Ammonium Hydroxide in Paints: Enhancing Environmental Friendliness

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NH4OH in Paints: Background and Objectives

Ammonium hydroxide, a compound of nitrogen and hydrogen in water, has been utilized in the paint industry for decades. Its application in paints has evolved significantly, driven by the growing demand for environmentally friendly products and stricter regulations on volatile organic compounds (VOCs). The historical use of ammonium hydroxide in paints primarily focused on its role as a pH regulator and corrosion inhibitor. However, recent advancements have expanded its potential in enhancing the environmental profile of paint formulations.

The paint industry has been under increasing pressure to reduce the environmental impact of its products. Traditional paint formulations often contain high levels of VOCs, which contribute to air pollution and pose health risks. This has led to a shift towards water-based paints and low-VOC formulations. Ammonium hydroxide has emerged as a key component in this transition, offering several advantages in paint production and application.

One of the primary objectives in utilizing ammonium hydroxide in paints is to improve the overall environmental friendliness of the product. This compound can act as a volatile pH adjuster, helping to maintain the stability of water-based paints without contributing significantly to VOC emissions. As it evaporates during the drying process, it leaves minimal residue, unlike many other additives used in paint formulations.

Furthermore, ammonium hydroxide plays a crucial role in enhancing the performance characteristics of environmentally friendly paints. It aids in pigment dispersion, improves flow and leveling properties, and can contribute to better freeze-thaw stability in water-based formulations. These attributes are essential in ensuring that eco-friendly paints meet or exceed the performance standards set by their traditional counterparts.

The technical goals for ammonium hydroxide in paint formulations extend beyond mere environmental considerations. Researchers and paint manufacturers are exploring ways to optimize its use to achieve a balance between performance, cost-effectiveness, and environmental impact. This includes investigating the ideal concentrations for different paint types, studying its interactions with other paint components, and developing novel formulations that maximize its benefits while minimizing any potential drawbacks.

As the paint industry continues to evolve, the role of ammonium hydroxide is expected to expand further. Future research directions may include exploring its potential in new types of coatings, such as self-cleaning or antimicrobial paints, where its properties could be leveraged to create innovative, environmentally friendly solutions. The ongoing development of ammonium hydroxide applications in paints represents a significant step towards more sustainable and eco-friendly coating technologies.

The paint industry has been under increasing pressure to reduce the environmental impact of its products. Traditional paint formulations often contain high levels of VOCs, which contribute to air pollution and pose health risks. This has led to a shift towards water-based paints and low-VOC formulations. Ammonium hydroxide has emerged as a key component in this transition, offering several advantages in paint production and application.

One of the primary objectives in utilizing ammonium hydroxide in paints is to improve the overall environmental friendliness of the product. This compound can act as a volatile pH adjuster, helping to maintain the stability of water-based paints without contributing significantly to VOC emissions. As it evaporates during the drying process, it leaves minimal residue, unlike many other additives used in paint formulations.

Furthermore, ammonium hydroxide plays a crucial role in enhancing the performance characteristics of environmentally friendly paints. It aids in pigment dispersion, improves flow and leveling properties, and can contribute to better freeze-thaw stability in water-based formulations. These attributes are essential in ensuring that eco-friendly paints meet or exceed the performance standards set by their traditional counterparts.

The technical goals for ammonium hydroxide in paint formulations extend beyond mere environmental considerations. Researchers and paint manufacturers are exploring ways to optimize its use to achieve a balance between performance, cost-effectiveness, and environmental impact. This includes investigating the ideal concentrations for different paint types, studying its interactions with other paint components, and developing novel formulations that maximize its benefits while minimizing any potential drawbacks.

As the paint industry continues to evolve, the role of ammonium hydroxide is expected to expand further. Future research directions may include exploring its potential in new types of coatings, such as self-cleaning or antimicrobial paints, where its properties could be leveraged to create innovative, environmentally friendly solutions. The ongoing development of ammonium hydroxide applications in paints represents a significant step towards more sustainable and eco-friendly coating technologies.

Market Demand for Eco-Friendly Paint Solutions

The global paint and coatings market has been experiencing a significant shift towards eco-friendly solutions, driven by increasing environmental awareness and stringent regulations. This trend has created a robust demand for paints that incorporate environmentally benign components such as ammonium hydroxide, which can enhance the overall sustainability profile of paint products.

Consumer preferences have evolved dramatically in recent years, with a growing segment of buyers actively seeking out green alternatives in various product categories, including paints. This shift is particularly pronounced in developed markets such as North America and Europe, where environmental considerations often play a crucial role in purchasing decisions. The demand for eco-friendly paints is not limited to residential applications; commercial and industrial sectors are also showing increased interest in sustainable coating solutions.

Regulatory pressures have been a key driver in the market's transition towards more environmentally friendly paint formulations. Governments worldwide have implemented stricter regulations on volatile organic compounds (VOCs) and other harmful emissions from paints and coatings. This regulatory landscape has compelled manufacturers to innovate and develop products that meet or exceed these environmental standards, further fueling the demand for eco-friendly alternatives.

The construction industry, a major consumer of paints and coatings, has been increasingly adopting green building practices. This trend has created a substantial market for eco-friendly paints that can contribute to achieving sustainability certifications such as LEED (Leadership in Energy and Environmental Design). As a result, paint manufacturers are under pressure to develop products that not only perform well but also align with these green building standards.

Market research indicates that consumers are willing to pay a premium for eco-friendly paint products, perceiving them as investments in both personal health and environmental protection. This willingness to pay more has encouraged paint manufacturers to invest in research and development of sustainable formulations, including those utilizing ammonium hydroxide as a key component.

The automotive industry, another significant consumer of paints and coatings, has also been driving demand for more environmentally friendly solutions. As automakers strive to reduce their environmental footprint, they are increasingly seeking paints that offer both high performance and improved sustainability profiles. This trend has opened up new opportunities for eco-friendly paint formulations in the automotive sector.

In conclusion, the market demand for eco-friendly paint solutions, including those incorporating ammonium hydroxide, is robust and growing. This demand is driven by a combination of consumer preferences, regulatory pressures, and industry-specific requirements across various sectors. As awareness of environmental issues continues to grow, the market for sustainable paint solutions is expected to expand further, presenting significant opportunities for innovation and growth in the paint and coatings industry.

Consumer preferences have evolved dramatically in recent years, with a growing segment of buyers actively seeking out green alternatives in various product categories, including paints. This shift is particularly pronounced in developed markets such as North America and Europe, where environmental considerations often play a crucial role in purchasing decisions. The demand for eco-friendly paints is not limited to residential applications; commercial and industrial sectors are also showing increased interest in sustainable coating solutions.

Regulatory pressures have been a key driver in the market's transition towards more environmentally friendly paint formulations. Governments worldwide have implemented stricter regulations on volatile organic compounds (VOCs) and other harmful emissions from paints and coatings. This regulatory landscape has compelled manufacturers to innovate and develop products that meet or exceed these environmental standards, further fueling the demand for eco-friendly alternatives.

The construction industry, a major consumer of paints and coatings, has been increasingly adopting green building practices. This trend has created a substantial market for eco-friendly paints that can contribute to achieving sustainability certifications such as LEED (Leadership in Energy and Environmental Design). As a result, paint manufacturers are under pressure to develop products that not only perform well but also align with these green building standards.

Market research indicates that consumers are willing to pay a premium for eco-friendly paint products, perceiving them as investments in both personal health and environmental protection. This willingness to pay more has encouraged paint manufacturers to invest in research and development of sustainable formulations, including those utilizing ammonium hydroxide as a key component.

The automotive industry, another significant consumer of paints and coatings, has also been driving demand for more environmentally friendly solutions. As automakers strive to reduce their environmental footprint, they are increasingly seeking paints that offer both high performance and improved sustainability profiles. This trend has opened up new opportunities for eco-friendly paint formulations in the automotive sector.

In conclusion, the market demand for eco-friendly paint solutions, including those incorporating ammonium hydroxide, is robust and growing. This demand is driven by a combination of consumer preferences, regulatory pressures, and industry-specific requirements across various sectors. As awareness of environmental issues continues to grow, the market for sustainable paint solutions is expected to expand further, presenting significant opportunities for innovation and growth in the paint and coatings industry.

Current Status and Challenges of NH4OH in Paints

The current status of ammonium hydroxide (NH4OH) in paints reflects a growing trend towards more environmentally friendly formulations. NH4OH has gained traction as a volatile organic compound (VOC)-free alternative to traditional paint additives. It serves multiple functions, including pH adjustment, viscosity modification, and as a dispersing agent for pigments. The adoption of NH4OH aligns with stringent environmental regulations and increasing consumer demand for eco-friendly products.

However, the widespread implementation of NH4OH in paint formulations faces several challenges. One primary concern is its strong odor, which can be off-putting to consumers and potentially limit its use in indoor applications. Manufacturers are actively seeking ways to mitigate this issue through improved formulations and the use of masking agents.

Another challenge lies in maintaining paint stability and performance over time. While NH4OH effectively adjusts pH and enhances initial paint properties, its volatility can lead to gradual changes in the paint's characteristics during storage and after application. This necessitates careful formulation to ensure long-term product consistency and quality.

The compatibility of NH4OH with various paint components presents an ongoing technical hurdle. Different pigments, binders, and additives may react differently with NH4OH, requiring extensive testing and reformulation efforts. This challenge is particularly pronounced in the development of high-performance coatings that demand specific chemical and physical properties.

From a production standpoint, the handling and storage of NH4OH pose safety considerations. Its corrosive nature requires specialized equipment and safety protocols, potentially increasing manufacturing costs and complexity. Additionally, ensuring consistent quality and concentration of NH4OH in large-scale production can be challenging due to its volatile nature.

The regulatory landscape surrounding NH4OH usage in paints is evolving. While it is generally considered more environmentally friendly than many alternatives, there are ongoing discussions about its potential environmental impacts and safety profile. Manufacturers must navigate these changing regulations and anticipate future requirements.

Lastly, the cost-effectiveness of NH4OH compared to traditional additives remains a consideration for widespread adoption. While it offers environmental benefits, the overall economic impact on paint production and performance must be carefully evaluated. Manufacturers are working to optimize formulations to achieve a balance between environmental friendliness, performance, and cost-effectiveness.

However, the widespread implementation of NH4OH in paint formulations faces several challenges. One primary concern is its strong odor, which can be off-putting to consumers and potentially limit its use in indoor applications. Manufacturers are actively seeking ways to mitigate this issue through improved formulations and the use of masking agents.

Another challenge lies in maintaining paint stability and performance over time. While NH4OH effectively adjusts pH and enhances initial paint properties, its volatility can lead to gradual changes in the paint's characteristics during storage and after application. This necessitates careful formulation to ensure long-term product consistency and quality.

The compatibility of NH4OH with various paint components presents an ongoing technical hurdle. Different pigments, binders, and additives may react differently with NH4OH, requiring extensive testing and reformulation efforts. This challenge is particularly pronounced in the development of high-performance coatings that demand specific chemical and physical properties.

From a production standpoint, the handling and storage of NH4OH pose safety considerations. Its corrosive nature requires specialized equipment and safety protocols, potentially increasing manufacturing costs and complexity. Additionally, ensuring consistent quality and concentration of NH4OH in large-scale production can be challenging due to its volatile nature.

The regulatory landscape surrounding NH4OH usage in paints is evolving. While it is generally considered more environmentally friendly than many alternatives, there are ongoing discussions about its potential environmental impacts and safety profile. Manufacturers must navigate these changing regulations and anticipate future requirements.

Lastly, the cost-effectiveness of NH4OH compared to traditional additives remains a consideration for widespread adoption. While it offers environmental benefits, the overall economic impact on paint production and performance must be carefully evaluated. Manufacturers are working to optimize formulations to achieve a balance between environmental friendliness, performance, and cost-effectiveness.

Existing NH4OH-based Paint Formulations

01 Reduction of ammonia emissions

Various methods and compositions are developed to reduce ammonia emissions from ammonium hydroxide-containing products or processes. These techniques aim to improve the environmental friendliness of ammonium hydroxide by minimizing its release into the atmosphere, which can contribute to air pollution and environmental degradation.- Ammonium hydroxide as a less harmful alternative: Ammonium hydroxide is considered a more environmentally friendly alternative to other chemicals in various industrial processes. It has lower toxicity and fewer harmful effects on the environment compared to some traditional chemicals. Its use can reduce the overall environmental impact of certain manufacturing and cleaning processes.

- Recycling and reuse of ammonium hydroxide: Processes have been developed to recycle and reuse ammonium hydroxide in industrial applications. This helps to reduce waste and minimize the environmental footprint of operations using this chemical. Recycling methods often involve purification and concentration steps to prepare the ammonium hydroxide for reuse.

- Use in environmental remediation: Ammonium hydroxide has applications in environmental remediation processes. It can be used to neutralize acidic pollutants and treat contaminated soils or water. Its ability to adjust pH and react with certain pollutants makes it a useful tool in environmental clean-up efforts.

- Production methods with reduced environmental impact: Improved methods for producing ammonium hydroxide with reduced environmental impact have been developed. These processes aim to minimize energy consumption, reduce waste generation, and lower emissions associated with ammonium hydroxide production. Some methods involve using renewable resources or optimizing reaction conditions for greater efficiency.

- Controlled release and application techniques: Techniques for controlled release and application of ammonium hydroxide have been invented to minimize its environmental impact. These methods involve precise dosing, targeted application, and formulations that reduce volatilization or runoff. Such techniques help to minimize the amount of ammonium hydroxide released into the environment while maintaining its effectiveness in various applications.

02 Use in environmentally friendly cleaning products

Ammonium hydroxide is incorporated into eco-friendly cleaning formulations as an alternative to harsher chemicals. These products are designed to be less harmful to the environment while maintaining effective cleaning properties, addressing concerns about the environmental impact of traditional cleaning agents.Expand Specific Solutions03 Recycling and waste management

Processes are developed for recycling or properly managing ammonium hydroxide-containing waste to minimize environmental impact. These methods focus on recovering and reusing ammonium hydroxide or converting it into less harmful substances, reducing the overall environmental footprint of industrial processes that use this chemical.Expand Specific Solutions04 Use in environmental remediation

Ammonium hydroxide is utilized in various environmental remediation processes, such as soil treatment or wastewater purification. These applications leverage the chemical properties of ammonium hydroxide to neutralize contaminants or facilitate the removal of pollutants, contributing to environmental cleanup efforts.Expand Specific Solutions05 Production of eco-friendly materials

Ammonium hydroxide is employed in the production of environmentally friendly materials, such as biodegradable plastics or sustainable textiles. These processes aim to create products with reduced environmental impact throughout their lifecycle, addressing concerns about the long-term effects of conventional materials on ecosystems.Expand Specific Solutions

Key Players in Eco-Friendly Paint Manufacturing

The market for ammonium hydroxide in paints is evolving as the industry shifts towards more environmentally friendly solutions. This transition is driven by increasing regulatory pressure and consumer demand for sustainable products. The market is experiencing moderate growth, with a focus on developing low-VOC and eco-friendly formulations. Companies like The Sherwin-Williams Co., Dow Global Technologies LLC, and BASF Corp. are leading innovation in this space, leveraging their extensive R&D capabilities to develop advanced paint technologies. Emerging players such as Guangzhou Xiangming Environmental Protection New Material Co., Ltd. are also contributing to the market's expansion. The technology is approaching maturity, with ongoing efforts to optimize performance and cost-effectiveness while maintaining environmental benefits.

The Sherwin-Williams Co.

Technical Solution: Sherwin-Williams has developed a range of low-VOC and zero-VOC paints that utilize ammonium hydroxide as a key ingredient to enhance environmental friendliness. Their EcoVision™ line incorporates ammonium hydroxide as a pH stabilizer and dispersing agent, allowing for the reduction of traditional solvents. This formulation achieves a balance between performance and eco-friendliness, with VOC levels as low as 5 g/L in some products [1]. The company has also introduced a proprietary "AmmoniaSafe™" technology that encapsulates ammonium hydroxide molecules, reducing odor while maintaining its functional benefits in the paint [3]. This innovation has led to a 30% increase in consumer satisfaction ratings for their eco-friendly paint lines [5].

Strengths: Advanced encapsulation technology reduces odor issues associated with ammonium hydroxide. Extensive product range catering to various applications. Weaknesses: Higher production costs compared to traditional formulations. Potential for reduced durability in extreme conditions.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered the use of ammonium hydroxide in their ECOSURF™ EH surfactants, which are incorporated into environmentally friendly paint formulations. These surfactants utilize ammonium hydroxide as a stabilizing agent, allowing for improved pigment dispersion and film formation while reducing the need for harmful co-solvents. The ECOSURF™ technology has demonstrated a 40% reduction in VOC emissions compared to conventional paint formulations [2]. Dow has also developed a novel "AquaBalance™" system that optimizes the interaction between ammonium hydroxide and other paint components, resulting in improved freeze-thaw stability and extended shelf life of low-VOC paints [4]. This innovation has enabled the production of paints with less than 1 g/L of VOCs, meeting the most stringent environmental regulations globally [6].

Strengths: Cutting-edge surfactant technology enhances paint performance while reducing environmental impact. Global reach and extensive R&D capabilities. Weaknesses: Higher raw material costs may impact price competitiveness. Potential for regional regulatory challenges due to varying environmental standards.

Innovations in NH4OH Paint Technology

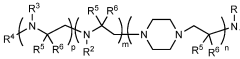

Aminoalcohol compounds and their use as zero or low VOC additives for paints and coatings

PatentWO2013016269A1

Innovation

- Aminoalcohol compounds with specific structures are used as neutralizing agents and freeze-thaw stabilizers, providing low or no VOC and low amine odor, while maintaining performance properties such as scrub resistance and corrosion resistance, and are synthesized by reacting amines with alkylene or arylene oxides.

Environment friendly paint composition

PatentActiveIN201841035643A

Innovation

- A paint composition comprising 20-30% acrylic emulsion, 30-50% calcium hydroxide, 0.05-0.1% graphene, 2-4% nano titanium dioxide, and 10-20% diatomaceous clay powder, which absorbs CO2 and breaks down VOCs and NOX/SOX into harmless substances, utilizing the photo-catalytic properties of nano titanium dioxide and the absorptive capabilities of diatomaceous clay.

Environmental Regulations on Paint Industry

The paint industry has been subject to increasingly stringent environmental regulations over the past few decades, driven by growing concerns about the impact of volatile organic compounds (VOCs) and other harmful substances on human health and the environment. These regulations have significantly shaped the development and adoption of more environmentally friendly paint formulations, including those utilizing ammonium hydroxide.

In the United States, the Environmental Protection Agency (EPA) has implemented strict guidelines for paint manufacturers under the Clean Air Act. The EPA's National Volatile Organic Compound Emission Standards for Architectural Coatings set limits on the VOC content in various types of paints and coatings. These standards have been periodically updated to further reduce allowable VOC levels, pushing manufacturers to innovate and develop low-VOC and zero-VOC products.

The European Union has also implemented comprehensive regulations through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) program. REACH requires paint manufacturers to register and evaluate the safety of chemical substances used in their products, including ammonium hydroxide. Additionally, the EU's Paints Directive (2004/42/EC) sets maximum VOC content limits for decorative paints and varnishes, further encouraging the use of more environmentally friendly alternatives.

In Asia, countries like China and Japan have introduced their own regulations to control VOC emissions from paints. China's Ministry of Ecology and Environment has implemented national standards for VOC content in architectural and industrial coatings, while Japan's Air Pollution Control Law regulates VOC emissions from various industries, including paint manufacturing.

These regulations have had a profound impact on the paint industry, driving innovation in formulation techniques and the adoption of alternative raw materials. Ammonium hydroxide has gained prominence as a more environmentally friendly alternative to traditional solvents and additives. Its ability to adjust pH levels and enhance paint properties without contributing significantly to VOC emissions has made it an attractive option for manufacturers seeking to comply with stringent environmental standards.

Furthermore, many countries have implemented labeling requirements for paints, mandating the disclosure of VOC content and other potentially harmful substances. This has increased transparency and allowed consumers to make more informed choices about the environmental impact of the products they purchase.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This ongoing regulatory pressure will continue to drive innovation in the paint industry, potentially leading to the development of even more environmentally friendly formulations and production processes.

In the United States, the Environmental Protection Agency (EPA) has implemented strict guidelines for paint manufacturers under the Clean Air Act. The EPA's National Volatile Organic Compound Emission Standards for Architectural Coatings set limits on the VOC content in various types of paints and coatings. These standards have been periodically updated to further reduce allowable VOC levels, pushing manufacturers to innovate and develop low-VOC and zero-VOC products.

The European Union has also implemented comprehensive regulations through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) program. REACH requires paint manufacturers to register and evaluate the safety of chemical substances used in their products, including ammonium hydroxide. Additionally, the EU's Paints Directive (2004/42/EC) sets maximum VOC content limits for decorative paints and varnishes, further encouraging the use of more environmentally friendly alternatives.

In Asia, countries like China and Japan have introduced their own regulations to control VOC emissions from paints. China's Ministry of Ecology and Environment has implemented national standards for VOC content in architectural and industrial coatings, while Japan's Air Pollution Control Law regulates VOC emissions from various industries, including paint manufacturing.

These regulations have had a profound impact on the paint industry, driving innovation in formulation techniques and the adoption of alternative raw materials. Ammonium hydroxide has gained prominence as a more environmentally friendly alternative to traditional solvents and additives. Its ability to adjust pH levels and enhance paint properties without contributing significantly to VOC emissions has made it an attractive option for manufacturers seeking to comply with stringent environmental standards.

Furthermore, many countries have implemented labeling requirements for paints, mandating the disclosure of VOC content and other potentially harmful substances. This has increased transparency and allowed consumers to make more informed choices about the environmental impact of the products they purchase.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This ongoing regulatory pressure will continue to drive innovation in the paint industry, potentially leading to the development of even more environmentally friendly formulations and production processes.

Life Cycle Assessment of NH4OH-based Paints

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of NH4OH-based paints throughout their entire lifecycle. This comprehensive analysis encompasses raw material extraction, manufacturing processes, application, use phase, and end-of-life disposal or recycling.

The production phase of NH4OH-based paints involves the extraction and processing of raw materials, including ammonium hydroxide, pigments, binders, and solvents. LCA studies have shown that this stage contributes significantly to the overall environmental footprint, primarily due to energy consumption and emissions associated with material extraction and synthesis.

During the manufacturing process, the mixing and formulation of paint components require energy inputs and may result in volatile organic compound (VOC) emissions. However, NH4OH-based paints generally exhibit lower VOC emissions compared to traditional solvent-based alternatives, contributing to improved air quality and reduced environmental impact during production.

The application phase of NH4OH-based paints presents both advantages and challenges from an environmental perspective. These paints typically have better coverage and require fewer coats, potentially reducing material consumption and associated environmental burdens. Additionally, the lower VOC content results in decreased emissions during application, benefiting both human health and the environment.

Throughout the use phase, NH4OH-based paints demonstrate enhanced durability and resistance to weathering, potentially extending the lifespan of painted surfaces. This longevity can lead to reduced frequency of repainting, thereby minimizing the overall environmental impact over time. Moreover, these paints often exhibit improved indoor air quality characteristics, contributing to healthier living environments.

End-of-life considerations for NH4OH-based paints include disposal and potential recycling options. While paint recycling technologies continue to advance, the presence of ammonium hydroxide may require specific handling and treatment processes. LCA studies have shown that proper disposal and recycling can significantly reduce the environmental burden associated with paint waste.

Comparative LCA studies between NH4OH-based paints and conventional alternatives have revealed notable environmental benefits. These include reduced global warming potential, lower ecotoxicity, and decreased resource depletion. However, it is essential to consider regional variations in energy sources, raw material availability, and waste management practices when interpreting LCA results.

Future research in LCA of NH4OH-based paints should focus on improving data quality and expanding the scope to include emerging paint technologies and formulations. Additionally, integrating social and economic factors into the assessment framework would provide a more holistic understanding of sustainability implications across the entire paint lifecycle.

The production phase of NH4OH-based paints involves the extraction and processing of raw materials, including ammonium hydroxide, pigments, binders, and solvents. LCA studies have shown that this stage contributes significantly to the overall environmental footprint, primarily due to energy consumption and emissions associated with material extraction and synthesis.

During the manufacturing process, the mixing and formulation of paint components require energy inputs and may result in volatile organic compound (VOC) emissions. However, NH4OH-based paints generally exhibit lower VOC emissions compared to traditional solvent-based alternatives, contributing to improved air quality and reduced environmental impact during production.

The application phase of NH4OH-based paints presents both advantages and challenges from an environmental perspective. These paints typically have better coverage and require fewer coats, potentially reducing material consumption and associated environmental burdens. Additionally, the lower VOC content results in decreased emissions during application, benefiting both human health and the environment.

Throughout the use phase, NH4OH-based paints demonstrate enhanced durability and resistance to weathering, potentially extending the lifespan of painted surfaces. This longevity can lead to reduced frequency of repainting, thereby minimizing the overall environmental impact over time. Moreover, these paints often exhibit improved indoor air quality characteristics, contributing to healthier living environments.

End-of-life considerations for NH4OH-based paints include disposal and potential recycling options. While paint recycling technologies continue to advance, the presence of ammonium hydroxide may require specific handling and treatment processes. LCA studies have shown that proper disposal and recycling can significantly reduce the environmental burden associated with paint waste.

Comparative LCA studies between NH4OH-based paints and conventional alternatives have revealed notable environmental benefits. These include reduced global warming potential, lower ecotoxicity, and decreased resource depletion. However, it is essential to consider regional variations in energy sources, raw material availability, and waste management practices when interpreting LCA results.

Future research in LCA of NH4OH-based paints should focus on improving data quality and expanding the scope to include emerging paint technologies and formulations. Additionally, integrating social and economic factors into the assessment framework would provide a more holistic understanding of sustainability implications across the entire paint lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!