipment leasing arrangements, and hydrogen-as-a-service business models are emerging to distribute initial investment burdens and accelerate deployment. These innovative approaches can improve project IRR by 3-5 percentage points compared to traditional financing structures.

Long-term economic projections indicate improving feasibility as technology matures and scales. Current levelized cost of hydrogen from ammonia cracking ranges from $4-7 per kg, with projections suggesting potential reduction to $2.50-4.00 per kg by 2030 as catalyst efficiency improves and equipment costs decline through manufacturing scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!