EMI Shielding Materials for High-Frequency Electronic Devices

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Background and Objectives

Electromagnetic Interference (EMI) has emerged as a critical concern in the rapidly evolving landscape of electronic devices, particularly as operating frequencies continue to increase. The history of EMI shielding can be traced back to the mid-20th century when electronic devices began to proliferate. Initially, simple metal enclosures were sufficient for most applications, but as device complexity increased, more sophisticated solutions became necessary.

The evolution of EMI shielding technology has been closely tied to advancements in electronic miniaturization and increased operating frequencies. From the 1980s to early 2000s, shielding solutions primarily focused on conductive coatings and metal-based composites. The past decade has witnessed a significant shift toward nanomaterial-based solutions and multi-functional shields that address thermal management alongside EMI protection.

Current trends in EMI shielding technology are moving toward lightweight, thin, and flexible materials that can be integrated into increasingly compact electronic devices. The integration of 5G technology, IoT devices, and high-frequency computing systems has accelerated the need for advanced shielding solutions that can effectively operate across broader frequency spectrums, particularly in the gigahertz range.

The primary objective of this research is to evaluate and develop next-generation EMI shielding materials specifically designed for high-frequency electronic devices operating above 5 GHz. These materials must demonstrate superior shielding effectiveness while maintaining minimal thickness and weight to accommodate modern device design constraints.

Secondary objectives include identifying sustainable and cost-effective materials that can replace traditional metal-based shields, exploring multi-functional materials that provide both EMI shielding and thermal management capabilities, and developing manufacturing processes that enable mass production of these advanced materials.

The research aims to address several key technical challenges, including the development of materials with consistent shielding effectiveness across broad frequency ranges, minimizing signal loss in high-speed data transmission, and ensuring compatibility with automated assembly processes. Additionally, the research will explore the potential of emerging materials such as MXenes, graphene-based composites, and metamaterials for next-generation shielding applications.

By establishing a comprehensive understanding of EMI shielding technology evolution and clearly defining research objectives, this investigation seeks to contribute meaningful advancements to the field of electromagnetic compatibility in high-frequency electronic devices, ultimately supporting the continued miniaturization and performance improvement of modern electronics.

The evolution of EMI shielding technology has been closely tied to advancements in electronic miniaturization and increased operating frequencies. From the 1980s to early 2000s, shielding solutions primarily focused on conductive coatings and metal-based composites. The past decade has witnessed a significant shift toward nanomaterial-based solutions and multi-functional shields that address thermal management alongside EMI protection.

Current trends in EMI shielding technology are moving toward lightweight, thin, and flexible materials that can be integrated into increasingly compact electronic devices. The integration of 5G technology, IoT devices, and high-frequency computing systems has accelerated the need for advanced shielding solutions that can effectively operate across broader frequency spectrums, particularly in the gigahertz range.

The primary objective of this research is to evaluate and develop next-generation EMI shielding materials specifically designed for high-frequency electronic devices operating above 5 GHz. These materials must demonstrate superior shielding effectiveness while maintaining minimal thickness and weight to accommodate modern device design constraints.

Secondary objectives include identifying sustainable and cost-effective materials that can replace traditional metal-based shields, exploring multi-functional materials that provide both EMI shielding and thermal management capabilities, and developing manufacturing processes that enable mass production of these advanced materials.

The research aims to address several key technical challenges, including the development of materials with consistent shielding effectiveness across broad frequency ranges, minimizing signal loss in high-speed data transmission, and ensuring compatibility with automated assembly processes. Additionally, the research will explore the potential of emerging materials such as MXenes, graphene-based composites, and metamaterials for next-generation shielding applications.

By establishing a comprehensive understanding of EMI shielding technology evolution and clearly defining research objectives, this investigation seeks to contribute meaningful advancements to the field of electromagnetic compatibility in high-frequency electronic devices, ultimately supporting the continued miniaturization and performance improvement of modern electronics.

Market Analysis for High-Frequency Shielding Solutions

The global market for EMI shielding materials in high-frequency electronic devices is experiencing robust growth, driven by the rapid expansion of 5G technology, IoT devices, and advanced electronics across multiple industries. Current market valuations indicate that the high-frequency EMI shielding materials sector reached approximately 6.8 billion USD in 2022, with projections suggesting a compound annual growth rate of 5.7% through 2028.

Consumer electronics remains the dominant application segment, accounting for nearly 40% of the total market share. This is primarily due to the increasing integration of high-frequency components in smartphones, tablets, and wearable devices. The telecommunications sector follows closely, representing about 30% of market demand, largely fueled by the ongoing global 5G infrastructure deployment.

Automotive electronics has emerged as the fastest-growing segment, with demand increasing at nearly 8% annually. This surge is attributed to the rising incorporation of advanced driver assistance systems (ADAS), infotainment systems, and the gradual transition toward electric and autonomous vehicles, all of which require sophisticated EMI shielding solutions.

Regionally, Asia-Pacific dominates the market with approximately 45% share, with China, Japan, South Korea, and Taiwan serving as manufacturing hubs for electronic components and devices. North America and Europe collectively account for about 40% of the market, with particular strength in aerospace, defense, and medical device applications where high-performance shielding is critical.

Customer requirements are increasingly focused on multifunctional shielding materials that offer not only excellent EMI attenuation at frequencies above 6 GHz but also provide thermal management capabilities, lightweight properties, and environmental sustainability. This trend is particularly evident in portable electronics and aerospace applications where weight considerations are paramount.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers prioritize cost-effective solutions, medical and aerospace sectors demonstrate willingness to invest in premium shielding materials that offer superior performance and reliability. The average price point for high-performance shielding materials has decreased by approximately 15% over the past five years due to manufacturing innovations and increased competition.

Supply chain dynamics have shifted notably since 2020, with many manufacturers adopting regionalization strategies to mitigate disruption risks. This has led to the emergence of specialized suppliers focusing on specific industry verticals, offering customized shielding solutions rather than generic products. The market is witnessing increased collaboration between material scientists and device manufacturers to develop application-specific shielding technologies that address the unique challenges of high-frequency operations.

Consumer electronics remains the dominant application segment, accounting for nearly 40% of the total market share. This is primarily due to the increasing integration of high-frequency components in smartphones, tablets, and wearable devices. The telecommunications sector follows closely, representing about 30% of market demand, largely fueled by the ongoing global 5G infrastructure deployment.

Automotive electronics has emerged as the fastest-growing segment, with demand increasing at nearly 8% annually. This surge is attributed to the rising incorporation of advanced driver assistance systems (ADAS), infotainment systems, and the gradual transition toward electric and autonomous vehicles, all of which require sophisticated EMI shielding solutions.

Regionally, Asia-Pacific dominates the market with approximately 45% share, with China, Japan, South Korea, and Taiwan serving as manufacturing hubs for electronic components and devices. North America and Europe collectively account for about 40% of the market, with particular strength in aerospace, defense, and medical device applications where high-performance shielding is critical.

Customer requirements are increasingly focused on multifunctional shielding materials that offer not only excellent EMI attenuation at frequencies above 6 GHz but also provide thermal management capabilities, lightweight properties, and environmental sustainability. This trend is particularly evident in portable electronics and aerospace applications where weight considerations are paramount.

Price sensitivity varies significantly across application segments. While consumer electronics manufacturers prioritize cost-effective solutions, medical and aerospace sectors demonstrate willingness to invest in premium shielding materials that offer superior performance and reliability. The average price point for high-performance shielding materials has decreased by approximately 15% over the past five years due to manufacturing innovations and increased competition.

Supply chain dynamics have shifted notably since 2020, with many manufacturers adopting regionalization strategies to mitigate disruption risks. This has led to the emergence of specialized suppliers focusing on specific industry verticals, offering customized shielding solutions rather than generic products. The market is witnessing increased collaboration between material scientists and device manufacturers to develop application-specific shielding technologies that address the unique challenges of high-frequency operations.

Current EMI Shielding Technologies and Challenges

The electromagnetic interference (EMI) shielding landscape has evolved significantly over the past decade, with current technologies broadly categorized into metallic, conductive polymer composites, and carbon-based solutions. Traditional metallic shields, including aluminum, copper, and steel alloys, remain prevalent due to their high conductivity and established manufacturing processes. These materials typically achieve shielding effectiveness of 60-120 dB across a wide frequency range, making them suitable for many applications despite their weight limitations.

Conductive polymer composites represent a growing segment, combining the processability of polymers with the conductivity of metal fillers or inherently conductive polymers. Notable examples include polypyrrole, polyaniline, and PEDOT:PSS incorporated into thermoplastic matrices. These materials offer flexibility and weight reduction compared to metals but generally provide lower shielding effectiveness (40-80 dB) and face challenges in maintaining consistent electrical properties during processing.

Carbon-based shielding materials have gained significant attention, particularly graphene, carbon nanotubes (CNTs), and carbon fiber composites. These materials offer exceptional electrical conductivity combined with lightweight properties. Graphene-based composites have demonstrated shielding effectiveness exceeding 90 dB at high frequencies while maintaining minimal thickness, representing a significant advancement in the field.

Despite these developments, several critical challenges persist in EMI shielding for high-frequency electronic devices. The miniaturization trend in electronics has created a demand for ultra-thin shielding solutions that maintain effectiveness without compromising device dimensions. Current materials struggle to provide adequate shielding at thicknesses below 100 μm, particularly in the expanding 5G frequency bands (24-40 GHz).

Thermal management presents another significant challenge, as many shielding materials with high electrical conductivity also conduct heat, potentially affecting device performance. The industry seeks solutions that can simultaneously provide EMI shielding while offering thermal insulation or controlled heat dissipation properties.

Manufacturing scalability remains problematic, particularly for advanced materials like graphene and CNT composites. Current production methods face limitations in consistency, cost-effectiveness, and integration with existing electronics manufacturing processes. The precise control of nanomaterial dispersion within polymer matrices continues to challenge large-scale implementation.

Environmental concerns have also emerged as a critical factor, with regulations increasingly restricting the use of certain metals and chemicals commonly found in shielding materials. The industry is actively seeking sustainable alternatives that maintain performance while reducing environmental impact throughout the product lifecycle.

Conductive polymer composites represent a growing segment, combining the processability of polymers with the conductivity of metal fillers or inherently conductive polymers. Notable examples include polypyrrole, polyaniline, and PEDOT:PSS incorporated into thermoplastic matrices. These materials offer flexibility and weight reduction compared to metals but generally provide lower shielding effectiveness (40-80 dB) and face challenges in maintaining consistent electrical properties during processing.

Carbon-based shielding materials have gained significant attention, particularly graphene, carbon nanotubes (CNTs), and carbon fiber composites. These materials offer exceptional electrical conductivity combined with lightweight properties. Graphene-based composites have demonstrated shielding effectiveness exceeding 90 dB at high frequencies while maintaining minimal thickness, representing a significant advancement in the field.

Despite these developments, several critical challenges persist in EMI shielding for high-frequency electronic devices. The miniaturization trend in electronics has created a demand for ultra-thin shielding solutions that maintain effectiveness without compromising device dimensions. Current materials struggle to provide adequate shielding at thicknesses below 100 μm, particularly in the expanding 5G frequency bands (24-40 GHz).

Thermal management presents another significant challenge, as many shielding materials with high electrical conductivity also conduct heat, potentially affecting device performance. The industry seeks solutions that can simultaneously provide EMI shielding while offering thermal insulation or controlled heat dissipation properties.

Manufacturing scalability remains problematic, particularly for advanced materials like graphene and CNT composites. Current production methods face limitations in consistency, cost-effectiveness, and integration with existing electronics manufacturing processes. The precise control of nanomaterial dispersion within polymer matrices continues to challenge large-scale implementation.

Environmental concerns have also emerged as a critical factor, with regulations increasingly restricting the use of certain metals and chemicals commonly found in shielding materials. The industry is actively seeking sustainable alternatives that maintain performance while reducing environmental impact throughout the product lifecycle.

State-of-the-Art EMI Shielding Solutions

01 Conductive materials for EMI shielding

Various conductive materials can be incorporated into EMI shielding solutions to improve shielding effectiveness. These materials include metals like copper and aluminum, conductive polymers, and carbon-based materials such as graphene and carbon nanotubes. The conductivity of these materials allows them to reflect and absorb electromagnetic radiation, thereby reducing electromagnetic interference. The selection of appropriate conductive materials is crucial for achieving optimal shielding performance across different frequency ranges.- Conductive materials for EMI shielding: Various conductive materials can be incorporated into EMI shielding solutions to enhance shielding effectiveness. These materials include metals like copper and aluminum, conductive polymers, and carbon-based materials such as graphene and carbon nanotubes. The conductivity of these materials allows them to reflect and absorb electromagnetic waves, thereby reducing electromagnetic interference. The selection of appropriate conductive materials is crucial for achieving optimal shielding effectiveness across different frequency ranges.

- Multilayer shielding structures: Multilayer structures can significantly improve EMI shielding effectiveness by combining different materials with complementary properties. These structures typically consist of alternating layers of conductive and absorptive materials, creating a comprehensive barrier against electromagnetic radiation. The multiple interfaces between layers enhance reflection and absorption of electromagnetic waves at different frequencies. This approach allows for customization of shielding effectiveness across specific frequency ranges while maintaining structural integrity and other required physical properties.

- Testing and measurement of shielding effectiveness: Various methods and equipment are used to measure and evaluate the effectiveness of EMI shielding materials. These include network analyzers, shielded enclosures, and specialized testing chambers that can quantify the attenuation of electromagnetic signals across different frequency ranges. Standardized testing protocols ensure consistent evaluation of shielding performance, allowing for comparison between different materials and designs. Advanced testing techniques can identify weak points in shielding systems and help optimize material composition and structure for specific applications.

- Flexible and conformal shielding solutions: Flexible EMI shielding materials offer advantages for applications requiring conformability to complex geometries or where movement is necessary. These materials include conductive fabrics, elastomers with conductive fillers, and thin metallic foils with adhesive backing. The flexibility allows for better coverage of irregular surfaces and can reduce installation complexity while maintaining effective shielding. These materials are particularly valuable in portable electronics, wearable devices, and applications where weight and space constraints are significant considerations.

- Composite materials with enhanced shielding properties: Composite materials combining polymers with conductive fillers offer tailored EMI shielding solutions with additional beneficial properties. These composites can be engineered to provide specific levels of shielding effectiveness while maintaining desirable mechanical properties such as lightweight, corrosion resistance, and ease of processing. The type, size, orientation, and concentration of conductive fillers within the polymer matrix significantly influence the shielding effectiveness. Advanced manufacturing techniques allow for precise control of these parameters to optimize performance for specific applications.

02 Multilayer shielding structures

Multilayer structures can significantly enhance EMI shielding effectiveness by combining different materials with complementary properties. These structures typically consist of alternating layers of conductive and absorptive materials, which work together to reflect, absorb, and dissipate electromagnetic radiation. The layered approach allows for customization of shielding properties to address specific frequency ranges and provides improved mechanical stability. Additionally, multilayer designs can offer advantages such as reduced weight and thickness compared to single-layer solutions.Expand Specific Solutions03 Testing and measurement of shielding effectiveness

Various methods and equipment are used to measure and evaluate the effectiveness of EMI shielding materials. These include network analyzers, shielded enclosures, and specialized test fixtures that can quantify parameters such as insertion loss, reflection loss, and absorption. Testing procedures often follow standardized protocols to ensure consistent and comparable results across different materials and applications. Accurate measurement of shielding effectiveness is essential for validating material performance and ensuring compliance with electromagnetic compatibility requirements.Expand Specific Solutions04 Flexible and conformal shielding solutions

Flexible EMI shielding materials offer advantages for applications requiring conformability to complex geometries or where movement is expected. These materials include conductive fabrics, elastomers impregnated with conductive particles, and thin metallic foils with adhesive backings. Flexible shields can be applied directly to electronic components or integrated into housings and enclosures. Their ability to maintain shielding effectiveness while accommodating bending, stretching, or compression makes them particularly valuable in portable electronics, wearable devices, and applications with space constraints.Expand Specific Solutions05 Composite materials with enhanced shielding properties

Composite materials combining polymers with conductive fillers offer tailorable EMI shielding effectiveness while maintaining desirable mechanical properties. These composites typically incorporate conductive particles such as metal powders, carbon fibers, or metallic coatings dispersed within a polymer matrix. The concentration and distribution of conductive fillers significantly impact the shielding performance. Advanced composites may also incorporate specialized additives to enhance specific properties such as heat dissipation or corrosion resistance, making them suitable for demanding environments while providing effective electromagnetic interference protection.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The EMI shielding materials market for high-frequency electronic devices is currently in a growth phase, with increasing demand driven by the proliferation of electronic devices and wireless technologies. The global market size is estimated to reach $7-8 billion by 2025, growing at a CAGR of approximately 5.5%. Technologically, the field is moderately mature but continuously evolving, with companies like 3M Innovative Properties, Henkel AG, and Parker-Hannifin leading commercial applications through advanced polymer-based and metal-composite solutions. Research institutions such as UESTC and Xi'an Jiaotong University are advancing fundamental research, while specialized firms like AMOGREENTECH and MTC Micro Tech Components are developing niche applications. The competitive landscape shows a mix of established materials giants and specialized EMI solution providers, with increasing collaboration between industry and academic institutions to address challenges in higher frequency applications.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced EMI shielding materials utilizing their proprietary microreplication technology to create precision-engineered conductive surfaces. Their solution incorporates multi-layered composite structures with conductive particles (typically silver, copper, or nickel) embedded in polymer matrices. These materials achieve shielding effectiveness of 60-80 dB across frequencies from 1-10 GHz[1]. 3M's approach focuses on lightweight, flexible shielding options including specialized tapes, films, and fabrics that can be precisely applied to complex geometries. Their recent innovations include thermally conductive EMI materials that simultaneously manage heat dissipation while providing electromagnetic shielding, addressing two critical challenges in high-frequency device design with a single material solution[3].

Strengths: Exceptional conformability to complex surfaces; dual-functionality materials addressing both thermal and EMI issues; established global manufacturing capabilities ensuring consistent quality. Weaknesses: Higher cost compared to basic shielding solutions; some products require specific application techniques for optimal performance; certain formulations may have limited high-temperature stability.

AMOGREENTECH Co., Ltd.

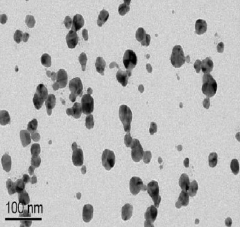

Technical Solution: AMOGREENTECH has pioneered eco-friendly EMI shielding materials specifically designed for high-frequency applications. Their flagship technology utilizes metal-coated carbon fiber composites that achieve shielding effectiveness exceeding 70 dB in the 800 MHz to 18 GHz range[2]. The company's innovative approach involves a proprietary nano-layering process that creates ultra-thin (50-200 μm) shielding materials with minimal impact on device dimensions. Their AMOGREEN series incorporates environmentally sustainable components while maintaining high conductivity through specialized surface treatments. The materials feature self-adhesive properties for easy integration into manufacturing processes and demonstrate exceptional durability with stable performance across -40°C to 150°C operating temperatures[4]. Recent developments include their hybrid organic-inorganic composites that combine the flexibility of polymers with the superior shielding capabilities of precisely distributed metallic nanoparticles.

Strengths: Industry-leading environmental credentials with reduced heavy metal content; exceptional thickness-to-performance ratio; strong adhesion properties eliminating need for additional bonding agents. Weaknesses: Higher initial cost compared to traditional materials; limited availability in certain global regions; requires specialized handling during manufacturing integration.

Key Patents and Technical Innovations

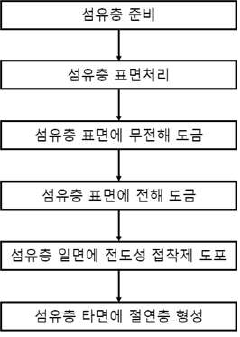

High-frequency EMI shielding material with high flexibility and manufacturing thereof

PatentActiveKR1020220141084A

Innovation

- A high-frequency EMI shielding material is developed by plating a metal on fibers, comprising a conductive adhesive layer, a metal-plated fiber layer, and an insulating layer, with specific porosity and contact ratios to enhance adhesion and conductivity.

Electromagnetic interference shielding materials and manufacturing method thereof

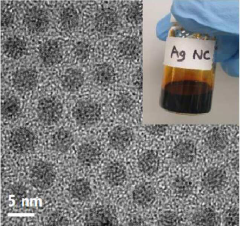

PatentActiveKR1020230091224A

Innovation

- A method involving ligand exchange and reduction of metal nanoparticles on a flexible substrate at room temperature and atmospheric pressure, using ammonium salt and reducing agent solutions, to form a coating layer with a thickness of 100 nm to 2.0 μm, enabling efficient charge transport and mechanical stability.

Environmental Impact and Sustainability

The environmental implications of EMI shielding materials have become increasingly significant as electronic device production continues to escalate globally. Traditional EMI shielding solutions often rely on metals like copper, aluminum, and nickel, which present substantial environmental challenges throughout their lifecycle. The mining and processing of these metals contribute to habitat destruction, water pollution, and significant carbon emissions. Additionally, the manufacturing processes for conventional shielding materials typically involve energy-intensive methods and environmentally harmful chemical treatments.

The disposal phase presents perhaps the most pressing environmental concern. Many electronic devices with metallic EMI shields end up in landfills, where they can leach heavy metals and other toxins into soil and groundwater. The difficulty in separating these materials from electronic waste further complicates recycling efforts, contributing to the growing e-waste crisis that affects ecosystems worldwide.

Recent sustainability initiatives have driven research toward more environmentally friendly EMI shielding alternatives. Biodegradable polymers reinforced with conductive fillers represent a promising direction, offering comparable shielding effectiveness while significantly reducing environmental impact. Carbon-based materials such as graphene and carbon nanotubes present another sustainable pathway, as they can be derived from renewable resources and require less energy-intensive processing than traditional metals.

Life cycle assessment (LCA) studies indicate that newer composite materials can reduce the carbon footprint of EMI shielding by up to 40% compared to conventional metal-based solutions. Furthermore, these materials often enable design innovations that reduce overall material usage while maintaining or improving shielding performance.

Regulatory frameworks are increasingly influencing material selection in this field. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the transition toward more sustainable shielding materials. Similarly, electronic manufacturers pursuing certifications like EPEAT or TCO must demonstrate environmental considerations in their material choices.

Looking forward, circular economy principles are beginning to reshape EMI shielding material development. Research into recyclable and recoverable shielding materials is gaining momentum, with particular focus on designs that facilitate easy separation and recovery at end-of-life. Some innovative approaches include water-soluble temporary EMI shields and modular designs that allow for component-level recycling rather than whole-device disposal.

The disposal phase presents perhaps the most pressing environmental concern. Many electronic devices with metallic EMI shields end up in landfills, where they can leach heavy metals and other toxins into soil and groundwater. The difficulty in separating these materials from electronic waste further complicates recycling efforts, contributing to the growing e-waste crisis that affects ecosystems worldwide.

Recent sustainability initiatives have driven research toward more environmentally friendly EMI shielding alternatives. Biodegradable polymers reinforced with conductive fillers represent a promising direction, offering comparable shielding effectiveness while significantly reducing environmental impact. Carbon-based materials such as graphene and carbon nanotubes present another sustainable pathway, as they can be derived from renewable resources and require less energy-intensive processing than traditional metals.

Life cycle assessment (LCA) studies indicate that newer composite materials can reduce the carbon footprint of EMI shielding by up to 40% compared to conventional metal-based solutions. Furthermore, these materials often enable design innovations that reduce overall material usage while maintaining or improving shielding performance.

Regulatory frameworks are increasingly influencing material selection in this field. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have accelerated the transition toward more sustainable shielding materials. Similarly, electronic manufacturers pursuing certifications like EPEAT or TCO must demonstrate environmental considerations in their material choices.

Looking forward, circular economy principles are beginning to reshape EMI shielding material development. Research into recyclable and recoverable shielding materials is gaining momentum, with particular focus on designs that facilitate easy separation and recovery at end-of-life. Some innovative approaches include water-soluble temporary EMI shields and modular designs that allow for component-level recycling rather than whole-device disposal.

Standards and Compliance Requirements

Compliance with electromagnetic interference (EMI) standards is critical for high-frequency electronic devices to ensure proper functionality, safety, and market access. The International Electrotechnical Commission (IEC) and the International Special Committee on Radio Interference (CISPR) establish the foundational EMI standards globally, with CISPR 22 specifically addressing information technology equipment emissions limits.

In the United States, the Federal Communications Commission (FCC) enforces Part 15 regulations, which mandate strict EMI emission limits for electronic devices. These regulations classify devices into Class A (industrial/commercial) and Class B (residential) categories, with Class B having more stringent requirements due to proximity to sensitive consumer equipment. Similarly, the European Union enforces the Electromagnetic Compatibility (EMC) Directive 2014/30/EU, requiring CE marking for products sold within the EU market.

Military and aerospace applications follow specialized standards such as MIL-STD-461G, which outlines comprehensive EMI testing methodologies and limits for defense systems. These standards are particularly rigorous due to the critical nature of military electronic systems and their operational environments.

Testing methodologies for EMI shielding materials must adhere to ASTM D4935 for planar materials and IEEE-STD-299 for enclosures and larger shielding systems. These standards define precise measurement protocols for shielding effectiveness across various frequency ranges, typically from 30 MHz to 40 GHz for high-frequency applications.

The increasing operational frequencies of modern electronic devices, particularly with the advent of 5G technology (up to 71 GHz), have necessitated updates to existing standards. Regulatory bodies are actively developing new testing protocols for millimeter-wave frequencies, creating challenges for material manufacturers who must demonstrate compliance across expanded frequency ranges.

Material certification requirements vary by industry and application. Medical device shielding materials must comply with IEC 60601-1-2 for electromagnetic compatibility in healthcare environments. Automotive electronics follow standards like CISPR 25 and ISO 11452, addressing both emissions and immunity requirements for vehicle components.

Emerging trends in compliance include the development of harmonized global standards to reduce regulatory fragmentation and the integration of sustainability criteria into EMI shielding material certification. Environmental regulations such as RoHS and REACH increasingly impact material selection, restricting the use of certain heavy metals and chemicals traditionally employed in shielding applications.

Companies developing new EMI shielding materials must implement comprehensive compliance testing early in the development cycle to avoid costly redesigns and market delays. Documentation of shielding performance across all relevant frequency bands has become a standard requirement for material specification sheets in high-frequency applications.

In the United States, the Federal Communications Commission (FCC) enforces Part 15 regulations, which mandate strict EMI emission limits for electronic devices. These regulations classify devices into Class A (industrial/commercial) and Class B (residential) categories, with Class B having more stringent requirements due to proximity to sensitive consumer equipment. Similarly, the European Union enforces the Electromagnetic Compatibility (EMC) Directive 2014/30/EU, requiring CE marking for products sold within the EU market.

Military and aerospace applications follow specialized standards such as MIL-STD-461G, which outlines comprehensive EMI testing methodologies and limits for defense systems. These standards are particularly rigorous due to the critical nature of military electronic systems and their operational environments.

Testing methodologies for EMI shielding materials must adhere to ASTM D4935 for planar materials and IEEE-STD-299 for enclosures and larger shielding systems. These standards define precise measurement protocols for shielding effectiveness across various frequency ranges, typically from 30 MHz to 40 GHz for high-frequency applications.

The increasing operational frequencies of modern electronic devices, particularly with the advent of 5G technology (up to 71 GHz), have necessitated updates to existing standards. Regulatory bodies are actively developing new testing protocols for millimeter-wave frequencies, creating challenges for material manufacturers who must demonstrate compliance across expanded frequency ranges.

Material certification requirements vary by industry and application. Medical device shielding materials must comply with IEC 60601-1-2 for electromagnetic compatibility in healthcare environments. Automotive electronics follow standards like CISPR 25 and ISO 11452, addressing both emissions and immunity requirements for vehicle components.

Emerging trends in compliance include the development of harmonized global standards to reduce regulatory fragmentation and the integration of sustainability criteria into EMI shielding material certification. Environmental regulations such as RoHS and REACH increasingly impact material selection, restricting the use of certain heavy metals and chemicals traditionally employed in shielding applications.

Companies developing new EMI shielding materials must implement comprehensive compliance testing early in the development cycle to avoid costly redesigns and market delays. Documentation of shielding performance across all relevant frequency bands has become a standard requirement for material specification sheets in high-frequency applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!