Analysis of Magnetic and Conductive Fillers in EMI Shielding Composites

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Evolution and Objectives

Electromagnetic interference (EMI) shielding has evolved significantly over the past decades, driven by the proliferation of electronic devices and the increasing demand for electromagnetic compatibility. The journey began in the mid-20th century with simple metal enclosures providing rudimentary shielding. As electronics miniaturized and became ubiquitous, traditional metal shields proved inadequate due to weight, corrosion susceptibility, and manufacturing complexity.

The 1970s and 1980s marked the emergence of conductive polymer composites as viable alternatives, offering lighter weight and design flexibility. These early composites primarily utilized carbon-based fillers such as carbon black and graphite. The 1990s witnessed the introduction of metal-based fillers including aluminum, copper, and nickel particles, which enhanced shielding effectiveness but often at the cost of increased weight and processing difficulties.

A paradigm shift occurred in the early 2000s with the development of advanced magnetic fillers such as ferrites, carbonyl iron, and various magnetic nanoparticles. These materials provided absorption-dominant shielding mechanisms rather than reflection-based protection, addressing concerns about secondary EMI pollution. The integration of magnetic fillers with conductive components created synergistic effects, dramatically improving shielding performance across broader frequency ranges.

Recent technological advancements have focused on nano-engineered fillers, including carbon nanotubes, graphene, MXenes, and hybrid magnetic-conductive nanostructures. These materials offer exceptional shielding effectiveness at lower loading levels, preserving the mechanical properties and processability of the host polymers. The current research frontier explores hierarchical composite structures with precisely controlled filler distributions and orientations to optimize shielding performance.

The primary objective of contemporary EMI shielding research is to develop lightweight, flexible, and environmentally sustainable composites that provide superior protection across the expanding electromagnetic spectrum, particularly in the high-frequency ranges used by 5G and upcoming 6G technologies. Researchers aim to achieve shielding effectiveness exceeding 60 dB with filler loadings below 10 wt%, while maintaining mechanical integrity and ease of processing.

Additional objectives include developing multifunctional composites that combine EMI shielding with other desirable properties such as thermal management, flame retardancy, and self-healing capabilities. The ultimate goal is to establish design principles and predictive models that enable tailored EMI shielding solutions for specific applications, from consumer electronics to aerospace systems, medical devices, and emerging autonomous vehicles.

The 1970s and 1980s marked the emergence of conductive polymer composites as viable alternatives, offering lighter weight and design flexibility. These early composites primarily utilized carbon-based fillers such as carbon black and graphite. The 1990s witnessed the introduction of metal-based fillers including aluminum, copper, and nickel particles, which enhanced shielding effectiveness but often at the cost of increased weight and processing difficulties.

A paradigm shift occurred in the early 2000s with the development of advanced magnetic fillers such as ferrites, carbonyl iron, and various magnetic nanoparticles. These materials provided absorption-dominant shielding mechanisms rather than reflection-based protection, addressing concerns about secondary EMI pollution. The integration of magnetic fillers with conductive components created synergistic effects, dramatically improving shielding performance across broader frequency ranges.

Recent technological advancements have focused on nano-engineered fillers, including carbon nanotubes, graphene, MXenes, and hybrid magnetic-conductive nanostructures. These materials offer exceptional shielding effectiveness at lower loading levels, preserving the mechanical properties and processability of the host polymers. The current research frontier explores hierarchical composite structures with precisely controlled filler distributions and orientations to optimize shielding performance.

The primary objective of contemporary EMI shielding research is to develop lightweight, flexible, and environmentally sustainable composites that provide superior protection across the expanding electromagnetic spectrum, particularly in the high-frequency ranges used by 5G and upcoming 6G technologies. Researchers aim to achieve shielding effectiveness exceeding 60 dB with filler loadings below 10 wt%, while maintaining mechanical integrity and ease of processing.

Additional objectives include developing multifunctional composites that combine EMI shielding with other desirable properties such as thermal management, flame retardancy, and self-healing capabilities. The ultimate goal is to establish design principles and predictive models that enable tailored EMI shielding solutions for specific applications, from consumer electronics to aerospace systems, medical devices, and emerging autonomous vehicles.

Market Analysis for EMI Shielding Solutions

The global EMI shielding solutions market has experienced robust growth in recent years, driven primarily by the proliferation of electronic devices and the increasing need for electromagnetic compatibility. The market was valued at approximately 6.2 billion USD in 2022 and is projected to reach 8.5 billion USD by 2027, representing a compound annual growth rate (CAGR) of 6.5%.

The automotive sector constitutes a significant portion of the EMI shielding market, accounting for nearly 25% of the total demand. This is attributed to the increasing integration of electronic components in modern vehicles, particularly in electric and autonomous vehicles. The consumer electronics segment follows closely, representing about 22% of the market share, with smartphones, tablets, and wearable devices being the primary contributors.

Healthcare equipment manufacturers have emerged as rapidly growing consumers of EMI shielding solutions, with a market growth rate exceeding 8% annually. This trend is driven by the increasing sophistication of medical devices and the critical importance of preventing electromagnetic interference in life-supporting equipment.

Regionally, Asia-Pacific dominates the market with approximately 40% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America and Europe follow with 30% and 25% market shares respectively, with the remaining 5% distributed across other regions.

The demand for lightweight and effective EMI shielding materials has created a significant opportunity for composite materials incorporating magnetic and conductive fillers. These composites offer advantages over traditional metal-based solutions, including weight reduction, corrosion resistance, and design flexibility. Market analysis indicates that polymer-based composites with conductive fillers currently hold about 35% of the materials market, while those with magnetic fillers account for approximately 20%.

Customer requirements are increasingly focused on multifunctional materials that provide not only EMI shielding but also thermal management capabilities. This trend is particularly evident in the aerospace and defense sectors, where space and weight constraints are critical considerations.

Price sensitivity varies significantly across different market segments. While consumer electronics manufacturers prioritize cost-effectiveness, aerospace and medical device manufacturers place greater emphasis on performance reliability and are willing to pay premium prices for advanced shielding solutions.

The automotive sector constitutes a significant portion of the EMI shielding market, accounting for nearly 25% of the total demand. This is attributed to the increasing integration of electronic components in modern vehicles, particularly in electric and autonomous vehicles. The consumer electronics segment follows closely, representing about 22% of the market share, with smartphones, tablets, and wearable devices being the primary contributors.

Healthcare equipment manufacturers have emerged as rapidly growing consumers of EMI shielding solutions, with a market growth rate exceeding 8% annually. This trend is driven by the increasing sophistication of medical devices and the critical importance of preventing electromagnetic interference in life-supporting equipment.

Regionally, Asia-Pacific dominates the market with approximately 40% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America and Europe follow with 30% and 25% market shares respectively, with the remaining 5% distributed across other regions.

The demand for lightweight and effective EMI shielding materials has created a significant opportunity for composite materials incorporating magnetic and conductive fillers. These composites offer advantages over traditional metal-based solutions, including weight reduction, corrosion resistance, and design flexibility. Market analysis indicates that polymer-based composites with conductive fillers currently hold about 35% of the materials market, while those with magnetic fillers account for approximately 20%.

Customer requirements are increasingly focused on multifunctional materials that provide not only EMI shielding but also thermal management capabilities. This trend is particularly evident in the aerospace and defense sectors, where space and weight constraints are critical considerations.

Price sensitivity varies significantly across different market segments. While consumer electronics manufacturers prioritize cost-effectiveness, aerospace and medical device manufacturers place greater emphasis on performance reliability and are willing to pay premium prices for advanced shielding solutions.

Current Challenges in Composite Shielding Materials

Despite significant advancements in EMI shielding composites, several critical challenges persist in the development and application of these materials. The integration of magnetic and conductive fillers into polymer matrices presents complex manufacturing hurdles that impede widespread industrial adoption. One primary challenge is achieving uniform dispersion of fillers throughout the polymer matrix, as agglomeration frequently occurs due to strong van der Waals forces between nanoparticles, particularly with carbon-based fillers like graphene and carbon nanotubes.

The percolation threshold represents another significant obstacle, as achieving effective conductivity requires sufficient filler content to form conductive networks. However, high filler loadings often compromise the mechanical properties of the composite, creating an inherent trade-off between EMI shielding effectiveness and structural integrity. This balance becomes particularly critical in applications requiring both robust mechanical performance and effective shielding.

Processing challenges further complicate composite development, as high-viscosity mixtures resulting from filler addition create difficulties in conventional manufacturing processes such as injection molding and extrusion. These processing limitations restrict the geometric complexity and dimensional precision achievable in final components, constraining design freedom for engineers.

Durability and environmental stability present ongoing concerns, with many composite materials exhibiting performance degradation under thermal cycling, humidity, and UV exposure. This vulnerability limits their application in harsh environments such as aerospace, automotive, and outdoor telecommunications infrastructure where long-term reliability is essential.

Cost-effectiveness remains a significant barrier to widespread adoption, particularly for composites incorporating advanced nanomaterials like graphene, carbon nanotubes, and specialized magnetic particles. The high production costs of these fillers, combined with complex processing requirements, result in finished materials that are often prohibitively expensive for mass-market applications.

Multifunctionality integration presents another frontier challenge, as modern applications increasingly demand materials that simultaneously provide EMI shielding alongside other properties such as thermal management, flame retardancy, and structural support. Developing composites that effectively balance these diverse requirements without compromising core shielding performance requires sophisticated material design approaches.

Standardization and characterization methodologies also remain underdeveloped, with inconsistent testing protocols across the industry creating difficulties in comparing performance between different composite formulations. This lack of standardization impedes knowledge transfer and slows the pace of innovation in the field.

The percolation threshold represents another significant obstacle, as achieving effective conductivity requires sufficient filler content to form conductive networks. However, high filler loadings often compromise the mechanical properties of the composite, creating an inherent trade-off between EMI shielding effectiveness and structural integrity. This balance becomes particularly critical in applications requiring both robust mechanical performance and effective shielding.

Processing challenges further complicate composite development, as high-viscosity mixtures resulting from filler addition create difficulties in conventional manufacturing processes such as injection molding and extrusion. These processing limitations restrict the geometric complexity and dimensional precision achievable in final components, constraining design freedom for engineers.

Durability and environmental stability present ongoing concerns, with many composite materials exhibiting performance degradation under thermal cycling, humidity, and UV exposure. This vulnerability limits their application in harsh environments such as aerospace, automotive, and outdoor telecommunications infrastructure where long-term reliability is essential.

Cost-effectiveness remains a significant barrier to widespread adoption, particularly for composites incorporating advanced nanomaterials like graphene, carbon nanotubes, and specialized magnetic particles. The high production costs of these fillers, combined with complex processing requirements, result in finished materials that are often prohibitively expensive for mass-market applications.

Multifunctionality integration presents another frontier challenge, as modern applications increasingly demand materials that simultaneously provide EMI shielding alongside other properties such as thermal management, flame retardancy, and structural support. Developing composites that effectively balance these diverse requirements without compromising core shielding performance requires sophisticated material design approaches.

Standardization and characterization methodologies also remain underdeveloped, with inconsistent testing protocols across the industry creating difficulties in comparing performance between different composite formulations. This lack of standardization impedes knowledge transfer and slows the pace of innovation in the field.

Comparative Analysis of Filler-Based Shielding Solutions

01 Carbon-based conductive fillers for EMI shielding

Carbon-based materials such as carbon nanotubes, graphene, and carbon black are effective conductive fillers in EMI shielding composites. These materials provide excellent electrical conductivity and can form interconnected networks within the polymer matrix, creating pathways for the dissipation of electromagnetic radiation. The high aspect ratio of carbon nanotubes and graphene sheets enhances their effectiveness at lower loading levels, resulting in lightweight yet highly effective EMI shielding materials.- Metal-based fillers for EMI shielding: Metal-based fillers such as metal particles, flakes, and fibers are incorporated into polymer matrices to enhance electromagnetic interference (EMI) shielding effectiveness. These conductive fillers create pathways for electrical current, allowing the composite to reflect and absorb electromagnetic waves. Common metal fillers include copper, aluminum, silver, and nickel, which can be used in various forms to achieve different levels of conductivity and shielding performance.

- Magnetic materials for EMI absorption: Magnetic materials such as ferrites, iron oxides, and other ferromagnetic compounds are used in EMI shielding composites to enhance absorption of electromagnetic waves. These materials convert electromagnetic energy into heat through magnetic hysteresis and eddy current losses. The incorporation of magnetic fillers like carbonyl iron powder, ferrite powders, and magnetic nanoparticles can significantly improve the absorption properties of EMI shielding composites, especially in the high-frequency range.

- Carbon-based conductive fillers: Carbon-based materials such as carbon nanotubes, graphene, carbon black, and carbon fibers are widely used as conductive fillers in EMI shielding composites. These materials offer excellent electrical conductivity, lightweight properties, and corrosion resistance compared to metal fillers. The high aspect ratio of carbon nanotubes and graphene sheets allows for the formation of conductive networks at relatively low loading levels, resulting in effective EMI shielding without significantly increasing the weight or compromising the mechanical properties of the composite.

- Hybrid filler systems for enhanced EMI shielding: Hybrid filler systems combining different types of conductive and magnetic materials can create synergistic effects that enhance EMI shielding performance. By incorporating both conductive fillers (for reflection) and magnetic fillers (for absorption), these composites can provide broadband EMI shielding across a wide frequency range. Examples include combinations of metal particles with carbon nanotubes, ferrite particles with graphene, or nickel-coated carbon fibers. These hybrid systems often achieve higher shielding effectiveness at lower total filler loadings compared to single-filler systems.

- Polymer matrix selection and processing techniques: The selection of polymer matrix and processing techniques significantly impacts the dispersion of fillers and the resulting EMI shielding performance. Thermoplastics, thermosets, and elastomers can be used as matrices, each offering different processing options and end-use properties. Advanced processing techniques such as in-situ polymerization, solution blending, and specialized extrusion methods help achieve uniform dispersion of fillers, which is crucial for optimal EMI shielding performance. Surface modification of fillers can improve their compatibility with the polymer matrix, enhancing dispersion and interfacial adhesion.

02 Metal-based magnetic fillers for EMI absorption

Metal-based magnetic fillers such as iron, nickel, cobalt, and their alloys or oxides can be incorporated into polymer matrices to enhance EMI shielding through absorption mechanisms. These magnetic particles interact with the magnetic component of electromagnetic waves, converting the energy into heat through magnetic losses. The combination of magnetic particles with conductive fillers creates a synergistic effect, where reflection and absorption mechanisms work together to provide comprehensive EMI shielding across a wide frequency range.Expand Specific Solutions03 Hybrid filler systems for enhanced EMI shielding performance

Hybrid filler systems combining different types of conductive and magnetic materials can significantly enhance EMI shielding effectiveness. By incorporating multiple fillers with complementary properties, such as metal particles with carbon nanotubes or graphene with ferrites, the resulting composites can achieve superior shielding through multiple mechanisms including reflection, absorption, and multiple internal reflections. These hybrid systems often allow for reduced overall filler loading while maintaining or improving shielding performance, resulting in better mechanical properties and processability.Expand Specific Solutions04 Nanostructured fillers for lightweight EMI shielding

Nanostructured fillers, including nanoparticles, nanowires, and nanofibers, offer significant advantages for EMI shielding applications due to their high surface area and unique properties at the nanoscale. These materials can achieve effective EMI shielding at much lower loading levels compared to conventional fillers, resulting in lightweight composites. Additionally, nanostructured fillers can be surface-modified to improve dispersion within the polymer matrix and enhance interfacial interactions, leading to better mechanical properties and more uniform shielding performance.Expand Specific Solutions05 Processing techniques for optimized filler dispersion

Various processing techniques can be employed to optimize the dispersion of magnetic and conductive fillers in polymer matrices for EMI shielding applications. Methods such as solution blending, melt mixing, in-situ polymerization, and layer-by-layer assembly can significantly impact the distribution and orientation of fillers within the composite. Proper dispersion prevents agglomeration of fillers and ensures the formation of effective conductive networks throughout the material. Additionally, techniques like magnetic field alignment during processing can orient magnetic particles to maximize their interaction with electromagnetic waves, enhancing the overall shielding effectiveness of the composite.Expand Specific Solutions

Key Manufacturers and Research Institutions

The EMI shielding composites market is in a growth phase, driven by increasing electronic device proliferation and electromagnetic pollution concerns. The global market is projected to expand significantly, with magnetic and conductive fillers playing a crucial role in performance enhancement. Leading companies like 3M, Laird Technologies, and Parker-Hannifin are advancing commercial applications, while research institutions such as Beijing Institute of Technology and Guangdong University of Technology are developing next-generation materials. Technical maturity varies across filler types, with established players like Henkel and LG Innotek focusing on hybrid solutions combining magnetic materials (ferrites, metal alloys) with conductive elements (carbon-based materials, metal particles) to achieve optimal shielding effectiveness across broader frequency ranges.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced EMI shielding composites utilizing a multi-layered approach that combines magnetic and conductive fillers. Their technology incorporates ferrite-based magnetic particles (typically NiZn or MnZn ferrites) dispersed in a polymer matrix, coupled with highly conductive materials such as silver-coated copper particles or carbon nanotubes. This dual-filler system creates both absorption and reflection mechanisms for electromagnetic interference. The magnetic particles provide low-frequency absorption through magnetic loss mechanisms, while the conductive network formed by metallic fillers offers reflection-based shielding at higher frequencies. 3M's proprietary processing techniques ensure uniform dispersion of fillers while maintaining the mechanical integrity and flexibility of the composite. Their solutions typically achieve shielding effectiveness of 60-80 dB across a wide frequency range (10 MHz to 18 GHz), making them suitable for various electronic applications.

Strengths: Excellent broad-spectrum shielding performance; maintains mechanical flexibility; established manufacturing infrastructure for consistent quality. Weaknesses: Higher cost compared to single-filler solutions; potential for increased weight in applications where lightweight materials are critical.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed innovative EMI shielding composites under their BERGQUIST® and LOCTITE® brands that incorporate both magnetic and conductive fillers in specialized polymer matrices. Their approach focuses on synergistic combinations of nickel-zinc ferrite particles with silver-coated aluminum flakes and carbon nanostructures. The company utilizes a proprietary "dual-phase matrix" where magnetic particles are encapsulated in a thermally conductive polymer phase while conductive fillers form networks in an electrically conductive phase. This structure allows simultaneous thermal management and EMI shielding. Henkel's materials achieve shielding effectiveness of 50-75 dB across 100 MHz to 10 GHz. A key innovation is their development of printable and sprayable EMI shielding formulations that can be directly applied to electronic components, eliminating the need for separate shielding components. These materials incorporate nano-scale magnetic particles (30-100 nm) and micron-sized conductive flakes in carefully controlled ratios to maintain processability while maximizing shielding performance.

Strengths: Excellent integration with existing electronic manufacturing processes; dual functionality for thermal management and EMI shielding; good adhesion to various substrates. Weaknesses: Some formulations have limited environmental resistance; performance may degrade at extremely high frequencies (>20 GHz).

Critical Patents in Magnetic-Conductive Composite Design

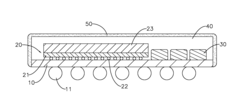

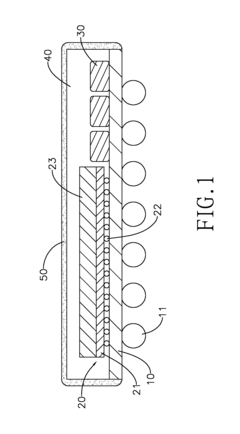

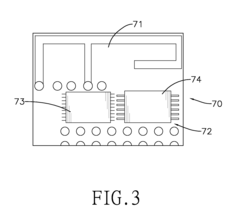

Electromagnetic interference shielding material, electromagnetic interference shielding device, method for making the electromagnetic interference shielding device, electromagnetic interference shielding package module and appliance

PatentInactiveUS20150085462A1

Innovation

- A mixture comprising 70 wt % to 98 wt % of dendritic copper filler, flaky copper filler, resin binder, and diluent is used to create an adjustable EMI shielding material that can be applied via screen printing or spraying, hardened at 120-160°C, providing effective shielding with adjustable thickness and low cost.

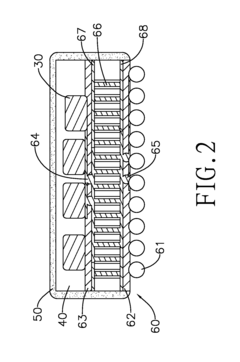

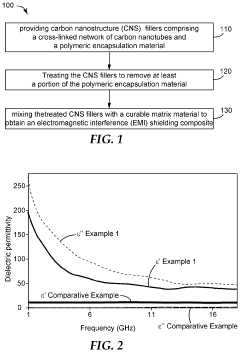

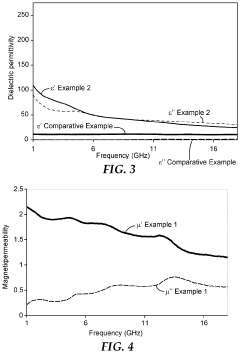

High frequency electromagnetic interference (EMI) composites

PatentActiveUS11369050B2

Innovation

- The use of carbon nanostructure (CNS) fillers, comprising cross-linked carbon nanotubes partially encapsulated with polymeric materials, where the polymeric encapsulation is partially removed to decrease dielectric polarization, and these fillers are dispersed in a curable matrix material to create an EMI shielding composite with improved absorption properties.

Environmental Impact and Sustainability Considerations

The environmental impact of EMI shielding composites has become increasingly significant as electronic devices proliferate globally. Traditional EMI shielding materials often contain heavy metals and toxic substances that pose serious environmental concerns throughout their lifecycle. Magnetic fillers such as ferrites and iron-based compounds, while effective for shielding, can contribute to mining-related environmental degradation and energy-intensive processing methods that generate substantial carbon emissions.

Conductive fillers present their own sustainability challenges. Carbon-based fillers like graphene and carbon nanotubes require energy-intensive production processes, though they generally have lower environmental toxicity compared to metal-based alternatives. Metal fillers such as copper, silver, and nickel raise concerns regarding resource depletion and end-of-life disposal issues, as improper handling can lead to soil and water contamination.

Recent sustainability trends in EMI shielding composite development focus on biodegradable matrices combined with more environmentally benign fillers. Research into bio-based conductive fillers derived from agricultural waste and sustainable carbon sources shows promising results for reducing environmental footprint while maintaining acceptable shielding performance. Additionally, the development of water-based processing methods rather than solvent-based approaches significantly reduces volatile organic compound emissions during manufacturing.

Lifecycle assessment studies indicate that the environmental impact of EMI shielding composites extends beyond production to include use-phase energy efficiency and end-of-life considerations. Composites that enable lighter electronic devices can contribute to reduced energy consumption during operation, while those designed for recyclability or biodegradability address growing electronic waste concerns.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have driven innovation toward less toxic EMI shielding solutions. Similarly, emerging circular economy policies are pushing manufacturers to consider the entire lifecycle environmental impact of their materials.

Future sustainable development in EMI shielding composites will likely focus on renewable resource utilization, reduced energy consumption in processing, and design for recyclability. Promising approaches include the development of multifunctional composites that combine EMI shielding with other properties such as thermal management or structural reinforcement, thereby reducing the overall material requirements and associated environmental impacts.

Conductive fillers present their own sustainability challenges. Carbon-based fillers like graphene and carbon nanotubes require energy-intensive production processes, though they generally have lower environmental toxicity compared to metal-based alternatives. Metal fillers such as copper, silver, and nickel raise concerns regarding resource depletion and end-of-life disposal issues, as improper handling can lead to soil and water contamination.

Recent sustainability trends in EMI shielding composite development focus on biodegradable matrices combined with more environmentally benign fillers. Research into bio-based conductive fillers derived from agricultural waste and sustainable carbon sources shows promising results for reducing environmental footprint while maintaining acceptable shielding performance. Additionally, the development of water-based processing methods rather than solvent-based approaches significantly reduces volatile organic compound emissions during manufacturing.

Lifecycle assessment studies indicate that the environmental impact of EMI shielding composites extends beyond production to include use-phase energy efficiency and end-of-life considerations. Composites that enable lighter electronic devices can contribute to reduced energy consumption during operation, while those designed for recyclability or biodegradability address growing electronic waste concerns.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic materials. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have driven innovation toward less toxic EMI shielding solutions. Similarly, emerging circular economy policies are pushing manufacturers to consider the entire lifecycle environmental impact of their materials.

Future sustainable development in EMI shielding composites will likely focus on renewable resource utilization, reduced energy consumption in processing, and design for recyclability. Promising approaches include the development of multifunctional composites that combine EMI shielding with other properties such as thermal management or structural reinforcement, thereby reducing the overall material requirements and associated environmental impacts.

Standardization and Testing Protocols for EMI Composites

The standardization of testing protocols for EMI shielding composites represents a critical aspect in the advancement and commercial application of these materials. Currently, several international organizations including IEEE, ASTM International, and IEC have established various standards for evaluating the electromagnetic interference shielding effectiveness of materials. These standards provide methodologies for measuring shielding effectiveness across different frequency ranges, typically from 30 MHz to 18 GHz.

One of the primary testing methods is the coaxial transmission line method (ASTM D4935), which is widely used for measuring the shielding effectiveness of flat materials. This method involves placing a sample between two sections of a coaxial line and measuring the attenuation of electromagnetic waves. The advantage of this approach lies in its reproducibility and relatively simple setup, though it is limited to specific frequency ranges.

For more comprehensive evaluations, the nested reverberation chamber technique (IEEE 299) offers testing capabilities across broader frequency ranges and provides data on both absorption and reflection losses. This method more accurately simulates real-world electromagnetic environments but requires sophisticated equipment and expertise.

A significant challenge in the field is the lack of standardized protocols specifically designed for composite materials containing magnetic and conductive fillers. Current standards often do not account for the unique properties of these composites, such as frequency-dependent behavior, anisotropic properties, and the synergistic effects between different types of fillers.

The development of new testing protocols must address several key considerations. First, they should accommodate the evaluation of both near-field and far-field shielding performance, as these can differ significantly for composite materials. Second, protocols must account for environmental factors such as temperature, humidity, and mechanical stress, which can significantly impact the performance of EMI shielding composites.

International harmonization of testing standards represents another critical need. Currently, differences between standards used in North America, Europe, and Asia create challenges for global product development and certification. Efforts toward creating unified global standards would facilitate international trade and accelerate technological advancement in this field.

Future standardization efforts should also incorporate methodologies for evaluating the durability and long-term performance of EMI shielding composites, as these factors are crucial for applications in aerospace, automotive, and consumer electronics industries where product lifecycles span many years.

One of the primary testing methods is the coaxial transmission line method (ASTM D4935), which is widely used for measuring the shielding effectiveness of flat materials. This method involves placing a sample between two sections of a coaxial line and measuring the attenuation of electromagnetic waves. The advantage of this approach lies in its reproducibility and relatively simple setup, though it is limited to specific frequency ranges.

For more comprehensive evaluations, the nested reverberation chamber technique (IEEE 299) offers testing capabilities across broader frequency ranges and provides data on both absorption and reflection losses. This method more accurately simulates real-world electromagnetic environments but requires sophisticated equipment and expertise.

A significant challenge in the field is the lack of standardized protocols specifically designed for composite materials containing magnetic and conductive fillers. Current standards often do not account for the unique properties of these composites, such as frequency-dependent behavior, anisotropic properties, and the synergistic effects between different types of fillers.

The development of new testing protocols must address several key considerations. First, they should accommodate the evaluation of both near-field and far-field shielding performance, as these can differ significantly for composite materials. Second, protocols must account for environmental factors such as temperature, humidity, and mechanical stress, which can significantly impact the performance of EMI shielding composites.

International harmonization of testing standards represents another critical need. Currently, differences between standards used in North America, Europe, and Asia create challenges for global product development and certification. Efforts toward creating unified global standards would facilitate international trade and accelerate technological advancement in this field.

Future standardization efforts should also incorporate methodologies for evaluating the durability and long-term performance of EMI shielding composites, as these factors are crucial for applications in aerospace, automotive, and consumer electronics industries where product lifecycles span many years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!