Research on EMI Shielding Effectiveness of Conductive Composites

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Shielding Background and Objectives

Electromagnetic interference (EMI) has become a critical concern in modern electronic systems due to the proliferation of wireless communication technologies and electronic devices operating at increasingly higher frequencies. The evolution of EMI shielding technology can be traced back to the mid-20th century when basic metal enclosures were primarily used to contain electromagnetic radiation. As electronic devices became more compact and complex, traditional metal shielding solutions proved inadequate due to their weight, corrosion susceptibility, and limited design flexibility.

The development trajectory of conductive composites for EMI shielding has accelerated significantly over the past two decades, driven by the miniaturization of electronic components and the increasing demand for lightweight, flexible, and cost-effective shielding materials. These composites typically consist of a polymer matrix embedded with conductive fillers such as carbon-based materials (graphene, carbon nanotubes, carbon fibers), metallic particles, or conductive polymers, offering a promising alternative to conventional metal shields.

Current technological trends in EMI shielding are moving toward multifunctional materials that not only provide effective electromagnetic protection but also offer additional properties such as thermal management, mechanical strength, and environmental resistance. The integration of nanotechnology has opened new avenues for enhancing shielding effectiveness through precise control of material structure at the nanoscale, enabling unprecedented performance improvements.

The primary objective of research on EMI shielding effectiveness of conductive composites is to develop next-generation materials that can achieve superior shielding performance (>60 dB) across a broad frequency spectrum (from MHz to GHz range) while maintaining lightweight characteristics and manufacturing feasibility. This involves understanding the fundamental mechanisms of electromagnetic wave interaction with composite structures and optimizing material composition and morphology accordingly.

Additional research goals include establishing reliable testing methodologies for evaluating shielding effectiveness under various environmental conditions, developing scalable and cost-effective manufacturing processes for industrial implementation, and exploring environmentally sustainable materials and production techniques to align with global sustainability initiatives.

The technological roadmap for conductive composite EMI shielding aims to address the increasing challenges posed by 5G networks, Internet of Things (IoT) devices, autonomous vehicles, and other emerging technologies that operate at higher frequencies and require more sophisticated electromagnetic compatibility solutions. This includes developing adaptive shielding materials that can respond dynamically to changing electromagnetic environments and exploring hybrid solutions that combine multiple shielding mechanisms for enhanced performance.

Understanding the historical context, current state, and future directions of conductive composite EMI shielding technology is essential for identifying innovation opportunities and establishing realistic technical objectives that can drive meaningful advancements in this critical field.

The development trajectory of conductive composites for EMI shielding has accelerated significantly over the past two decades, driven by the miniaturization of electronic components and the increasing demand for lightweight, flexible, and cost-effective shielding materials. These composites typically consist of a polymer matrix embedded with conductive fillers such as carbon-based materials (graphene, carbon nanotubes, carbon fibers), metallic particles, or conductive polymers, offering a promising alternative to conventional metal shields.

Current technological trends in EMI shielding are moving toward multifunctional materials that not only provide effective electromagnetic protection but also offer additional properties such as thermal management, mechanical strength, and environmental resistance. The integration of nanotechnology has opened new avenues for enhancing shielding effectiveness through precise control of material structure at the nanoscale, enabling unprecedented performance improvements.

The primary objective of research on EMI shielding effectiveness of conductive composites is to develop next-generation materials that can achieve superior shielding performance (>60 dB) across a broad frequency spectrum (from MHz to GHz range) while maintaining lightweight characteristics and manufacturing feasibility. This involves understanding the fundamental mechanisms of electromagnetic wave interaction with composite structures and optimizing material composition and morphology accordingly.

Additional research goals include establishing reliable testing methodologies for evaluating shielding effectiveness under various environmental conditions, developing scalable and cost-effective manufacturing processes for industrial implementation, and exploring environmentally sustainable materials and production techniques to align with global sustainability initiatives.

The technological roadmap for conductive composite EMI shielding aims to address the increasing challenges posed by 5G networks, Internet of Things (IoT) devices, autonomous vehicles, and other emerging technologies that operate at higher frequencies and require more sophisticated electromagnetic compatibility solutions. This includes developing adaptive shielding materials that can respond dynamically to changing electromagnetic environments and exploring hybrid solutions that combine multiple shielding mechanisms for enhanced performance.

Understanding the historical context, current state, and future directions of conductive composite EMI shielding technology is essential for identifying innovation opportunities and establishing realistic technical objectives that can drive meaningful advancements in this critical field.

Market Analysis for EMI Shielding Solutions

The global market for EMI shielding solutions has experienced significant growth in recent years, driven by the proliferation of electronic devices and the increasing need for electromagnetic compatibility. The market was valued at approximately $6.2 billion in 2020 and is projected to reach $9.8 billion by 2027, growing at a CAGR of 6.8% during the forecast period.

The demand for EMI shielding solutions is primarily fueled by the telecommunications and consumer electronics sectors, which together account for over 50% of the market share. The rapid expansion of 5G infrastructure worldwide has created substantial opportunities for EMI shielding materials, as higher frequencies require more effective shielding solutions to prevent interference.

Automotive electronics represent another fast-growing segment, with an estimated growth rate of 8.2% annually. The increasing integration of electronic components in vehicles, particularly in electric and autonomous vehicles, has heightened the need for reliable EMI shielding to ensure proper functioning of critical systems and prevent electromagnetic interference between components.

Regionally, Asia-Pacific dominates the market with approximately 40% share, attributed to the strong presence of electronics manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. North America follows with around 28% market share, driven by advanced telecommunications infrastructure and defense applications.

The healthcare sector is emerging as a promising market for EMI shielding solutions, growing at 7.5% annually. Medical devices require robust protection against electromagnetic interference to ensure accurate diagnostics and patient safety, creating specialized demand for high-performance shielding materials.

Conductive composites specifically have gained significant traction in the EMI shielding market, with a market size of approximately $2.1 billion in 2020. These materials offer advantages such as lightweight properties, design flexibility, and corrosion resistance compared to traditional metal-based solutions. Carbon-based composites, including carbon fiber reinforced polymers and graphene-enhanced materials, are experiencing the fastest growth at 9.3% annually.

Customer preferences are increasingly shifting toward multifunctional shielding materials that offer additional benefits beyond EMI protection, such as thermal management, structural integrity, and environmental sustainability. This trend is driving innovation in conductive composite formulations that can address multiple performance requirements simultaneously.

Price sensitivity varies significantly across application sectors, with consumer electronics manufacturers prioritizing cost-effectiveness, while aerospace and defense applications focus primarily on performance reliability regardless of cost premium. This market segmentation creates diverse opportunities for different types of conductive composite solutions across the value spectrum.

The demand for EMI shielding solutions is primarily fueled by the telecommunications and consumer electronics sectors, which together account for over 50% of the market share. The rapid expansion of 5G infrastructure worldwide has created substantial opportunities for EMI shielding materials, as higher frequencies require more effective shielding solutions to prevent interference.

Automotive electronics represent another fast-growing segment, with an estimated growth rate of 8.2% annually. The increasing integration of electronic components in vehicles, particularly in electric and autonomous vehicles, has heightened the need for reliable EMI shielding to ensure proper functioning of critical systems and prevent electromagnetic interference between components.

Regionally, Asia-Pacific dominates the market with approximately 40% share, attributed to the strong presence of electronics manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. North America follows with around 28% market share, driven by advanced telecommunications infrastructure and defense applications.

The healthcare sector is emerging as a promising market for EMI shielding solutions, growing at 7.5% annually. Medical devices require robust protection against electromagnetic interference to ensure accurate diagnostics and patient safety, creating specialized demand for high-performance shielding materials.

Conductive composites specifically have gained significant traction in the EMI shielding market, with a market size of approximately $2.1 billion in 2020. These materials offer advantages such as lightweight properties, design flexibility, and corrosion resistance compared to traditional metal-based solutions. Carbon-based composites, including carbon fiber reinforced polymers and graphene-enhanced materials, are experiencing the fastest growth at 9.3% annually.

Customer preferences are increasingly shifting toward multifunctional shielding materials that offer additional benefits beyond EMI protection, such as thermal management, structural integrity, and environmental sustainability. This trend is driving innovation in conductive composite formulations that can address multiple performance requirements simultaneously.

Price sensitivity varies significantly across application sectors, with consumer electronics manufacturers prioritizing cost-effectiveness, while aerospace and defense applications focus primarily on performance reliability regardless of cost premium. This market segmentation creates diverse opportunities for different types of conductive composite solutions across the value spectrum.

Current Status and Challenges in Conductive Composites

The global landscape of conductive composites for EMI shielding applications has witnessed significant advancements in recent years, with research institutions and industries across North America, Europe, and Asia-Pacific regions making substantial contributions. Current state-of-the-art conductive composites typically achieve shielding effectiveness ranging from 20-90 dB across frequencies of 30 MHz to 18 GHz, depending on material composition and structural design.

Despite these achievements, several critical challenges persist in the development and application of conductive composites for EMI shielding. The primary technical hurdle remains the trade-off between electrical conductivity and mechanical properties. As conductive filler content increases to enhance shielding effectiveness, mechanical integrity often deteriorates, resulting in brittle materials unsuitable for practical applications requiring flexibility or durability.

Another significant challenge is the dispersion and distribution of conductive fillers within the polymer matrix. Agglomeration of fillers, particularly nanomaterials like carbon nanotubes and graphene, creates inconsistent conductivity networks and reduces overall shielding performance. This non-uniform distribution leads to unpredictable shielding effectiveness and compromises quality control in manufacturing processes.

Cost-effectiveness presents another substantial barrier to widespread adoption. High-performance conductive fillers such as silver nanoparticles, carbon nanotubes, and graphene remain expensive for mass production, limiting commercial viability. Additionally, complex processing techniques required for optimal dispersion further increase production costs.

Environmental stability poses ongoing concerns, as many conductive composites exhibit degradation in shielding performance when exposed to moisture, UV radiation, or temperature fluctuations. This susceptibility to environmental factors restricts their application in harsh operating conditions and reduces long-term reliability.

Geographically, research leadership in conductive composites shows distinct patterns. North American institutions lead in fundamental research and novel material development, while Asian manufacturers, particularly in China and South Korea, dominate in scaled production and commercial applications. European research centers excel in specialized high-performance composites for aerospace and automotive applications.

The scalability of laboratory-developed composites to industrial production represents a persistent challenge. Many promising materials demonstrate excellent shielding properties at small scales but encounter significant performance degradation when manufactured using conventional industrial processes. This scale-up gap hinders technology transfer from research to commercial applications.

Despite these achievements, several critical challenges persist in the development and application of conductive composites for EMI shielding. The primary technical hurdle remains the trade-off between electrical conductivity and mechanical properties. As conductive filler content increases to enhance shielding effectiveness, mechanical integrity often deteriorates, resulting in brittle materials unsuitable for practical applications requiring flexibility or durability.

Another significant challenge is the dispersion and distribution of conductive fillers within the polymer matrix. Agglomeration of fillers, particularly nanomaterials like carbon nanotubes and graphene, creates inconsistent conductivity networks and reduces overall shielding performance. This non-uniform distribution leads to unpredictable shielding effectiveness and compromises quality control in manufacturing processes.

Cost-effectiveness presents another substantial barrier to widespread adoption. High-performance conductive fillers such as silver nanoparticles, carbon nanotubes, and graphene remain expensive for mass production, limiting commercial viability. Additionally, complex processing techniques required for optimal dispersion further increase production costs.

Environmental stability poses ongoing concerns, as many conductive composites exhibit degradation in shielding performance when exposed to moisture, UV radiation, or temperature fluctuations. This susceptibility to environmental factors restricts their application in harsh operating conditions and reduces long-term reliability.

Geographically, research leadership in conductive composites shows distinct patterns. North American institutions lead in fundamental research and novel material development, while Asian manufacturers, particularly in China and South Korea, dominate in scaled production and commercial applications. European research centers excel in specialized high-performance composites for aerospace and automotive applications.

The scalability of laboratory-developed composites to industrial production represents a persistent challenge. Many promising materials demonstrate excellent shielding properties at small scales but encounter significant performance degradation when manufactured using conventional industrial processes. This scale-up gap hinders technology transfer from research to commercial applications.

Existing EMI Shielding Composite Solutions

01 Carbon-based conductive fillers for EMI shielding

Carbon-based materials such as carbon nanotubes, graphene, and carbon black can be incorporated into polymer matrices to create conductive composites with excellent EMI shielding properties. These carbon fillers create conductive networks within the composite that can effectively absorb and reflect electromagnetic radiation. The high aspect ratio of carbon nanotubes and graphene sheets particularly enhances the formation of conductive pathways at lower loading levels, resulting in lightweight composites with superior shielding effectiveness.- Carbon-based conductive fillers for EMI shielding: Carbon-based materials such as carbon nanotubes, graphene, and carbon black can be incorporated into polymer matrices to create conductive composites with excellent EMI shielding properties. These carbon fillers create conductive networks within the composite that can effectively absorb and reflect electromagnetic radiation. The high aspect ratio of carbon nanotubes and graphene sheets enables effective shielding at lower loading levels, maintaining the mechanical properties of the composite while providing superior EMI protection.

- Metal-based conductive composites for EMI shielding: Metal particles, fibers, and meshes can be incorporated into polymer matrices to create effective EMI shielding materials. These metal-based composites typically utilize copper, silver, nickel, or aluminum as conductive fillers. The metal particles create conductive pathways that reflect and absorb electromagnetic radiation. These composites can be designed with varying metal content to achieve specific shielding effectiveness levels for different applications, from consumer electronics to military equipment.

- Multilayer composite structures for enhanced EMI shielding: Multilayer composite structures can be designed to provide enhanced EMI shielding through the combination of different materials with complementary properties. These structures typically include conductive layers for reflection and absorption of electromagnetic waves, separated by insulating or absorbing layers. The multilayer approach allows for optimization of both shielding effectiveness and other properties such as weight, thickness, and mechanical strength, making these composites suitable for applications in aerospace, automotive, and portable electronics.

- Conductive polymer composites for flexible EMI shielding: Intrinsically conductive polymers or polymer composites with conductive fillers can be formulated to create flexible EMI shielding materials. These materials combine the processability and flexibility of polymers with the electrical conductivity needed for EMI shielding. Conductive polymers such as polyaniline, polypyrrole, and PEDOT:PSS can be used alone or in combination with other conductive fillers to achieve the desired shielding effectiveness while maintaining flexibility, making them ideal for applications requiring conformable shielding solutions.

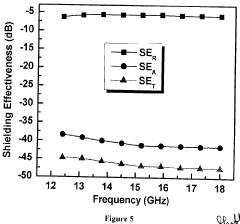

- Testing and measurement methods for EMI shielding effectiveness: Various testing and measurement methods are employed to evaluate the EMI shielding effectiveness of conductive composites. These include standardized techniques such as the shielded room method, coaxial transmission line method, and free-space method. Advanced characterization techniques can measure parameters such as reflection loss, absorption loss, and total shielding effectiveness across different frequency ranges. These measurements are crucial for validating the performance of EMI shielding materials and ensuring they meet the requirements for specific applications in electronics, telecommunications, and defense sectors.

02 Metal-based conductive composites for EMI shielding

Metal particles, fibers, and meshes can be incorporated into polymer matrices to create effective EMI shielding materials. These metal-based composites typically utilize copper, aluminum, silver, or nickel as conductive fillers. The metal components create a conductive network that reflects and absorbs electromagnetic radiation. These composites can be designed with varying metal content to achieve specific shielding effectiveness levels for different applications, from consumer electronics to military equipment.Expand Specific Solutions03 Multilayer composite structures for enhanced EMI shielding

Multilayer composite structures can be designed to provide enhanced EMI shielding through the combination of different materials with complementary properties. These structures typically include conductive layers for reflection and absorption of electromagnetic waves, separated by insulating or absorbing layers. The layered approach allows for optimization of both shielding effectiveness and other properties such as mechanical strength, flexibility, and thermal management. This design strategy is particularly effective for applications requiring high-performance EMI shielding across a broad frequency range.Expand Specific Solutions04 Polymer-based conductive composites with specialized additives

Polymer matrices can be enhanced with specialized additives to create conductive composites with improved EMI shielding properties. These additives include conductive polymers, ionic compounds, and hybrid organic-inorganic materials that can improve the dispersion of conductive fillers or contribute directly to conductivity. The polymer matrix provides flexibility, processability, and environmental resistance while the additives create the conductive pathways necessary for EMI shielding. These composites can be tailored for specific applications by selecting appropriate polymer types and additive combinations.Expand Specific Solutions05 Testing and measurement methods for EMI shielding effectiveness

Various testing and measurement techniques are employed to evaluate the EMI shielding effectiveness of conductive composites. These methods include network analyzer measurements, shielded room testing, and specialized fixtures that can quantify the ability of materials to attenuate electromagnetic radiation across different frequency ranges. Advanced characterization techniques also examine the relationship between material structure, conductivity, and shielding performance. These testing protocols are essential for validating shielding performance and ensuring that composites meet the requirements for specific applications in electronics, telecommunications, and other industries.Expand Specific Solutions

Key Industry Players in Conductive Composites

The EMI shielding effectiveness of conductive composites market is currently in a growth phase, with increasing demand driven by electronics miniaturization and electromagnetic pollution concerns. The global market size is expanding rapidly, projected to reach significant valuation due to applications in electronics, automotive, and aerospace industries. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include established corporations like 3M Innovative Properties, Henkel AG, Laird Technologies, and Samsung Electronics, who possess extensive patent portfolios and manufacturing capabilities. Academic institutions such as University of Science & Technology Beijing and Indian Institute of Science contribute significant research advancements. The competitive landscape features collaboration between material manufacturers and electronics companies to develop next-generation shielding solutions with improved performance-to-weight ratios.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced EMI shielding composites utilizing their proprietary microreplication technology to create precisely structured conductive materials. Their EMI shielding portfolio includes conductive adhesives with uniformly dispersed metal particles (silver, nickel, copper) in acrylic and epoxy matrices, achieving shielding effectiveness of 60-90 dB across 1-10 GHz frequency ranges. 3M's innovation extends to their development of carbon-based composites incorporating graphene and carbon nanotubes (CNTs) that provide lightweight alternatives to metal-filled systems. Their patented manufacturing process ensures homogeneous dispersion of conductive fillers at optimized loading levels, balancing conductivity with mechanical properties. 3M has also pioneered hybrid shielding materials combining multiple conductive fillers (metal particles with carbon nanostructures) to create synergistic effects that enhance shielding performance while reducing overall filler content.

Strengths: Excellent adhesion properties combined with high shielding effectiveness; versatile form factors including films, tapes, and moldable compounds. Weaknesses: Some formulations show performance degradation in high-humidity environments; higher cost compared to conventional metal shielding solutions.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed innovative conductive composite materials under their BERGQUIST and LOCTITE brands specifically engineered for EMI shielding applications. Their technology focuses on silver-filled epoxy systems that provide both thermal management and EMI shielding capabilities, achieving shielding effectiveness of 50-85 dB across frequencies from 100 MHz to 6 GHz. Henkel's proprietary manufacturing process ensures uniform dispersion of conductive particles within the polymer matrix while maintaining processability for various application methods including screen printing, dispensing, and stencil printing. Their recent innovations include development of hybrid filler systems combining silver flakes with carbon nanostructures to reduce silver content while maintaining shielding performance. Henkel has also pioneered reworkable EMI shielding materials that allow for component repair and replacement without compromising the integrity of the shielding system, particularly valuable in high-reliability electronics applications.

Strengths: Dual functionality providing both thermal management and EMI shielding; excellent adhesion to various substrate materials including FR4, aluminum, and ceramics. Weaknesses: Higher cost due to silver content; potential for silver migration in high-humidity environments if not properly formulated with migration inhibitors.

Critical Patents in Conductive Composite Shielding

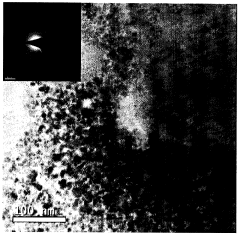

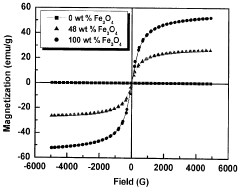

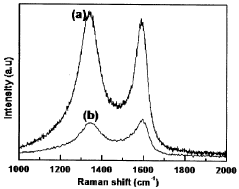

Electromagnetic interference (EMI) shielding nanocomposites with enhanced absorption based on superparamagnetic particles decorated porous carbon

PatentActiveIN2754DEL2013A

Innovation

- Superparamagnetic nanoparticles decorated porous carbon nano composites are created, combining electrical conductivity, magnetic properties, and porosity to achieve improved EMI shielding through a combination of magnetic losses and multiple reflection losses, with a method involving surfactant-capped nanoparticles and specific processing steps to achieve 10-60 weight % loading.

Environmental Impact and Sustainability Factors

The environmental impact of conductive composites for EMI shielding applications represents a critical consideration in their development and implementation. Traditional EMI shielding materials often rely on heavy metals like nickel, copper, and silver, which pose significant environmental concerns regarding resource depletion, energy-intensive mining operations, and end-of-life disposal challenges. Conductive composites offer promising alternatives that can potentially reduce these environmental burdens while maintaining effective shielding performance.

Manufacturing processes for conductive composites typically consume less energy compared to conventional metal-based shielding solutions. Carbon-based fillers such as graphene, carbon nanotubes, and carbon black derive from more abundant resources and generally require lower processing temperatures than metal extraction and purification. This translates to reduced carbon footprints across the production lifecycle, with some studies indicating up to 30-40% reduction in greenhouse gas emissions compared to traditional metal shielding materials.

Waste management represents another crucial sustainability factor. Conductive polymer composites can be designed with recyclability in mind, incorporating thermoplastic matrices that allow for material recovery and reprocessing. This contrasts sharply with metal-plated plastics or metal foils that often end up in landfills due to difficulties in separating the conductive and non-conductive components. Recent advances in biodegradable conductive polymers further enhance end-of-life sustainability options.

Water usage and toxicity concerns also favor conductive composites over traditional metal-based solutions. Metal plating processes typically involve hazardous chemicals and generate contaminated wastewater requiring extensive treatment. In contrast, many conductive composite manufacturing methods employ water-based or solvent-free approaches, significantly reducing both water consumption and the release of harmful substances into the environment.

Lightweight characteristics of conductive composites contribute to sustainability in transportation applications. When used in automotive or aerospace industries, the weight reduction compared to metal shielding can lead to improved fuel efficiency and reduced emissions throughout the product lifecycle. Studies suggest that for every 10% reduction in vehicle weight, fuel consumption decreases by approximately 6-8%.

Regulatory frameworks increasingly emphasize environmental considerations, with directives like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) limiting the use of certain metals and chemicals in electronic applications. Conductive composites formulated with environmentally benign materials offer manufacturers compliance advantages while avoiding potential future restrictions on materials of concern.

Manufacturing processes for conductive composites typically consume less energy compared to conventional metal-based shielding solutions. Carbon-based fillers such as graphene, carbon nanotubes, and carbon black derive from more abundant resources and generally require lower processing temperatures than metal extraction and purification. This translates to reduced carbon footprints across the production lifecycle, with some studies indicating up to 30-40% reduction in greenhouse gas emissions compared to traditional metal shielding materials.

Waste management represents another crucial sustainability factor. Conductive polymer composites can be designed with recyclability in mind, incorporating thermoplastic matrices that allow for material recovery and reprocessing. This contrasts sharply with metal-plated plastics or metal foils that often end up in landfills due to difficulties in separating the conductive and non-conductive components. Recent advances in biodegradable conductive polymers further enhance end-of-life sustainability options.

Water usage and toxicity concerns also favor conductive composites over traditional metal-based solutions. Metal plating processes typically involve hazardous chemicals and generate contaminated wastewater requiring extensive treatment. In contrast, many conductive composite manufacturing methods employ water-based or solvent-free approaches, significantly reducing both water consumption and the release of harmful substances into the environment.

Lightweight characteristics of conductive composites contribute to sustainability in transportation applications. When used in automotive or aerospace industries, the weight reduction compared to metal shielding can lead to improved fuel efficiency and reduced emissions throughout the product lifecycle. Studies suggest that for every 10% reduction in vehicle weight, fuel consumption decreases by approximately 6-8%.

Regulatory frameworks increasingly emphasize environmental considerations, with directives like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) limiting the use of certain metals and chemicals in electronic applications. Conductive composites formulated with environmentally benign materials offer manufacturers compliance advantages while avoiding potential future restrictions on materials of concern.

Standards and Testing Methodologies

The evaluation of EMI shielding effectiveness in conductive composites requires standardized testing methodologies to ensure reliable and comparable results across different materials and applications. The IEEE Standard 299 serves as a fundamental framework for measuring the effectiveness of electromagnetic shielding enclosures, providing guidelines for frequency ranges from 9 kHz to 18 GHz. This standard has been widely adopted by researchers and industries to establish baseline performance metrics for conductive composite materials.

ASTM D4935 represents another critical standard specifically designed for planar materials, employing a coaxial transmission line method that allows for precise measurement of thin sheet materials. This methodology is particularly valuable for conductive composites, as it accommodates the evaluation of flexible and rigid samples with thicknesses typically ranging from 0.1 to 3 mm, covering frequencies from 30 MHz to 1.5 GHz.

For higher frequency applications, the MIL-STD-285 provides comprehensive testing protocols that extend beyond 18 GHz, addressing the growing demand for shielding solutions in advanced electronic systems and telecommunications. These standards collectively establish a robust framework for quantitative assessment of shielding performance.

Testing methodologies for conductive composites generally fall into three categories: far-field testing, near-field testing, and transmission line techniques. Far-field testing utilizes anechoic chambers where samples are positioned between transmitting and receiving antennas, allowing for free-space measurements that closely simulate real-world electromagnetic environments. This approach, while resource-intensive, provides highly accurate data for large-scale applications.

Near-field testing employs specialized probes positioned in close proximity to the sample surface, enabling detailed mapping of localized shielding characteristics. This method proves invaluable for identifying potential weak points in composite structures and understanding the spatial distribution of shielding effectiveness.

Transmission line techniques, including waveguide and coaxial methods, offer controlled impedance environments for precise measurements across specific frequency bands. The nested reverberation chamber method has emerged as an advanced technique for evaluating complex geometries and assembled components, providing statistical averaging that minimizes measurement uncertainties associated with directional variations in shielding performance.

Recent developments in testing methodologies have focused on addressing the unique challenges presented by emerging conductive composites, including the development of specialized fixtures for nanocomposites and the implementation of in-situ monitoring techniques that track shielding performance under mechanical stress or environmental exposure.

ASTM D4935 represents another critical standard specifically designed for planar materials, employing a coaxial transmission line method that allows for precise measurement of thin sheet materials. This methodology is particularly valuable for conductive composites, as it accommodates the evaluation of flexible and rigid samples with thicknesses typically ranging from 0.1 to 3 mm, covering frequencies from 30 MHz to 1.5 GHz.

For higher frequency applications, the MIL-STD-285 provides comprehensive testing protocols that extend beyond 18 GHz, addressing the growing demand for shielding solutions in advanced electronic systems and telecommunications. These standards collectively establish a robust framework for quantitative assessment of shielding performance.

Testing methodologies for conductive composites generally fall into three categories: far-field testing, near-field testing, and transmission line techniques. Far-field testing utilizes anechoic chambers where samples are positioned between transmitting and receiving antennas, allowing for free-space measurements that closely simulate real-world electromagnetic environments. This approach, while resource-intensive, provides highly accurate data for large-scale applications.

Near-field testing employs specialized probes positioned in close proximity to the sample surface, enabling detailed mapping of localized shielding characteristics. This method proves invaluable for identifying potential weak points in composite structures and understanding the spatial distribution of shielding effectiveness.

Transmission line techniques, including waveguide and coaxial methods, offer controlled impedance environments for precise measurements across specific frequency bands. The nested reverberation chamber method has emerged as an advanced technique for evaluating complex geometries and assembled components, providing statistical averaging that minimizes measurement uncertainties associated with directional variations in shielding performance.

Recent developments in testing methodologies have focused on addressing the unique challenges presented by emerging conductive composites, including the development of specialized fixtures for nanocomposites and the implementation of in-situ monitoring techniques that track shielding performance under mechanical stress or environmental exposure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!