Research on Flexible EMI Shielding Films for Wearable Electronics

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible EMI Shielding Technology Background and Objectives

Electromagnetic interference (EMI) shielding has become increasingly critical in modern electronics, particularly as devices continue to miniaturize and integrate more complex functionalities. The evolution of wearable technology has created a unique set of challenges for EMI shielding, as traditional rigid metal-based shields are incompatible with the flexibility and comfort requirements of wearable devices. This has catalyzed significant research and development in flexible EMI shielding materials over the past decade, transitioning from conventional metal foils to innovative composite materials.

The technological trajectory of flexible EMI shielding has progressed through several distinct phases. Initially, thin metal foils provided adequate shielding but lacked the necessary flexibility for wearable applications. This limitation led to the development of metal-coated fabrics and conductive polymers in the early 2010s, which offered improved flexibility but often with compromised shielding effectiveness. Recent advancements have focused on nanomaterial-based solutions, including graphene, carbon nanotubes, and metallic nanowires, which demonstrate promising combinations of flexibility, lightweight properties, and shielding performance.

Current market trends indicate a growing demand for wearable electronics across healthcare, fitness, and consumer electronics sectors, with projections suggesting a compound annual growth rate exceeding 15% through 2028. This expansion necessitates corresponding advancements in flexible EMI shielding technologies that can accommodate the diverse form factors and operating environments of wearable devices while maintaining electromagnetic compatibility.

The primary technical objective of this research is to develop flexible EMI shielding films that achieve a shielding effectiveness of at least 60 dB across the frequency range of 1-10 GHz, while maintaining mechanical flexibility with a bending radius below 5 mm and a thickness not exceeding 100 μm. Additionally, these materials must demonstrate durability under repeated mechanical stress, resistance to environmental factors such as moisture and temperature fluctuations, and compatibility with mass production techniques to ensure commercial viability.

Secondary objectives include exploring multifunctional capabilities, such as integrating thermal management properties, transparency for display applications, and stretchability for conformable electronics. The research also aims to establish standardized testing methodologies specifically designed for flexible EMI shielding materials, as current industry standards primarily address rigid shielding solutions and may not adequately characterize the performance of flexible alternatives under realistic operating conditions.

This technological evolution is expected to continue advancing toward more sophisticated composite structures that combine multiple functional materials at the nanoscale, potentially enabling unprecedented combinations of electromagnetic shielding, flexibility, and additional functionalities tailored to specific wearable applications.

The technological trajectory of flexible EMI shielding has progressed through several distinct phases. Initially, thin metal foils provided adequate shielding but lacked the necessary flexibility for wearable applications. This limitation led to the development of metal-coated fabrics and conductive polymers in the early 2010s, which offered improved flexibility but often with compromised shielding effectiveness. Recent advancements have focused on nanomaterial-based solutions, including graphene, carbon nanotubes, and metallic nanowires, which demonstrate promising combinations of flexibility, lightweight properties, and shielding performance.

Current market trends indicate a growing demand for wearable electronics across healthcare, fitness, and consumer electronics sectors, with projections suggesting a compound annual growth rate exceeding 15% through 2028. This expansion necessitates corresponding advancements in flexible EMI shielding technologies that can accommodate the diverse form factors and operating environments of wearable devices while maintaining electromagnetic compatibility.

The primary technical objective of this research is to develop flexible EMI shielding films that achieve a shielding effectiveness of at least 60 dB across the frequency range of 1-10 GHz, while maintaining mechanical flexibility with a bending radius below 5 mm and a thickness not exceeding 100 μm. Additionally, these materials must demonstrate durability under repeated mechanical stress, resistance to environmental factors such as moisture and temperature fluctuations, and compatibility with mass production techniques to ensure commercial viability.

Secondary objectives include exploring multifunctional capabilities, such as integrating thermal management properties, transparency for display applications, and stretchability for conformable electronics. The research also aims to establish standardized testing methodologies specifically designed for flexible EMI shielding materials, as current industry standards primarily address rigid shielding solutions and may not adequately characterize the performance of flexible alternatives under realistic operating conditions.

This technological evolution is expected to continue advancing toward more sophisticated composite structures that combine multiple functional materials at the nanoscale, potentially enabling unprecedented combinations of electromagnetic shielding, flexibility, and additional functionalities tailored to specific wearable applications.

Market Demand Analysis for Wearable Electronics Shielding

The wearable electronics market has experienced exponential growth over the past decade, evolving from simple fitness trackers to sophisticated health monitoring systems, smart clothing, and augmented reality devices. This expansion has created a substantial demand for specialized EMI shielding solutions that can protect these sensitive electronic components while maintaining the flexibility and comfort essential for wearable applications.

Market research indicates that the global wearable technology market is projected to reach $265 billion by 2026, growing at a CAGR of approximately 18% from 2021. Within this broader market, the demand for EMI shielding materials specifically designed for wearable electronics represents a rapidly expanding segment, estimated to grow at 22% annually through 2025.

Consumer electronics remains the dominant application sector, accounting for nearly 65% of the flexible EMI shielding film market. Healthcare wearables represent the fastest-growing segment, driven by increasing adoption of remote patient monitoring systems and medical-grade wearable devices that require robust EMI protection to ensure accurate data collection and transmission.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate due to the concentration of electronics manufacturing facilities and increasing consumer adoption of wearable technologies in countries like China, South Korea, and Japan.

Key market drivers include the miniaturization of electronic components, which increases their susceptibility to electromagnetic interference, and the proliferation of wireless communication technologies in wearable devices. The integration of multiple wireless protocols (Bluetooth, Wi-Fi, NFC, cellular) within single devices has significantly elevated EMI shielding requirements.

Consumer expectations for thinner, lighter, and more comfortable wearable devices are pushing manufacturers to seek ultra-thin shielding solutions that maintain effectiveness while adding minimal bulk and weight. Additionally, the growing trend toward sustainable electronics has created demand for environmentally friendly shielding materials that can replace traditional options containing heavy metals or non-recyclable components.

Market challenges include price sensitivity, particularly in consumer-grade wearables where manufacturers face intense pressure to reduce costs while maintaining performance. The technical challenge of achieving high shielding effectiveness without compromising flexibility or breathability represents another significant market constraint that innovative materials must address.

Market research indicates that the global wearable technology market is projected to reach $265 billion by 2026, growing at a CAGR of approximately 18% from 2021. Within this broader market, the demand for EMI shielding materials specifically designed for wearable electronics represents a rapidly expanding segment, estimated to grow at 22% annually through 2025.

Consumer electronics remains the dominant application sector, accounting for nearly 65% of the flexible EMI shielding film market. Healthcare wearables represent the fastest-growing segment, driven by increasing adoption of remote patient monitoring systems and medical-grade wearable devices that require robust EMI protection to ensure accurate data collection and transmission.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate due to the concentration of electronics manufacturing facilities and increasing consumer adoption of wearable technologies in countries like China, South Korea, and Japan.

Key market drivers include the miniaturization of electronic components, which increases their susceptibility to electromagnetic interference, and the proliferation of wireless communication technologies in wearable devices. The integration of multiple wireless protocols (Bluetooth, Wi-Fi, NFC, cellular) within single devices has significantly elevated EMI shielding requirements.

Consumer expectations for thinner, lighter, and more comfortable wearable devices are pushing manufacturers to seek ultra-thin shielding solutions that maintain effectiveness while adding minimal bulk and weight. Additionally, the growing trend toward sustainable electronics has created demand for environmentally friendly shielding materials that can replace traditional options containing heavy metals or non-recyclable components.

Market challenges include price sensitivity, particularly in consumer-grade wearables where manufacturers face intense pressure to reduce costs while maintaining performance. The technical challenge of achieving high shielding effectiveness without compromising flexibility or breathability represents another significant market constraint that innovative materials must address.

Current Status and Challenges in Flexible EMI Shielding

The current landscape of flexible EMI shielding technology for wearable electronics presents a complex interplay of significant advancements and persistent challenges. Globally, research institutions and companies have made substantial progress in developing thin, lightweight, and conformable EMI shielding materials that can effectively protect sensitive electronic components while maintaining the flexibility required for wearable applications. These developments have primarily focused on conductive polymer composites, metallic mesh structures, and carbon-based nanomaterials such as graphene and carbon nanotubes.

Despite these advancements, several critical technical challenges continue to impede widespread adoption. The fundamental trade-off between shielding effectiveness and flexibility remains a significant obstacle. Traditional EMI shielding materials like metal foils offer excellent shielding properties but lack the flexibility needed for wearable applications, while highly flexible materials often provide insufficient shielding performance, particularly at higher frequencies increasingly used in modern communication systems.

Durability presents another major challenge, as flexible EMI shields must withstand repeated mechanical deformation, including bending, folding, and stretching, without degradation in performance. Current solutions often show diminished shielding effectiveness after multiple deformation cycles, limiting their practical lifespan in wearable devices that undergo constant movement and stress.

Manufacturing scalability also poses significant constraints. Many laboratory-developed solutions utilize complex fabrication processes that are difficult to scale for mass production. The precision required for creating uniform, defect-free shielding layers across large areas remains technically challenging and cost-prohibitive for commercial applications.

Geographically, research in this field shows distinct regional characteristics. East Asian countries, particularly Japan, South Korea, and China, lead in patent filings related to flexible EMI shielding materials, with a focus on applications in consumer electronics. North American and European research institutions tend to emphasize fundamental material science innovations and specialized applications in medical and military domains.

Environmental concerns represent an emerging challenge, as many current EMI shielding solutions incorporate materials that pose end-of-life disposal issues. The use of heavy metals, difficult-to-recycle composites, and potentially toxic components conflicts with growing sustainability requirements in electronics manufacturing.

Integration complexity with other wearable components further complicates implementation. EMI shields must coexist with sensors, antennas, and power systems without compromising their functionality, while simultaneously protecting against both external interference and containing emissions from the device itself. This multi-functional requirement creates design constraints that have not been fully resolved by current technological approaches.

Despite these advancements, several critical technical challenges continue to impede widespread adoption. The fundamental trade-off between shielding effectiveness and flexibility remains a significant obstacle. Traditional EMI shielding materials like metal foils offer excellent shielding properties but lack the flexibility needed for wearable applications, while highly flexible materials often provide insufficient shielding performance, particularly at higher frequencies increasingly used in modern communication systems.

Durability presents another major challenge, as flexible EMI shields must withstand repeated mechanical deformation, including bending, folding, and stretching, without degradation in performance. Current solutions often show diminished shielding effectiveness after multiple deformation cycles, limiting their practical lifespan in wearable devices that undergo constant movement and stress.

Manufacturing scalability also poses significant constraints. Many laboratory-developed solutions utilize complex fabrication processes that are difficult to scale for mass production. The precision required for creating uniform, defect-free shielding layers across large areas remains technically challenging and cost-prohibitive for commercial applications.

Geographically, research in this field shows distinct regional characteristics. East Asian countries, particularly Japan, South Korea, and China, lead in patent filings related to flexible EMI shielding materials, with a focus on applications in consumer electronics. North American and European research institutions tend to emphasize fundamental material science innovations and specialized applications in medical and military domains.

Environmental concerns represent an emerging challenge, as many current EMI shielding solutions incorporate materials that pose end-of-life disposal issues. The use of heavy metals, difficult-to-recycle composites, and potentially toxic components conflicts with growing sustainability requirements in electronics manufacturing.

Integration complexity with other wearable components further complicates implementation. EMI shields must coexist with sensors, antennas, and power systems without compromising their functionality, while simultaneously protecting against both external interference and containing emissions from the device itself. This multi-functional requirement creates design constraints that have not been fully resolved by current technological approaches.

Current Technical Solutions for Wearable EMI Protection

01 Conductive materials for flexible EMI shielding films

Various conductive materials can be incorporated into flexible films to provide effective EMI shielding. These materials include metal foils, conductive polymers, carbon-based materials (such as graphene and carbon nanotubes), and metal meshes. The selection of conductive materials affects the shielding effectiveness, flexibility, and durability of the EMI shielding film. These materials can be applied as coatings or embedded within polymer matrices to create flexible shielding solutions that maintain conductivity even when bent or flexed.- Conductive materials for EMI shielding films: Various conductive materials can be incorporated into flexible films to provide effective EMI shielding. These materials include metal foils, conductive polymers, carbon-based materials (such as graphene and carbon nanotubes), and metal meshes. The selection of conductive materials affects the shielding effectiveness, flexibility, and durability of the EMI shielding film. These materials can be applied as coatings or embedded within polymer matrices to create flexible shielding solutions.

- Multilayer structures for enhanced flexibility and shielding: Multilayer film structures combine different materials to achieve both flexibility and effective EMI shielding. These structures typically include a flexible substrate (such as polyester or polyimide), conductive layers, and protective coatings. The layered approach allows for optimization of mechanical properties while maintaining shielding effectiveness. Some designs incorporate adhesive layers to facilitate application to electronic components or housings, while maintaining conformability to complex surfaces.

- Transparent EMI shielding solutions: Transparent EMI shielding films are developed for applications requiring both optical clarity and electromagnetic protection, such as display screens and optical sensors. These films typically utilize transparent conductive materials like indium tin oxide (ITO), metal nanowires, or conductive meshes with openings smaller than visible light wavelengths. The challenge is balancing optical transparency with sufficient conductivity for effective EMI shielding, while maintaining the flexibility needed for modern electronic devices.

- Integration with electronic devices and housings: Flexible EMI shielding films can be integrated with electronic device housings and components through various attachment methods. These include adhesive bonding, mechanical fastening, and direct lamination during manufacturing. The films can be designed to conform to complex geometries while maintaining continuous shielding coverage. Some solutions incorporate grounding features to ensure proper electrical connection to the device's ground plane, enhancing the overall EMI protection system.

- Testing and performance measurement of EMI shielding films: Specialized testing methods are used to evaluate the performance of flexible EMI shielding films. These include shielding effectiveness measurements across different frequency ranges, flexibility and adhesion testing, environmental durability assessments, and compatibility testing with target applications. Testing standards such as ASTM and IEEE protocols are commonly employed to ensure consistent evaluation. Advanced techniques like near-field scanning and impedance analysis help characterize the films' electromagnetic properties under various conditions.

02 Multilayer structures for enhanced EMI shielding performance

Multilayer film structures can significantly improve EMI shielding effectiveness while maintaining flexibility. These structures typically combine different functional layers, such as conductive layers, adhesive layers, protective layers, and insulating layers. The strategic arrangement of these layers can enhance shielding across a broader frequency range and provide additional benefits such as heat dissipation, moisture resistance, and mechanical protection. Multilayer designs allow for optimization of both shielding performance and physical properties required for specific applications.Expand Specific Solutions03 Transparent EMI shielding solutions

Transparent EMI shielding films are essential for display applications and optical devices that require both visibility and protection from electromagnetic interference. These films typically utilize transparent conductive materials such as indium tin oxide (ITO), metal nanowires, conductive polymers, or ultrathin metal meshes. The challenge in developing these films lies in balancing optical transparency with sufficient conductivity for effective EMI shielding. Advanced manufacturing techniques enable the creation of transparent shields with minimal impact on display quality while providing adequate protection against electromagnetic radiation.Expand Specific Solutions04 Flexible EMI shielding for electronic enclosures and housings

Specialized flexible EMI shielding solutions are designed for electronic enclosures, housings, and cases to protect sensitive components from electromagnetic interference. These solutions include conductive gaskets, flexible shields that conform to irregular surfaces, and films that can be applied to the interior of device housings. The flexibility of these materials allows them to maintain continuous electrical contact even with complex geometries or when components are in motion. These shielding solutions are particularly important for portable electronics, automotive applications, and medical devices where space constraints and design flexibility are critical considerations.Expand Specific Solutions05 Manufacturing methods for flexible EMI shielding films

Various manufacturing techniques are employed to produce flexible EMI shielding films with consistent performance characteristics. These methods include vacuum deposition, sputtering, electroless plating, lamination, screen printing, and roll-to-roll processing. Each technique offers different advantages in terms of cost, scalability, precision, and compatibility with various substrate materials. Advanced manufacturing processes enable the creation of increasingly thin, lightweight, and flexible shielding solutions while maintaining or improving shielding effectiveness. The choice of manufacturing method significantly impacts the film's physical properties, durability, and overall performance in EMI shielding applications.Expand Specific Solutions

Key Industry Players in Flexible EMI Shielding Market

The flexible EMI shielding films market for wearable electronics is in a growth phase, driven by increasing demand for lightweight, conformable protection solutions. The market is expanding rapidly with an estimated value exceeding $500 million, fueled by the proliferation of wearable devices. Technologically, the field is advancing from traditional metal-based solutions toward innovative composite materials. Leading players include established corporations like 3M Innovative Properties and Hon Hai Precision Industry (Foxconn) with extensive manufacturing capabilities, alongside specialized firms such as Guangzhou Fangbang Electronics and AMOGREENTECH focusing on high-performance materials. Academic institutions like Drexel University and research organizations including KIST are driving fundamental innovations, while companies like Tatsuta Electric Wire & Cable and Vorbeck Materials are commercializing advanced solutions incorporating nanomaterials and conductive polymers.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced flexible EMI shielding films utilizing their proprietary microreplication technology combined with conductive materials. Their solution incorporates a multi-layer structure with metalized polymer films that maintain flexibility while providing effective electromagnetic interference protection. The technology employs precision-engineered microstructures that enhance shielding effectiveness across a broad frequency range (1-10 GHz) while maintaining optical transparency where needed. 3M's approach includes specialized adhesive systems that ensure durability during flexing and bending cycles, critical for wearable applications. Their films incorporate nanoscale conductive materials including silver nanowires and graphene derivatives that create a continuous conductive network while maintaining mechanical flexibility. The company has optimized their manufacturing process to produce ultra-thin films (less than 50 μm) that meet the demanding requirements of modern wearable electronics while providing shielding effectiveness of 30-60 dB.

Strengths: Industry-leading adhesive technology ensures excellent durability and reliability; established global manufacturing capabilities allow for consistent quality and supply chain stability; extensive R&D resources enable continuous innovation. Weaknesses: Higher cost compared to some competitors; some solutions may prioritize shielding effectiveness over maximum flexibility.

AMOGREENTECH Co., Ltd.

Technical Solution: AMOGREENTECH has pioneered eco-friendly flexible EMI shielding solutions specifically designed for wearable electronics. Their technology utilizes a proprietary blend of conductive polymers and metal-coated fibers that create a lightweight, highly flexible shielding material. The company's flagship product, AMO Shield, employs a unique multi-layer structure that combines different conductive materials to achieve broadband shielding effectiveness (20-40 dB across 0.5-6 GHz). Their manufacturing process involves precision coating techniques that deposit nanoscale conductive layers on flexible substrates while maintaining uniform thickness and conductivity. AMOGREENTECH has developed specialized surface treatment methods that enhance adhesion between layers while preserving flexibility through thousands of bending cycles. Their films incorporate environmentally friendly materials that reduce the use of heavy metals while maintaining excellent shielding performance. The company has also developed customizable solutions that can be tailored to specific wearable device requirements, including transparency levels, thickness constraints, and specific EMI frequency blocking needs.

Strengths: Strong focus on environmentally friendly materials gives competitive advantage in eco-conscious markets; specialized expertise in wearable applications; excellent flexibility-to-shielding ratio. Weaknesses: Relatively newer player in the market compared to established competitors; limited production capacity may affect ability to serve very large customers.

Core Patents and Innovations in Flexible Shielding Materials

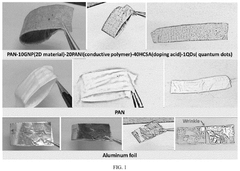

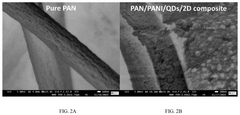

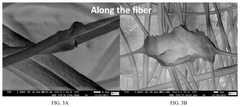

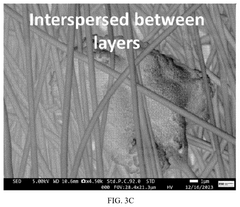

Polymer nanocomposite flexible films for electromagnetic interference shielding

PatentActiveUS12416104B1

Innovation

- Development of polymer-based fiber thin films incorporating quantum dots (QDs) and two-dimensional (2D) conductive nanomaterials within a dual polymer matrix, which are ultra-flexible, lightweight, and have high electrical conductivity, achieving effective EMI shielding through a multilayer structure with aligned and interspersed nanomaterials.

Electromagnetic interference (EMI) shielding products using titanium monoxide (TiO) based materials

PatentActiveUS10932398B2

Innovation

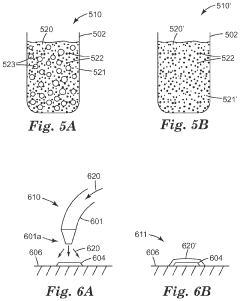

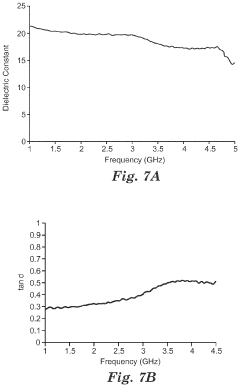

- Composite materials incorporating titanium monoxide (TiO) ceramic particles dispersed in a polymeric matrix, such as fluorocarbon-based polymers, exhibit high dielectric and magnetic loss tangents, effectively mitigating EMI across a broad frequency range by absorbing electromagnetic radiation.

Environmental Impact and Sustainability Considerations

The environmental impact of flexible EMI shielding films for wearable electronics represents a critical consideration as these technologies become increasingly prevalent. Traditional EMI shielding materials often contain heavy metals and toxic substances that pose significant environmental hazards throughout their lifecycle. Particularly concerning are conventional films incorporating nickel, silver, and copper, which can leach into ecosystems when improperly disposed of, causing long-term environmental contamination and potential harm to aquatic organisms.

Manufacturing processes for these shielding films typically involve energy-intensive methods and environmentally harmful chemicals, including strong acids and organic solvents that generate substantial waste streams. The carbon footprint associated with production is further exacerbated by the high-temperature processing requirements of many metallic shielding materials, contributing to greenhouse gas emissions and climate change impacts.

Recent sustainability initiatives have focused on developing eco-friendly alternatives that maintain effective EMI shielding performance. Biodegradable polymers combined with conductive fillers derived from renewable resources show promising results. Carbon-based materials such as graphene and carbon nanotubes offer superior environmental profiles compared to traditional metal-based solutions, with reduced toxicity and potential for recycling. Additionally, research into naturally derived conductive materials, including cellulose nanofibers and lignin-based composites, represents an emerging frontier in sustainable EMI shielding.

End-of-life considerations present particular challenges for wearable electronics incorporating EMI shielding. The intimate integration of different materials complicates recycling efforts, often resulting in these components entering landfills. Innovative design approaches emphasizing material separability and modular construction can significantly enhance recyclability. Some manufacturers have implemented take-back programs specifically targeting the recovery of valuable metals from shielding films.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic components. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have driven manufacturers toward less toxic alternatives. Similarly, emerging standards for electronic waste management are creating incentives for designing more environmentally benign shielding solutions.

Life cycle assessment (LCA) studies comparing traditional and emerging EMI shielding technologies reveal that water-based processing methods and ambient-temperature manufacturing techniques can reduce environmental impacts by up to 40%. These findings underscore the importance of holistic approaches to sustainability that consider raw material sourcing, manufacturing efficiency, product longevity, and end-of-life management in developing next-generation flexible EMI shielding films for wearable electronics.

Manufacturing processes for these shielding films typically involve energy-intensive methods and environmentally harmful chemicals, including strong acids and organic solvents that generate substantial waste streams. The carbon footprint associated with production is further exacerbated by the high-temperature processing requirements of many metallic shielding materials, contributing to greenhouse gas emissions and climate change impacts.

Recent sustainability initiatives have focused on developing eco-friendly alternatives that maintain effective EMI shielding performance. Biodegradable polymers combined with conductive fillers derived from renewable resources show promising results. Carbon-based materials such as graphene and carbon nanotubes offer superior environmental profiles compared to traditional metal-based solutions, with reduced toxicity and potential for recycling. Additionally, research into naturally derived conductive materials, including cellulose nanofibers and lignin-based composites, represents an emerging frontier in sustainable EMI shielding.

End-of-life considerations present particular challenges for wearable electronics incorporating EMI shielding. The intimate integration of different materials complicates recycling efforts, often resulting in these components entering landfills. Innovative design approaches emphasizing material separability and modular construction can significantly enhance recyclability. Some manufacturers have implemented take-back programs specifically targeting the recovery of valuable metals from shielding films.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic components. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have driven manufacturers toward less toxic alternatives. Similarly, emerging standards for electronic waste management are creating incentives for designing more environmentally benign shielding solutions.

Life cycle assessment (LCA) studies comparing traditional and emerging EMI shielding technologies reveal that water-based processing methods and ambient-temperature manufacturing techniques can reduce environmental impacts by up to 40%. These findings underscore the importance of holistic approaches to sustainability that consider raw material sourcing, manufacturing efficiency, product longevity, and end-of-life management in developing next-generation flexible EMI shielding films for wearable electronics.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for flexible EMI shielding films represents a critical factor in their commercial viability for wearable electronics applications. Current production methods vary significantly in their adaptability to mass production, with vacuum-based techniques like sputtering and evaporation facing substantial challenges in scaling up while maintaining cost-effectiveness. These methods require expensive equipment and create production bottlenecks that limit throughput. In contrast, solution-based processes such as screen printing, spray coating, and roll-to-roll manufacturing demonstrate superior scalability potential, with the latter emerging as particularly promising for high-volume production of flexible EMI shields.

Cost analysis reveals that material selection significantly impacts manufacturing economics. Traditional metal-based EMI shielding materials like copper and silver offer excellent performance but at premium prices, especially when considering the high-purity requirements for electronics applications. Emerging alternatives such as carbon-based materials (graphene, carbon nanotubes) and conductive polymers present potentially lower material costs but often require more complex processing steps that may offset initial savings. A comprehensive cost model must account for raw materials (30-40% of total cost), processing (25-35%), quality control (10-15%), and overhead expenses (15-20%).

Production yield rates present another crucial economic consideration, with current industry standards for flexible EMI films ranging from 85-95% depending on the manufacturing technique employed. Higher-precision methods typically deliver better quality but at reduced yields during early implementation phases. The learning curve effect is particularly evident in newer technologies, where production costs typically decrease by 15-20% with each doubling of cumulative production volume as processes are optimized and refined.

Energy consumption metrics vary substantially across manufacturing approaches, with vacuum-based methods requiring 3-5 times more energy input than solution-based alternatives. This energy differential translates directly to operational costs and environmental impact considerations, becoming increasingly important as sustainability metrics factor into production decisions. Manufacturers must balance these energy considerations against performance requirements and production volumes.

Equipment investment represents a significant barrier to entry, with specialized coating and metallization systems requiring capital expenditures of $2-10 million depending on production capacity and precision requirements. This substantial upfront investment necessitates careful market analysis to ensure sufficient demand exists to justify the manufacturing scale. Smaller manufacturers increasingly explore contract manufacturing arrangements or strategic partnerships to mitigate these capital requirements while maintaining access to advanced production capabilities.

Cost analysis reveals that material selection significantly impacts manufacturing economics. Traditional metal-based EMI shielding materials like copper and silver offer excellent performance but at premium prices, especially when considering the high-purity requirements for electronics applications. Emerging alternatives such as carbon-based materials (graphene, carbon nanotubes) and conductive polymers present potentially lower material costs but often require more complex processing steps that may offset initial savings. A comprehensive cost model must account for raw materials (30-40% of total cost), processing (25-35%), quality control (10-15%), and overhead expenses (15-20%).

Production yield rates present another crucial economic consideration, with current industry standards for flexible EMI films ranging from 85-95% depending on the manufacturing technique employed. Higher-precision methods typically deliver better quality but at reduced yields during early implementation phases. The learning curve effect is particularly evident in newer technologies, where production costs typically decrease by 15-20% with each doubling of cumulative production volume as processes are optimized and refined.

Energy consumption metrics vary substantially across manufacturing approaches, with vacuum-based methods requiring 3-5 times more energy input than solution-based alternatives. This energy differential translates directly to operational costs and environmental impact considerations, becoming increasingly important as sustainability metrics factor into production decisions. Manufacturers must balance these energy considerations against performance requirements and production volumes.

Equipment investment represents a significant barrier to entry, with specialized coating and metallization systems requiring capital expenditures of $2-10 million depending on production capacity and precision requirements. This substantial upfront investment necessitates careful market analysis to ensure sufficient demand exists to justify the manufacturing scale. Smaller manufacturers increasingly explore contract manufacturing arrangements or strategic partnerships to mitigate these capital requirements while maintaining access to advanced production capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!