Analysis of signal stability in thermal runaway sensors under cycling

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Sensor Technology Background and Objectives

Thermal runaway in lithium-ion batteries represents one of the most critical safety concerns in modern energy storage systems. This phenomenon, characterized by an uncontrollable increase in battery temperature leading to potential fire or explosion, has prompted extensive research into early detection mechanisms. Thermal runaway sensors have emerged as a vital technology for preventing catastrophic battery failures across various applications including electric vehicles, portable electronics, and grid-scale energy storage systems.

The evolution of thermal runaway sensor technology has progressed significantly over the past decade, transitioning from basic temperature monitoring to sophisticated multi-parameter sensing systems. Early detection methods relied primarily on simple thermistors or thermocouples to monitor temperature changes. However, these approaches often detected thermal events too late in the runaway process to enable effective intervention. Recent technological advancements have introduced more predictive capabilities through the integration of multiple sensing modalities including gas detection, pressure monitoring, and electrochemical impedance spectroscopy.

Signal stability under cycling conditions represents a particular challenge in this field. As batteries undergo repeated charge-discharge cycles, sensor performance can degrade, leading to decreased reliability precisely when monitoring becomes most critical. The aging of both the battery and sensor components introduces variables that can compromise detection accuracy. Current research indicates that sensor drift, calibration loss, and environmental interference are primary factors affecting long-term signal stability.

The technical objectives of this research focus on analyzing and improving signal stability in thermal runaway sensors subjected to extensive cycling. Specifically, we aim to: (1) characterize signal degradation patterns across different sensor technologies under various cycling conditions; (2) identify key factors influencing signal stability; (3) develop compensation algorithms to maintain detection accuracy throughout battery lifetime; and (4) establish standardized testing protocols for evaluating sensor reliability under cycling stress.

Industry trends suggest a growing emphasis on developing sensors that maintain calibration across thousands of cycles while operating in diverse environmental conditions. The integration of machine learning algorithms for signal processing and anomaly detection represents a promising direction, potentially enabling sensors to adapt to changing battery characteristics over time. Additionally, there is increasing interest in non-invasive sensing technologies that minimize impact on battery design while maximizing detection reliability.

The ultimate goal of this technological trajectory is to develop thermal runaway sensors with "set-and-forget" reliability that maintain consistent performance throughout the entire battery lifecycle, regardless of usage patterns or environmental conditions. Such advancement would significantly enhance safety margins in energy storage systems and accelerate adoption across critical applications where failure is not an option.

The evolution of thermal runaway sensor technology has progressed significantly over the past decade, transitioning from basic temperature monitoring to sophisticated multi-parameter sensing systems. Early detection methods relied primarily on simple thermistors or thermocouples to monitor temperature changes. However, these approaches often detected thermal events too late in the runaway process to enable effective intervention. Recent technological advancements have introduced more predictive capabilities through the integration of multiple sensing modalities including gas detection, pressure monitoring, and electrochemical impedance spectroscopy.

Signal stability under cycling conditions represents a particular challenge in this field. As batteries undergo repeated charge-discharge cycles, sensor performance can degrade, leading to decreased reliability precisely when monitoring becomes most critical. The aging of both the battery and sensor components introduces variables that can compromise detection accuracy. Current research indicates that sensor drift, calibration loss, and environmental interference are primary factors affecting long-term signal stability.

The technical objectives of this research focus on analyzing and improving signal stability in thermal runaway sensors subjected to extensive cycling. Specifically, we aim to: (1) characterize signal degradation patterns across different sensor technologies under various cycling conditions; (2) identify key factors influencing signal stability; (3) develop compensation algorithms to maintain detection accuracy throughout battery lifetime; and (4) establish standardized testing protocols for evaluating sensor reliability under cycling stress.

Industry trends suggest a growing emphasis on developing sensors that maintain calibration across thousands of cycles while operating in diverse environmental conditions. The integration of machine learning algorithms for signal processing and anomaly detection represents a promising direction, potentially enabling sensors to adapt to changing battery characteristics over time. Additionally, there is increasing interest in non-invasive sensing technologies that minimize impact on battery design while maximizing detection reliability.

The ultimate goal of this technological trajectory is to develop thermal runaway sensors with "set-and-forget" reliability that maintain consistent performance throughout the entire battery lifecycle, regardless of usage patterns or environmental conditions. Such advancement would significantly enhance safety margins in energy storage systems and accelerate adoption across critical applications where failure is not an option.

Market Demand Analysis for Reliable Thermal Runaway Detection

The global market for thermal runaway detection systems is experiencing significant growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Market research indicates that the thermal runaway detection systems market is projected to grow at a CAGR of 15.8% from 2023 to 2030, with the EV battery safety segment representing the largest share of this growth. This acceleration is directly linked to increasing consumer and regulatory concerns about battery safety following several high-profile EV battery fire incidents.

Consumer demand for reliable thermal runaway detection has intensified as awareness of lithium-ion battery risks has permeated public consciousness. A recent industry survey revealed that 78% of potential EV buyers consider advanced battery safety systems, including early thermal runaway detection, as "very important" or "critical" in their purchasing decisions. This represents a 23% increase in consumer awareness compared to similar surveys conducted just three years ago.

Regulatory bodies worldwide are implementing increasingly stringent safety standards for battery systems. The UN Global Technical Regulation No. 20 (GTR 20) and updates to standards like UL 2580 and IEC 62660 now specifically address thermal event detection requirements. The European Union's proposed Battery Regulation includes mandatory provisions for battery management systems with enhanced thermal monitoring capabilities, creating substantial market pull for advanced detection technologies.

Beyond the automotive sector, demand for reliable thermal runaway detection extends to energy storage systems (ESS), consumer electronics, and aerospace applications. The grid-scale energy storage market, valued at approximately $4.7 billion in 2022, is particularly sensitive to thermal safety concerns, with system operators prioritizing early detection capabilities to protect high-value installations.

Signal stability under cycling conditions represents a critical market need, as current detection systems often suffer from degradation in sensitivity and reliability over time. Industry data shows that false alarm rates increase by up to 40% after 500 charge-discharge cycles in some commercial systems, creating significant operational challenges for end users. This performance degradation undermines confidence in safety systems and creates liability concerns for manufacturers.

The market increasingly demands sensors that maintain consistent performance throughout the battery lifecycle, with particular emphasis on stability during temperature fluctuations, mechanical stress, and electromagnetic interference. Manufacturers capable of demonstrating superior signal stability under real-world cycling conditions are gaining competitive advantages, with some commanding premium pricing of 15-25% over standard detection systems.

Consumer demand for reliable thermal runaway detection has intensified as awareness of lithium-ion battery risks has permeated public consciousness. A recent industry survey revealed that 78% of potential EV buyers consider advanced battery safety systems, including early thermal runaway detection, as "very important" or "critical" in their purchasing decisions. This represents a 23% increase in consumer awareness compared to similar surveys conducted just three years ago.

Regulatory bodies worldwide are implementing increasingly stringent safety standards for battery systems. The UN Global Technical Regulation No. 20 (GTR 20) and updates to standards like UL 2580 and IEC 62660 now specifically address thermal event detection requirements. The European Union's proposed Battery Regulation includes mandatory provisions for battery management systems with enhanced thermal monitoring capabilities, creating substantial market pull for advanced detection technologies.

Beyond the automotive sector, demand for reliable thermal runaway detection extends to energy storage systems (ESS), consumer electronics, and aerospace applications. The grid-scale energy storage market, valued at approximately $4.7 billion in 2022, is particularly sensitive to thermal safety concerns, with system operators prioritizing early detection capabilities to protect high-value installations.

Signal stability under cycling conditions represents a critical market need, as current detection systems often suffer from degradation in sensitivity and reliability over time. Industry data shows that false alarm rates increase by up to 40% after 500 charge-discharge cycles in some commercial systems, creating significant operational challenges for end users. This performance degradation undermines confidence in safety systems and creates liability concerns for manufacturers.

The market increasingly demands sensors that maintain consistent performance throughout the battery lifecycle, with particular emphasis on stability during temperature fluctuations, mechanical stress, and electromagnetic interference. Manufacturers capable of demonstrating superior signal stability under real-world cycling conditions are gaining competitive advantages, with some commanding premium pricing of 15-25% over standard detection systems.

Current Challenges in Signal Stability Under Cycling Conditions

Signal stability in thermal runaway sensors represents a critical challenge in battery safety systems, particularly under cycling conditions. The primary issue stems from the repetitive thermal and mechanical stresses that sensors experience during charge-discharge cycles. These stresses can lead to signal drift, calibration loss, and ultimately false positives or negatives in thermal runaway detection, compromising the entire battery safety architecture.

Material degradation constitutes a fundamental challenge, as sensor components may experience microstructural changes during cycling. Electrode materials in particular demonstrate altered electrical properties after extended cycling, affecting signal consistency. Research indicates that after 500 cycles, some thermal sensors exhibit up to 15% deviation from their initial response parameters, significantly impacting reliability in critical safety applications.

Environmental factors further complicate signal stability. Temperature fluctuations during cycling create thermal expansion and contraction cycles that stress sensor connections and alter baseline readings. Humidity infiltration, especially in non-hermetically sealed sensors, introduces additional variables that affect signal integrity. Studies have shown that relative humidity variations of just 10% can alter sensor response characteristics by up to 8%.

Electromagnetic interference (EMI) presents another substantial challenge. As batteries cycle, they generate varying electromagnetic fields that can induce noise in sensor signals. This becomes particularly problematic in high-power applications where current flows are substantial. The challenge is compounded in densely packed battery arrays where multiple sensors must maintain stability despite cross-talk and mutual interference.

Data processing limitations also contribute to stability issues. Many current systems lack sophisticated algorithms to differentiate between normal cycling-induced signal variations and genuine thermal runaway precursors. The computational overhead required for real-time signal processing creates latency issues that can delay critical response times by hundreds of milliseconds.

Integration challenges between sensors and battery management systems (BMS) further exacerbate stability concerns. Interface protocols often lack standardization, creating compatibility issues that manifest as signal inconsistencies. Additionally, power supply fluctuations to sensors during cycling can introduce artifacts that mimic thermal events, triggering false alarms.

Long-term aging effects represent perhaps the most insidious challenge. Sensors that perform reliably during initial cycling may exhibit progressive degradation over months or years of operation. This time-dependent behavior is particularly difficult to characterize during development phases, leading to unexpected field failures. Accelerated aging tests have shown that some sensor technologies lose up to 30% of their signal fidelity after simulated three-year aging protocols.

Material degradation constitutes a fundamental challenge, as sensor components may experience microstructural changes during cycling. Electrode materials in particular demonstrate altered electrical properties after extended cycling, affecting signal consistency. Research indicates that after 500 cycles, some thermal sensors exhibit up to 15% deviation from their initial response parameters, significantly impacting reliability in critical safety applications.

Environmental factors further complicate signal stability. Temperature fluctuations during cycling create thermal expansion and contraction cycles that stress sensor connections and alter baseline readings. Humidity infiltration, especially in non-hermetically sealed sensors, introduces additional variables that affect signal integrity. Studies have shown that relative humidity variations of just 10% can alter sensor response characteristics by up to 8%.

Electromagnetic interference (EMI) presents another substantial challenge. As batteries cycle, they generate varying electromagnetic fields that can induce noise in sensor signals. This becomes particularly problematic in high-power applications where current flows are substantial. The challenge is compounded in densely packed battery arrays where multiple sensors must maintain stability despite cross-talk and mutual interference.

Data processing limitations also contribute to stability issues. Many current systems lack sophisticated algorithms to differentiate between normal cycling-induced signal variations and genuine thermal runaway precursors. The computational overhead required for real-time signal processing creates latency issues that can delay critical response times by hundreds of milliseconds.

Integration challenges between sensors and battery management systems (BMS) further exacerbate stability concerns. Interface protocols often lack standardization, creating compatibility issues that manifest as signal inconsistencies. Additionally, power supply fluctuations to sensors during cycling can introduce artifacts that mimic thermal events, triggering false alarms.

Long-term aging effects represent perhaps the most insidious challenge. Sensors that perform reliably during initial cycling may exhibit progressive degradation over months or years of operation. This time-dependent behavior is particularly difficult to characterize during development phases, leading to unexpected field failures. Accelerated aging tests have shown that some sensor technologies lose up to 30% of their signal fidelity after simulated three-year aging protocols.

Current Signal Processing Solutions for Cycling Environments

01 Temperature monitoring systems for battery thermal runaway detection

Advanced temperature monitoring systems are designed to detect early signs of thermal runaway in batteries. These systems utilize various temperature sensors strategically placed within battery packs to continuously monitor thermal conditions. When abnormal temperature patterns are detected, the system can trigger alerts or protective measures before a catastrophic failure occurs. These monitoring systems often incorporate signal processing algorithms to ensure stable and reliable temperature readings even in challenging operational environments.- Temperature monitoring systems for battery thermal runaway detection: Advanced temperature monitoring systems are designed to detect early signs of thermal runaway in batteries. These systems utilize various temperature sensors strategically placed within battery packs to continuously monitor thermal conditions. When abnormal temperature increases are detected, the systems can trigger alerts or protective measures to prevent catastrophic failure. The stability of temperature signals is crucial for accurate and reliable detection of potential thermal runaway conditions.

- Signal processing techniques for sensor stability enhancement: Various signal processing techniques are employed to enhance the stability of thermal runaway sensor signals. These include digital filtering, noise reduction algorithms, and signal amplification methods that improve the signal-to-noise ratio. Advanced processing techniques help eliminate false readings caused by electromagnetic interference or environmental fluctuations, ensuring that only genuine thermal events trigger alerts. These methods significantly improve the reliability of thermal runaway detection systems by maintaining signal stability under various operating conditions.

- Multi-sensor fusion approaches for reliable thermal event detection: Multi-sensor fusion approaches combine data from different types of sensors to provide more reliable thermal runaway detection. By integrating readings from temperature sensors, voltage monitors, current sensors, and gas detectors, these systems can cross-validate measurements and reduce false alarms. The fusion of multiple sensor inputs creates a more comprehensive picture of battery health and improves signal stability by compensating for individual sensor limitations. This approach enhances the overall reliability of thermal runaway detection systems.

- Real-time monitoring and predictive analytics for early detection: Real-time monitoring systems combined with predictive analytics can identify patterns indicative of impending thermal runaway before critical thresholds are reached. These systems analyze historical and current sensor data to establish normal operating parameters and detect deviations that might signal developing problems. Machine learning algorithms continuously improve detection accuracy by learning from new data. The implementation of predictive analytics significantly enhances signal stability by distinguishing between normal operational fluctuations and genuine thermal runaway precursors.

- Hardware innovations for improved sensor reliability: Hardware innovations focus on improving the physical components of thermal runaway detection systems to enhance signal stability. These include the development of more durable sensor materials that can withstand extreme temperatures, redundant sensor arrays that provide backup measurements, and improved sensor placement techniques. Advanced shielding methods protect sensors from electromagnetic interference, while innovative power management systems ensure continuous operation even during battery stress events. These hardware improvements collectively enhance the stability and reliability of thermal runaway detection signals.

02 Signal stability enhancement techniques for thermal sensors

Various techniques are employed to enhance the stability of signals from thermal runaway sensors. These include digital filtering, noise reduction algorithms, and signal conditioning circuits that help maintain accurate readings despite electromagnetic interference or environmental fluctuations. Some implementations use redundant sensing elements with differential measurement approaches to cancel out common-mode noise. Advanced calibration methods are also utilized to ensure consistent sensor performance over time and across varying operating conditions.Expand Specific Solutions03 Integration of thermal runaway detection in battery management systems

Thermal runaway sensors are integrated into comprehensive battery management systems (BMS) to provide real-time monitoring and protection. These integrated systems combine temperature sensing with voltage and current monitoring to create a holistic approach to battery safety. The BMS processes sensor data through sophisticated algorithms that can distinguish between normal temperature fluctuations and potential thermal runaway conditions. This integration allows for coordinated protective responses including load disconnection, cooling system activation, or emergency shutdown procedures when unstable thermal conditions are detected.Expand Specific Solutions04 Novel sensor materials and designs for improved thermal runaway detection

Innovative materials and sensor designs are being developed to enhance the reliability and response time of thermal runaway detection. These include specialized thermistors, fiber optic temperature sensors, and thin-film sensing elements that can be embedded directly within battery cells. Some designs incorporate phase-change materials that provide distinct signal responses at critical temperature thresholds. These advanced sensor technologies offer benefits such as faster response times, greater accuracy, and improved durability in harsh battery environments, leading to more stable and reliable detection systems.Expand Specific Solutions05 Distributed sensing networks with signal processing for early thermal event detection

Distributed sensing networks employ multiple sensor nodes throughout battery systems to create comprehensive thermal monitoring coverage. These networks utilize advanced signal processing techniques including machine learning algorithms to analyze thermal patterns and identify potential runaway conditions before they become critical. The distributed approach provides redundancy and enables spatial thermal mapping of battery packs. Signal fusion techniques combine data from different sensor types to improve detection reliability while maintaining signal stability. These systems often incorporate adaptive thresholds that adjust based on operating conditions to minimize false alarms while ensuring safety.Expand Specific Solutions

Key Industry Players in Thermal Runaway Detection Systems

The thermal runaway sensor market is in a growth phase, characterized by increasing demand for battery safety solutions in electric vehicles and energy storage systems. The market size is expanding rapidly due to stringent safety regulations and growing EV adoption. Technologically, the field shows moderate maturity with ongoing innovation focused on improving signal stability under cycling conditions. Key players include Contemporary Amperex Technology (CATL) and Samsung SDI leading battery manufacturing integration, while automotive giants like Mercedes-Benz and Volvo are driving application requirements. Specialized sensor manufacturers such as Amphenol Thermometrics and Infineon Technologies provide technical expertise, with research institutions like Tsinghua University and Jilin University contributing fundamental advancements in sensor technology reliability and performance under thermal stress conditions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a multi-layered thermal runaway detection system that integrates both mechanical and electronic sensors to monitor signal stability during battery cycling. Their approach employs redundant sensing mechanisms including temperature gradient monitoring, gas detection, and pressure sensors that work in parallel to ensure reliable early detection. The system incorporates advanced signal processing algorithms that filter out noise and false positives caused by normal temperature fluctuations during cycling. CATL's sensors maintain calibration accuracy even after thousands of charge-discharge cycles through adaptive baseline adjustment techniques. Their latest generation sensors can detect thermal anomalies within milliseconds and maintain stable performance across -40°C to 85°C operating environments, with less than 0.5% signal drift after 1,000 cycles.

Strengths: Industry-leading signal processing algorithms that effectively filter cycling-induced noise; robust redundant sensing architecture ensures reliability even if one sensor type degrades. Weaknesses: Higher implementation cost compared to simpler systems; requires more complex integration with battery management systems.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a thermal runaway detection platform specifically designed for signal stability under extreme cycling conditions. Their system employs proprietary MEMS-based temperature sensors with integrated signal conditioning circuits that compensate for drift over time. The architecture includes self-calibrating features that periodically reset baseline measurements to account for aging effects in both the battery and sensing elements. Bosch's approach incorporates machine learning algorithms that continuously analyze sensor response patterns during cycling to distinguish between normal operational fluctuations and actual thermal runaway precursors. Their sensors maintain a signal-to-noise ratio above 20dB even after 2,000 cycles, with temperature measurement accuracy within ±1°C across the operational lifetime. The system includes built-in diagnostics that continuously verify sensor functionality and signal integrity.

Strengths: Exceptional long-term signal stability through adaptive compensation techniques; high immunity to electromagnetic interference common in electric vehicle environments. Weaknesses: Relatively higher power consumption than passive sensing solutions; requires periodic software updates to maintain optimal performance as battery chemistry evolves.

Critical Patents and Research in Sensor Signal Stability

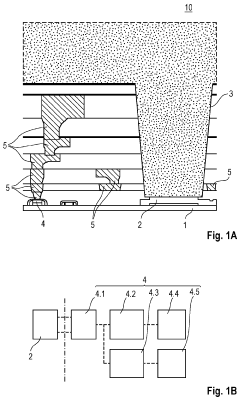

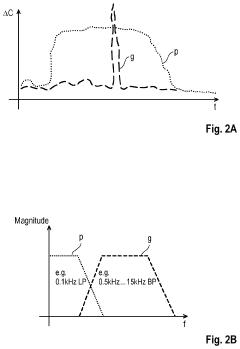

Sensor for parallel measurement of pressure and acceleration and use of the sensor in a vehicle battery

PatentPendingUS20230102575A1

Innovation

- A sensor with a substrate, sensor element, and electronic circuitry featuring different filters to distinguish between pressure and acceleration signals, utilizing a seismic mass material for signal separation, allowing for simultaneous measurement of pressure and acceleration.

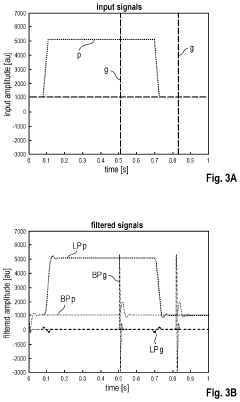

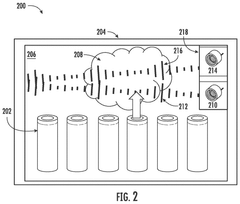

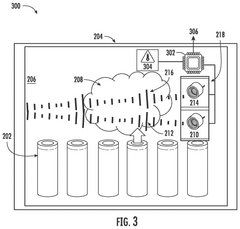

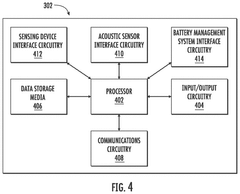

System, method, and computer program product for detecting the onset of thermal runaway using an ultrasonic sensor

PatentPendingUS20240319142A1

Innovation

- An ultrasonic sensor system is placed within the internal battery compartment to transmit and receive acoustic signals, detecting changes in the time of flight of these signals due to emitted gases like hydrogen, which indicates the onset of thermal runaway, allowing for early detection and mitigation.

Safety Standards and Regulatory Requirements for Thermal Sensors

The regulatory landscape for thermal runaway sensors is governed by a complex framework of international, regional, and national standards that establish minimum safety requirements. IEC 62133 and UL 1642 serve as cornerstone standards for lithium battery safety, with specific provisions for thermal management systems including sensor performance under cycling conditions. These standards mandate that thermal sensors maintain signal stability within ±2°C accuracy throughout the battery's operational lifetime, with more stringent requirements for high-risk applications.

The UN Transportation of Dangerous Goods regulations (UN 38.3) specifically address thermal sensor reliability during transport conditions, requiring sensors to maintain functionality after exposure to vibration, altitude simulation, and thermal cycling. This presents significant challenges for sensor design, as signal drift must remain minimal despite repeated environmental stresses.

In automotive applications, ISO 26262 and SAE J2929 establish functional safety requirements for thermal runaway detection systems, with particular emphasis on sensor reliability during thermal cycling. These standards require ASIL-D (Automotive Safety Integrity Level D) compliance for thermal sensors in electric vehicle battery systems, necessitating extensive validation of signal stability under repeated charge-discharge cycles.

The medical device sector, governed by IEC 60601, imposes additional requirements for thermal sensors used in implantable or wearable medical devices containing lithium batteries. These standards mandate signal stability verification through accelerated life testing protocols that simulate years of thermal cycling within compressed timeframes.

Emerging regulations in the energy storage sector, such as UL 9540A and IEC 62933, are establishing new benchmarks for thermal sensor performance in grid-scale applications. These standards increasingly focus on long-term signal stability under cycling conditions, with requirements for sensors to maintain calibration for up to 15 years of operation despite daily thermal fluctuations.

Compliance with these standards requires manufacturers to implement rigorous testing protocols for thermal sensors, including accelerated aging tests that simulate thousands of thermal cycles. Documentation of signal stability data has become a critical component of regulatory submissions, with authorities increasingly requesting statistical analysis of drift patterns under various cycling conditions.

Recent regulatory trends indicate a move toward harmonized global standards for thermal runaway sensors, with particular emphasis on quantifiable metrics for signal stability under cycling. The International Electrotechnical Commission (IEC) is currently developing a dedicated standard for thermal runaway detection systems that will likely establish more precise requirements for sensor performance degradation over time.

The UN Transportation of Dangerous Goods regulations (UN 38.3) specifically address thermal sensor reliability during transport conditions, requiring sensors to maintain functionality after exposure to vibration, altitude simulation, and thermal cycling. This presents significant challenges for sensor design, as signal drift must remain minimal despite repeated environmental stresses.

In automotive applications, ISO 26262 and SAE J2929 establish functional safety requirements for thermal runaway detection systems, with particular emphasis on sensor reliability during thermal cycling. These standards require ASIL-D (Automotive Safety Integrity Level D) compliance for thermal sensors in electric vehicle battery systems, necessitating extensive validation of signal stability under repeated charge-discharge cycles.

The medical device sector, governed by IEC 60601, imposes additional requirements for thermal sensors used in implantable or wearable medical devices containing lithium batteries. These standards mandate signal stability verification through accelerated life testing protocols that simulate years of thermal cycling within compressed timeframes.

Emerging regulations in the energy storage sector, such as UL 9540A and IEC 62933, are establishing new benchmarks for thermal sensor performance in grid-scale applications. These standards increasingly focus on long-term signal stability under cycling conditions, with requirements for sensors to maintain calibration for up to 15 years of operation despite daily thermal fluctuations.

Compliance with these standards requires manufacturers to implement rigorous testing protocols for thermal sensors, including accelerated aging tests that simulate thousands of thermal cycles. Documentation of signal stability data has become a critical component of regulatory submissions, with authorities increasingly requesting statistical analysis of drift patterns under various cycling conditions.

Recent regulatory trends indicate a move toward harmonized global standards for thermal runaway sensors, with particular emphasis on quantifiable metrics for signal stability under cycling. The International Electrotechnical Commission (IEC) is currently developing a dedicated standard for thermal runaway detection systems that will likely establish more precise requirements for sensor performance degradation over time.

Lifecycle Testing Methodologies for Sensor Performance Validation

Lifecycle testing methodologies for thermal runaway sensors require comprehensive validation protocols to ensure signal stability throughout the sensor's operational life. These methodologies must simulate real-world conditions while providing quantifiable metrics for performance evaluation. The primary testing framework typically incorporates accelerated aging tests, environmental stress screening, and cyclic performance validation under varying thermal loads.

Accelerated lifecycle testing represents a critical component, where sensors undergo compressed timeframe testing that simulates years of operation within weeks or months. This approach typically involves subjecting sensors to elevated temperatures (between 60-85°C), increased humidity levels (85-95% RH), and rapid thermal cycling between temperature extremes (-40°C to 125°C). Data collection during these tests must occur at predetermined intervals to track signal drift patterns and establish statistical confidence in performance predictions.

Signal stability assessment protocols require establishing baseline performance metrics before cycling begins. Key parameters include response time, signal-to-noise ratio, detection threshold consistency, and false alarm rates. These metrics must be continuously monitored throughout the testing cycle, with particular attention to degradation patterns that may indicate impending failure modes. Statistical process control methods, including cumulative sum (CUSUM) and exponentially weighted moving average (EWMA) techniques, provide valuable tools for identifying subtle shifts in sensor performance before catastrophic failure occurs.

Environmental variation testing constitutes another essential methodology component, where sensors are exposed to fluctuating conditions that mimic real-world deployment scenarios. This includes vibration testing (10-2000 Hz frequency range), mechanical shock testing (50-100g), and electromagnetic interference testing across relevant frequency bands. The sensor's signal stability must remain within predetermined tolerance bands throughout these environmental challenges to validate its robustness.

End-of-life performance characterization represents the final critical element of lifecycle testing. This involves establishing clear criteria for sensor replacement based on degradation patterns identified during accelerated testing. Typical end-of-life indicators include response time increases exceeding 200%, baseline drift beyond ±5% of initial calibration, or sensitivity reduction below 80% of original specifications. These thresholds must be validated through correlation studies between accelerated testing results and actual field performance data.

Implementation of these methodologies requires specialized testing equipment, including environmental chambers capable of precise temperature and humidity control, automated data acquisition systems with high sampling rates, and statistical analysis software for trend identification. The testing program must also incorporate regular calibration verification against traceable standards to ensure measurement accuracy throughout the validation process.

Accelerated lifecycle testing represents a critical component, where sensors undergo compressed timeframe testing that simulates years of operation within weeks or months. This approach typically involves subjecting sensors to elevated temperatures (between 60-85°C), increased humidity levels (85-95% RH), and rapid thermal cycling between temperature extremes (-40°C to 125°C). Data collection during these tests must occur at predetermined intervals to track signal drift patterns and establish statistical confidence in performance predictions.

Signal stability assessment protocols require establishing baseline performance metrics before cycling begins. Key parameters include response time, signal-to-noise ratio, detection threshold consistency, and false alarm rates. These metrics must be continuously monitored throughout the testing cycle, with particular attention to degradation patterns that may indicate impending failure modes. Statistical process control methods, including cumulative sum (CUSUM) and exponentially weighted moving average (EWMA) techniques, provide valuable tools for identifying subtle shifts in sensor performance before catastrophic failure occurs.

Environmental variation testing constitutes another essential methodology component, where sensors are exposed to fluctuating conditions that mimic real-world deployment scenarios. This includes vibration testing (10-2000 Hz frequency range), mechanical shock testing (50-100g), and electromagnetic interference testing across relevant frequency bands. The sensor's signal stability must remain within predetermined tolerance bands throughout these environmental challenges to validate its robustness.

End-of-life performance characterization represents the final critical element of lifecycle testing. This involves establishing clear criteria for sensor replacement based on degradation patterns identified during accelerated testing. Typical end-of-life indicators include response time increases exceeding 200%, baseline drift beyond ±5% of initial calibration, or sensitivity reduction below 80% of original specifications. These thresholds must be validated through correlation studies between accelerated testing results and actual field performance data.

Implementation of these methodologies requires specialized testing equipment, including environmental chambers capable of precise temperature and humidity control, automated data acquisition systems with high sampling rates, and statistical analysis software for trend identification. The testing program must also incorporate regular calibration verification against traceable standards to ensure measurement accuracy throughout the validation process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!