How Polymer-Based EMI Shielding Composites Enhance Device Safety

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer EMI Shielding Evolution and Objectives

Electromagnetic interference (EMI) shielding has evolved significantly over the past decades, transitioning from traditional metal-based solutions to more versatile polymer-based composites. The journey began in the 1970s with rudimentary conductive polymer blends, primarily developed for anti-static applications rather than comprehensive EMI shielding. By the 1980s, researchers started exploring carbon-filled polymers, marking the first deliberate attempts to create lightweight alternatives to metal shields.

The 1990s witnessed a paradigm shift with the introduction of intrinsically conductive polymers like polyaniline and polypyrrole, which offered conductivity without sacrificing the inherent advantages of polymeric materials. This period established the foundation for modern polymer-based EMI shielding technology, though commercial applications remained limited due to processing challenges and inconsistent performance.

The early 2000s brought revolutionary advancements with the discovery and incorporation of nanomaterials such as carbon nanotubes and graphene into polymer matrices. These nanocomposites demonstrated exceptional EMI shielding effectiveness while maintaining the lightweight and flexible characteristics essential for modern electronic devices. The miniaturization trend in electronics during this period further accelerated research into thin, conformable shielding solutions.

Recent developments have focused on multifunctional polymer composites that simultaneously address EMI shielding, thermal management, and mechanical protection. The integration of hybrid fillers—combining metallic nanoparticles with carbon-based materials—has emerged as a promising approach to achieve synergistic effects and overcome the limitations of single-filler systems.

The primary objective of current polymer-based EMI shielding research is to develop materials that provide superior protection against electromagnetic radiation while meeting the increasingly stringent requirements of modern electronic devices. This includes achieving shielding effectiveness comparable to traditional metal solutions (>60 dB across a wide frequency range) while maintaining the weight advantage of polymers.

Another critical goal is enhancing the sustainability profile of these materials through biodegradable polymers and environmentally friendly fillers, addressing growing concerns about electronic waste. Researchers are also targeting cost-effective manufacturing processes that enable mass production without compromising performance, as current high-performance composites often involve complex fabrication methods.

Looking forward, the field aims to develop "smart" EMI shielding materials with adaptive properties that respond to varying electromagnetic environments, potentially revolutionizing protection strategies for sensitive electronics. The ultimate objective remains creating versatile, high-performance polymer composites that can be tailored to specific applications across industries, from consumer electronics to aerospace and medical devices.

The 1990s witnessed a paradigm shift with the introduction of intrinsically conductive polymers like polyaniline and polypyrrole, which offered conductivity without sacrificing the inherent advantages of polymeric materials. This period established the foundation for modern polymer-based EMI shielding technology, though commercial applications remained limited due to processing challenges and inconsistent performance.

The early 2000s brought revolutionary advancements with the discovery and incorporation of nanomaterials such as carbon nanotubes and graphene into polymer matrices. These nanocomposites demonstrated exceptional EMI shielding effectiveness while maintaining the lightweight and flexible characteristics essential for modern electronic devices. The miniaturization trend in electronics during this period further accelerated research into thin, conformable shielding solutions.

Recent developments have focused on multifunctional polymer composites that simultaneously address EMI shielding, thermal management, and mechanical protection. The integration of hybrid fillers—combining metallic nanoparticles with carbon-based materials—has emerged as a promising approach to achieve synergistic effects and overcome the limitations of single-filler systems.

The primary objective of current polymer-based EMI shielding research is to develop materials that provide superior protection against electromagnetic radiation while meeting the increasingly stringent requirements of modern electronic devices. This includes achieving shielding effectiveness comparable to traditional metal solutions (>60 dB across a wide frequency range) while maintaining the weight advantage of polymers.

Another critical goal is enhancing the sustainability profile of these materials through biodegradable polymers and environmentally friendly fillers, addressing growing concerns about electronic waste. Researchers are also targeting cost-effective manufacturing processes that enable mass production without compromising performance, as current high-performance composites often involve complex fabrication methods.

Looking forward, the field aims to develop "smart" EMI shielding materials with adaptive properties that respond to varying electromagnetic environments, potentially revolutionizing protection strategies for sensitive electronics. The ultimate objective remains creating versatile, high-performance polymer composites that can be tailored to specific applications across industries, from consumer electronics to aerospace and medical devices.

Market Demand Analysis for EMI Protection Solutions

The global market for EMI protection solutions has experienced significant growth in recent years, driven primarily by the proliferation of electronic devices across various sectors. The current market size for EMI shielding materials is estimated to reach $9.2 billion by 2026, with a compound annual growth rate (CAGR) of approximately 5.8% from 2021 to 2026. This growth trajectory reflects the increasing demand for effective electromagnetic interference protection across multiple industries.

Consumer electronics represents the largest market segment for EMI shielding solutions, accounting for nearly 32% of the total market share. The rapid adoption of smartphones, tablets, wearable technology, and other portable devices has created substantial demand for lightweight, effective EMI protection materials. Polymer-based composites are particularly valued in this sector due to their ability to provide adequate shielding while maintaining the sleek, lightweight design consumers expect.

The automotive industry has emerged as the fastest-growing market for EMI shielding, with a projected CAGR of 7.3% through 2026. This surge is directly linked to the increasing integration of electronic systems in vehicles, particularly in electric and autonomous vehicles. As automotive manufacturers continue to incorporate more sophisticated electronic components, the need for reliable EMI protection becomes critical to ensure proper functionality and safety compliance.

Healthcare and medical devices constitute another significant market segment, valued at approximately $1.4 billion in 2021. Medical equipment manufacturers face strict regulatory requirements regarding electromagnetic compatibility, driving demand for high-performance shielding solutions. Polymer-based EMI shields are particularly valuable in medical applications due to their biocompatibility, design flexibility, and non-corrosive properties.

Regional analysis indicates that Asia-Pacific dominates the global EMI shielding market, accounting for approximately 41% of the total market share. This dominance is attributed to the region's robust electronics manufacturing ecosystem, particularly in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow with market shares of 28% and 23% respectively, with growth primarily driven by advancements in telecommunications, defense, and automotive sectors.

Market research indicates a clear shift in customer preferences toward environmentally sustainable EMI shielding solutions. This trend has accelerated the development of polymer-based composites that offer reduced environmental impact compared to traditional metal-based shields. Industry surveys suggest that 67% of electronics manufacturers now consider environmental sustainability as a key factor in their material selection process for EMI protection.

Consumer electronics represents the largest market segment for EMI shielding solutions, accounting for nearly 32% of the total market share. The rapid adoption of smartphones, tablets, wearable technology, and other portable devices has created substantial demand for lightweight, effective EMI protection materials. Polymer-based composites are particularly valued in this sector due to their ability to provide adequate shielding while maintaining the sleek, lightweight design consumers expect.

The automotive industry has emerged as the fastest-growing market for EMI shielding, with a projected CAGR of 7.3% through 2026. This surge is directly linked to the increasing integration of electronic systems in vehicles, particularly in electric and autonomous vehicles. As automotive manufacturers continue to incorporate more sophisticated electronic components, the need for reliable EMI protection becomes critical to ensure proper functionality and safety compliance.

Healthcare and medical devices constitute another significant market segment, valued at approximately $1.4 billion in 2021. Medical equipment manufacturers face strict regulatory requirements regarding electromagnetic compatibility, driving demand for high-performance shielding solutions. Polymer-based EMI shields are particularly valuable in medical applications due to their biocompatibility, design flexibility, and non-corrosive properties.

Regional analysis indicates that Asia-Pacific dominates the global EMI shielding market, accounting for approximately 41% of the total market share. This dominance is attributed to the region's robust electronics manufacturing ecosystem, particularly in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow with market shares of 28% and 23% respectively, with growth primarily driven by advancements in telecommunications, defense, and automotive sectors.

Market research indicates a clear shift in customer preferences toward environmentally sustainable EMI shielding solutions. This trend has accelerated the development of polymer-based composites that offer reduced environmental impact compared to traditional metal-based shields. Industry surveys suggest that 67% of electronics manufacturers now consider environmental sustainability as a key factor in their material selection process for EMI protection.

Current Challenges in Polymer-Based EMI Shielding

Despite significant advancements in polymer-based EMI shielding technology, several critical challenges continue to impede its widespread adoption and optimal performance. The inherent insulating nature of polymers presents a fundamental contradiction to the conductivity requirements of effective EMI shielding. While various conductive fillers can enhance electrical properties, achieving the necessary conductivity levels without compromising the polymer's mechanical integrity remains problematic.

The percolation threshold—the minimum filler concentration required to form conductive networks—represents a significant technical hurdle. Too little conductive filler results in inadequate shielding, while excessive amounts can deteriorate mechanical properties and processability. This delicate balance creates a narrow operational window that complicates manufacturing processes and limits design flexibility.

Dispersion quality of conductive fillers within the polymer matrix continues to challenge researchers and manufacturers alike. Agglomeration of fillers, particularly nanomaterials like carbon nanotubes or graphene, creates inconsistent shielding performance across the material. These non-uniform distributions lead to "hot spots" and "dead zones" in EMI protection, compromising overall device safety.

The multi-frequency shielding capability presents another substantial challenge. Modern electronic devices operate across increasingly broad frequency spectrums, from MHz to GHz ranges. Current polymer composites often exhibit frequency-dependent shielding effectiveness, performing well in certain frequency bands while leaving vulnerabilities in others. This inconsistency becomes particularly problematic in complex electronic environments where multiple signal frequencies coexist.

Durability and environmental stability remain persistent concerns. Polymer-based shields can degrade when exposed to environmental factors such as temperature fluctuations, humidity, UV radiation, and chemical contaminants. This degradation may compromise shielding effectiveness over time, creating potential safety risks in long-term applications.

Manufacturing scalability presents significant obstacles to widespread commercial implementation. Laboratory-scale successes often fail to translate to mass production environments due to processing challenges, quality control issues, and cost considerations. The complex rheological behavior of highly filled polymer systems can cause processing difficulties in conventional manufacturing equipment.

Cost-effectiveness continues to be a major barrier, particularly when compared to traditional metal-based shielding solutions. The incorporation of specialized conductive fillers, especially advanced nanomaterials, significantly increases material costs. Additionally, the processing complexities associated with achieving uniform dispersion and consistent properties further elevate manufacturing expenses.

The percolation threshold—the minimum filler concentration required to form conductive networks—represents a significant technical hurdle. Too little conductive filler results in inadequate shielding, while excessive amounts can deteriorate mechanical properties and processability. This delicate balance creates a narrow operational window that complicates manufacturing processes and limits design flexibility.

Dispersion quality of conductive fillers within the polymer matrix continues to challenge researchers and manufacturers alike. Agglomeration of fillers, particularly nanomaterials like carbon nanotubes or graphene, creates inconsistent shielding performance across the material. These non-uniform distributions lead to "hot spots" and "dead zones" in EMI protection, compromising overall device safety.

The multi-frequency shielding capability presents another substantial challenge. Modern electronic devices operate across increasingly broad frequency spectrums, from MHz to GHz ranges. Current polymer composites often exhibit frequency-dependent shielding effectiveness, performing well in certain frequency bands while leaving vulnerabilities in others. This inconsistency becomes particularly problematic in complex electronic environments where multiple signal frequencies coexist.

Durability and environmental stability remain persistent concerns. Polymer-based shields can degrade when exposed to environmental factors such as temperature fluctuations, humidity, UV radiation, and chemical contaminants. This degradation may compromise shielding effectiveness over time, creating potential safety risks in long-term applications.

Manufacturing scalability presents significant obstacles to widespread commercial implementation. Laboratory-scale successes often fail to translate to mass production environments due to processing challenges, quality control issues, and cost considerations. The complex rheological behavior of highly filled polymer systems can cause processing difficulties in conventional manufacturing equipment.

Cost-effectiveness continues to be a major barrier, particularly when compared to traditional metal-based shielding solutions. The incorporation of specialized conductive fillers, especially advanced nanomaterials, significantly increases material costs. Additionally, the processing complexities associated with achieving uniform dispersion and consistent properties further elevate manufacturing expenses.

Contemporary Polymer Composite Shielding Solutions

01 Conductive polymer composites for EMI shielding

Polymer composites incorporating conductive materials such as carbon nanotubes, graphene, or metal particles can provide effective EMI shielding while maintaining device safety. These composites offer advantages including lightweight construction, flexibility, and corrosion resistance compared to traditional metal shields. The conductive fillers create pathways for electromagnetic waves to be absorbed or reflected, preventing interference with sensitive electronic components while maintaining safety standards.- Conductive polymer composites for EMI shielding: Polymer-based composites incorporating conductive materials such as carbon nanotubes, graphene, or metal particles can effectively shield electromagnetic interference while maintaining safety standards. These composites offer advantages including lightweight construction, flexibility, and corrosion resistance compared to traditional metal shields. The conductive fillers create a network within the polymer matrix that attenuates electromagnetic waves through reflection and absorption mechanisms.

- Heat dissipation and thermal management in EMI shielding: Effective thermal management is crucial for device safety in polymer-based EMI shielding applications. Specialized composites can be formulated to enhance thermal conductivity while maintaining electromagnetic shielding effectiveness. These materials incorporate thermally conductive fillers that help dissipate heat generated by electronic components, preventing overheating and potential safety hazards while simultaneously providing EMI protection.

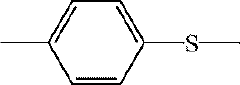

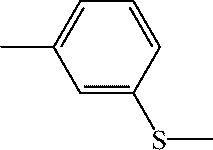

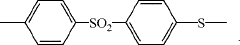

- Flame retardant EMI shielding materials: Safety-enhanced polymer composites for EMI shielding incorporate flame retardant additives to reduce fire hazards in electronic devices. These specialized formulations maintain effective electromagnetic shielding while meeting stringent flammability standards. The flame retardant components can include halogenated compounds, phosphorus-based additives, or mineral fillers that suppress combustion or promote char formation, thereby enhancing device safety without compromising shielding performance.

- Environmentally safe and biocompatible EMI shielding: Environmentally friendly and biocompatible polymer composites address safety concerns related to toxicity and environmental impact. These materials utilize non-toxic fillers and polymer matrices that maintain effective EMI shielding while eliminating hazardous substances like heavy metals or halogenated compounds. Such composites are particularly important for wearable electronics, medical devices, and consumer products where human contact is frequent, ensuring both electromagnetic protection and user safety.

- Structural integrity and mechanical stability for device protection: Polymer-based EMI shielding composites with enhanced mechanical properties provide improved structural integrity and impact resistance, protecting sensitive electronic components from physical damage. These materials combine electromagnetic shielding functionality with mechanical reinforcement through specialized fillers or fiber reinforcements. The resulting composites maintain their shielding effectiveness even under mechanical stress or impact, ensuring continued device protection and operational safety in challenging environments.

02 Heat dissipation and thermal management in EMI shielding

Effective thermal management is crucial for device safety in polymer-based EMI shielding applications. Specialized polymer composites can be formulated to provide both EMI shielding and heat dissipation properties, preventing overheating of electronic components. These materials incorporate thermally conductive fillers that help transfer heat away from sensitive components while maintaining electromagnetic shielding effectiveness, thereby enhancing overall device safety and reliability.Expand Specific Solutions03 Multilayer shielding structures for enhanced safety

Multilayer polymer-based EMI shielding structures can provide enhanced device safety through complementary protection mechanisms. These structures typically combine layers with different functionalities, such as absorption, reflection, and grounding capabilities. By utilizing multiple layers with varying compositions, these shields can effectively attenuate electromagnetic radiation across a broader frequency range while maintaining mechanical integrity and safety compliance, protecting both the device and users.Expand Specific Solutions04 Flame retardant EMI shielding materials

Incorporating flame retardant additives into polymer-based EMI shielding composites enhances device safety by reducing fire hazards. These specialized formulations maintain effective electromagnetic interference protection while meeting stringent flammability standards required for electronic devices. The flame retardant additives can be integrated with conductive fillers to create materials that provide dual functionality without compromising shielding performance, ensuring both electromagnetic compatibility and fire safety.Expand Specific Solutions05 Environmental and biocompatibility considerations

Safety-focused polymer-based EMI shielding materials address environmental and biocompatibility concerns through the use of non-toxic, recyclable, or biodegradable components. These advanced materials are designed to minimize potential health risks associated with traditional EMI shielding while maintaining effective protection against electromagnetic interference. By eliminating hazardous substances and ensuring compatibility with human contact, these shielding solutions enhance safety for both manufacturing processes and end-users of electronic devices.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The polymer-based EMI shielding composites market is in a growth phase, driven by increasing electronic device proliferation and electromagnetic interference concerns. The market is projected to expand significantly as demand for lightweight, effective shielding solutions grows across consumer electronics, automotive, and telecommunications sectors. Leading companies like 3M Innovative Properties, Laird Technologies, and Hon Hai Precision Industry are advancing the technology through innovative composite formulations, while academic institutions such as University of Electronic Science & Technology of China and Sichuan University contribute fundamental research. The technology is reaching maturity with commercial applications, though continuous innovation focuses on enhancing shielding effectiveness, reducing weight, and improving manufacturing processes. Competition is intensifying as traditional materials manufacturers and electronics companies develop proprietary solutions to meet stringent safety and performance requirements.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced polymer-based EMI shielding composites through their Electrically Conductive Adhesive Transfer Tapes (ECATT) and EMI absorbing materials product lines. Their technology utilizes a proprietary blend of conductive fillers, including nickel-coated carbon fibers and silver-coated glass spheres, dispersed within acrylic and silicone polymer matrices. These composites achieve shielding effectiveness of 40-80 dB across frequencies from 10 MHz to 18 GHz while maintaining flexibility and adhesion properties[6]. 3M's approach includes multi-layer constructions where different polymer layers are optimized for specific functions: adhesion, conductivity, and environmental protection. Their VHB™ Tape-based EMI solutions combine mechanical bonding with electrical conductivity, eliminating the need for mechanical fasteners in device assembly while providing effective EMI shielding. The company has also developed specialized formulations for flexible electronics and wearable devices that maintain shielding performance even under repeated bending and flexing (up to 100,000 cycles with less than 10% degradation in shielding effectiveness).

Strengths: Excellent adhesion to various substrates; maintains performance under environmental stressors (temperature, humidity); combines multiple functions (bonding, sealing, shielding) in a single material. Weaknesses: May have higher initial cost compared to traditional shielding methods; thickness requirements for optimal performance may limit use in ultra-thin devices; potential for adhesive degradation in certain chemical environments.

Hon Hai Precision Industry Co., Ltd.

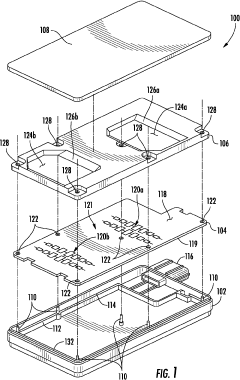

Technical Solution: Hon Hai (Foxconn) has developed sophisticated polymer-based EMI shielding solutions specifically designed for consumer electronics manufacturing. Their approach utilizes a conformal shielding technology that combines specialized conductive polymers with precision application methods. The company's proprietary EMI shielding composites incorporate silver-coated copper particles (15-20% by volume) suspended in a modified polyurethane matrix, creating a sprayable solution that can be robotically applied to PCB components with precision down to 0.1mm[4]. This technology achieves shielding effectiveness of 40-80 dB across the 800 MHz to 6 GHz range while adding only 0.2-0.3mm thickness to components. Hon Hai has integrated this solution into their manufacturing processes for smartphones, tablets, and wearable devices, allowing for component-level shielding rather than traditional board-level approaches. Their system includes specialized curing processes that ensure adhesion to various substrate materials while maintaining flexibility to withstand thermal cycling and mechanical stress during device operation.

Strengths: Highly adaptable to automated manufacturing processes; enables selective component shielding for space-constrained devices; excellent adhesion to various substrate materials. Weaknesses: Requires specialized application equipment; potential for increased manufacturing complexity; may have higher implementation costs for smaller production runs.

Key Patents and Innovations in Conductive Polymers

EMI Shielding Polymer Composition

PatentPendingUS20230203271A1

Innovation

- A polymer composition with recycled carbon fibers distributed within a thermoplastic polymer matrix, exhibiting effective EMI shielding and absorbency across a wide frequency range, along with good mechanical properties.

Composite polymeric material for EMI shielding

PatentActiveUS7589284B2

Innovation

- A composite polymeric material is developed by blending a non-conductive polymer with an inherently conductive polymer and electrically conductive fillers, forming an intimate mixture that avoids macro-phase separation, which can be used to create flexible gaskets and coatings with enhanced EMI shielding, conductivity, tensile, and flexural strength.

Environmental Impact and Sustainability Factors

The environmental implications of polymer-based EMI shielding composites represent a critical dimension in their development and application. Traditional EMI shielding materials, particularly those based on metals, often present significant environmental challenges throughout their lifecycle. These include energy-intensive mining operations, toxic chemical processes during manufacturing, and limited recyclability at end-of-life.

Polymer-based EMI shielding composites offer promising alternatives with potentially reduced environmental footprints. Many polymer matrices can be derived from renewable resources or recycled materials, decreasing dependence on virgin petroleum-based feedstocks. The manufacturing processes for these composites typically require lower processing temperatures compared to metals, resulting in reduced energy consumption and associated greenhouse gas emissions.

However, the environmental profile of these composites varies significantly depending on the specific conductive fillers employed. Carbon-based fillers such as graphene and carbon nanotubes present mixed sustainability credentials. While they enable highly effective shielding at lower loading levels (reducing overall material usage), their production often involves energy-intensive processes and potentially hazardous chemicals.

The incorporation of metallic nanoparticles presents particular challenges from a sustainability perspective. Though used in smaller quantities than in traditional metal shields, these particles may contain rare or precious metals with significant extraction impacts. Additionally, the potential for nanoparticle release during use or disposal raises ecotoxicological concerns that require further investigation.

End-of-life management represents another crucial sustainability consideration. The heterogeneous nature of polymer composites can complicate recycling efforts, particularly when containing multiple filler types. Recent research has focused on developing thermally reversible polymer matrices or using compatible polymer-filler combinations that facilitate material recovery and reprocessing.

Regulatory frameworks worldwide are increasingly emphasizing lifecycle assessment and circular economy principles for electronic components. This trend is driving innovation toward more environmentally benign EMI shielding solutions, including biodegradable polymers, bio-based conductive fillers, and designs that facilitate disassembly and material recovery.

The industry is witnessing growing adoption of green chemistry principles in the synthesis of conductive fillers and polymer matrices. Approaches such as solvent-free processing, aqueous-based systems, and supercritical CO2 technologies are being explored to minimize environmental impacts while maintaining or enhancing shielding performance.

Polymer-based EMI shielding composites offer promising alternatives with potentially reduced environmental footprints. Many polymer matrices can be derived from renewable resources or recycled materials, decreasing dependence on virgin petroleum-based feedstocks. The manufacturing processes for these composites typically require lower processing temperatures compared to metals, resulting in reduced energy consumption and associated greenhouse gas emissions.

However, the environmental profile of these composites varies significantly depending on the specific conductive fillers employed. Carbon-based fillers such as graphene and carbon nanotubes present mixed sustainability credentials. While they enable highly effective shielding at lower loading levels (reducing overall material usage), their production often involves energy-intensive processes and potentially hazardous chemicals.

The incorporation of metallic nanoparticles presents particular challenges from a sustainability perspective. Though used in smaller quantities than in traditional metal shields, these particles may contain rare or precious metals with significant extraction impacts. Additionally, the potential for nanoparticle release during use or disposal raises ecotoxicological concerns that require further investigation.

End-of-life management represents another crucial sustainability consideration. The heterogeneous nature of polymer composites can complicate recycling efforts, particularly when containing multiple filler types. Recent research has focused on developing thermally reversible polymer matrices or using compatible polymer-filler combinations that facilitate material recovery and reprocessing.

Regulatory frameworks worldwide are increasingly emphasizing lifecycle assessment and circular economy principles for electronic components. This trend is driving innovation toward more environmentally benign EMI shielding solutions, including biodegradable polymers, bio-based conductive fillers, and designs that facilitate disassembly and material recovery.

The industry is witnessing growing adoption of green chemistry principles in the synthesis of conductive fillers and polymer matrices. Approaches such as solvent-free processing, aqueous-based systems, and supercritical CO2 technologies are being explored to minimize environmental impacts while maintaining or enhancing shielding performance.

Safety Standards and Regulatory Compliance

The regulatory landscape for EMI shielding in electronic devices has evolved significantly over the past decades, with increasingly stringent requirements to ensure both device functionality and user safety. Polymer-based EMI shielding composites must comply with various international standards, including those set by the International Electrotechnical Commission (IEC), the Federal Communications Commission (FCC), and the European Union's Electromagnetic Compatibility (EMC) Directive.

The IEC 61000 series provides comprehensive guidelines for electromagnetic compatibility, with specific sections addressing emission limits and immunity requirements. For consumer electronics utilizing polymer-based EMI shields, compliance with CISPR 22/EN 55022 for information technology equipment and CISPR 24/EN 55024 for immunity characteristics is mandatory. These standards establish the maximum allowable electromagnetic interference levels that devices may generate and must withstand.

In the United States, the FCC regulations under Title 47 CFR Part 15 govern unintentional radiators, requiring electronic devices to operate without causing harmful interference. Polymer-based EMI shielding solutions must demonstrate effectiveness in limiting emissions below these thresholds during certification testing. Similarly, the European Union's EMC Directive 2014/30/EU mandates that all electronic equipment must not generate electromagnetic disturbances exceeding specified levels.

For medical devices, the requirements become even more rigorous. The IEC 60601-1-2 standard specifically addresses electromagnetic compatibility for medical electrical equipment. Polymer-based EMI shields used in medical applications must provide sufficient protection to ensure device functionality even in challenging electromagnetic environments, such as those found in hospitals with multiple high-powered electronic systems operating simultaneously.

The automotive industry follows standards like CISPR 25 and ISO 11452, which define test methods and limits for vehicle components. As vehicles incorporate more electronic systems, polymer-based EMI shielding becomes critical for ensuring both safety and functionality, particularly in emerging autonomous driving technologies where electromagnetic interference could have severe safety implications.

Military and aerospace applications adhere to MIL-STD-461 in the United States and similar standards internationally, imposing the most demanding requirements for EMI shielding. These standards specify rigorous testing procedures for electromagnetic emission and susceptibility across extreme environmental conditions, where polymer-based solutions must maintain their shielding effectiveness.

Compliance with these regulations requires manufacturers to conduct extensive testing of polymer-based EMI shielding composites under various conditions, including temperature extremes, humidity variations, and mechanical stress. Documentation of these tests forms a critical component of the product certification process, enabling market access across different regions and industries.

The IEC 61000 series provides comprehensive guidelines for electromagnetic compatibility, with specific sections addressing emission limits and immunity requirements. For consumer electronics utilizing polymer-based EMI shields, compliance with CISPR 22/EN 55022 for information technology equipment and CISPR 24/EN 55024 for immunity characteristics is mandatory. These standards establish the maximum allowable electromagnetic interference levels that devices may generate and must withstand.

In the United States, the FCC regulations under Title 47 CFR Part 15 govern unintentional radiators, requiring electronic devices to operate without causing harmful interference. Polymer-based EMI shielding solutions must demonstrate effectiveness in limiting emissions below these thresholds during certification testing. Similarly, the European Union's EMC Directive 2014/30/EU mandates that all electronic equipment must not generate electromagnetic disturbances exceeding specified levels.

For medical devices, the requirements become even more rigorous. The IEC 60601-1-2 standard specifically addresses electromagnetic compatibility for medical electrical equipment. Polymer-based EMI shields used in medical applications must provide sufficient protection to ensure device functionality even in challenging electromagnetic environments, such as those found in hospitals with multiple high-powered electronic systems operating simultaneously.

The automotive industry follows standards like CISPR 25 and ISO 11452, which define test methods and limits for vehicle components. As vehicles incorporate more electronic systems, polymer-based EMI shielding becomes critical for ensuring both safety and functionality, particularly in emerging autonomous driving technologies where electromagnetic interference could have severe safety implications.

Military and aerospace applications adhere to MIL-STD-461 in the United States and similar standards internationally, imposing the most demanding requirements for EMI shielding. These standards specify rigorous testing procedures for electromagnetic emission and susceptibility across extreme environmental conditions, where polymer-based solutions must maintain their shielding effectiveness.

Compliance with these regulations requires manufacturers to conduct extensive testing of polymer-based EMI shielding composites under various conditions, including temperature extremes, humidity variations, and mechanical stress. Documentation of these tests forms a critical component of the product certification process, enabling market access across different regions and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!