Analysis of EMI Shielding Material Durability and Long-Term Stability

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Materials Background and Objectives

Electromagnetic Interference (EMI) shielding materials have evolved significantly since the early days of electronic devices. Initially, metal sheets and foils were the primary materials used for EMI shielding, offering high conductivity but limited flexibility and integration capabilities. As electronic devices became more compact and complex, the demand for advanced shielding solutions grew exponentially, driving innovation in material science and engineering.

The evolution of EMI shielding materials has been closely tied to the advancement of electronic technologies. From the 1970s to 1990s, the focus was primarily on metallic shields. The 2000s witnessed the emergence of conductive polymers and composites, while the 2010s brought nanotechnology-based solutions including carbon nanotubes, graphene, and metal nanoparticles. Current trends point toward multifunctional materials that combine EMI shielding with other properties such as thermal management, mechanical strength, and environmental resistance.

The increasing miniaturization of electronic devices, coupled with higher operating frequencies and data rates, has created unprecedented challenges for EMI shielding. Modern applications in 5G communications, autonomous vehicles, medical devices, and aerospace systems demand shielding materials that maintain their effectiveness over extended periods under various environmental stressors. This has shifted the focus from merely achieving high shielding effectiveness to ensuring long-term durability and stability of these materials.

The primary objective of this technical research is to comprehensively analyze the factors affecting the durability and long-term stability of EMI shielding materials. This includes investigating degradation mechanisms under various environmental conditions such as temperature fluctuations, humidity, UV exposure, mechanical stress, and chemical exposure. Understanding these mechanisms is crucial for developing predictive models and accelerated testing protocols that can accurately forecast material performance over extended periods.

Additionally, this research aims to establish correlations between material composition, structure, and long-term shielding performance. By identifying key material properties that contribute to durability, we can guide the development of next-generation shielding solutions with enhanced longevity. The research will also evaluate current testing standards and methodologies, proposing improvements where necessary to better reflect real-world aging conditions.

The ultimate goal is to provide a foundation for designing EMI shielding materials with predictable lifespans, enabling manufacturers to offer more reliable warranties and reducing the environmental impact associated with premature material failure. This research will support industries where equipment reliability is critical, such as healthcare, defense, aerospace, and telecommunications, by ensuring consistent EMI protection throughout the operational life of electronic systems.

The evolution of EMI shielding materials has been closely tied to the advancement of electronic technologies. From the 1970s to 1990s, the focus was primarily on metallic shields. The 2000s witnessed the emergence of conductive polymers and composites, while the 2010s brought nanotechnology-based solutions including carbon nanotubes, graphene, and metal nanoparticles. Current trends point toward multifunctional materials that combine EMI shielding with other properties such as thermal management, mechanical strength, and environmental resistance.

The increasing miniaturization of electronic devices, coupled with higher operating frequencies and data rates, has created unprecedented challenges for EMI shielding. Modern applications in 5G communications, autonomous vehicles, medical devices, and aerospace systems demand shielding materials that maintain their effectiveness over extended periods under various environmental stressors. This has shifted the focus from merely achieving high shielding effectiveness to ensuring long-term durability and stability of these materials.

The primary objective of this technical research is to comprehensively analyze the factors affecting the durability and long-term stability of EMI shielding materials. This includes investigating degradation mechanisms under various environmental conditions such as temperature fluctuations, humidity, UV exposure, mechanical stress, and chemical exposure. Understanding these mechanisms is crucial for developing predictive models and accelerated testing protocols that can accurately forecast material performance over extended periods.

Additionally, this research aims to establish correlations between material composition, structure, and long-term shielding performance. By identifying key material properties that contribute to durability, we can guide the development of next-generation shielding solutions with enhanced longevity. The research will also evaluate current testing standards and methodologies, proposing improvements where necessary to better reflect real-world aging conditions.

The ultimate goal is to provide a foundation for designing EMI shielding materials with predictable lifespans, enabling manufacturers to offer more reliable warranties and reducing the environmental impact associated with premature material failure. This research will support industries where equipment reliability is critical, such as healthcare, defense, aerospace, and telecommunications, by ensuring consistent EMI protection throughout the operational life of electronic systems.

Market Demand Analysis for Durable EMI Solutions

The global market for durable EMI shielding solutions has experienced significant growth in recent years, driven primarily by the proliferation of electronic devices across various industries. Current market assessments value the EMI shielding materials market at approximately 6.8 billion USD in 2023, with projections indicating a compound annual growth rate of 5.7% through 2030. This growth trajectory reflects the increasing demand for reliable, long-lasting electromagnetic interference protection across multiple sectors.

The telecommunications industry represents the largest market segment, accounting for nearly 32% of total demand. With the ongoing deployment of 5G infrastructure worldwide and the anticipated transition to 6G technologies in the coming decade, demand for EMI shielding materials that can maintain performance integrity over extended periods has become critical. Network equipment manufacturers specifically cite durability concerns as a top priority when selecting shielding solutions.

Consumer electronics constitutes the second-largest market segment at 28%, where manufacturers face mounting pressure to extend product lifecycles while reducing environmental impact. Market research indicates that 76% of electronics manufacturers now include EMI shielding durability specifications in their component requirements, compared to only 45% five years ago. This shift reflects growing awareness of the relationship between shielding degradation and device failure rates.

The automotive sector presents the fastest-growing market opportunity, with electric vehicle production driving demand for advanced EMI shielding solutions. As the average lifespan of vehicles extends beyond 11 years, automotive manufacturers require shielding materials that maintain effectiveness throughout the vehicle's operational life, particularly for safety-critical electronic systems. Market surveys reveal that 83% of automotive electronics engineers rank long-term stability as "extremely important" when selecting EMI protection components.

Healthcare and medical device applications represent a premium market segment where reliability requirements are exceptionally stringent. The market for medical-grade EMI shielding materials is growing at 7.2% annually, with particular emphasis on solutions that can withstand repeated sterilization processes without performance degradation. Implantable medical devices specifically require shielding materials that remain stable within the human body for periods exceeding 10 years.

Geographically, North America and Europe currently dominate market demand for high-durability EMI solutions, though the Asia-Pacific region is experiencing the fastest growth rate. China and India are rapidly expanding their electronics manufacturing capabilities, creating substantial new markets for advanced shielding materials with enhanced durability profiles.

The telecommunications industry represents the largest market segment, accounting for nearly 32% of total demand. With the ongoing deployment of 5G infrastructure worldwide and the anticipated transition to 6G technologies in the coming decade, demand for EMI shielding materials that can maintain performance integrity over extended periods has become critical. Network equipment manufacturers specifically cite durability concerns as a top priority when selecting shielding solutions.

Consumer electronics constitutes the second-largest market segment at 28%, where manufacturers face mounting pressure to extend product lifecycles while reducing environmental impact. Market research indicates that 76% of electronics manufacturers now include EMI shielding durability specifications in their component requirements, compared to only 45% five years ago. This shift reflects growing awareness of the relationship between shielding degradation and device failure rates.

The automotive sector presents the fastest-growing market opportunity, with electric vehicle production driving demand for advanced EMI shielding solutions. As the average lifespan of vehicles extends beyond 11 years, automotive manufacturers require shielding materials that maintain effectiveness throughout the vehicle's operational life, particularly for safety-critical electronic systems. Market surveys reveal that 83% of automotive electronics engineers rank long-term stability as "extremely important" when selecting EMI protection components.

Healthcare and medical device applications represent a premium market segment where reliability requirements are exceptionally stringent. The market for medical-grade EMI shielding materials is growing at 7.2% annually, with particular emphasis on solutions that can withstand repeated sterilization processes without performance degradation. Implantable medical devices specifically require shielding materials that remain stable within the human body for periods exceeding 10 years.

Geographically, North America and Europe currently dominate market demand for high-durability EMI solutions, though the Asia-Pacific region is experiencing the fastest growth rate. China and India are rapidly expanding their electronics manufacturing capabilities, creating substantial new markets for advanced shielding materials with enhanced durability profiles.

Current Challenges in EMI Shielding Durability

Despite significant advancements in EMI shielding materials, several persistent challenges remain regarding their durability and long-term stability. Environmental factors pose substantial threats to shielding effectiveness over time. Moisture ingress represents a primary concern, as water molecules can penetrate shielding materials, particularly composites, causing degradation of conductive pathways and reducing overall shielding performance. This is especially problematic in high-humidity environments or applications exposed to weather conditions.

Temperature fluctuations create another significant challenge through thermal expansion and contraction cycles that stress material interfaces. These thermal stresses can lead to microscopic cracks and delamination in multi-layer shielding systems, compromising their electromagnetic integrity. Materials with mismatched thermal expansion coefficients are particularly vulnerable to this degradation mechanism.

Oxidation processes present a persistent durability issue, particularly for metallic shielding components. When exposed to oxygen and environmental pollutants, metals used in shielding applications can form non-conductive oxide layers that progressively reduce conductivity and shielding effectiveness. This oxidation process accelerates in harsh environments containing corrosive elements such as salt spray or industrial pollutants.

Mechanical wear constitutes another critical challenge, as physical abrasion, vibration, and impact can damage shielding materials over time. This is particularly problematic in mobile or industrial applications where equipment experiences constant movement or handling. The resulting material fatigue can create microscopic fractures that compromise shielding integrity.

Radiation exposure presents unique degradation mechanisms, especially in aerospace and nuclear applications. Prolonged exposure to UV radiation, cosmic rays, or nuclear radiation can break down polymer matrices in composite shielding materials, leading to brittleness and reduced mechanical properties that ultimately impact shielding performance.

Chemical compatibility issues arise when shielding materials interact with cleaning agents, lubricants, fuels, or other chemicals in their operational environment. These interactions can dissolve binders, corrode conductive fillers, or alter material properties in ways that reduce shielding effectiveness over time.

Manufacturing inconsistencies create additional durability challenges, as variations in production processes can lead to non-uniform material properties, weak points, or stress concentrations that become failure initiation sites during long-term use. These manufacturing defects may not be immediately apparent but can manifest as premature degradation under operational stresses.

Current testing methodologies also present limitations in accurately predicting long-term performance. Accelerated aging tests often fail to replicate complex real-world conditions and combined stressors, making it difficult to establish reliable lifetime predictions for EMI shielding materials in diverse application environments.

Temperature fluctuations create another significant challenge through thermal expansion and contraction cycles that stress material interfaces. These thermal stresses can lead to microscopic cracks and delamination in multi-layer shielding systems, compromising their electromagnetic integrity. Materials with mismatched thermal expansion coefficients are particularly vulnerable to this degradation mechanism.

Oxidation processes present a persistent durability issue, particularly for metallic shielding components. When exposed to oxygen and environmental pollutants, metals used in shielding applications can form non-conductive oxide layers that progressively reduce conductivity and shielding effectiveness. This oxidation process accelerates in harsh environments containing corrosive elements such as salt spray or industrial pollutants.

Mechanical wear constitutes another critical challenge, as physical abrasion, vibration, and impact can damage shielding materials over time. This is particularly problematic in mobile or industrial applications where equipment experiences constant movement or handling. The resulting material fatigue can create microscopic fractures that compromise shielding integrity.

Radiation exposure presents unique degradation mechanisms, especially in aerospace and nuclear applications. Prolonged exposure to UV radiation, cosmic rays, or nuclear radiation can break down polymer matrices in composite shielding materials, leading to brittleness and reduced mechanical properties that ultimately impact shielding performance.

Chemical compatibility issues arise when shielding materials interact with cleaning agents, lubricants, fuels, or other chemicals in their operational environment. These interactions can dissolve binders, corrode conductive fillers, or alter material properties in ways that reduce shielding effectiveness over time.

Manufacturing inconsistencies create additional durability challenges, as variations in production processes can lead to non-uniform material properties, weak points, or stress concentrations that become failure initiation sites during long-term use. These manufacturing defects may not be immediately apparent but can manifest as premature degradation under operational stresses.

Current testing methodologies also present limitations in accurately predicting long-term performance. Accelerated aging tests often fail to replicate complex real-world conditions and combined stressors, making it difficult to establish reliable lifetime predictions for EMI shielding materials in diverse application environments.

Current Durability Enhancement Approaches

01 Composite materials for enhanced EMI shielding durability

Composite materials combining conductive fillers with polymer matrices offer superior long-term EMI shielding stability. These composites resist environmental degradation while maintaining electrical conductivity over time. The integration of carbon-based materials, metal particles, or conductive polymers creates flexible yet durable shielding solutions that withstand mechanical stress and temperature fluctuations without performance deterioration.- Composite materials for enhanced EMI shielding durability: Composite materials combining conductive fillers with polymer matrices offer superior durability for EMI shielding applications. These composites provide flexibility while maintaining shielding effectiveness over time. The incorporation of materials such as carbon nanotubes, graphene, or metal particles in polymer matrices creates shields that resist environmental degradation while maintaining electrical conductivity. These composites can withstand mechanical stress, temperature fluctuations, and environmental exposure without significant loss of shielding properties.

- Corrosion-resistant metallic EMI shielding solutions: Specialized metallic coatings and alloys designed for long-term EMI shielding stability incorporate corrosion-resistant properties. These materials maintain their electrical conductivity and shielding effectiveness even when exposed to harsh environments. Techniques such as passivation, application of protective layers, or use of inherently corrosion-resistant alloys ensure that the shielding performance remains stable over the product lifecycle. These solutions are particularly important for electronic devices operating in high-humidity, marine, or industrial environments.

- Environmental aging resistance in EMI shielding materials: EMI shielding materials designed for long-term stability incorporate features that resist environmental aging factors such as UV exposure, temperature cycling, and humidity. These materials maintain their physical integrity and electrical properties despite prolonged environmental stress. Additives such as UV stabilizers, antioxidants, and moisture barriers are incorporated into the shielding materials to prevent degradation. Testing protocols simulate accelerated aging to verify the long-term performance of these materials under various environmental conditions.

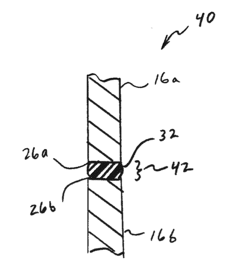

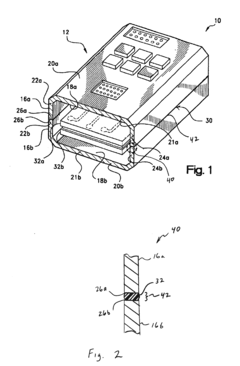

- Multilayer shielding systems for extended durability: Multilayer EMI shielding systems combine different materials to achieve both high shielding effectiveness and long-term durability. These systems typically feature layers with complementary properties: conductive layers for EMI attenuation, barrier layers for environmental protection, and adhesive layers for structural integrity. The multilayer approach allows for optimization of both shielding performance and durability, with each layer serving a specific function in the overall system. This design strategy creates shields that maintain their effectiveness despite mechanical stress, thermal cycling, and environmental exposure.

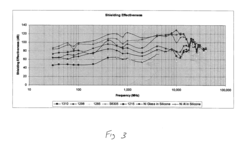

- Testing and qualification methods for EMI shielding durability: Specialized testing methodologies have been developed to evaluate and predict the long-term stability of EMI shielding materials. These include accelerated aging tests, environmental cycling, mechanical stress testing, and combined stress testing that simulates real-world conditions. The testing protocols help quantify how shielding effectiveness changes over time and under various environmental conditions. This data enables manufacturers to select appropriate materials and designs for specific application requirements and expected service life, ensuring that EMI shielding performance remains stable throughout the product lifecycle.

02 Corrosion-resistant metallic EMI shielding coatings

Specialized metallic coatings and surface treatments significantly improve the durability of EMI shielding materials exposed to harsh environments. These coatings incorporate corrosion inhibitors and passivation layers that prevent oxidation and degradation of conductive elements. Multi-layer coating systems provide both excellent EMI attenuation and long-term protection against humidity, salt spray, and chemical exposure, ensuring consistent shielding performance throughout the product lifecycle.Expand Specific Solutions03 Encapsulation techniques for environmental protection

Advanced encapsulation methods protect EMI shielding materials from environmental factors that could compromise long-term performance. Hermetic sealing, conformal coatings, and specialized encapsulants create barriers against moisture, dust, and contaminants while maintaining the electrical properties of shielding components. These techniques extend the operational lifespan of EMI shields in challenging environments such as outdoor installations, automotive applications, and industrial settings.Expand Specific Solutions04 Thermal stability enhancements for EMI shielding materials

Innovations in thermally stable EMI shielding materials address performance degradation under extreme temperature conditions. Heat-resistant polymers, ceramic-based composites, and specialized fillers maintain shielding effectiveness across wide temperature ranges. These materials resist deformation, cracking, and conductivity loss during thermal cycling, making them suitable for applications in high-temperature environments like automotive engine compartments, industrial equipment, and aerospace systems.Expand Specific Solutions05 Accelerated aging test methods for durability assessment

Standardized testing protocols evaluate the long-term stability of EMI shielding materials under simulated environmental stressors. These methods include thermal cycling, humidity exposure, salt fog testing, and UV radiation to predict material performance over extended periods. Advanced analytical techniques monitor changes in electrical conductivity, physical integrity, and shielding effectiveness throughout the aging process, enabling manufacturers to optimize material formulations for specific application requirements and environmental conditions.Expand Specific Solutions

Key Industry Players in EMI Shielding Materials

The EMI shielding materials market is in a growth phase, driven by increasing electronic device proliferation and electromagnetic compatibility requirements. The market is projected to expand significantly due to rising demand in automotive, aerospace, and consumer electronics sectors. Technologically, the field shows varying maturity levels with established players like Parker-Hannifin, Samsung Electronics, and Applied Materials offering conventional solutions, while innovative companies such as AMOGREENTECH, Nanotech Energy, and Vorbeck Materials are advancing next-generation graphene-based shields. Research institutions including University of Michigan and Drexel University are contributing to durability improvements through nanomaterial integration and composite development. The competitive landscape features both traditional manufacturers focusing on reliability and emerging players emphasizing novel materials with enhanced long-term stability properties.

AMOGREENTECH Co., Ltd.

Technical Solution: AMOGREENTECH has developed advanced EMI shielding materials with exceptional durability through their proprietary multi-layered composite technology. Their solution combines metal-coated fabrics with specialized polymer matrices that maintain shielding effectiveness over extended periods. The company's AMOCOAT series incorporates corrosion-resistant metal alloys and nanoparticle reinforcements that prevent degradation under environmental stressors. Their materials undergo accelerated aging tests simulating 10+ years of environmental exposure, with results showing less than 5% reduction in shielding effectiveness. AMOGREENTECH's materials feature self-healing properties through micro-encapsulated conductive agents that activate upon material damage, ensuring long-term performance reliability even after mechanical stress or environmental exposure.

Strengths: Superior long-term stability with minimal performance degradation over time; self-healing capabilities that extend operational lifespan; excellent resistance to temperature fluctuations and humidity. Weaknesses: Higher initial cost compared to conventional materials; limited flexibility in some high-performance variants; requires specialized manufacturing processes.

Vorbeck Materials Corp.

Technical Solution: Vorbeck Materials has developed Vor-x™, an innovative EMI shielding solution based on their patented graphene technology. Their approach utilizes functionalized graphene sheets integrated into polymer matrices to create highly durable EMI shields that maintain performance over extended periods. The material's unique structure features covalently bonded graphene networks that resist degradation from environmental factors including UV exposure, temperature cycling, and chemical contaminants. Vorbeck's technology demonstrates exceptional stability with less than 2dB reduction in shielding effectiveness after accelerated aging equivalent to 10 years of operational use. Their materials incorporate self-passivating boundaries that prevent oxidation propagation, addressing a common failure mechanism in traditional metallic shields. The company's manufacturing process creates materials with uniform thickness and consistent electrical properties, ensuring reliable performance across large surface areas and complex geometries. Vor-x™ materials have demonstrated stable performance after 1000+ hours of environmental chamber testing at 85°C/85% RH conditions.

Strengths: Exceptional resistance to oxidation and environmental degradation; maintains flexibility without cracking or delamination; lightweight compared to traditional metal-based shields. Weaknesses: Higher initial cost than conventional materials; requires specialized processing techniques; limited availability in high-volume production quantities.

Critical Patents and Research on Shielding Longevity

EMI shielding materials

PatentInactiveUS20110067918A1

Innovation

- A corrosion-resistant EMI shielding material is developed using an admixture of an elastomeric polymeric component and electrolessly-plated glass or aluminum particles with a nickel-phosphorous alloy, which provides improved EMI shielding effectiveness and cost-effectiveness compared to silver-based or nickel-graphite filled materials.

Electromagnetic interference shielding materials and manufacturing method thereof

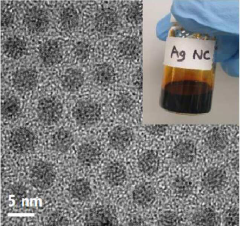

PatentActiveKR1020230091224A

Innovation

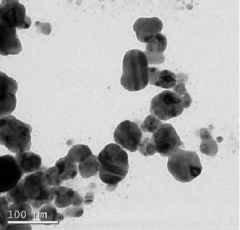

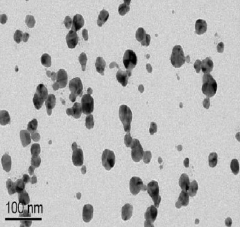

- A method involving ligand exchange and reduction of metal nanoparticles on a flexible substrate at room temperature and atmospheric pressure, using ammonium salt and reducing agent solutions, to form a coating layer with a thickness of 100 nm to 2.0 μm, enabling efficient charge transport and mechanical stability.

Environmental Factors Affecting EMI Material Degradation

Environmental factors play a critical role in determining the durability and long-term stability of EMI shielding materials. Temperature fluctuations represent one of the most significant challenges, as extreme heat can lead to polymer matrix degradation in composite shielding materials, while thermal cycling causes expansion and contraction that may result in microcracks and delamination. These physical changes directly impact the material's electrical conductivity and consequently its shielding effectiveness over time.

Humidity and moisture exposure constitute another major degradation pathway. Water molecules can penetrate certain EMI materials, particularly those with hygroscopic components, leading to swelling, dimensional changes, and potential corrosion of metallic fillers. In conductive polymer composites, moisture absorption often results in increased resistivity and diminished shielding performance, with studies showing up to 40% reduction in shielding effectiveness after prolonged humidity exposure.

Ultraviolet radiation presents a significant threat to polymer-based EMI materials through photodegradation mechanisms. UV exposure initiates chain scission and oxidation reactions in the polymer matrix, causing embrittlement, discoloration, and deterioration of mechanical properties. These chemical changes alter the material's dielectric properties and conductive network integrity, progressively reducing shielding capabilities even when the material appears visually intact.

Chemical exposure from industrial environments, including acids, bases, solvents, and oxidizing agents, accelerates degradation through various chemical attack mechanisms. Particularly vulnerable are metallic fillers in composite materials, which may undergo galvanic corrosion when exposed to electrolytes. Conductive particles can become oxidized, forming insulating oxide layers that disrupt the conductive network essential for EMI shielding.

Mechanical stress and vibration contribute to material fatigue and structural changes over time. Continuous or cyclical mechanical loading can lead to particle-matrix debonding in composite materials, creating discontinuities in the conductive network. This is especially problematic in applications where EMI materials are subjected to constant vibration, such as in automotive or aerospace environments.

Synergistic effects between multiple environmental factors often accelerate degradation beyond what would be expected from individual factors alone. For instance, the combination of high temperature and humidity creates particularly aggressive conditions for most EMI materials, with degradation rates up to three times faster than either factor in isolation. This highlights the importance of testing materials under combined environmental stressors rather than single-factor evaluations.

Humidity and moisture exposure constitute another major degradation pathway. Water molecules can penetrate certain EMI materials, particularly those with hygroscopic components, leading to swelling, dimensional changes, and potential corrosion of metallic fillers. In conductive polymer composites, moisture absorption often results in increased resistivity and diminished shielding performance, with studies showing up to 40% reduction in shielding effectiveness after prolonged humidity exposure.

Ultraviolet radiation presents a significant threat to polymer-based EMI materials through photodegradation mechanisms. UV exposure initiates chain scission and oxidation reactions in the polymer matrix, causing embrittlement, discoloration, and deterioration of mechanical properties. These chemical changes alter the material's dielectric properties and conductive network integrity, progressively reducing shielding capabilities even when the material appears visually intact.

Chemical exposure from industrial environments, including acids, bases, solvents, and oxidizing agents, accelerates degradation through various chemical attack mechanisms. Particularly vulnerable are metallic fillers in composite materials, which may undergo galvanic corrosion when exposed to electrolytes. Conductive particles can become oxidized, forming insulating oxide layers that disrupt the conductive network essential for EMI shielding.

Mechanical stress and vibration contribute to material fatigue and structural changes over time. Continuous or cyclical mechanical loading can lead to particle-matrix debonding in composite materials, creating discontinuities in the conductive network. This is especially problematic in applications where EMI materials are subjected to constant vibration, such as in automotive or aerospace environments.

Synergistic effects between multiple environmental factors often accelerate degradation beyond what would be expected from individual factors alone. For instance, the combination of high temperature and humidity creates particularly aggressive conditions for most EMI materials, with degradation rates up to three times faster than either factor in isolation. This highlights the importance of testing materials under combined environmental stressors rather than single-factor evaluations.

Testing Standards and Certification Requirements

The evaluation of EMI shielding materials requires adherence to rigorous testing standards and certification requirements to ensure consistent performance across different applications and environments. Key international standards include IEEE 299, which provides methods for measuring the effectiveness of electromagnetic shielding enclosures, and MIL-STD-461, which establishes requirements for the control of electromagnetic interference characteristics of subsystems and equipment.

ASTM D4935 specifically addresses the measurement of shielding effectiveness of planar materials, providing a standardized approach for comparing different shielding solutions. For long-term durability assessment, IEC 60068 series standards outline environmental testing procedures that simulate accelerated aging conditions, including temperature cycling, humidity exposure, and salt spray tests.

Certification bodies such as UL (Underwriters Laboratories) and TÜV require comprehensive documentation of material performance over time. UL 746C specifically addresses the evaluation of polymeric materials used in electrical equipment, including their long-term stability under various environmental conditions. The European EMC Directive 2014/30/EU mandates that all electronic equipment sold within the European Economic Area must meet specific electromagnetic compatibility requirements.

Testing protocols typically include initial characterization followed by accelerated aging tests. ASTM G154 and ASTM G155 provide standard practices for operating fluorescent and xenon-arc light apparatus for UV exposure of nonmetallic materials, which is crucial for evaluating outdoor durability of composite EMI shielding materials. For materials intended for aerospace applications, additional standards such as RTCA DO-160 must be met, which includes rigorous environmental conditions testing.

Material certification often requires cyclic testing to simulate real-world usage conditions. ISO 9227 outlines salt spray testing methods that are particularly relevant for evaluating corrosion resistance of metallic components in EMI shielding materials. For medical device applications, additional biocompatibility testing according to ISO 10993 may be required if the shielding material comes into contact with patients or healthcare providers.

Emerging standards are beginning to address the specific challenges of new composite and nanomaterial-based EMI shields. The IEC Technical Committee 113 is developing standards for nanotechnology in electronics, which will impact certification requirements for next-generation shielding materials. Compliance with these evolving standards will be essential for market acceptance and regulatory approval of innovative EMI shielding solutions.

ASTM D4935 specifically addresses the measurement of shielding effectiveness of planar materials, providing a standardized approach for comparing different shielding solutions. For long-term durability assessment, IEC 60068 series standards outline environmental testing procedures that simulate accelerated aging conditions, including temperature cycling, humidity exposure, and salt spray tests.

Certification bodies such as UL (Underwriters Laboratories) and TÜV require comprehensive documentation of material performance over time. UL 746C specifically addresses the evaluation of polymeric materials used in electrical equipment, including their long-term stability under various environmental conditions. The European EMC Directive 2014/30/EU mandates that all electronic equipment sold within the European Economic Area must meet specific electromagnetic compatibility requirements.

Testing protocols typically include initial characterization followed by accelerated aging tests. ASTM G154 and ASTM G155 provide standard practices for operating fluorescent and xenon-arc light apparatus for UV exposure of nonmetallic materials, which is crucial for evaluating outdoor durability of composite EMI shielding materials. For materials intended for aerospace applications, additional standards such as RTCA DO-160 must be met, which includes rigorous environmental conditions testing.

Material certification often requires cyclic testing to simulate real-world usage conditions. ISO 9227 outlines salt spray testing methods that are particularly relevant for evaluating corrosion resistance of metallic components in EMI shielding materials. For medical device applications, additional biocompatibility testing according to ISO 10993 may be required if the shielding material comes into contact with patients or healthcare providers.

Emerging standards are beginning to address the specific challenges of new composite and nanomaterial-based EMI shields. The IEC Technical Committee 113 is developing standards for nanotechnology in electronics, which will impact certification requirements for next-generation shielding materials. Compliance with these evolving standards will be essential for market acceptance and regulatory approval of innovative EMI shielding solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!