EMI Shielding Material Optimization for Aerospace and Defense Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Evolution and Objectives

Electromagnetic Interference (EMI) shielding has evolved significantly since its inception in the early 20th century. Initially, EMI shielding relied primarily on metallic enclosures and simple conductive materials to protect sensitive electronics from external electromagnetic radiation. The aerospace and defense sectors have been at the forefront of EMI shielding technology development due to the critical nature of their electronic systems and the harsh electromagnetic environments in which they operate.

The evolution of EMI shielding materials has been driven by several key factors, including the miniaturization of electronic components, increasing operating frequencies, and the need for multifunctional materials that provide not only EMI shielding but also structural integrity, thermal management, and weight reduction. Traditional metallic shields have gradually given way to advanced composite materials, conductive polymers, and nanomaterial-based solutions that offer superior performance while meeting the stringent requirements of aerospace and defense applications.

In recent years, the development of EMI shielding materials has accelerated with the advent of nanotechnology, enabling the creation of materials with unprecedented combinations of electrical conductivity, mechanical strength, and lightweight properties. Carbon-based nanomaterials such as graphene, carbon nanotubes, and carbon nanofibers have emerged as promising candidates for next-generation EMI shielding solutions due to their exceptional electrical conductivity and mechanical properties.

The primary objectives of EMI shielding material optimization for aerospace and defense applications are multifaceted. First, to develop materials that provide effective shielding across a broad frequency spectrum, particularly in the high-frequency ranges used in modern communication and radar systems. Second, to minimize the weight penalty associated with EMI shielding, which is crucial for aerospace applications where every gram matters. Third, to ensure durability and reliability under extreme environmental conditions, including temperature fluctuations, radiation exposure, and mechanical stress.

Additionally, there is a growing emphasis on developing environmentally sustainable EMI shielding solutions that reduce reliance on rare earth elements and toxic materials. This objective aligns with broader industry trends toward green manufacturing and sustainable material development. The integration of EMI shielding functionality with other material properties, such as thermal management, structural reinforcement, and radiation protection, represents another key goal in the ongoing evolution of these technologies.

Looking forward, the trajectory of EMI shielding technology is moving toward smart, adaptive materials that can dynamically respond to changing electromagnetic environments, providing optimal protection while minimizing energy consumption and system complexity. This evolution represents a paradigm shift from passive to active shielding strategies, opening new frontiers in electromagnetic compatibility engineering for next-generation aerospace and defense systems.

The evolution of EMI shielding materials has been driven by several key factors, including the miniaturization of electronic components, increasing operating frequencies, and the need for multifunctional materials that provide not only EMI shielding but also structural integrity, thermal management, and weight reduction. Traditional metallic shields have gradually given way to advanced composite materials, conductive polymers, and nanomaterial-based solutions that offer superior performance while meeting the stringent requirements of aerospace and defense applications.

In recent years, the development of EMI shielding materials has accelerated with the advent of nanotechnology, enabling the creation of materials with unprecedented combinations of electrical conductivity, mechanical strength, and lightweight properties. Carbon-based nanomaterials such as graphene, carbon nanotubes, and carbon nanofibers have emerged as promising candidates for next-generation EMI shielding solutions due to their exceptional electrical conductivity and mechanical properties.

The primary objectives of EMI shielding material optimization for aerospace and defense applications are multifaceted. First, to develop materials that provide effective shielding across a broad frequency spectrum, particularly in the high-frequency ranges used in modern communication and radar systems. Second, to minimize the weight penalty associated with EMI shielding, which is crucial for aerospace applications where every gram matters. Third, to ensure durability and reliability under extreme environmental conditions, including temperature fluctuations, radiation exposure, and mechanical stress.

Additionally, there is a growing emphasis on developing environmentally sustainable EMI shielding solutions that reduce reliance on rare earth elements and toxic materials. This objective aligns with broader industry trends toward green manufacturing and sustainable material development. The integration of EMI shielding functionality with other material properties, such as thermal management, structural reinforcement, and radiation protection, represents another key goal in the ongoing evolution of these technologies.

Looking forward, the trajectory of EMI shielding technology is moving toward smart, adaptive materials that can dynamically respond to changing electromagnetic environments, providing optimal protection while minimizing energy consumption and system complexity. This evolution represents a paradigm shift from passive to active shielding strategies, opening new frontiers in electromagnetic compatibility engineering for next-generation aerospace and defense systems.

Aerospace Defense Market Requirements Analysis

The aerospace and defense sectors present unique and stringent requirements for EMI shielding materials, driven by the extreme operational environments and mission-critical nature of their applications. Market analysis reveals a growing demand for advanced EMI shielding solutions, with the global aerospace and defense EMI shielding market projected to reach $1.2 billion by 2026, growing at a CAGR of 5.7% from 2021.

Primary market drivers include the increasing electronic content in modern aircraft and defense systems, rising electromagnetic pollution, and stricter electromagnetic compatibility (EMC) regulations. The proliferation of wireless communication systems, radar technologies, and electronic warfare capabilities has created complex electromagnetic environments that demand superior shielding performance.

Weight reduction remains a paramount requirement in aerospace applications, where every gram impacts fuel efficiency and operational range. The industry seeks EMI shielding materials that offer high shielding effectiveness while maintaining minimal weight penalties, typically targeting weight reductions of 15-30% compared to traditional metallic shields without compromising performance.

Thermal management presents another critical challenge, as aerospace and defense electronics often operate in extreme temperature environments ranging from -65°C to +150°C. Shielding materials must maintain their electrical and mechanical properties across this temperature range while potentially contributing to overall thermal management solutions.

Durability requirements are exceptionally demanding, with materials needing to withstand vibration, shock (up to 20G in some military applications), humidity, salt spray, and exposure to various fluids including fuels and hydraulic fluids. Service lifespans typically exceed 20 years, necessitating exceptional long-term stability and minimal performance degradation.

Multi-functionality has emerged as a key market requirement, with customers seeking materials that provide not only EMI shielding but also structural support, thermal management, and potentially stealth characteristics. This trend toward integrated solutions is reshaping material development priorities.

Regional analysis indicates that North America dominates the aerospace and defense EMI shielding market, accounting for approximately 40% of global demand, followed by Europe and Asia-Pacific. Defense modernization programs in emerging economies are creating new market opportunities, particularly for cost-effective solutions that meet international standards.

Regulatory compliance represents a significant market factor, with materials needing to meet standards including MIL-STD-461, RTCA DO-160, and various environmental regulations limiting the use of hazardous substances. The trend toward "green" shielding solutions free from hexavalent chromium, cadmium, and other restricted substances is accelerating, creating demand for environmentally sustainable alternatives.

Primary market drivers include the increasing electronic content in modern aircraft and defense systems, rising electromagnetic pollution, and stricter electromagnetic compatibility (EMC) regulations. The proliferation of wireless communication systems, radar technologies, and electronic warfare capabilities has created complex electromagnetic environments that demand superior shielding performance.

Weight reduction remains a paramount requirement in aerospace applications, where every gram impacts fuel efficiency and operational range. The industry seeks EMI shielding materials that offer high shielding effectiveness while maintaining minimal weight penalties, typically targeting weight reductions of 15-30% compared to traditional metallic shields without compromising performance.

Thermal management presents another critical challenge, as aerospace and defense electronics often operate in extreme temperature environments ranging from -65°C to +150°C. Shielding materials must maintain their electrical and mechanical properties across this temperature range while potentially contributing to overall thermal management solutions.

Durability requirements are exceptionally demanding, with materials needing to withstand vibration, shock (up to 20G in some military applications), humidity, salt spray, and exposure to various fluids including fuels and hydraulic fluids. Service lifespans typically exceed 20 years, necessitating exceptional long-term stability and minimal performance degradation.

Multi-functionality has emerged as a key market requirement, with customers seeking materials that provide not only EMI shielding but also structural support, thermal management, and potentially stealth characteristics. This trend toward integrated solutions is reshaping material development priorities.

Regional analysis indicates that North America dominates the aerospace and defense EMI shielding market, accounting for approximately 40% of global demand, followed by Europe and Asia-Pacific. Defense modernization programs in emerging economies are creating new market opportunities, particularly for cost-effective solutions that meet international standards.

Regulatory compliance represents a significant market factor, with materials needing to meet standards including MIL-STD-461, RTCA DO-160, and various environmental regulations limiting the use of hazardous substances. The trend toward "green" shielding solutions free from hexavalent chromium, cadmium, and other restricted substances is accelerating, creating demand for environmentally sustainable alternatives.

Current EMI Shielding Technologies and Barriers

The electromagnetic interference (EMI) shielding landscape for aerospace and defense applications currently employs several established technologies, each with specific advantages and limitations. Metal-based shields, particularly those utilizing aluminum, copper, and nickel alloys, remain the industry standard due to their excellent conductivity and relatively low cost. These materials typically achieve shielding effectiveness of 60-120 dB across a wide frequency range, making them suitable for many critical applications.

Conductive polymer composites represent a growing segment, offering reduced weight compared to traditional metal shields. These materials incorporate conductive fillers such as carbon nanotubes, graphene, or metallic particles within polymer matrices. While they provide weight savings of 30-50% compared to metal shields, they generally deliver lower shielding effectiveness (40-80 dB) and face challenges in maintaining consistent electrical properties across production batches.

Metamaterial-based shields have emerged as a promising technology, engineered with precise micro or nanostructures to manipulate electromagnetic waves. These advanced materials can achieve targeted frequency responses and potentially reduce thickness by 40-60% compared to conventional shields, though they currently face significant manufacturing complexity and high production costs.

Despite these technological options, several barriers impede optimal EMI shielding in aerospace and defense applications. Weight constraints represent a primary challenge, as every additional gram impacts fuel efficiency and payload capacity. Current metal-based solutions add considerable weight to aircraft and satellite systems, creating an ongoing trade-off between protection and performance.

Multifunctional requirements present another significant hurdle. Modern aerospace systems demand materials that simultaneously provide EMI shielding, thermal management, structural support, and resistance to harsh environmental conditions. Few existing materials effectively address all these requirements without compromise.

Manufacturing complexity and scalability issues affect advanced solutions like metamaterials and specialized composites. The precision required for these materials often involves sophisticated production techniques that are difficult to scale for large aerospace components while maintaining consistent properties and reasonable costs.

Harsh operating environments in aerospace and defense applications further complicate shielding solutions. Materials must withstand extreme temperature fluctuations (-65°C to +150°C), vacuum conditions, radiation exposure, and mechanical stress while maintaining shielding performance throughout the system's operational lifetime, which may extend to decades for certain defense platforms.

Conductive polymer composites represent a growing segment, offering reduced weight compared to traditional metal shields. These materials incorporate conductive fillers such as carbon nanotubes, graphene, or metallic particles within polymer matrices. While they provide weight savings of 30-50% compared to metal shields, they generally deliver lower shielding effectiveness (40-80 dB) and face challenges in maintaining consistent electrical properties across production batches.

Metamaterial-based shields have emerged as a promising technology, engineered with precise micro or nanostructures to manipulate electromagnetic waves. These advanced materials can achieve targeted frequency responses and potentially reduce thickness by 40-60% compared to conventional shields, though they currently face significant manufacturing complexity and high production costs.

Despite these technological options, several barriers impede optimal EMI shielding in aerospace and defense applications. Weight constraints represent a primary challenge, as every additional gram impacts fuel efficiency and payload capacity. Current metal-based solutions add considerable weight to aircraft and satellite systems, creating an ongoing trade-off between protection and performance.

Multifunctional requirements present another significant hurdle. Modern aerospace systems demand materials that simultaneously provide EMI shielding, thermal management, structural support, and resistance to harsh environmental conditions. Few existing materials effectively address all these requirements without compromise.

Manufacturing complexity and scalability issues affect advanced solutions like metamaterials and specialized composites. The precision required for these materials often involves sophisticated production techniques that are difficult to scale for large aerospace components while maintaining consistent properties and reasonable costs.

Harsh operating environments in aerospace and defense applications further complicate shielding solutions. Materials must withstand extreme temperature fluctuations (-65°C to +150°C), vacuum conditions, radiation exposure, and mechanical stress while maintaining shielding performance throughout the system's operational lifetime, which may extend to decades for certain defense platforms.

State-of-the-Art EMI Shielding Solutions

01 Conductive composite materials for EMI shielding

Composite materials incorporating conductive fillers such as carbon nanotubes, graphene, or metal particles can be optimized for EMI shielding applications. These materials combine the mechanical properties of polymers with the electrical conductivity of metals or carbon-based materials, creating effective shields against electromagnetic interference. The composition, concentration, and distribution of conductive fillers within the matrix material significantly impact the shielding effectiveness while maintaining other desirable properties like weight reduction and corrosion resistance.- Conductive composite materials for EMI shielding: Composite materials incorporating conductive elements such as carbon nanotubes, graphene, or metal particles can be optimized for EMI shielding applications. These materials combine the lightweight properties of polymers with the electrical conductivity of metals or carbon-based materials, creating effective shields against electromagnetic interference. The composition, concentration, and dispersion of conductive fillers within the polymer matrix can be adjusted to achieve desired shielding effectiveness while maintaining mechanical properties.

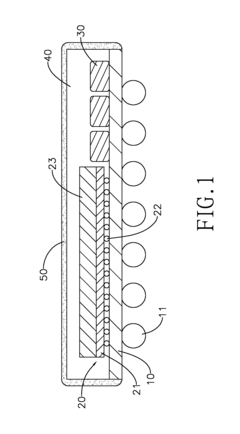

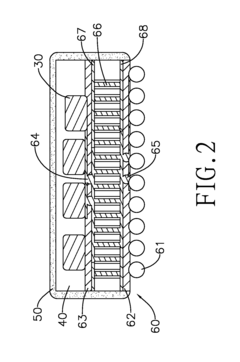

- Multilayer shielding structures: Multilayer structures consisting of different materials with complementary properties can provide enhanced EMI shielding performance. These structures typically combine layers with varying electrical conductivity, magnetic permeability, and dielectric properties to address different frequency ranges and types of electromagnetic radiation. By optimizing the thickness, sequence, and composition of each layer, these structures can achieve superior shielding effectiveness compared to single-material solutions while potentially reducing overall weight and thickness.

- Metal-based EMI shielding solutions: Metal-based solutions remain fundamental in EMI shielding applications due to their high electrical conductivity. These include metal foils, meshes, coatings, and enclosures made from materials such as aluminum, copper, nickel, or various alloys. The optimization of these solutions involves considerations of material thickness, surface treatment, contact resistance, and manufacturing techniques to balance shielding effectiveness with weight, cost, and corrosion resistance requirements.

- Flexible and conformal EMI shielding materials: Flexible and conformal shielding materials address the challenges of protecting complex geometries and components that require movement or flexibility. These materials include conductive elastomers, fabrics, coatings, and adhesives that can conform to irregular surfaces while maintaining electrical continuity. The optimization of these materials focuses on maintaining shielding effectiveness during bending, stretching, or compression, as well as ensuring durability over repeated mechanical stress cycles.

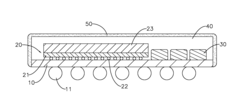

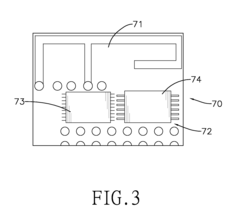

- Integration of EMI shielding in electronic packaging: The integration of EMI shielding directly into electronic packaging represents an advanced approach to electromagnetic compatibility. This includes techniques such as conformal shielding, compartmentalization, embedded ground planes, and on-chip shielding structures. Optimization in this area focuses on miniaturization, thermal management compatibility, and manufacturing processes that allow for cost-effective mass production while maintaining reliable electrical connections and sufficient shielding effectiveness.

02 Multilayer shielding structures

Multilayer structures consisting of different materials with complementary properties can enhance EMI shielding effectiveness. These structures typically combine layers with varying conductivity, permeability, and absorption characteristics to provide comprehensive protection against a wide frequency range of electromagnetic radiation. By optimizing the thickness, sequence, and composition of each layer, these structures can achieve superior shielding performance while addressing other requirements such as heat dissipation, mechanical strength, and environmental resistance.Expand Specific Solutions03 Nanomaterial-enhanced EMI shielding solutions

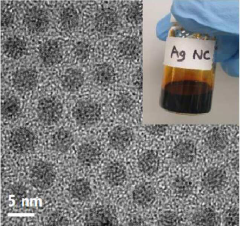

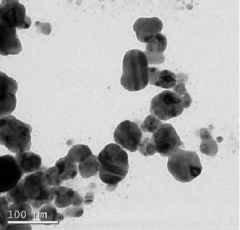

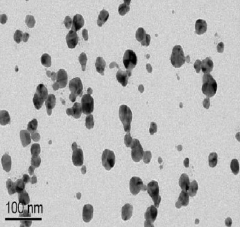

Nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles offer exceptional EMI shielding properties due to their unique electrical, thermal, and mechanical characteristics. When incorporated into polymers or other matrices, these nanomaterials create lightweight yet highly effective shielding materials. The optimization of nanomaterial dispersion, orientation, and interfacial bonding with the host matrix is crucial for maximizing shielding effectiveness while minimizing material usage and maintaining processability.Expand Specific Solutions04 Flexible and conformal EMI shielding materials

Flexible and conformal EMI shielding materials are designed to provide effective electromagnetic interference protection for complex geometries and dynamic applications. These materials typically utilize conductive elastomers, fabrics, or thin films that can conform to irregular surfaces while maintaining their shielding properties. The optimization focuses on achieving a balance between flexibility, durability, and shielding effectiveness through material selection, manufacturing processes, and structural design considerations.Expand Specific Solutions05 EMI shielding gaskets and interface materials

Specialized gaskets and interface materials are critical components in EMI shielding systems, ensuring continuous electrical contact between shielding enclosures and preventing electromagnetic leakage at seams and joints. These materials are typically designed with conductive elastomers, metal-filled silicones, or mesh structures that provide both environmental sealing and electrical conductivity. Optimization involves balancing compression characteristics, conductivity, corrosion resistance, and long-term performance under various environmental conditions.Expand Specific Solutions

Leading EMI Shielding Material Manufacturers

The EMI shielding materials market for aerospace and defense applications is in a growth phase, driven by increasing electronic integration in modern aircraft and defense systems. The market is expanding at a CAGR of approximately 5-7%, with global value estimated at $1.2-1.5 billion. Technologically, the field is moderately mature but evolving rapidly with innovations in lightweight composite materials. Leading players include established industrial giants like Henkel AG, Parker-Hannifin, 3M Innovative Properties, and Honeywell International Technologies, who leverage extensive R&D capabilities. Emerging competitors like Nanotech Energy are advancing graphene-based solutions, while research institutions such as Sichuan University and CSIR are developing next-generation materials with enhanced performance characteristics. The competitive landscape is characterized by increasing focus on lightweight, multi-functional shielding materials that meet stringent aerospace requirements.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive suite of EMI shielding materials optimized for aerospace and defense applications. Their technology platform centers on advanced composite materials that combine multiple functional layers to achieve superior electromagnetic protection while addressing the unique challenges of aerospace environments. 3M's Electrically Conductive Adhesive Transfer Tapes (ECATTs) provide both bonding and EMI shielding in a single application, featuring proprietary conductive particle technology that maintains electrical conductivity even under mechanical stress and vibration. For critical defense electronics, 3M has engineered specialized EMI absorbers with tailored frequency responses that can attenuate signals from 1-40 GHz with up to 25 dB absorption at targeted frequencies[3]. Their lightweight metal-coated fabrics provide 60-80 dB shielding while adding minimal weight to aircraft components. 3M's advanced manufacturing capabilities allow for precision die-cutting and custom formulations to meet specific military specifications. Their materials undergo rigorous testing for environmental factors including altitude, humidity cycling, salt fog exposure, and fluid resistance to ensure performance reliability in extreme conditions encountered in aerospace and defense applications.

Strengths: Extensive material science expertise allowing customization for specific frequency ranges and environmental conditions; solutions that integrate multiple functions (bonding, sealing, shielding) to reduce assembly steps; global manufacturing capabilities ensuring supply chain security for defense applications. Weaknesses: Some specialized solutions require specific application techniques; certain high-performance materials have higher cost compared to standard commercial options; some formulations have limited shelf life in extreme storage conditions.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered advanced EMI shielding materials specifically engineered for aerospace and defense applications through their Specialty Materials division. Their flagship technology incorporates nano-scale metal particles dispersed within high-performance polymers to create lightweight, flexible shields with exceptional durability. Honeywell's proprietary MetShield™ technology utilizes precisely controlled metal deposition processes to create ultra-thin conductive layers (typically 2-5 microns) on composite substrates, reducing weight by up to 40% compared to traditional metal foils while maintaining 60-80 dB shielding effectiveness across 1-18 GHz frequency ranges[2]. For avionics applications, they've developed specialized coatings that combine EMI shielding with infrared reflectivity and anti-static properties. Their advanced manufacturing processes allow for complex geometries and conformal application to aircraft components. Honeywell's materials are specifically formulated to withstand extreme aerospace environments, including resistance to hydraulic fluids, de-icing chemicals, and UV radiation, with operational temperature ranges from -65°C to +260°C.

Strengths: Exceptional weight-to-performance ratio critical for aerospace applications; multi-functional materials that address multiple protection requirements simultaneously; proven long-term durability in extreme aerospace environments. Weaknesses: Higher initial cost compared to conventional shielding solutions; some specialized formulations require specific application equipment; certain high-performance variants have limited shelf life before application.

Critical Patents in Aerospace EMI Protection

Electromagnetic interference shielding material, electromagnetic interference shielding device, method for making the electromagnetic interference shielding device, electromagnetic interference shielding package module and appliance

PatentInactiveUS20150085462A1

Innovation

- A mixture comprising 70 wt % to 98 wt % of dendritic copper filler, flaky copper filler, resin binder, and diluent is used to create an adjustable EMI shielding material that can be applied via screen printing or spraying, hardened at 120-160°C, providing effective shielding with adjustable thickness and low cost.

Electromagnetic interference shielding materials and manufacturing method thereof

PatentActiveKR1020230091224A

Innovation

- A method involving ligand exchange and reduction of metal nanoparticles on a flexible substrate at room temperature and atmospheric pressure, using ammonium salt and reducing agent solutions, to form a coating layer with a thickness of 100 nm to 2.0 μm, enabling efficient charge transport and mechanical stability.

Military Standards and Compliance Requirements

Compliance with military standards is paramount for EMI shielding materials in aerospace and defense applications. The primary regulatory framework includes MIL-STD-461, which establishes electromagnetic interference requirements for equipment and subsystems. This standard has evolved through multiple revisions, with the current MIL-STD-461G version implementing more stringent requirements for modern electronic warfare environments. The standard defines specific test methods and limits for conducted and radiated emissions, as well as susceptibility to various electromagnetic phenomena.

MIL-STD-464 complements these requirements by addressing electromagnetic environmental effects at the system level, ensuring that platforms can operate effectively in complex electromagnetic environments without degradation. For aerospace applications specifically, RTCA DO-160 provides environmental conditions and test procedures for airborne equipment, with sections dedicated to EMI/EMC requirements that must be satisfied for civil and military aircraft certification.

Defense contractors must also adhere to MIL-DTL-83528, which specifies detailed requirements for electrically conductive elastomeric shielding gaskets, a critical component in many EMI shielding solutions. This specification includes parameters for shielding effectiveness across various frequency ranges, compression-deflection characteristics, and environmental durability.

International standards such as NATO AECTP-500 establish additional requirements for NATO member countries, ensuring interoperability of defense systems across allied forces. These standards often incorporate more severe testing conditions to account for battlefield electromagnetic environments, including high-power microwave threats and electromagnetic pulse (EMP) scenarios.

Compliance verification requires rigorous testing in specialized facilities, including anechoic chambers and reverberation chambers that can simulate various electromagnetic environments. Testing protocols must follow MIL-STD-462 methodologies, with documentation requirements specified in MIL-HDBK-237.

Recent regulatory trends show increasing emphasis on cybersecurity aspects of EMI shielding, as sophisticated adversaries may exploit electromagnetic vulnerabilities for intelligence gathering or system disruption. This has led to the development of new test protocols under the Cybersecurity Maturity Model Certification (CMMC) framework that incorporate EMI security considerations.

Material manufacturers must maintain comprehensive documentation of compliance testing, material composition, and manufacturing processes to satisfy defense acquisition requirements. This documentation becomes part of the Technical Data Package (TDP) required for defense procurement and must be maintained throughout the product lifecycle to support configuration management and obsolescence management programs.

MIL-STD-464 complements these requirements by addressing electromagnetic environmental effects at the system level, ensuring that platforms can operate effectively in complex electromagnetic environments without degradation. For aerospace applications specifically, RTCA DO-160 provides environmental conditions and test procedures for airborne equipment, with sections dedicated to EMI/EMC requirements that must be satisfied for civil and military aircraft certification.

Defense contractors must also adhere to MIL-DTL-83528, which specifies detailed requirements for electrically conductive elastomeric shielding gaskets, a critical component in many EMI shielding solutions. This specification includes parameters for shielding effectiveness across various frequency ranges, compression-deflection characteristics, and environmental durability.

International standards such as NATO AECTP-500 establish additional requirements for NATO member countries, ensuring interoperability of defense systems across allied forces. These standards often incorporate more severe testing conditions to account for battlefield electromagnetic environments, including high-power microwave threats and electromagnetic pulse (EMP) scenarios.

Compliance verification requires rigorous testing in specialized facilities, including anechoic chambers and reverberation chambers that can simulate various electromagnetic environments. Testing protocols must follow MIL-STD-462 methodologies, with documentation requirements specified in MIL-HDBK-237.

Recent regulatory trends show increasing emphasis on cybersecurity aspects of EMI shielding, as sophisticated adversaries may exploit electromagnetic vulnerabilities for intelligence gathering or system disruption. This has led to the development of new test protocols under the Cybersecurity Maturity Model Certification (CMMC) framework that incorporate EMI security considerations.

Material manufacturers must maintain comprehensive documentation of compliance testing, material composition, and manufacturing processes to satisfy defense acquisition requirements. This documentation becomes part of the Technical Data Package (TDP) required for defense procurement and must be maintained throughout the product lifecycle to support configuration management and obsolescence management programs.

Weight-Performance Optimization Strategies

In aerospace and defense applications, the optimization of EMI shielding materials represents a critical balance between weight reduction and performance enhancement. Traditional shielding solutions often add significant weight to systems, directly impacting fuel efficiency, payload capacity, and operational range of aircraft and defense platforms. The industry has therefore developed several strategic approaches to optimize this weight-performance relationship.

Material composition engineering stands as a primary optimization strategy, with composite materials leading the advancement. Carbon-based composites incorporating graphene, carbon nanotubes (CNTs), and carbon fiber reinforced polymers (CFRPs) offer exceptional EMI shielding effectiveness while maintaining low density profiles. These materials achieve shielding effectiveness of 30-60 dB while reducing weight by up to 40% compared to conventional metal shields.

Multilayer thin-film technologies represent another significant advancement, utilizing alternating layers of conductive and dielectric materials at microscale thicknesses. This approach creates multiple reflection and absorption interfaces that effectively attenuate electromagnetic radiation across broad frequency spectrums while minimizing the overall material mass. Recent developments have achieved comparable shielding performance to traditional solutions with weight reductions of 50-70%.

Geometric optimization techniques leverage advanced computational modeling to design shielding structures with minimal material usage. Techniques such as topology optimization and lattice structures create precisely engineered void patterns that maintain structural integrity and shielding effectiveness while significantly reducing mass. These approaches have demonstrated weight savings of 30-45% in practical applications.

Surface treatment methodologies offer complementary optimization strategies by enhancing the electromagnetic properties of base materials through specialized coatings and treatments. Conductive polymer coatings, metallic nanoparticle sprays, and plasma-deposited thin films can transform lightweight substrates into effective EMI shields without substantial weight penalties.

Integration of multifunctional materials represents perhaps the most promising frontier in weight-performance optimization. These advanced materials simultaneously serve structural, thermal management, and EMI shielding functions, eliminating the need for separate components. Self-healing conductive polymers, metamaterials with engineered electromagnetic properties, and ceramic-polymer hybrids exemplify this approach, offering weight reductions of up to 60% compared to traditional multi-component solutions.

The implementation of these optimization strategies requires sophisticated testing protocols to validate real-world performance across operational conditions, including temperature extremes, vibration, and radiation exposure typical in aerospace and defense environments.

Material composition engineering stands as a primary optimization strategy, with composite materials leading the advancement. Carbon-based composites incorporating graphene, carbon nanotubes (CNTs), and carbon fiber reinforced polymers (CFRPs) offer exceptional EMI shielding effectiveness while maintaining low density profiles. These materials achieve shielding effectiveness of 30-60 dB while reducing weight by up to 40% compared to conventional metal shields.

Multilayer thin-film technologies represent another significant advancement, utilizing alternating layers of conductive and dielectric materials at microscale thicknesses. This approach creates multiple reflection and absorption interfaces that effectively attenuate electromagnetic radiation across broad frequency spectrums while minimizing the overall material mass. Recent developments have achieved comparable shielding performance to traditional solutions with weight reductions of 50-70%.

Geometric optimization techniques leverage advanced computational modeling to design shielding structures with minimal material usage. Techniques such as topology optimization and lattice structures create precisely engineered void patterns that maintain structural integrity and shielding effectiveness while significantly reducing mass. These approaches have demonstrated weight savings of 30-45% in practical applications.

Surface treatment methodologies offer complementary optimization strategies by enhancing the electromagnetic properties of base materials through specialized coatings and treatments. Conductive polymer coatings, metallic nanoparticle sprays, and plasma-deposited thin films can transform lightweight substrates into effective EMI shields without substantial weight penalties.

Integration of multifunctional materials represents perhaps the most promising frontier in weight-performance optimization. These advanced materials simultaneously serve structural, thermal management, and EMI shielding functions, eliminating the need for separate components. Self-healing conductive polymers, metamaterials with engineered electromagnetic properties, and ceramic-polymer hybrids exemplify this approach, offering weight reductions of up to 60% compared to traditional multi-component solutions.

The implementation of these optimization strategies requires sophisticated testing protocols to validate real-world performance across operational conditions, including temperature extremes, vibration, and radiation exposure typical in aerospace and defense environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!