How EMI Shielding Performance is Affected by Environmental Conditions

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Background and Objectives

Electromagnetic Interference (EMI) shielding has become increasingly critical in modern electronic systems due to the proliferation of wireless technologies and electronic devices operating at higher frequencies. The evolution of EMI shielding technology traces back to the early days of radio communications, where simple metal enclosures were used to prevent signal interference. As electronic systems became more complex and miniaturized, the need for sophisticated shielding solutions grew exponentially.

The technological trajectory of EMI shielding has seen significant advancements from basic metal shields to composite materials incorporating conductive polymers, carbon-based materials, and metallic nanostructures. This evolution has been driven by the dual requirements of effective shielding performance and adaptability to diverse form factors in modern electronics. Recent developments have focused on lightweight, flexible, and environmentally sustainable shielding materials that can be integrated into increasingly compact electronic devices.

Environmental conditions represent a critical yet often overlooked factor affecting EMI shielding performance. Temperature fluctuations, humidity variations, mechanical stress, and exposure to chemicals can significantly alter the electrical conductivity, physical integrity, and overall effectiveness of shielding materials. Understanding these environmental impacts is essential for designing robust EMI solutions that maintain performance across diverse operating conditions.

The primary objective of this technical research is to comprehensively analyze how various environmental factors influence EMI shielding effectiveness and to establish design guidelines for environmentally resilient shielding solutions. Specifically, we aim to quantify the relationship between environmental parameters and shielding performance metrics, identify failure mechanisms under extreme conditions, and develop predictive models for long-term shielding reliability.

This research addresses the growing industry need for EMI shielding solutions that can withstand challenging environments in automotive, aerospace, industrial, and outdoor telecommunications applications. As electronic systems increasingly operate in harsh conditions, from extreme temperatures in automotive engine compartments to high humidity in marine applications, the demand for environmentally stable shielding has become paramount.

Additionally, we seek to explore emerging materials and composite structures that offer superior environmental resistance while maintaining or enhancing shielding effectiveness. This includes investigation into hydrophobic coatings, temperature-resistant polymers, and self-healing materials that could revolutionize EMI shielding in extreme environments. The findings will contribute to establishing new industry standards for environmental testing of EMI shielding materials and systems.

The technological trajectory of EMI shielding has seen significant advancements from basic metal shields to composite materials incorporating conductive polymers, carbon-based materials, and metallic nanostructures. This evolution has been driven by the dual requirements of effective shielding performance and adaptability to diverse form factors in modern electronics. Recent developments have focused on lightweight, flexible, and environmentally sustainable shielding materials that can be integrated into increasingly compact electronic devices.

Environmental conditions represent a critical yet often overlooked factor affecting EMI shielding performance. Temperature fluctuations, humidity variations, mechanical stress, and exposure to chemicals can significantly alter the electrical conductivity, physical integrity, and overall effectiveness of shielding materials. Understanding these environmental impacts is essential for designing robust EMI solutions that maintain performance across diverse operating conditions.

The primary objective of this technical research is to comprehensively analyze how various environmental factors influence EMI shielding effectiveness and to establish design guidelines for environmentally resilient shielding solutions. Specifically, we aim to quantify the relationship between environmental parameters and shielding performance metrics, identify failure mechanisms under extreme conditions, and develop predictive models for long-term shielding reliability.

This research addresses the growing industry need for EMI shielding solutions that can withstand challenging environments in automotive, aerospace, industrial, and outdoor telecommunications applications. As electronic systems increasingly operate in harsh conditions, from extreme temperatures in automotive engine compartments to high humidity in marine applications, the demand for environmentally stable shielding has become paramount.

Additionally, we seek to explore emerging materials and composite structures that offer superior environmental resistance while maintaining or enhancing shielding effectiveness. This includes investigation into hydrophobic coatings, temperature-resistant polymers, and self-healing materials that could revolutionize EMI shielding in extreme environments. The findings will contribute to establishing new industry standards for environmental testing of EMI shielding materials and systems.

Market Demand Analysis for Environmental-Resistant EMI Solutions

The global market for EMI shielding solutions with environmental resistance capabilities is experiencing robust growth, driven by the increasing deployment of electronic systems in harsh environments. Current market valuations indicate that the EMI shielding materials market is projected to reach approximately $9.2 billion by 2026, with environmental-resistant solutions representing a significant growth segment within this market.

Industries such as aerospace, defense, automotive, and industrial automation are primary drivers of demand for environmentally resistant EMI shielding. These sectors require electronic systems that can maintain electromagnetic compatibility while withstanding extreme temperatures, humidity, salt spray, vibration, and chemical exposure. The automotive industry, in particular, shows accelerating demand as electric vehicles proliferate, requiring sophisticated EMI protection for sensitive battery management systems and power electronics that must function across diverse environmental conditions.

Healthcare and medical device manufacturers represent another expanding market segment, with requirements for EMI shielding solutions that can withstand sterilization processes, cleaning chemicals, and varying humidity levels while maintaining biocompatibility. Market research indicates that medical electronics requiring environmental-resistant EMI protection are growing at a compound annual rate exceeding 7%.

Telecommunications infrastructure, especially with the global rollout of 5G networks, presents substantial market opportunities. Outdoor equipment faces temperature extremes, precipitation, UV exposure, and pollution, all while requiring effective EMI shielding to maintain signal integrity. This segment is expected to grow at over 8% annually through 2027.

Consumer electronics manufacturers are increasingly seeking environmentally resistant EMI solutions for portable devices, wearables, and IoT products that consumers use in diverse settings from beaches to mountain environments. This trend is reflected in the growing demand for IP-rated consumer devices with reliable EMI protection.

Regional analysis reveals that North America and Europe currently lead in adoption of premium environmental-resistant EMI solutions, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and electronics manufacturing expansion. Countries with extreme climate conditions, such as those in the Middle East, Northern Europe, and tropical regions, show particularly strong demand for specialized solutions that can withstand their unique environmental challenges.

Market surveys indicate that customers are increasingly willing to pay premium prices for EMI shielding solutions with proven environmental durability, as the cost of field failures in harsh environments far exceeds the incremental cost of enhanced protection. This value proposition is driving innovation and creating opportunities for specialized solution providers who can demonstrate superior performance across multiple environmental stressors.

Industries such as aerospace, defense, automotive, and industrial automation are primary drivers of demand for environmentally resistant EMI shielding. These sectors require electronic systems that can maintain electromagnetic compatibility while withstanding extreme temperatures, humidity, salt spray, vibration, and chemical exposure. The automotive industry, in particular, shows accelerating demand as electric vehicles proliferate, requiring sophisticated EMI protection for sensitive battery management systems and power electronics that must function across diverse environmental conditions.

Healthcare and medical device manufacturers represent another expanding market segment, with requirements for EMI shielding solutions that can withstand sterilization processes, cleaning chemicals, and varying humidity levels while maintaining biocompatibility. Market research indicates that medical electronics requiring environmental-resistant EMI protection are growing at a compound annual rate exceeding 7%.

Telecommunications infrastructure, especially with the global rollout of 5G networks, presents substantial market opportunities. Outdoor equipment faces temperature extremes, precipitation, UV exposure, and pollution, all while requiring effective EMI shielding to maintain signal integrity. This segment is expected to grow at over 8% annually through 2027.

Consumer electronics manufacturers are increasingly seeking environmentally resistant EMI solutions for portable devices, wearables, and IoT products that consumers use in diverse settings from beaches to mountain environments. This trend is reflected in the growing demand for IP-rated consumer devices with reliable EMI protection.

Regional analysis reveals that North America and Europe currently lead in adoption of premium environmental-resistant EMI solutions, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and electronics manufacturing expansion. Countries with extreme climate conditions, such as those in the Middle East, Northern Europe, and tropical regions, show particularly strong demand for specialized solutions that can withstand their unique environmental challenges.

Market surveys indicate that customers are increasingly willing to pay premium prices for EMI shielding solutions with proven environmental durability, as the cost of field failures in harsh environments far exceeds the incremental cost of enhanced protection. This value proposition is driving innovation and creating opportunities for specialized solution providers who can demonstrate superior performance across multiple environmental stressors.

Current EMI Shielding Technologies and Environmental Challenges

The electromagnetic interference (EMI) shielding landscape has evolved significantly over the past decade, with various technologies emerging to address the growing challenges of electromagnetic pollution. Current EMI shielding solutions primarily fall into three categories: metallic shields, conductive polymer composites, and emerging nanomaterial-based shields.

Metallic shields, including aluminum, copper, and steel enclosures, remain the most widely implemented solution due to their high conductivity and established manufacturing processes. These traditional shields typically offer attenuation levels of 60-120 dB across a wide frequency range. However, they face significant environmental challenges, particularly in high-humidity and corrosive environments where oxidation can dramatically reduce shielding effectiveness over time.

Conductive polymer composites represent the second generation of shielding materials, combining the processability of polymers with the conductivity of metal fillers. These materials offer moderate shielding effectiveness (typically 30-70 dB) while providing advantages in weight reduction and corrosion resistance. However, their performance is highly susceptible to temperature fluctuations, with many composites experiencing significant degradation in shielding effectiveness at temperatures exceeding 85°C due to polymer matrix expansion.

Nanomaterial-based shields, including graphene, carbon nanotubes, and MXenes, represent the cutting edge of EMI shielding technology. These materials can achieve exceptional shielding effectiveness (up to 90 dB) at much lower thicknesses than conventional materials. However, their environmental stability presents significant challenges, with humidity-induced agglomeration and oxidation being primary concerns that limit their practical implementation.

Environmental factors pose substantial challenges to all shielding technologies. Humidity accelerates corrosion in metallic shields and causes swelling in polymer composites, leading to decreased conductivity networks. Temperature cycling induces mechanical stress through differential thermal expansion, creating microcracks that compromise shield integrity. UV radiation degrades polymer matrices in composite shields, while salt spray environments rapidly accelerate corrosion processes in metallic components.

Altitude variations present unique challenges through pressure differentials that can deform shield enclosures and change the dielectric properties of air gaps within composite materials. Vibration and mechanical stress, particularly in automotive and aerospace applications, can lead to fatigue failure at connection points and gradual degradation of shielding effectiveness.

The industry currently lacks standardized testing protocols that accurately simulate real-world environmental conditions over extended periods. Most shielding materials are tested under ideal laboratory conditions, creating a significant gap between specified performance and actual field performance. This disconnect represents one of the most pressing challenges in advancing EMI shielding technology for demanding environmental applications.

Metallic shields, including aluminum, copper, and steel enclosures, remain the most widely implemented solution due to their high conductivity and established manufacturing processes. These traditional shields typically offer attenuation levels of 60-120 dB across a wide frequency range. However, they face significant environmental challenges, particularly in high-humidity and corrosive environments where oxidation can dramatically reduce shielding effectiveness over time.

Conductive polymer composites represent the second generation of shielding materials, combining the processability of polymers with the conductivity of metal fillers. These materials offer moderate shielding effectiveness (typically 30-70 dB) while providing advantages in weight reduction and corrosion resistance. However, their performance is highly susceptible to temperature fluctuations, with many composites experiencing significant degradation in shielding effectiveness at temperatures exceeding 85°C due to polymer matrix expansion.

Nanomaterial-based shields, including graphene, carbon nanotubes, and MXenes, represent the cutting edge of EMI shielding technology. These materials can achieve exceptional shielding effectiveness (up to 90 dB) at much lower thicknesses than conventional materials. However, their environmental stability presents significant challenges, with humidity-induced agglomeration and oxidation being primary concerns that limit their practical implementation.

Environmental factors pose substantial challenges to all shielding technologies. Humidity accelerates corrosion in metallic shields and causes swelling in polymer composites, leading to decreased conductivity networks. Temperature cycling induces mechanical stress through differential thermal expansion, creating microcracks that compromise shield integrity. UV radiation degrades polymer matrices in composite shields, while salt spray environments rapidly accelerate corrosion processes in metallic components.

Altitude variations present unique challenges through pressure differentials that can deform shield enclosures and change the dielectric properties of air gaps within composite materials. Vibration and mechanical stress, particularly in automotive and aerospace applications, can lead to fatigue failure at connection points and gradual degradation of shielding effectiveness.

The industry currently lacks standardized testing protocols that accurately simulate real-world environmental conditions over extended periods. Most shielding materials are tested under ideal laboratory conditions, creating a significant gap between specified performance and actual field performance. This disconnect represents one of the most pressing challenges in advancing EMI shielding technology for demanding environmental applications.

Current Solutions for Environmental-Adaptive EMI Shielding

01 Conductive materials for EMI shielding

Various conductive materials can be incorporated into EMI shielding solutions to enhance shielding performance. These materials include metals, conductive polymers, and carbon-based materials that can effectively block electromagnetic interference. The conductivity of these materials allows them to reflect, absorb, or dissipate electromagnetic waves, thereby preventing them from penetrating protected components or devices. The selection of appropriate conductive materials is crucial for achieving optimal EMI shielding performance across different frequency ranges.- Conductive materials for EMI shielding: Various conductive materials can be incorporated into EMI shielding solutions to enhance shielding performance. These materials include metals, conductive polymers, and carbon-based materials that can effectively block electromagnetic interference. The conductivity of these materials allows them to reflect, absorb, or dissipate electromagnetic waves, thereby preventing them from penetrating sensitive electronic components. The selection of appropriate conductive materials is crucial for achieving optimal EMI shielding performance in different applications.

- Multilayer shielding structures: Multilayer structures can significantly improve EMI shielding performance by combining different materials with complementary properties. These structures typically consist of alternating layers of conductive and non-conductive materials, which can provide both reflection and absorption of electromagnetic waves. The layered approach allows for customization of the shielding solution to address specific frequency ranges and interference types. Additionally, multilayer structures can offer improved mechanical properties and durability compared to single-layer shields.

- Housing and enclosure designs for EMI protection: The design of electronic housings and enclosures plays a critical role in EMI shielding performance. Features such as gaskets, seams, apertures, and ventilation openings must be carefully engineered to maintain shielding integrity while allowing for necessary functionality. Specialized housing designs can incorporate conductive coatings, embedded shielding materials, or innovative structural elements to create a continuous Faraday cage effect. The effectiveness of these designs depends on factors such as material selection, manufacturing precision, and assembly techniques.

- Testing and measurement of shielding effectiveness: Accurate testing and measurement methods are essential for evaluating EMI shielding performance. Various techniques are employed to quantify shielding effectiveness across different frequency ranges, including plane wave testing, near-field scanning, and reverberation chamber testing. These measurements help determine the attenuation of electromagnetic waves provided by the shielding solution, typically expressed in decibels (dB). Standardized testing protocols ensure consistency and comparability of results, enabling manufacturers to validate compliance with regulatory requirements and performance specifications.

- Advanced manufacturing techniques for EMI shields: Innovative manufacturing techniques have been developed to enhance the performance and cost-effectiveness of EMI shielding solutions. These include methods such as selective metallization, 3D printing of conductive materials, injection molding with conductive fillers, and vacuum metallization. Advanced manufacturing approaches enable the creation of complex geometries, precise material distribution, and integration of shielding features directly into component designs. These techniques allow for miniaturization of shielding solutions while maintaining or improving performance, which is particularly important for modern compact electronic devices.

02 Multilayer shielding structures

Multilayer structures can significantly improve EMI shielding performance by combining different materials with complementary shielding properties. These structures typically consist of alternating layers of conductive and non-conductive materials, which can provide both reflection and absorption of electromagnetic waves. The layered approach allows for customization of the shielding solution to address specific frequency ranges and interference types. Additionally, multilayer structures can offer improved mechanical properties and durability compared to single-layer shields.Expand Specific Solutions03 Housing and enclosure designs for electronic devices

The design of housings and enclosures plays a critical role in EMI shielding performance. Specialized enclosure designs incorporate features such as conductive gaskets, seams, and vents that maintain shielding integrity while allowing for cooling and access. The geometry, material selection, and manufacturing techniques of these enclosures can significantly impact their ability to block electromagnetic interference. Properly designed housings ensure comprehensive shielding coverage while maintaining functionality and accessibility of the enclosed electronic components.Expand Specific Solutions04 Connector and interface shielding solutions

Connectors and interfaces represent potential weak points in EMI shielding systems, requiring specialized solutions to maintain shielding integrity. Shielded connectors incorporate conductive shells, gaskets, and grounding mechanisms to prevent electromagnetic leakage at connection points. These solutions ensure continuous shielding across device boundaries while maintaining electrical connectivity. Advanced connector designs balance shielding performance with factors such as size, weight, and ease of connection/disconnection, making them suitable for various applications from consumer electronics to military equipment.Expand Specific Solutions05 Testing and measurement of EMI shielding effectiveness

Accurate testing and measurement methods are essential for evaluating and validating EMI shielding performance. These methods include standardized tests for measuring shielding effectiveness across different frequency ranges, as well as specialized techniques for identifying shielding weaknesses. Testing equipment and methodologies can assess parameters such as insertion loss, reflection loss, and absorption characteristics of shielding materials and systems. Comprehensive testing ensures that shielding solutions meet regulatory requirements and perform effectively in real-world applications, providing reliable protection against electromagnetic interference.Expand Specific Solutions

Leading Manufacturers and Research Institutions in EMI Shielding

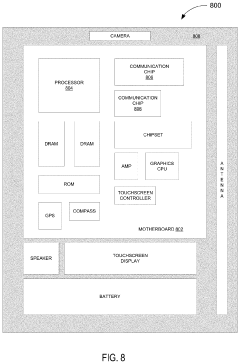

Environmental conditions significantly impact EMI shielding performance across various industries, with market dynamics reflecting both challenges and opportunities. The EMI shielding market is in a growth phase, expected to reach $9.2 billion by 2025, driven by increasing electronic device proliferation and stringent regulations. Temperature, humidity, mechanical stress, and aging all affect shielding effectiveness. Leading companies like Laird Technologies, Parker-Hannifin, and Samsung Electronics have developed advanced solutions addressing these environmental variables. Laird specializes in multi-environmental shielding materials, while Parker-Hannifin focuses on aerospace-grade solutions that maintain performance across extreme conditions. Newer entrants like Nanotech Energy are disrupting the market with graphene-based shields offering superior environmental stability, while established players such as Apple and Intel continue investing in proprietary shielding technologies for consumer electronics that maintain effectiveness across diverse operating environments.

Laird Technologies, Inc.

Technical Solution: Laird Technologies has developed advanced multi-layered EMI shielding solutions that adapt to varying environmental conditions. Their technology incorporates specialized elastomeric materials with embedded conductive particles that maintain conductivity across temperature ranges from -40°C to +125°C. The company's ECOSHIELD® line features humidity-resistant coatings that prevent oxidation and corrosion in high-moisture environments, maintaining shielding effectiveness above 80dB even after 1000 hours of salt spray testing. Laird's thermal management integration allows their shields to dissipate heat while maintaining EMI protection, addressing the dual challenges of thermal stress and electromagnetic interference. Their patented manufacturing process creates micro-perforations that allow pressure equalization in aerospace applications while maintaining shielding integrity across altitude changes.

Strengths: Superior performance in extreme temperature variations; excellent moisture and corrosion resistance; integrated thermal management capabilities. Weaknesses: Higher cost compared to basic shielding solutions; some designs require specialized installation processes; potential weight considerations for aerospace applications.

Henkel IP & Holding GmbH

Technical Solution: Henkel has pioneered environmentally-adaptive EMI shielding through their LOCTITE® ABLESTIK EMI shielding materials. Their technology utilizes nano-silver particles suspended in polymer matrices that maintain conductivity across diverse environmental conditions. The company's formulations feature self-healing properties that can recover from micro-fractures caused by thermal cycling, with testing showing maintained performance after 1000 thermal cycles from -55°C to +150°C. Henkel's coatings incorporate hydrophobic additives that repel moisture while maintaining breathability, preventing condensation buildup that could compromise shielding effectiveness. Their materials demonstrate less than 5% degradation in shielding performance after 2000 hours of humidity exposure at 85°C/85% RH. Henkel has also developed UV-resistant formulations specifically for outdoor applications that maintain shielding integrity despite solar radiation exposure.

Strengths: Excellent thermal cycling resilience; superior moisture resistance; self-healing capabilities for extended product life. Weaknesses: Higher initial material costs; requires specialized application equipment; some formulations have limited shelf life before application.

Key Technical Innovations in Environmental-Resistant Shielding

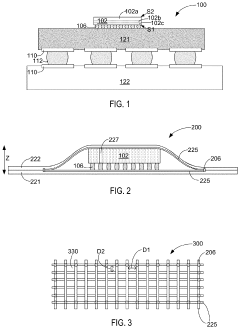

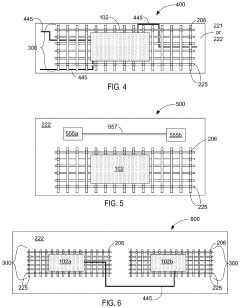

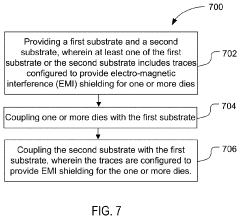

Electro-magnetic interference (EMI) shielding techniques and configurations

PatentInactiveUS10595409B2

Innovation

- The use of substrates with traces configured in a grid arrangement to provide EMI shielding, where one substrate is rigid and the other is flexible, allowing for a reduction in z-height and form factor, and potentially integrating additional functionalities like solar panels or displays, with interconnect structures forming a Faraday cage around the die.

High-Performance EMI Shielding Coating From Low-Cost Carbon Black with XLPE

PatentInactiveIN201841040343A

Innovation

- Development of a composite using XLPE and micro-scaled Carbon Black (CB) to enhance EMI shielding and maintain antistatic properties, with CB particles interacting effectively within the non-polar polymer matrix to form conducting networks, increasing shielding effectiveness and maintaining resistivity within the antistatic range.

Standards and Testing Protocols for Environmental EMI Performance

The evaluation of EMI shielding performance requires standardized testing protocols that account for various environmental conditions. The International Electrotechnical Commission (IEC) has established several standards, including IEC 61000 series, which specifically addresses electromagnetic compatibility testing under different environmental scenarios. These standards define measurement methodologies, acceptable performance levels, and reporting requirements for EMI shielding materials and systems.

ASTM D4935 provides a standardized method for measuring the electromagnetic shielding effectiveness of planar materials, while MIL-STD-461 outlines requirements for the control of electromagnetic interference characteristics of subsystems and equipment. These standards incorporate specific protocols for testing under varying temperature, humidity, and pressure conditions to ensure comprehensive performance assessment.

Environmental testing chambers play a crucial role in these protocols, allowing for controlled simulation of diverse conditions. Temperature cycling tests typically range from -40°C to +85°C, with humidity variations from 10% to 95% RH, enabling evaluation of shielding performance across operational extremes. The IEEE 299 standard specifically addresses shielding effectiveness measurements for enclosures, providing guidelines for testing under different environmental scenarios.

Testing protocols generally require multiple measurement points and repeated testing cycles to ensure statistical validity. For instance, the SAE ARP5583 standard recommends a minimum of three measurement cycles under each environmental condition, with stabilization periods between condition changes to allow materials to reach equilibrium.

Certification bodies like UL, TÜV, and SGS have developed specialized testing protocols that extend beyond basic standards, incorporating accelerated aging tests to predict long-term environmental effects on shielding performance. These protocols typically include salt spray exposure (ASTM B117), UV radiation testing (ASTM G154), and thermal shock cycling (IEC 60068-2-14).

Recent developments in testing standards have begun to address combined environmental effects, recognizing that real-world conditions rarely present isolated environmental factors. The IEC 60068 series now includes protocols for simultaneous exposure to multiple environmental stressors, providing more realistic performance assessments for EMI shielding solutions deployed in complex environments.

Compliance with these standards and protocols is increasingly becoming mandatory for products entering global markets, particularly in aerospace, automotive, medical, and telecommunications sectors where EMI shielding performance under environmental stress is critical to operational safety and reliability.

ASTM D4935 provides a standardized method for measuring the electromagnetic shielding effectiveness of planar materials, while MIL-STD-461 outlines requirements for the control of electromagnetic interference characteristics of subsystems and equipment. These standards incorporate specific protocols for testing under varying temperature, humidity, and pressure conditions to ensure comprehensive performance assessment.

Environmental testing chambers play a crucial role in these protocols, allowing for controlled simulation of diverse conditions. Temperature cycling tests typically range from -40°C to +85°C, with humidity variations from 10% to 95% RH, enabling evaluation of shielding performance across operational extremes. The IEEE 299 standard specifically addresses shielding effectiveness measurements for enclosures, providing guidelines for testing under different environmental scenarios.

Testing protocols generally require multiple measurement points and repeated testing cycles to ensure statistical validity. For instance, the SAE ARP5583 standard recommends a minimum of three measurement cycles under each environmental condition, with stabilization periods between condition changes to allow materials to reach equilibrium.

Certification bodies like UL, TÜV, and SGS have developed specialized testing protocols that extend beyond basic standards, incorporating accelerated aging tests to predict long-term environmental effects on shielding performance. These protocols typically include salt spray exposure (ASTM B117), UV radiation testing (ASTM G154), and thermal shock cycling (IEC 60068-2-14).

Recent developments in testing standards have begun to address combined environmental effects, recognizing that real-world conditions rarely present isolated environmental factors. The IEC 60068 series now includes protocols for simultaneous exposure to multiple environmental stressors, providing more realistic performance assessments for EMI shielding solutions deployed in complex environments.

Compliance with these standards and protocols is increasingly becoming mandatory for products entering global markets, particularly in aerospace, automotive, medical, and telecommunications sectors where EMI shielding performance under environmental stress is critical to operational safety and reliability.

Sustainability Aspects of EMI Shielding Materials

The sustainability of EMI shielding materials has become increasingly important as environmental regulations tighten and corporate social responsibility initiatives gain momentum. Traditional EMI shielding solutions often rely on materials with significant environmental footprints, including metals like copper, aluminum, and nickel, as well as various polymer composites containing carbon-based fillers.

Environmental impact assessments of EMI shielding materials reveal concerns throughout their lifecycle. Mining and processing of metals for conductive shields generates substantial carbon emissions, water pollution, and habitat disruption. Similarly, petroleum-based polymers used in composite shields contribute to resource depletion and end-of-life disposal challenges, as many are difficult to recycle or biodegrade.

Recent innovations are addressing these sustainability challenges through several approaches. Bio-based polymers derived from renewable resources are being developed as alternatives to petroleum-based matrices in composite shields. These materials offer comparable EMI shielding effectiveness while reducing carbon footprint and dependence on fossil resources. Research into biodegradable conductive fillers, such as cellulose nanofibers coated with conductive materials, represents another promising direction.

Recyclability has emerged as a critical design consideration for next-generation shielding materials. Thermoplastic-based composites that can be melted and reformed multiple times are replacing thermoset materials that cannot be easily recycled. Additionally, design for disassembly approaches enable easier separation of shielding components from electronic devices at end-of-life.

Energy efficiency in manufacturing processes is also receiving attention. Low-temperature processing methods for conductive coatings and additive manufacturing techniques reduce energy consumption compared to traditional metal fabrication processes. Water-based conductive coatings are replacing solvent-based alternatives, reducing volatile organic compound emissions during production.

Regulatory frameworks worldwide are increasingly influencing material selection for EMI shielding. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations limit the use of certain heavy metals and chemicals commonly found in shielding materials. These regulations are driving innovation toward more environmentally benign alternatives that maintain effective EMI protection performance.

Life cycle assessment (LCA) methodologies are being applied to evaluate the comprehensive environmental impact of shielding materials from raw material extraction through disposal. This holistic approach helps identify opportunities for improvement and enables meaningful comparisons between alternative materials and designs, supporting more sustainable decision-making in EMI shielding applications.

Environmental impact assessments of EMI shielding materials reveal concerns throughout their lifecycle. Mining and processing of metals for conductive shields generates substantial carbon emissions, water pollution, and habitat disruption. Similarly, petroleum-based polymers used in composite shields contribute to resource depletion and end-of-life disposal challenges, as many are difficult to recycle or biodegrade.

Recent innovations are addressing these sustainability challenges through several approaches. Bio-based polymers derived from renewable resources are being developed as alternatives to petroleum-based matrices in composite shields. These materials offer comparable EMI shielding effectiveness while reducing carbon footprint and dependence on fossil resources. Research into biodegradable conductive fillers, such as cellulose nanofibers coated with conductive materials, represents another promising direction.

Recyclability has emerged as a critical design consideration for next-generation shielding materials. Thermoplastic-based composites that can be melted and reformed multiple times are replacing thermoset materials that cannot be easily recycled. Additionally, design for disassembly approaches enable easier separation of shielding components from electronic devices at end-of-life.

Energy efficiency in manufacturing processes is also receiving attention. Low-temperature processing methods for conductive coatings and additive manufacturing techniques reduce energy consumption compared to traditional metal fabrication processes. Water-based conductive coatings are replacing solvent-based alternatives, reducing volatile organic compound emissions during production.

Regulatory frameworks worldwide are increasingly influencing material selection for EMI shielding. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations limit the use of certain heavy metals and chemicals commonly found in shielding materials. These regulations are driving innovation toward more environmentally benign alternatives that maintain effective EMI protection performance.

Life cycle assessment (LCA) methodologies are being applied to evaluate the comprehensive environmental impact of shielding materials from raw material extraction through disposal. This holistic approach helps identify opportunities for improvement and enables meaningful comparisons between alternative materials and designs, supporting more sustainable decision-making in EMI shielding applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!