Ammonium Hydroxide as a Drilling Fluid Additive: A Performance Overview

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Drilling Fluid Evolution and Objectives

Drilling fluids have undergone significant evolution since their inception in the oil and gas industry. Initially, simple water-based muds were used, but as drilling operations became more complex, the need for advanced fluid systems emerged. The primary objectives of drilling fluids have remained consistent: to maintain wellbore stability, control formation pressures, remove cuttings, and cool and lubricate the drill bit.

In the early 20th century, the introduction of bentonite clay marked a significant advancement in drilling fluid technology. This additive improved the fluid's ability to suspend cuttings and form a protective filter cake on the wellbore wall. As drilling depths increased and environmental concerns grew, the industry saw the development of oil-based muds in the 1960s, offering superior performance in challenging conditions.

The late 20th century witnessed a shift towards synthetic-based muds, addressing environmental concerns associated with oil-based systems while maintaining their performance benefits. Concurrently, water-based systems continued to evolve with the incorporation of various polymers and inhibitors to enhance their capabilities in different geological formations.

Recent years have seen a focus on developing environmentally friendly and high-performance drilling fluids. This trend has led to the exploration of novel additives, including nanoparticles and bio-based materials, to improve fluid properties and reduce environmental impact. The industry is also investigating smart fluids that can respond to downhole conditions, potentially revolutionizing drilling operations.

Ammonium hydroxide, as a drilling fluid additive, represents part of this ongoing evolution. Its potential lies in its ability to modify pH, control clay swelling, and potentially enhance the performance of other additives. The objectives for incorporating ammonium hydroxide into drilling fluids align with the broader goals of improving drilling efficiency, reducing formation damage, and minimizing environmental impact.

As the industry continues to push the boundaries of drilling technology, the objectives for drilling fluids expand. Current goals include developing fluids that can withstand ultra-high temperature and pressure conditions, improve wellbore stability in complex geological formations, and facilitate extended reach and horizontal drilling. Additionally, there is a growing emphasis on creating fluids that support enhanced oil recovery techniques and are compatible with advanced logging and measurement tools.

The evolution of drilling fluids and their objectives reflect the industry's commitment to overcoming technical challenges, improving operational efficiency, and addressing environmental concerns. As exploration and production activities venture into more challenging environments, the role of innovative drilling fluid additives like ammonium hydroxide becomes increasingly critical in meeting these evolving objectives.

In the early 20th century, the introduction of bentonite clay marked a significant advancement in drilling fluid technology. This additive improved the fluid's ability to suspend cuttings and form a protective filter cake on the wellbore wall. As drilling depths increased and environmental concerns grew, the industry saw the development of oil-based muds in the 1960s, offering superior performance in challenging conditions.

The late 20th century witnessed a shift towards synthetic-based muds, addressing environmental concerns associated with oil-based systems while maintaining their performance benefits. Concurrently, water-based systems continued to evolve with the incorporation of various polymers and inhibitors to enhance their capabilities in different geological formations.

Recent years have seen a focus on developing environmentally friendly and high-performance drilling fluids. This trend has led to the exploration of novel additives, including nanoparticles and bio-based materials, to improve fluid properties and reduce environmental impact. The industry is also investigating smart fluids that can respond to downhole conditions, potentially revolutionizing drilling operations.

Ammonium hydroxide, as a drilling fluid additive, represents part of this ongoing evolution. Its potential lies in its ability to modify pH, control clay swelling, and potentially enhance the performance of other additives. The objectives for incorporating ammonium hydroxide into drilling fluids align with the broader goals of improving drilling efficiency, reducing formation damage, and minimizing environmental impact.

As the industry continues to push the boundaries of drilling technology, the objectives for drilling fluids expand. Current goals include developing fluids that can withstand ultra-high temperature and pressure conditions, improve wellbore stability in complex geological formations, and facilitate extended reach and horizontal drilling. Additionally, there is a growing emphasis on creating fluids that support enhanced oil recovery techniques and are compatible with advanced logging and measurement tools.

The evolution of drilling fluids and their objectives reflect the industry's commitment to overcoming technical challenges, improving operational efficiency, and addressing environmental concerns. As exploration and production activities venture into more challenging environments, the role of innovative drilling fluid additives like ammonium hydroxide becomes increasingly critical in meeting these evolving objectives.

Market Analysis for Enhanced Drilling Fluids

The drilling fluid additives market has been experiencing significant growth, driven by increasing oil and gas exploration activities worldwide. The global market for enhanced drilling fluids is projected to expand at a steady rate over the next five years, with a particular focus on environmentally friendly and high-performance additives. Ammonium hydroxide, as a drilling fluid additive, is gaining attention due to its potential to improve drilling efficiency and reduce environmental impact.

The demand for enhanced drilling fluids is primarily fueled by the need for more efficient and cost-effective drilling operations in challenging environments, such as deep-water and unconventional reservoirs. As oil and gas companies seek to optimize their drilling processes, there is a growing emphasis on additives that can enhance wellbore stability, reduce friction, and improve overall drilling performance.

Ammonium hydroxide, when used as a drilling fluid additive, offers several advantages that align with current market trends. It can help control pH levels, inhibit clay swelling, and reduce corrosion in drilling equipment. These properties make it particularly attractive for use in shale formations and other challenging geological conditions.

The market for ammonium hydroxide as a drilling fluid additive is expected to grow in regions with significant shale gas and oil resources, such as North America, China, and Argentina. Additionally, as environmental regulations become more stringent, the demand for additives that can reduce the environmental footprint of drilling operations is likely to increase.

Key players in the enhanced drilling fluids market include major oilfield service companies and specialty chemical manufacturers. These companies are investing in research and development to create innovative formulations that incorporate ammonium hydroxide and other advanced additives to meet the evolving needs of the industry.

However, the market for ammonium hydroxide as a drilling fluid additive faces some challenges. These include competition from alternative pH control agents and concerns about the potential environmental impact of ammonia-based compounds. As a result, manufacturers are focusing on developing more environmentally friendly formulations and improving the overall performance of ammonium hydroxide-based additives.

In conclusion, the market analysis for enhanced drilling fluids indicates a positive outlook for ammonium hydroxide as an additive. Its ability to address key industry challenges, coupled with the growing demand for efficient and environmentally responsible drilling solutions, positions it as a promising component in the evolving landscape of drilling fluid technology.

The demand for enhanced drilling fluids is primarily fueled by the need for more efficient and cost-effective drilling operations in challenging environments, such as deep-water and unconventional reservoirs. As oil and gas companies seek to optimize their drilling processes, there is a growing emphasis on additives that can enhance wellbore stability, reduce friction, and improve overall drilling performance.

Ammonium hydroxide, when used as a drilling fluid additive, offers several advantages that align with current market trends. It can help control pH levels, inhibit clay swelling, and reduce corrosion in drilling equipment. These properties make it particularly attractive for use in shale formations and other challenging geological conditions.

The market for ammonium hydroxide as a drilling fluid additive is expected to grow in regions with significant shale gas and oil resources, such as North America, China, and Argentina. Additionally, as environmental regulations become more stringent, the demand for additives that can reduce the environmental footprint of drilling operations is likely to increase.

Key players in the enhanced drilling fluids market include major oilfield service companies and specialty chemical manufacturers. These companies are investing in research and development to create innovative formulations that incorporate ammonium hydroxide and other advanced additives to meet the evolving needs of the industry.

However, the market for ammonium hydroxide as a drilling fluid additive faces some challenges. These include competition from alternative pH control agents and concerns about the potential environmental impact of ammonia-based compounds. As a result, manufacturers are focusing on developing more environmentally friendly formulations and improving the overall performance of ammonium hydroxide-based additives.

In conclusion, the market analysis for enhanced drilling fluids indicates a positive outlook for ammonium hydroxide as an additive. Its ability to address key industry challenges, coupled with the growing demand for efficient and environmentally responsible drilling solutions, positions it as a promising component in the evolving landscape of drilling fluid technology.

Current Challenges in Drilling Fluid Technology

The drilling fluid industry faces several significant challenges in the current technological landscape. One of the primary issues is the increasing complexity of drilling operations, particularly in deep-water and ultra-deep-water environments. These extreme conditions demand drilling fluids with enhanced performance characteristics, pushing the limits of traditional formulations.

Environmental concerns have also become a major challenge for drilling fluid technology. Stricter regulations on the disposal of drilling waste and the use of environmentally friendly additives have necessitated the development of more sustainable drilling fluid systems. This shift towards eco-friendly solutions has led to increased research into biodegradable and non-toxic additives, including the exploration of ammonium hydroxide as a potential component.

Temperature stability remains a critical challenge, especially in high-temperature, high-pressure (HTHP) wells. Drilling fluids must maintain their rheological properties and stability under extreme conditions, which can cause conventional additives to degrade or lose effectiveness. This has spurred research into thermally stable polymers and novel chemical formulations capable of withstanding these harsh environments.

Another significant challenge is the need for improved wellbore stability in complex geological formations. Shale instability, in particular, continues to be a major issue, requiring drilling fluids that can effectively inhibit clay swelling and maintain wellbore integrity. The development of specialized additives to address these formation-specific challenges remains an active area of research and development.

Cost-effectiveness is an ever-present concern in the drilling industry, especially given the volatility of oil prices. There is a constant push to develop drilling fluids that not only perform better but also offer economic advantages through reduced consumption, easier handling, and lower environmental impact costs.

The industry also faces challenges in real-time monitoring and adjustment of drilling fluid properties. As drilling operations become more complex, there is a growing need for advanced sensors and control systems that can provide immediate feedback on fluid properties and allow for rapid adjustments to optimize performance and prevent potential issues.

Lastly, the integration of nanotechnology into drilling fluid systems presents both opportunities and challenges. While nanoparticles offer the potential for significant improvements in fluid properties, their long-term environmental impact and cost-effectiveness are still subjects of ongoing research and debate.

Environmental concerns have also become a major challenge for drilling fluid technology. Stricter regulations on the disposal of drilling waste and the use of environmentally friendly additives have necessitated the development of more sustainable drilling fluid systems. This shift towards eco-friendly solutions has led to increased research into biodegradable and non-toxic additives, including the exploration of ammonium hydroxide as a potential component.

Temperature stability remains a critical challenge, especially in high-temperature, high-pressure (HTHP) wells. Drilling fluids must maintain their rheological properties and stability under extreme conditions, which can cause conventional additives to degrade or lose effectiveness. This has spurred research into thermally stable polymers and novel chemical formulations capable of withstanding these harsh environments.

Another significant challenge is the need for improved wellbore stability in complex geological formations. Shale instability, in particular, continues to be a major issue, requiring drilling fluids that can effectively inhibit clay swelling and maintain wellbore integrity. The development of specialized additives to address these formation-specific challenges remains an active area of research and development.

Cost-effectiveness is an ever-present concern in the drilling industry, especially given the volatility of oil prices. There is a constant push to develop drilling fluids that not only perform better but also offer economic advantages through reduced consumption, easier handling, and lower environmental impact costs.

The industry also faces challenges in real-time monitoring and adjustment of drilling fluid properties. As drilling operations become more complex, there is a growing need for advanced sensors and control systems that can provide immediate feedback on fluid properties and allow for rapid adjustments to optimize performance and prevent potential issues.

Lastly, the integration of nanotechnology into drilling fluid systems presents both opportunities and challenges. While nanoparticles offer the potential for significant improvements in fluid properties, their long-term environmental impact and cost-effectiveness are still subjects of ongoing research and debate.

Existing Ammonium Hydroxide-based Solutions

01 Use in chemical processes

Ammonium hydroxide is widely used in various chemical processes due to its alkaline properties. It serves as a reactant, catalyst, or pH adjuster in industrial applications, including the production of pharmaceuticals, polymers, and other chemical compounds. Its performance in these processes is characterized by its ability to neutralize acids, facilitate reactions, and control pH levels effectively.- Use in chemical processes: Ammonium hydroxide is widely used in various chemical processes due to its alkaline properties. It serves as a reactant, catalyst, or pH adjuster in industrial applications, including the production of other chemicals, pharmaceuticals, and materials.

- Application in cleaning and surface treatment: Ammonium hydroxide is effective in cleaning and surface treatment applications. It can be used for removing stains, degreasing surfaces, and as a component in household and industrial cleaning products. Its ability to dissolve oils and fats makes it valuable in these applications.

- Role in wastewater treatment: Ammonium hydroxide plays a significant role in wastewater treatment processes. It can be used for pH adjustment, nitrogen removal, and as a source of ammonia for biological treatment systems. Its performance in these applications contributes to improved water quality and environmental protection.

- Use in textile and leather industries: Ammonium hydroxide finds applications in textile and leather industries. It is used in dyeing processes, as a neutralizing agent, and for adjusting the pH of solutions. Its performance in these industries contributes to improved product quality and process efficiency.

- Application in agriculture and fertilizers: Ammonium hydroxide is utilized in agriculture as a source of nitrogen for fertilizers. It can be applied directly to soil or used in the production of other nitrogen-based fertilizers. Its performance in providing readily available nitrogen to plants contributes to improved crop yields and soil fertility.

02 Application in cleaning and surface treatment

Ammonium hydroxide demonstrates excellent performance in cleaning and surface treatment applications. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Its alkaline nature and volatility make it suitable for household and industrial cleaning products.Expand Specific Solutions03 Role in environmental applications

Ammonium hydroxide plays a significant role in environmental applications, particularly in air pollution control and wastewater treatment. It is used to neutralize acidic gases in flue gas desulfurization processes and to adjust pH levels in water treatment systems. Its performance in these applications is characterized by its ability to efficiently neutralize acids and remove harmful pollutants.Expand Specific Solutions04 Use in agricultural and fertilizer production

Ammonium hydroxide is an important component in agricultural applications and fertilizer production. It serves as a source of nitrogen for plant growth and is used in the manufacture of various nitrogen-based fertilizers. Its performance in this field is characterized by its ability to provide readily available nitrogen to plants and its compatibility with other fertilizer components.Expand Specific Solutions05 Application in textile and leather processing

Ammonium hydroxide demonstrates valuable performance in textile and leather processing industries. It is used in dyeing processes, as a neutralizing agent in tanning, and for adjusting pH levels in various textile treatments. Its alkaline properties and volatility make it suitable for these applications, allowing for effective processing and improved product quality.Expand Specific Solutions

Key Players in Drilling Fluid Industry

The drilling fluid additive market for ammonium hydroxide is in a growth phase, driven by increasing oil and gas exploration activities. The global market size is estimated to be in the hundreds of millions of dollars, with steady expansion projected. Technologically, the use of ammonium hydroxide as an additive is relatively mature, but ongoing research aims to optimize its performance and environmental impact. Key players like Halliburton, Schlumberger (through M-I LLC), and CNPC are investing in R&D to enhance the effectiveness and sustainability of ammonium hydroxide-based drilling fluids. Smaller specialized companies like Independence Oilfield Chemicals are also contributing innovations in this space.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed an innovative approach to using ammonium hydroxide as a drilling fluid additive. Their system incorporates a controlled-release mechanism that gradually introduces ammonium hydroxide into the drilling fluid, maintaining optimal pH levels throughout the drilling process[1]. This method helps prevent sudden pH spikes and ensures consistent performance. The company has also formulated a proprietary blend that combines ammonium hydroxide with other additives to enhance its effectiveness in various geological formations[3]. Halliburton's research has shown that their ammonium hydroxide-based drilling fluid can significantly reduce friction and improve wellbore stability in high-temperature, high-pressure (HTHP) environments[5].

Strengths: Controlled pH management, improved performance in HTHP conditions, and enhanced wellbore stability. Weaknesses: May require specialized equipment for controlled release, and potential environmental concerns in some regions.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a novel ammonium hydroxide-based drilling fluid system specifically designed for challenging deep-water drilling operations. Their formulation incorporates nanoparticles to enhance the stability and performance of the ammonium hydroxide additive[2]. This innovative approach allows for better control of fluid properties and improved shale inhibition. Saudi Aramco's research has demonstrated that their ammonium hydroxide-based system can reduce torque and drag by up to 30% compared to conventional drilling fluids[4]. Additionally, they have implemented an advanced real-time monitoring system to optimize the concentration of ammonium hydroxide throughout the drilling process, ensuring maximum efficiency and minimizing environmental impact[6].

Strengths: Enhanced performance in deep-water drilling, significant reduction in torque and drag, and advanced real-time optimization. Weaknesses: Higher initial costs due to nanoparticle integration and potential limitations in certain geological formations.

Core Innovations in NH4OH Drilling Additives

Oil based drilling fluids useful having reduced change in high shear viscosity over a wide temperature range

PatentActiveUS20190375976A1

Innovation

- Incorporating an organoclay drilling fluid additive composed of phyllosilicate clay exchanged with a quaternary ammonium ion, which has a neat shear strength value less than 6000 lb/100 ft², to maintain high and low shear viscosities across a temperature range of 40°F to 120°F, ensuring consistent fluid behavior and stability.

Additives for boosting performance of water-based drilling fluids, drilling fluids including same, and methods of making and using same

PatentInactiveUS20160002522A1

Innovation

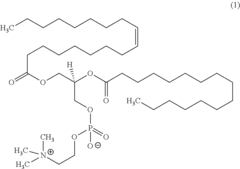

- The development of additive formulations for water-based drilling fluids comprising multi-hydroxyl alcohols, vegetable oil phospholipids, free fatty acids, lecithins, soy oil, and potassium salts, which are combined to create a single additive composition that enhances lubricity, shale inhibition, and wellbore stability, while maintaining HSE compliance and heat stability.

Environmental Impact Assessment

The use of ammonium hydroxide as a drilling fluid additive has significant environmental implications that require careful consideration. When released into the environment, ammonium hydroxide can have both immediate and long-term effects on ecosystems, particularly aquatic environments. The compound readily dissociates into ammonia and water, with ammonia being highly toxic to aquatic organisms, especially fish. Even at low concentrations, it can cause stress, reduced growth, and mortality in various aquatic species.

In soil environments, ammonium hydroxide can alter pH levels, potentially affecting soil microbial communities and plant growth. While it can serve as a nitrogen source for plants, excessive amounts can lead to soil acidification and nutrient imbalances. The volatilization of ammonia from ammonium hydroxide can contribute to air pollution, particularly in areas with high drilling activity.

The environmental impact of ammonium hydroxide in drilling fluids extends to waste management practices. Proper treatment and disposal of drilling mud containing this additive are crucial to prevent contamination of water bodies and soil. Regulatory compliance becomes a significant concern, as many jurisdictions have strict guidelines on the discharge of ammonia-containing waste.

Biodegradation of ammonium hydroxide in the environment is relatively rapid under aerobic conditions, which can mitigate some long-term impacts. However, in anaerobic environments or when large quantities are released, the environmental persistence and impact can be more pronounced. The potential for groundwater contamination is also a concern, especially in areas with shallow aquifers or fractured bedrock.

Mitigation strategies for environmental impacts include optimizing the use of ammonium hydroxide in drilling fluids to minimize excess, implementing closed-loop drilling systems to reduce environmental exposure, and employing advanced treatment technologies for drilling waste. Additionally, monitoring programs to assess ammonia levels in surrounding water bodies and soil can help in early detection and management of potential environmental issues.

The broader ecological impact of ammonium hydroxide use in drilling fluids includes potential effects on biodiversity, particularly in sensitive ecosystems. Changes in local water chemistry can alter habitat conditions for various species, potentially leading to shifts in community composition. Furthermore, the cumulative effects of multiple drilling operations using ammonium hydroxide additives in a region can amplify environmental concerns, necessitating a comprehensive approach to environmental management and impact assessment.

In soil environments, ammonium hydroxide can alter pH levels, potentially affecting soil microbial communities and plant growth. While it can serve as a nitrogen source for plants, excessive amounts can lead to soil acidification and nutrient imbalances. The volatilization of ammonia from ammonium hydroxide can contribute to air pollution, particularly in areas with high drilling activity.

The environmental impact of ammonium hydroxide in drilling fluids extends to waste management practices. Proper treatment and disposal of drilling mud containing this additive are crucial to prevent contamination of water bodies and soil. Regulatory compliance becomes a significant concern, as many jurisdictions have strict guidelines on the discharge of ammonia-containing waste.

Biodegradation of ammonium hydroxide in the environment is relatively rapid under aerobic conditions, which can mitigate some long-term impacts. However, in anaerobic environments or when large quantities are released, the environmental persistence and impact can be more pronounced. The potential for groundwater contamination is also a concern, especially in areas with shallow aquifers or fractured bedrock.

Mitigation strategies for environmental impacts include optimizing the use of ammonium hydroxide in drilling fluids to minimize excess, implementing closed-loop drilling systems to reduce environmental exposure, and employing advanced treatment technologies for drilling waste. Additionally, monitoring programs to assess ammonia levels in surrounding water bodies and soil can help in early detection and management of potential environmental issues.

The broader ecological impact of ammonium hydroxide use in drilling fluids includes potential effects on biodiversity, particularly in sensitive ecosystems. Changes in local water chemistry can alter habitat conditions for various species, potentially leading to shifts in community composition. Furthermore, the cumulative effects of multiple drilling operations using ammonium hydroxide additives in a region can amplify environmental concerns, necessitating a comprehensive approach to environmental management and impact assessment.

Health and Safety Considerations

The use of ammonium hydroxide as a drilling fluid additive necessitates careful consideration of health and safety aspects. Ammonium hydroxide, also known as aqueous ammonia, is a corrosive and toxic substance that can pose significant risks to workers and the environment if not handled properly.

Inhalation of ammonium hydroxide vapors can cause severe respiratory irritation, coughing, and shortness of breath. In high concentrations, it may lead to pulmonary edema and even death. Therefore, adequate ventilation and respiratory protection are crucial when working with this additive. Workers should be equipped with appropriate personal protective equipment (PPE), including respirators with ammonia-specific cartridges, chemical-resistant gloves, and protective eyewear.

Skin contact with ammonium hydroxide can result in chemical burns and dermatitis. Eye exposure can cause severe damage, potentially leading to blindness. Emergency eyewash stations and safety showers must be readily available in areas where this additive is used or stored. Regular safety training and drills should be conducted to ensure workers are prepared to respond to spills or exposure incidents promptly.

The storage and handling of ammonium hydroxide require special attention. It should be stored in well-ventilated areas, away from heat sources and incompatible materials such as strong acids, oxidizers, and certain metals. Proper labeling and secondary containment systems are essential to prevent accidental releases and minimize environmental impact.

Environmental considerations are also paramount. Ammonium hydroxide can be harmful to aquatic life and may cause long-term adverse effects in the aquatic environment. Proper disposal methods must be implemented to prevent contamination of water sources. Spill response plans should be in place, and teams should be trained in containment and cleanup procedures.

Regular health monitoring of workers exposed to ammonium hydroxide is advisable. This may include periodic lung function tests and skin examinations. Additionally, comprehensive risk assessments should be conducted to identify potential hazards and implement appropriate control measures.

When using ammonium hydroxide as a drilling fluid additive, it is crucial to consider its compatibility with other components of the drilling fluid system. Certain interactions could potentially lead to the release of ammonia gas or other hazardous reactions. Therefore, thorough testing and evaluation of the complete drilling fluid composition are necessary to ensure safety and stability during operations.

In conclusion, while ammonium hydroxide can offer benefits as a drilling fluid additive, its use must be carefully managed with a strong focus on health and safety. Implementing robust safety protocols, providing comprehensive training, and maintaining vigilant oversight are essential to mitigate risks and ensure the well-being of workers and the environment.

Inhalation of ammonium hydroxide vapors can cause severe respiratory irritation, coughing, and shortness of breath. In high concentrations, it may lead to pulmonary edema and even death. Therefore, adequate ventilation and respiratory protection are crucial when working with this additive. Workers should be equipped with appropriate personal protective equipment (PPE), including respirators with ammonia-specific cartridges, chemical-resistant gloves, and protective eyewear.

Skin contact with ammonium hydroxide can result in chemical burns and dermatitis. Eye exposure can cause severe damage, potentially leading to blindness. Emergency eyewash stations and safety showers must be readily available in areas where this additive is used or stored. Regular safety training and drills should be conducted to ensure workers are prepared to respond to spills or exposure incidents promptly.

The storage and handling of ammonium hydroxide require special attention. It should be stored in well-ventilated areas, away from heat sources and incompatible materials such as strong acids, oxidizers, and certain metals. Proper labeling and secondary containment systems are essential to prevent accidental releases and minimize environmental impact.

Environmental considerations are also paramount. Ammonium hydroxide can be harmful to aquatic life and may cause long-term adverse effects in the aquatic environment. Proper disposal methods must be implemented to prevent contamination of water sources. Spill response plans should be in place, and teams should be trained in containment and cleanup procedures.

Regular health monitoring of workers exposed to ammonium hydroxide is advisable. This may include periodic lung function tests and skin examinations. Additionally, comprehensive risk assessments should be conducted to identify potential hazards and implement appropriate control measures.

When using ammonium hydroxide as a drilling fluid additive, it is crucial to consider its compatibility with other components of the drilling fluid system. Certain interactions could potentially lead to the release of ammonia gas or other hazardous reactions. Therefore, thorough testing and evaluation of the complete drilling fluid composition are necessary to ensure safety and stability during operations.

In conclusion, while ammonium hydroxide can offer benefits as a drilling fluid additive, its use must be carefully managed with a strong focus on health and safety. Implementing robust safety protocols, providing comprehensive training, and maintaining vigilant oversight are essential to mitigate risks and ensure the well-being of workers and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!