Research on Lightweight EMI Shielding Materials for Portable Electronics

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Evolution and Objectives

Electromagnetic Interference (EMI) shielding has evolved significantly since the early days of electronics, transitioning from bulky metal enclosures to sophisticated engineered materials. The journey began in the 1940s with simple Faraday cages, progressing through the development of conductive paints and coatings in the 1970s, to today's advanced composite materials. This evolution has been driven by the miniaturization of electronic devices and the increasing density of components operating at higher frequencies.

The proliferation of portable electronics has created unprecedented challenges for EMI shielding. Modern smartphones, tablets, and wearable devices contain multiple wireless communication modules, processors, and sensors operating in close proximity. These components must function harmoniously without interference while maintaining the sleek, lightweight profiles consumers demand. Traditional shielding solutions that add significant weight or thickness have become increasingly impractical.

Current technological objectives in lightweight EMI shielding focus on achieving high shielding effectiveness (typically 30-60 dB across a wide frequency range) while minimizing weight, thickness, and manufacturing complexity. Materials must maintain flexibility to accommodate complex device geometries and withstand the thermal and mechanical stresses of modern manufacturing processes. Additionally, environmental considerations have become paramount, with growing pressure to develop solutions free from hazardous substances and amenable to recycling.

The integration of multiple functions into shielding materials represents another critical objective. Beyond EMI protection, modern shielding materials are increasingly expected to provide thermal management, structural support, or even energy storage capabilities. This multifunctionality helps maximize space utilization within compact devices and potentially reduces overall material usage and manufacturing steps.

Emerging technologies like 5G, IoT devices, and wearable healthcare monitors present new challenges, operating at higher frequencies (up to 60 GHz) where traditional shielding approaches may be less effective. The objective is to develop materials that maintain performance across this expanded frequency range while addressing the specific requirements of each application category.

Cost-effectiveness remains a fundamental consideration, particularly for consumer electronics produced at massive scales. Research objectives include not only developing materials with superior performance but ensuring they can be manufactured economically using processes compatible with existing production lines. The ideal solution balances technical performance with practical implementation considerations, enabling widespread adoption across the electronics industry.

The proliferation of portable electronics has created unprecedented challenges for EMI shielding. Modern smartphones, tablets, and wearable devices contain multiple wireless communication modules, processors, and sensors operating in close proximity. These components must function harmoniously without interference while maintaining the sleek, lightweight profiles consumers demand. Traditional shielding solutions that add significant weight or thickness have become increasingly impractical.

Current technological objectives in lightweight EMI shielding focus on achieving high shielding effectiveness (typically 30-60 dB across a wide frequency range) while minimizing weight, thickness, and manufacturing complexity. Materials must maintain flexibility to accommodate complex device geometries and withstand the thermal and mechanical stresses of modern manufacturing processes. Additionally, environmental considerations have become paramount, with growing pressure to develop solutions free from hazardous substances and amenable to recycling.

The integration of multiple functions into shielding materials represents another critical objective. Beyond EMI protection, modern shielding materials are increasingly expected to provide thermal management, structural support, or even energy storage capabilities. This multifunctionality helps maximize space utilization within compact devices and potentially reduces overall material usage and manufacturing steps.

Emerging technologies like 5G, IoT devices, and wearable healthcare monitors present new challenges, operating at higher frequencies (up to 60 GHz) where traditional shielding approaches may be less effective. The objective is to develop materials that maintain performance across this expanded frequency range while addressing the specific requirements of each application category.

Cost-effectiveness remains a fundamental consideration, particularly for consumer electronics produced at massive scales. Research objectives include not only developing materials with superior performance but ensuring they can be manufactured economically using processes compatible with existing production lines. The ideal solution balances technical performance with practical implementation considerations, enabling widespread adoption across the electronics industry.

Market Demand Analysis for Lightweight Shielding Solutions

The global market for lightweight EMI shielding solutions has experienced significant growth in recent years, primarily driven by the rapid expansion of portable electronics. Consumer demand for thinner, lighter, and more powerful electronic devices has created a substantial need for advanced shielding materials that can provide effective electromagnetic interference protection without adding excessive weight or bulk to the final product.

Market research indicates that the portable electronics segment, including smartphones, tablets, wearables, and ultralight laptops, represents the largest application area for lightweight shielding materials. This segment is projected to grow at a compound annual growth rate exceeding 7% through 2028, creating sustained demand for innovative shielding solutions.

The automotive electronics sector has emerged as another significant market driver, particularly with the increasing integration of advanced driver assistance systems and infotainment technologies in modern vehicles. Weight reduction remains a critical factor in automotive design, making lightweight EMI shielding materials highly desirable for this application.

Healthcare and medical devices constitute a rapidly expanding market segment for lightweight shielding materials. The proliferation of portable medical equipment, implantable devices, and wearable health monitors has created specialized requirements for biocompatible shielding solutions that maintain effectiveness while minimizing weight and size.

Consumer preferences are increasingly favoring devices with extended battery life, which directly correlates with the demand for lightweight components, including EMI shields. Market surveys reveal that consumers rank device weight and thickness among the top five purchasing considerations for portable electronics, creating commercial pressure for manufacturers to adopt lighter shielding solutions.

Regional market analysis shows Asia-Pacific dominating the demand landscape, accounting for approximately 45% of global consumption of lightweight EMI shielding materials. This concentration aligns with the region's position as the manufacturing hub for consumer electronics. North America and Europe follow as significant markets, with particular strength in high-performance applications requiring advanced materials.

Industry forecasts suggest that the overall market value for lightweight EMI shielding materials in portable electronics will reach several billion dollars by 2027. This growth trajectory is supported by increasing device complexity, higher operating frequencies in modern electronics, and stricter electromagnetic compatibility regulations across major markets.

The price sensitivity of the market varies significantly by application segment. While consumer electronics manufacturers typically prioritize cost-effectiveness, medical and aerospace applications demonstrate greater willingness to invest in premium shielding solutions that offer superior performance characteristics while maintaining minimal weight profiles.

Market research indicates that the portable electronics segment, including smartphones, tablets, wearables, and ultralight laptops, represents the largest application area for lightweight shielding materials. This segment is projected to grow at a compound annual growth rate exceeding 7% through 2028, creating sustained demand for innovative shielding solutions.

The automotive electronics sector has emerged as another significant market driver, particularly with the increasing integration of advanced driver assistance systems and infotainment technologies in modern vehicles. Weight reduction remains a critical factor in automotive design, making lightweight EMI shielding materials highly desirable for this application.

Healthcare and medical devices constitute a rapidly expanding market segment for lightweight shielding materials. The proliferation of portable medical equipment, implantable devices, and wearable health monitors has created specialized requirements for biocompatible shielding solutions that maintain effectiveness while minimizing weight and size.

Consumer preferences are increasingly favoring devices with extended battery life, which directly correlates with the demand for lightweight components, including EMI shields. Market surveys reveal that consumers rank device weight and thickness among the top five purchasing considerations for portable electronics, creating commercial pressure for manufacturers to adopt lighter shielding solutions.

Regional market analysis shows Asia-Pacific dominating the demand landscape, accounting for approximately 45% of global consumption of lightweight EMI shielding materials. This concentration aligns with the region's position as the manufacturing hub for consumer electronics. North America and Europe follow as significant markets, with particular strength in high-performance applications requiring advanced materials.

Industry forecasts suggest that the overall market value for lightweight EMI shielding materials in portable electronics will reach several billion dollars by 2027. This growth trajectory is supported by increasing device complexity, higher operating frequencies in modern electronics, and stricter electromagnetic compatibility regulations across major markets.

The price sensitivity of the market varies significantly by application segment. While consumer electronics manufacturers typically prioritize cost-effectiveness, medical and aerospace applications demonstrate greater willingness to invest in premium shielding solutions that offer superior performance characteristics while maintaining minimal weight profiles.

Current Challenges in Portable Electronics EMI Protection

The portable electronics industry faces significant challenges in electromagnetic interference (EMI) protection due to the increasing complexity and miniaturization of devices. As electronic components become more densely packed within smaller form factors, the risk of electromagnetic interference between components increases exponentially. This interference can lead to performance degradation, data corruption, and even complete device failure, making effective EMI shielding critical for modern portable electronics.

Weight constraints represent one of the most pressing challenges in EMI protection for portable devices. Traditional EMI shielding materials like metal sheets and foils add considerable weight, directly contradicting the industry's push toward lighter, more portable products. This weight-performance tradeoff forces manufacturers to compromise either on EMI protection or device portability, neither of which is acceptable in today's competitive market.

Space limitations further complicate EMI shielding implementation. The internal architecture of modern smartphones, tablets, and wearables leaves minimal room for shielding materials. Engineers must develop solutions that provide adequate protection while occupying minimal space, often requiring shielding materials with thicknesses measured in micrometers rather than millimeters.

Heat dissipation presents another significant challenge. Many current EMI shielding materials trap heat within devices, exacerbating thermal management issues already prevalent in compact electronics. This heat buildup can reduce component lifespan, trigger thermal throttling of processors, and in extreme cases, create safety hazards for users.

Manufacturing complexity also impedes effective EMI protection. Integrating shielding materials into increasingly complex device designs requires sophisticated manufacturing processes. Many current solutions demand additional assembly steps, increasing production costs and creating potential quality control issues in high-volume manufacturing environments.

Cost considerations remain a persistent challenge, particularly for consumer electronics. Effective EMI shielding materials often incorporate expensive components like silver, graphene, or specialized polymers, driving up the bill of materials. Manufacturers must balance protection requirements against cost constraints to maintain competitive pricing.

Environmental concerns have also emerged as a significant challenge. Many traditional EMI shielding materials contain environmentally harmful substances or are difficult to recycle. As regulations become more stringent and consumer awareness increases, the industry faces pressure to develop eco-friendly alternatives that maintain performance standards while reducing environmental impact.

Durability and longevity concerns further complicate EMI shielding selection. Portable devices face mechanical stress, temperature fluctuations, and other environmental factors that can degrade shielding effectiveness over time. Materials must maintain their protective properties throughout the expected device lifespan, which is increasingly difficult as consumers keep devices for longer periods.

Weight constraints represent one of the most pressing challenges in EMI protection for portable devices. Traditional EMI shielding materials like metal sheets and foils add considerable weight, directly contradicting the industry's push toward lighter, more portable products. This weight-performance tradeoff forces manufacturers to compromise either on EMI protection or device portability, neither of which is acceptable in today's competitive market.

Space limitations further complicate EMI shielding implementation. The internal architecture of modern smartphones, tablets, and wearables leaves minimal room for shielding materials. Engineers must develop solutions that provide adequate protection while occupying minimal space, often requiring shielding materials with thicknesses measured in micrometers rather than millimeters.

Heat dissipation presents another significant challenge. Many current EMI shielding materials trap heat within devices, exacerbating thermal management issues already prevalent in compact electronics. This heat buildup can reduce component lifespan, trigger thermal throttling of processors, and in extreme cases, create safety hazards for users.

Manufacturing complexity also impedes effective EMI protection. Integrating shielding materials into increasingly complex device designs requires sophisticated manufacturing processes. Many current solutions demand additional assembly steps, increasing production costs and creating potential quality control issues in high-volume manufacturing environments.

Cost considerations remain a persistent challenge, particularly for consumer electronics. Effective EMI shielding materials often incorporate expensive components like silver, graphene, or specialized polymers, driving up the bill of materials. Manufacturers must balance protection requirements against cost constraints to maintain competitive pricing.

Environmental concerns have also emerged as a significant challenge. Many traditional EMI shielding materials contain environmentally harmful substances or are difficult to recycle. As regulations become more stringent and consumer awareness increases, the industry faces pressure to develop eco-friendly alternatives that maintain performance standards while reducing environmental impact.

Durability and longevity concerns further complicate EMI shielding selection. Portable devices face mechanical stress, temperature fluctuations, and other environmental factors that can degrade shielding effectiveness over time. Materials must maintain their protective properties throughout the expected device lifespan, which is increasingly difficult as consumers keep devices for longer periods.

Contemporary Lightweight Shielding Material Solutions

01 Lightweight composite EMI shielding materials

Composite materials combining lightweight polymers with conductive fillers offer effective EMI shielding while maintaining low weight. These composites typically incorporate carbon-based materials (like carbon fiber, graphene, or carbon nanotubes), metal particles, or conductive polymers into a lightweight polymer matrix. The resulting materials provide significant EMI protection while being substantially lighter than traditional metal shields, making them ideal for portable electronics and aerospace applications.- Lightweight composite materials for EMI shielding: Composite materials combining lightweight polymers with conductive fillers offer effective EMI shielding while maintaining low weight. These composites typically incorporate carbon-based materials (such as carbon nanotubes, graphene, or carbon fiber), conductive polymers, or metallic particles dispersed in a polymer matrix. The resulting materials provide significant electromagnetic interference protection while being substantially lighter than traditional metal shields.

- Metal foam and honeycomb structures: Metal foams and honeycomb structures provide excellent EMI shielding effectiveness while significantly reducing weight compared to solid metal shields. These structures maintain high conductivity for EMI shielding while incorporating air pockets that reduce overall density. The cellular architecture offers mechanical strength and thermal management benefits alongside electromagnetic shielding, making them ideal for aerospace, automotive, and portable electronic applications where weight reduction is critical.

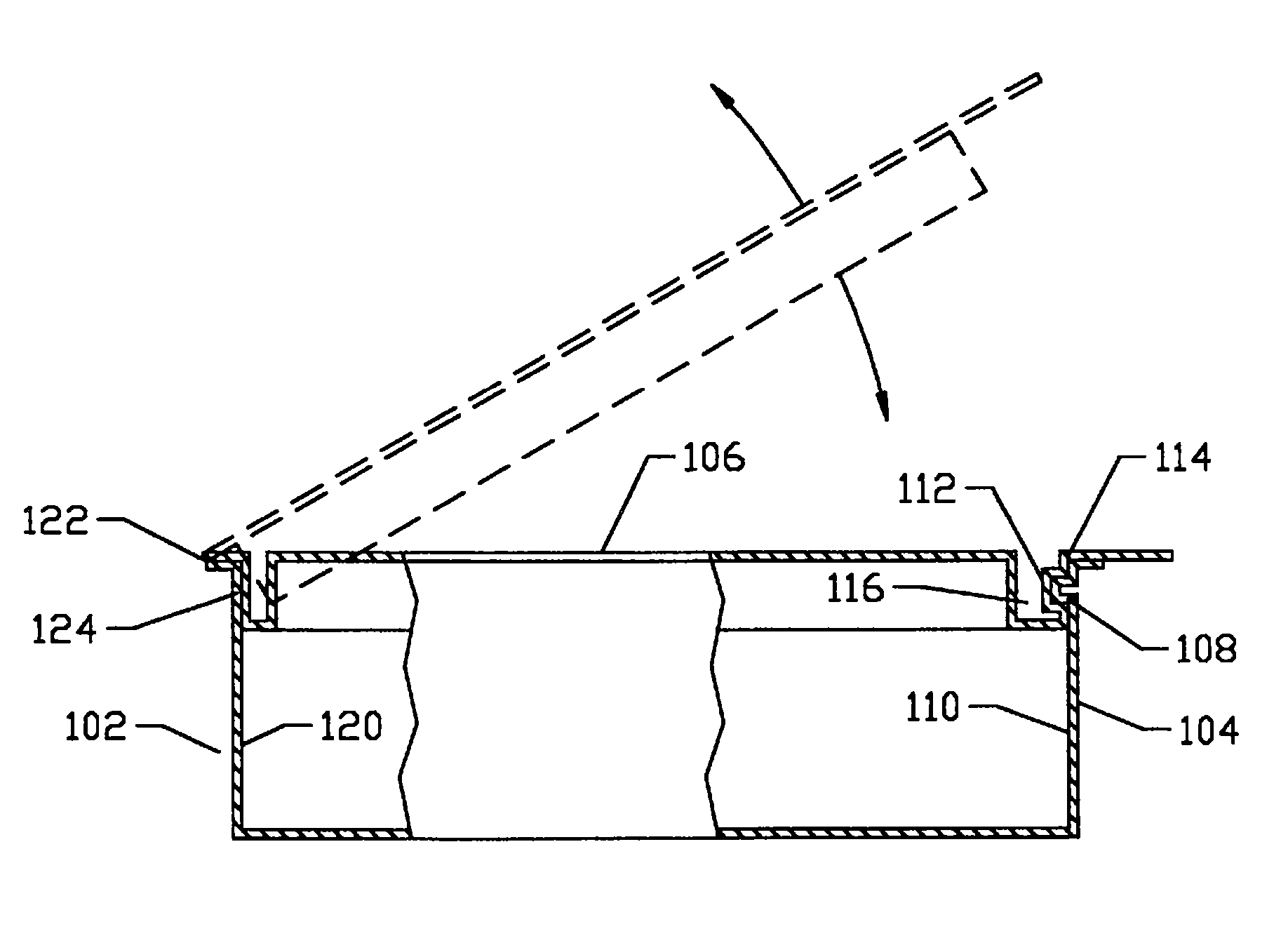

- Thin film and coating technologies: Ultrathin conductive coatings and films provide effective EMI shielding with minimal weight addition. These include vapor-deposited metallic layers, conductive paints, and sprayable shielding solutions that can be applied directly to electronic enclosures. The thin nature of these coatings (typically in the micron range) adds negligible weight while creating a conductive surface that blocks electromagnetic radiation. These solutions are particularly valuable for lightweight portable electronics and aerospace applications.

- Conductive fabric and textile-based shields: Lightweight conductive fabrics and textiles offer flexible EMI shielding solutions with minimal weight impact. These materials incorporate conductive fibers (such as metal-coated polymers, carbon-loaded textiles, or intrinsically conductive polymers) into traditional textile structures. The resulting fabrics provide effective electromagnetic shielding while maintaining flexibility, breathability, and extremely low weight, making them suitable for wearable electronics, portable devices, and applications requiring conformable shielding.

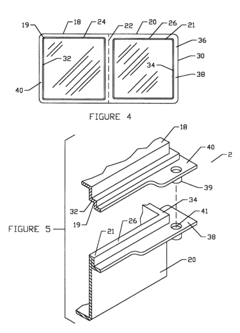

- Multilayer and gradient shielding structures: Multilayer and gradient shielding structures optimize weight-to-performance ratio by combining different materials in strategic configurations. These designs utilize layers of varying conductivity, permeability, and thickness to attenuate electromagnetic radiation across different frequency ranges. By carefully engineering the composition and arrangement of these layers, these structures achieve superior shielding effectiveness with minimal weight. Advanced designs incorporate impedance matching principles to maximize reflection and absorption of electromagnetic waves.

02 Metal foam and honeycomb structures for EMI shielding

Metal foams and honeycomb structures provide excellent EMI shielding effectiveness while significantly reducing weight compared to solid metal shields. These materials maintain high conductivity for EMI attenuation while incorporating air-filled voids that drastically reduce overall density. The cellular structure offers mechanical strength despite the weight reduction, making these materials suitable for applications requiring both structural integrity and EMI protection in weight-sensitive environments.Expand Specific Solutions03 Conductive coatings and thin films for lightweight shielding

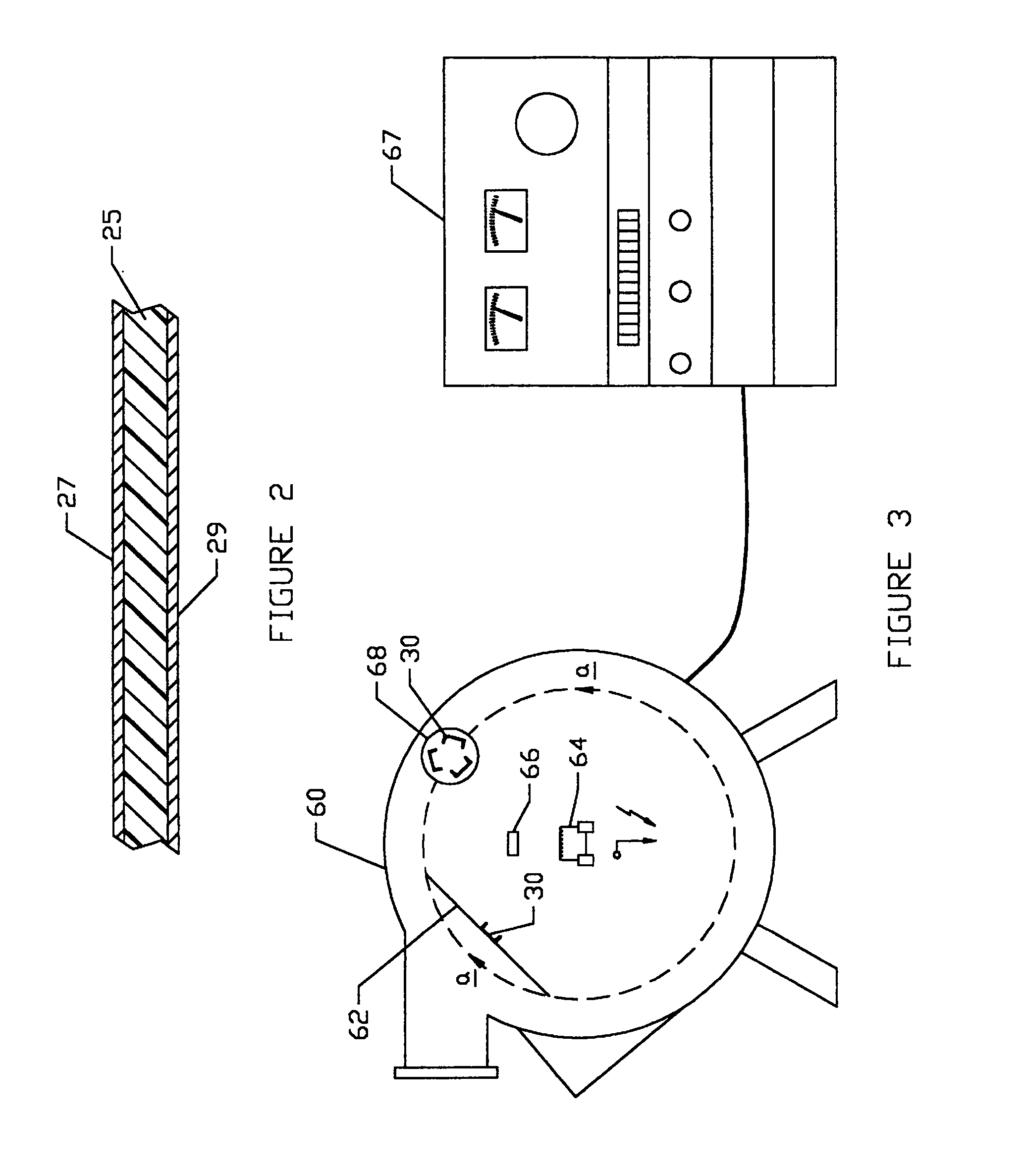

Ultrathin conductive coatings and films applied to lightweight substrates offer effective EMI shielding with minimal weight addition. These solutions include metal sprays, vacuum-deposited conductive layers, and printable conductive inks containing metallic or carbon-based particles. By applying a thin conductive layer to plastic housings or composite structures, these technologies provide EMI protection without the bulk and weight of traditional shielding methods, enabling sleeker and lighter electronic device designs.Expand Specific Solutions04 Fabric-based and flexible EMI shielding materials

Lightweight fabric-based and flexible EMI shielding materials incorporate conductive fibers or coatings into textiles and elastomers. These materials can be metallized fabrics, conductive textile composites, or flexible polymer sheets with embedded conductive elements. Their flexibility and low weight make them ideal for wearable electronics, aerospace applications, and conformable shielding needs where traditional rigid shields would be impractical due to weight or form factor constraints.Expand Specific Solutions05 Lightweight EMI gaskets and interface materials

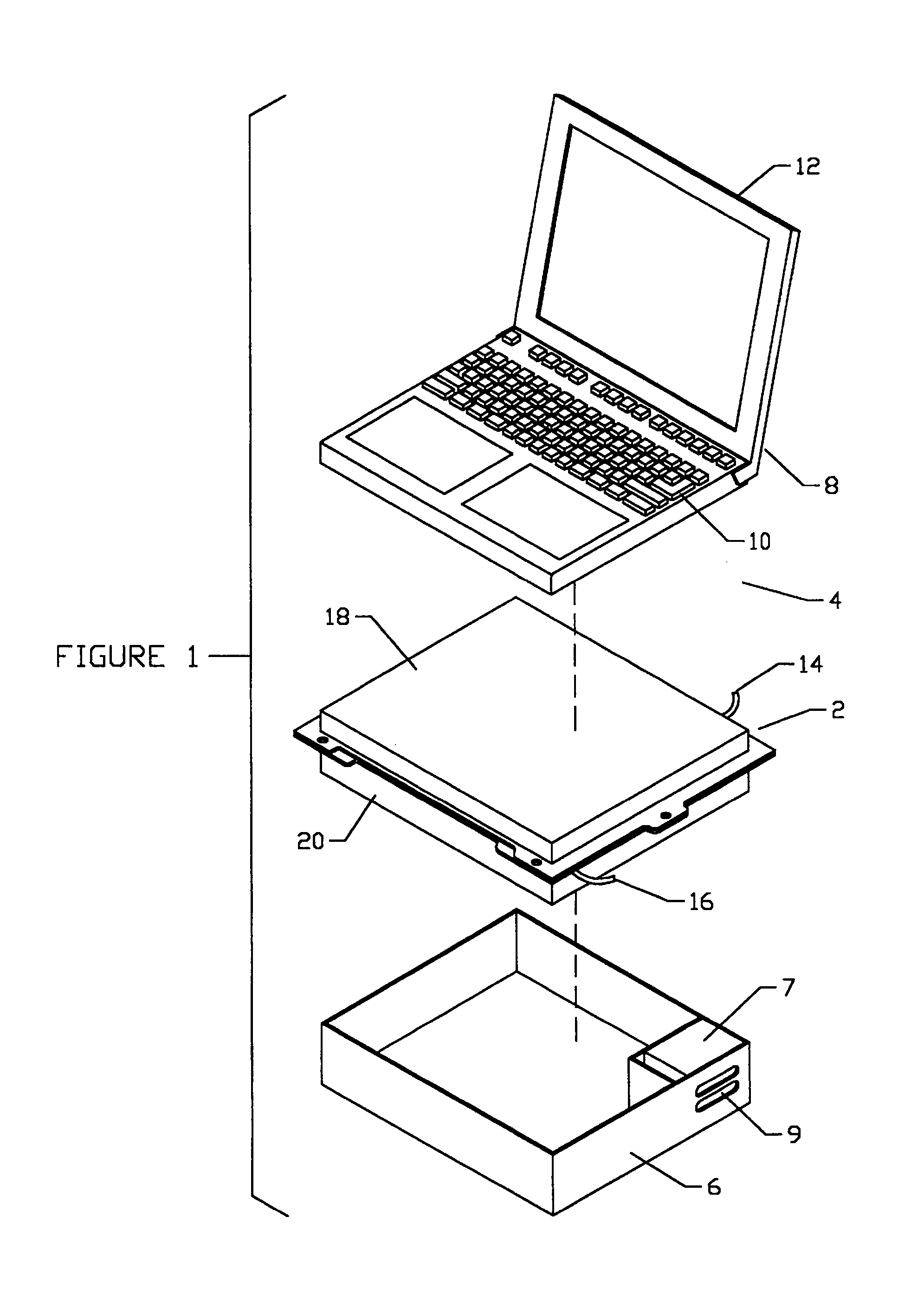

Specialized lightweight EMI gaskets and interface materials provide effective shielding at enclosure seams and component interfaces while minimizing added weight. These materials include conductive elastomers, foam-based gaskets with conductive coatings, and compressible mesh structures made from lightweight metals or metallized polymers. They ensure electrical continuity across joints without the bulk of traditional metal gaskets, maintaining shielding effectiveness in weight-sensitive applications like portable electronics and aerospace systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The lightweight EMI shielding materials market for portable electronics is in a growth phase, driven by increasing demand for thinner, lighter devices with robust electromagnetic interference protection. The market is expanding rapidly as consumer electronics proliferate globally. Technologically, the field is moderately mature but evolving, with companies pursuing different innovation paths. Industry leaders like 3M, Samsung Electronics, and LG Electronics focus on high-performance commercial solutions, while AMOGREENTECH and Vorbeck Materials specialize in advanced materials development. Research institutions such as Beihang University and Northeastern University contribute fundamental breakthroughs. The competitive landscape features collaboration between established electronics manufacturers (Hon Hai Precision) and materials specialists (W.L. Gore & Associates), creating an ecosystem where material innovation directly translates to product advancement.

AMOGREENTECH Co., Ltd.

Technical Solution: AMOGREENTECH has established itself as a specialist in advanced lightweight EMI shielding materials, particularly focusing on environmentally friendly solutions. Their flagship technology centers on metal-coated fabric and foam materials that provide exceptional flexibility and lightweight characteristics. Their AMOTECH EMI shielding products utilize proprietary metal deposition processes to create ultra-thin (typically 0.03-0.15mm) conductive layers on various substrate materials including polyester fabrics, polyurethane foams, and specialized polymer films. These materials achieve shielding effectiveness of 50-90 dB across frequency ranges from 300 MHz to 10 GHz. A key innovation from AMOGREENTECH is their development of nickel-free conductive materials that address growing concerns about nickel allergies and environmental regulations while maintaining high shielding performance. The company has also pioneered hybrid shielding materials that combine absorption and reflection mechanisms through carefully engineered multi-layer structures, effectively addressing both incoming and outgoing EMI issues in portable devices [9][11]. Their recent advancements include ultra-lightweight "meta-material" inspired structures that achieve higher shielding effectiveness than conventional materials of similar weight through precisely engineered geometric patterns that create electromagnetic bandgaps at targeted frequencies.

Strengths: Specialized focus on EMI shielding materials with extensive R&D capabilities; strong environmental credentials with nickel-free and low-toxicity formulations; excellent flexibility and conformability for complex device geometries. Weaknesses: More limited global manufacturing footprint compared to larger conglomerates; potentially higher costs for specialized high-performance materials; some solutions may require specific handling and application techniques.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced lightweight EMI shielding materials based on their proprietary metallized fabric technology. Their solution incorporates conductive fibers coated with metals like copper, nickel, and silver in non-woven or woven structures to create flexible, lightweight shields. The company's approach includes multi-layered composite materials that combine conductive polymers with metal-coated fabrics to achieve high shielding effectiveness across broad frequency ranges (1-10 GHz) while maintaining minimal thickness (typically 0.05-0.2mm). 3M's technology also features selective area shielding capabilities, allowing manufacturers to apply EMI protection only where needed, reducing overall weight and material usage. Their adhesive-backed EMI shielding tapes and films enable easy integration into portable electronic designs without significant redesign requirements [1][3]. Recent innovations include their Electrically Conductive Adhesive Transfer Tapes that provide both bonding and EMI shielding in a single application step.

Strengths: Excellent balance between shielding effectiveness and weight; versatile form factors (tapes, films, fabrics); established global manufacturing capabilities ensuring consistent quality and supply chain reliability. Weaknesses: Premium pricing compared to basic shielding solutions; some solutions may require specific application equipment for optimal performance; potential for adhesive degradation in extreme environmental conditions.

Key Patents and Breakthroughs in EMI Shielding

Electromagnetic Interference Shields for Electronic Devices

PatentInactiveUS20070199738A1

Innovation

- A thermoformable polymeric sheet is metallized using vacuum deposition techniques to create a lightweight, conductive enclosure that can be shaped to fit specific components, providing effective EMI shielding with reduced weight and increased design flexibility, and can be easily manufactured and recycled.

Polymer nanocomposite flexible films for electromagnetic interference shielding

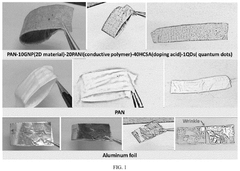

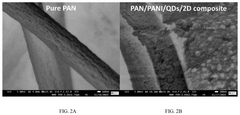

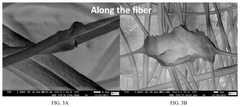

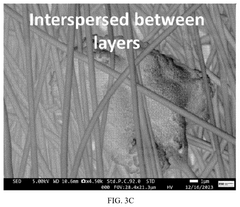

PatentActiveUS12416104B1

Innovation

- Development of polymer-based fiber thin films incorporating quantum dots (QDs) and two-dimensional (2D) conductive nanomaterials within a dual polymer matrix, which are ultra-flexible, lightweight, and have high electrical conductivity, achieving effective EMI shielding through a multilayer structure with aligned and interspersed nanomaterials.

Environmental Impact and Sustainability Considerations

The environmental impact of EMI shielding materials has become increasingly significant as portable electronics production continues to escalate globally. Traditional EMI shielding solutions often rely on metals like copper, aluminum, and nickel, which present substantial environmental challenges throughout their lifecycle. Mining these metals contributes to habitat destruction, water pollution, and significant carbon emissions. Furthermore, the processing and refinement of these metals require extensive energy consumption and often involve environmentally harmful chemicals.

The manufacturing processes for conventional EMI shields frequently employ toxic solvents and adhesives that release volatile organic compounds (VOCs), contributing to air pollution and potential health hazards for workers. Additionally, the composite nature of many shielding materials makes them difficult to separate at end-of-life, complicating recycling efforts and leading to increased electronic waste in landfills.

Recent sustainability initiatives have driven research toward bio-based and recyclable alternatives for EMI shielding. Carbon-based materials derived from renewable sources, such as cellulose nanofibers and lignin-based composites, show promising EMI shielding effectiveness while significantly reducing environmental footprint. These materials can often be produced using less energy-intensive processes and biodegradable precursors, addressing concerns across the entire product lifecycle.

Regulatory frameworks worldwide are increasingly mandating reduced environmental impact from electronic components. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives specifically target the reduction of harmful materials in electronics and promote recycling. These regulations have accelerated the development of halogen-free flame retardants and lead-free solders in EMI shielding applications.

Life Cycle Assessment (LCA) studies comparing traditional and emerging lightweight EMI shielding materials reveal significant differences in environmental impact. For instance, graphene-based shields typically show 40-60% lower carbon footprint compared to conventional metal-based solutions when considering extraction, processing, use, and disposal phases. However, the scalability of production for these advanced materials remains a challenge for widespread commercial adoption.

Circular economy principles are increasingly being applied to EMI shielding design, focusing on material recovery and reuse. Design for disassembly approaches enable easier separation of shielding components from electronic devices, facilitating material recovery. Some manufacturers have implemented take-back programs specifically for recovering valuable shielding materials, creating closed-loop systems that minimize waste and resource consumption while maintaining the technical performance required for effective EMI protection in portable electronics.

The manufacturing processes for conventional EMI shields frequently employ toxic solvents and adhesives that release volatile organic compounds (VOCs), contributing to air pollution and potential health hazards for workers. Additionally, the composite nature of many shielding materials makes them difficult to separate at end-of-life, complicating recycling efforts and leading to increased electronic waste in landfills.

Recent sustainability initiatives have driven research toward bio-based and recyclable alternatives for EMI shielding. Carbon-based materials derived from renewable sources, such as cellulose nanofibers and lignin-based composites, show promising EMI shielding effectiveness while significantly reducing environmental footprint. These materials can often be produced using less energy-intensive processes and biodegradable precursors, addressing concerns across the entire product lifecycle.

Regulatory frameworks worldwide are increasingly mandating reduced environmental impact from electronic components. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives specifically target the reduction of harmful materials in electronics and promote recycling. These regulations have accelerated the development of halogen-free flame retardants and lead-free solders in EMI shielding applications.

Life Cycle Assessment (LCA) studies comparing traditional and emerging lightweight EMI shielding materials reveal significant differences in environmental impact. For instance, graphene-based shields typically show 40-60% lower carbon footprint compared to conventional metal-based solutions when considering extraction, processing, use, and disposal phases. However, the scalability of production for these advanced materials remains a challenge for widespread commercial adoption.

Circular economy principles are increasingly being applied to EMI shielding design, focusing on material recovery and reuse. Design for disassembly approaches enable easier separation of shielding components from electronic devices, facilitating material recovery. Some manufacturers have implemented take-back programs specifically for recovering valuable shielding materials, creating closed-loop systems that minimize waste and resource consumption while maintaining the technical performance required for effective EMI protection in portable electronics.

Cost-Performance Analysis of Emerging Materials

The cost-performance ratio of EMI shielding materials represents a critical factor in their commercial viability for portable electronics applications. Traditional metallic shielding solutions, while effective, often come with significant cost implications, particularly when considering high-purity metals like silver and copper. Current market analysis indicates that these conventional materials average $15-25 per square meter for thin foils, with specialized high-performance variants commanding premiums of 30-50%.

Emerging carbon-based materials present a compelling alternative from a cost-performance perspective. Carbon nanotubes (CNTs), despite their superior shielding effectiveness of 60-80 dB, currently cost between $100-500 per kilogram depending on purity and structure. However, manufacturing scale economies have driven a 35% cost reduction over the past five years, suggesting continued downward price trends as production technologies mature.

Graphene-based composites offer perhaps the most promising cost trajectory among next-generation materials. Production costs have decreased from approximately $100 per gram to under $1 per gram for industrial-grade material within the past decade. When formulated into polymer composites, these materials achieve 40-60 dB shielding at material costs of $8-12 per square meter—approaching cost parity with traditional solutions while offering significant weight advantages.

MXene materials, though demonstrating exceptional performance metrics, remain economically challenging at current production scales. Laboratory-grade MXenes cost $200-600 per gram, translating to prohibitive implementation costs for mass-market electronics. Industry projections suggest a 60-70% cost reduction is necessary before commercial viability can be achieved in consumer electronics applications.

Conductive polymer composites represent the most immediately accessible cost-effective solution, with material costs ranging from $5-15 per square meter depending on filler content and polymer base. These materials typically deliver 30-50 dB shielding effectiveness, sufficient for many consumer applications, while offering manufacturing advantages through established polymer processing techniques.

Return on investment (ROI) analysis indicates that despite higher initial material costs, lightweight alternatives can deliver superior lifetime value through reduced transportation costs, extended device battery life due to weight reduction, and enhanced consumer satisfaction. Quantitative modeling suggests that premium lightweight shielding solutions commanding a 20-30% price premium can achieve ROI breakeven within 12-18 months in high-volume production scenarios.

Emerging carbon-based materials present a compelling alternative from a cost-performance perspective. Carbon nanotubes (CNTs), despite their superior shielding effectiveness of 60-80 dB, currently cost between $100-500 per kilogram depending on purity and structure. However, manufacturing scale economies have driven a 35% cost reduction over the past five years, suggesting continued downward price trends as production technologies mature.

Graphene-based composites offer perhaps the most promising cost trajectory among next-generation materials. Production costs have decreased from approximately $100 per gram to under $1 per gram for industrial-grade material within the past decade. When formulated into polymer composites, these materials achieve 40-60 dB shielding at material costs of $8-12 per square meter—approaching cost parity with traditional solutions while offering significant weight advantages.

MXene materials, though demonstrating exceptional performance metrics, remain economically challenging at current production scales. Laboratory-grade MXenes cost $200-600 per gram, translating to prohibitive implementation costs for mass-market electronics. Industry projections suggest a 60-70% cost reduction is necessary before commercial viability can be achieved in consumer electronics applications.

Conductive polymer composites represent the most immediately accessible cost-effective solution, with material costs ranging from $5-15 per square meter depending on filler content and polymer base. These materials typically deliver 30-50 dB shielding effectiveness, sufficient for many consumer applications, while offering manufacturing advantages through established polymer processing techniques.

Return on investment (ROI) analysis indicates that despite higher initial material costs, lightweight alternatives can deliver superior lifetime value through reduced transportation costs, extended device battery life due to weight reduction, and enhanced consumer satisfaction. Quantitative modeling suggests that premium lightweight shielding solutions commanding a 20-30% price premium can achieve ROI breakeven within 12-18 months in high-volume production scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!