Thermal runaway sensors with wireless monitoring capabilities

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Detection Technology Background and Objectives

Thermal runaway is a critical safety concern in lithium-ion battery systems, characterized by an uncontrollable, self-accelerating exothermic reaction that can lead to catastrophic battery failure, fires, and explosions. The development of thermal runaway detection technology has evolved significantly over the past decade, driven by the exponential growth in battery applications across electric vehicles, renewable energy storage systems, and portable electronics.

Early detection methods relied primarily on basic temperature monitoring, which often proved insufficient for timely intervention. The technological evolution progressed through several generations, from simple thermistors to more sophisticated multi-parameter sensing systems that monitor temperature gradients, gas emissions, and electrical parameters simultaneously.

The integration of wireless capabilities into thermal runaway detection systems represents a significant advancement in this field. Wireless monitoring enables real-time data transmission, remote diagnostics, and immediate alert systems that can significantly reduce response times during critical thermal events. This capability is particularly valuable in large-scale battery installations where wired solutions present logistical challenges and increased points of failure.

Current research objectives in thermal runaway detection with wireless monitoring capabilities focus on several key areas. First, enhancing the sensitivity and reliability of early detection mechanisms to identify precursors to thermal runaway before critical thresholds are reached. Second, developing low-power consumption sensors that can operate autonomously for extended periods without maintenance. Third, improving the robustness of wireless communication protocols to ensure reliable data transmission even in electromagnetically noisy environments typical of industrial settings.

Another significant objective is the miniaturization of sensor technology to enable integration directly within battery cells or modules without compromising battery performance or lifespan. This in-situ approach offers the potential for more accurate and earlier detection compared to external monitoring systems.

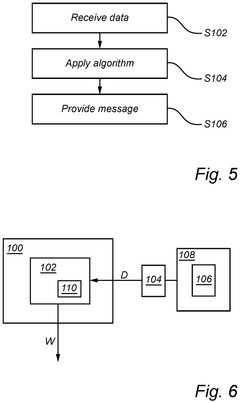

The development of advanced algorithms for data analysis represents another crucial research direction. Machine learning and artificial intelligence approaches are being explored to identify subtle patterns in sensor data that may indicate impending thermal events, potentially hours or days before conventional detection methods would trigger an alert.

Standardization efforts are also underway to establish industry-wide protocols for thermal runaway detection systems, ensuring interoperability between different manufacturers' components and facilitating wider adoption across various applications. These standards aim to define minimum performance requirements, testing methodologies, and communication protocols for wireless monitoring systems.

The ultimate goal of this technological development is to create a comprehensive safety ecosystem that can predict, prevent, and mitigate thermal runaway events across all lithium-ion battery applications, significantly reducing the risk of catastrophic failures and enhancing public confidence in battery technology.

Early detection methods relied primarily on basic temperature monitoring, which often proved insufficient for timely intervention. The technological evolution progressed through several generations, from simple thermistors to more sophisticated multi-parameter sensing systems that monitor temperature gradients, gas emissions, and electrical parameters simultaneously.

The integration of wireless capabilities into thermal runaway detection systems represents a significant advancement in this field. Wireless monitoring enables real-time data transmission, remote diagnostics, and immediate alert systems that can significantly reduce response times during critical thermal events. This capability is particularly valuable in large-scale battery installations where wired solutions present logistical challenges and increased points of failure.

Current research objectives in thermal runaway detection with wireless monitoring capabilities focus on several key areas. First, enhancing the sensitivity and reliability of early detection mechanisms to identify precursors to thermal runaway before critical thresholds are reached. Second, developing low-power consumption sensors that can operate autonomously for extended periods without maintenance. Third, improving the robustness of wireless communication protocols to ensure reliable data transmission even in electromagnetically noisy environments typical of industrial settings.

Another significant objective is the miniaturization of sensor technology to enable integration directly within battery cells or modules without compromising battery performance or lifespan. This in-situ approach offers the potential for more accurate and earlier detection compared to external monitoring systems.

The development of advanced algorithms for data analysis represents another crucial research direction. Machine learning and artificial intelligence approaches are being explored to identify subtle patterns in sensor data that may indicate impending thermal events, potentially hours or days before conventional detection methods would trigger an alert.

Standardization efforts are also underway to establish industry-wide protocols for thermal runaway detection systems, ensuring interoperability between different manufacturers' components and facilitating wider adoption across various applications. These standards aim to define minimum performance requirements, testing methodologies, and communication protocols for wireless monitoring systems.

The ultimate goal of this technological development is to create a comprehensive safety ecosystem that can predict, prevent, and mitigate thermal runaway events across all lithium-ion battery applications, significantly reducing the risk of catastrophic failures and enhancing public confidence in battery technology.

Market Demand Analysis for Wireless Thermal Runaway Monitoring

The global market for wireless thermal runaway monitoring systems is experiencing significant growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption and large-scale energy storage systems. Current market analysis indicates that the demand for these monitoring solutions is expected to grow at a compound annual growth rate of over 25% through 2030, reflecting the critical importance of battery safety in emerging clean energy technologies.

The primary market segments demonstrating strong demand include automotive manufacturers, grid-scale energy storage providers, consumer electronics producers, and aerospace applications. Among these, the EV sector represents the largest and fastest-growing segment, with manufacturers increasingly recognizing thermal runaway detection as a non-negotiable safety feature rather than a premium option.

Market research reveals that consumer concerns about battery safety significantly impact purchasing decisions, with 78% of potential EV buyers citing battery safety as a "very important" consideration. This consumer sentiment is reinforced by high-profile thermal runaway incidents that have resulted in costly recalls and reputational damage for manufacturers who failed to implement adequate monitoring systems.

Regulatory frameworks are evolving rapidly to address these safety concerns. Several major markets, including the European Union, China, and parts of North America, are developing or have implemented standards that effectively mandate advanced thermal monitoring capabilities in electric vehicles and stationary energy storage systems. These regulatory developments are accelerating market adoption beyond what organic demand would dictate.

From a geographical perspective, Asia-Pacific currently dominates the market due to its leadership in battery manufacturing and electric vehicle production. However, North American and European markets are showing the highest growth rates as their EV adoption accelerates and energy storage deployments expand.

The market demonstrates strong price sensitivity at the consumer level but relatively inelastic demand at the manufacturer level, where the cost of monitoring systems is minimal compared to the potential liability and recall costs associated with thermal runaway events. This dynamic creates a favorable environment for technology providers who can deliver reliable, cost-effective solutions.

Industry surveys indicate that wireless capabilities represent a significant value-add, with system integrators willing to pay premium prices for solutions that eliminate the complexity and failure points associated with wired monitoring systems. The ability to retrofit existing battery systems with wireless monitoring technology also represents a substantial secondary market opportunity, particularly for fleet operators and energy storage asset owners.

The primary market segments demonstrating strong demand include automotive manufacturers, grid-scale energy storage providers, consumer electronics producers, and aerospace applications. Among these, the EV sector represents the largest and fastest-growing segment, with manufacturers increasingly recognizing thermal runaway detection as a non-negotiable safety feature rather than a premium option.

Market research reveals that consumer concerns about battery safety significantly impact purchasing decisions, with 78% of potential EV buyers citing battery safety as a "very important" consideration. This consumer sentiment is reinforced by high-profile thermal runaway incidents that have resulted in costly recalls and reputational damage for manufacturers who failed to implement adequate monitoring systems.

Regulatory frameworks are evolving rapidly to address these safety concerns. Several major markets, including the European Union, China, and parts of North America, are developing or have implemented standards that effectively mandate advanced thermal monitoring capabilities in electric vehicles and stationary energy storage systems. These regulatory developments are accelerating market adoption beyond what organic demand would dictate.

From a geographical perspective, Asia-Pacific currently dominates the market due to its leadership in battery manufacturing and electric vehicle production. However, North American and European markets are showing the highest growth rates as their EV adoption accelerates and energy storage deployments expand.

The market demonstrates strong price sensitivity at the consumer level but relatively inelastic demand at the manufacturer level, where the cost of monitoring systems is minimal compared to the potential liability and recall costs associated with thermal runaway events. This dynamic creates a favorable environment for technology providers who can deliver reliable, cost-effective solutions.

Industry surveys indicate that wireless capabilities represent a significant value-add, with system integrators willing to pay premium prices for solutions that eliminate the complexity and failure points associated with wired monitoring systems. The ability to retrofit existing battery systems with wireless monitoring technology also represents a substantial secondary market opportunity, particularly for fleet operators and energy storage asset owners.

Current State and Challenges in Thermal Runaway Sensing

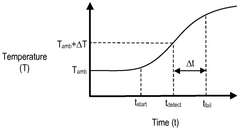

Thermal runaway sensing technology has evolved significantly over the past decade, with current systems employing various detection methods including temperature monitoring, gas sensing, voltage/current analysis, and impedance tracking. Temperature-based detection remains the most widely implemented approach, utilizing thermistors, thermocouples, and infrared sensors strategically placed within battery packs. However, these conventional methods often suffer from delayed response times and limited accuracy in predicting early-stage thermal events.

The global landscape of thermal runaway sensing technology shows regional variations in development focus. North American research institutions and companies primarily concentrate on advanced algorithm development for early detection, while Asian manufacturers, particularly in China, Japan, and South Korea, lead in sensor miniaturization and mass production capabilities. European entities have made significant contributions to safety standards and system integration approaches.

A critical challenge facing current thermal runaway sensing systems is the trade-off between sensitivity and false alarm rates. Highly sensitive systems can detect thermal anomalies earlier but may generate excessive false positives, while less sensitive systems reduce false alarms but potentially miss critical early warning signs. This balance remains a significant technical hurdle for widespread adoption.

Wireless monitoring capabilities, while advancing rapidly, still face substantial technical barriers. Current wireless sensors struggle with power consumption issues, as continuous monitoring and data transmission deplete battery resources quickly. Signal reliability within the electromagnetic-shielded environment of battery enclosures presents another major obstacle, with metal casings and dense cell arrangements creating significant interference.

Data processing represents another frontier challenge. The volume of sensor data generated by comprehensive monitoring systems requires sophisticated algorithms to filter noise, identify patterns, and trigger appropriate responses. Edge computing solutions are emerging but remain limited by the processing capabilities that can be integrated into compact battery management systems.

Standardization across the industry presents a non-technical but equally important challenge. The lack of unified protocols for thermal runaway detection thresholds, communication formats, and emergency response procedures hampers interoperability between systems from different manufacturers and complicates regulatory compliance efforts.

Cost considerations continue to constrain widespread implementation, particularly in consumer electronics and entry-level electric vehicles. Current high-precision wireless monitoring systems with comprehensive coverage can add significant expense to battery pack production, creating market resistance despite the clear safety benefits they provide.

The global landscape of thermal runaway sensing technology shows regional variations in development focus. North American research institutions and companies primarily concentrate on advanced algorithm development for early detection, while Asian manufacturers, particularly in China, Japan, and South Korea, lead in sensor miniaturization and mass production capabilities. European entities have made significant contributions to safety standards and system integration approaches.

A critical challenge facing current thermal runaway sensing systems is the trade-off between sensitivity and false alarm rates. Highly sensitive systems can detect thermal anomalies earlier but may generate excessive false positives, while less sensitive systems reduce false alarms but potentially miss critical early warning signs. This balance remains a significant technical hurdle for widespread adoption.

Wireless monitoring capabilities, while advancing rapidly, still face substantial technical barriers. Current wireless sensors struggle with power consumption issues, as continuous monitoring and data transmission deplete battery resources quickly. Signal reliability within the electromagnetic-shielded environment of battery enclosures presents another major obstacle, with metal casings and dense cell arrangements creating significant interference.

Data processing represents another frontier challenge. The volume of sensor data generated by comprehensive monitoring systems requires sophisticated algorithms to filter noise, identify patterns, and trigger appropriate responses. Edge computing solutions are emerging but remain limited by the processing capabilities that can be integrated into compact battery management systems.

Standardization across the industry presents a non-technical but equally important challenge. The lack of unified protocols for thermal runaway detection thresholds, communication formats, and emergency response procedures hampers interoperability between systems from different manufacturers and complicates regulatory compliance efforts.

Cost considerations continue to constrain widespread implementation, particularly in consumer electronics and entry-level electric vehicles. Current high-precision wireless monitoring systems with comprehensive coverage can add significant expense to battery pack production, creating market resistance despite the clear safety benefits they provide.

Current Wireless Sensor Network Solutions for Thermal Runaway

01 Wireless sensor networks for thermal runaway detection

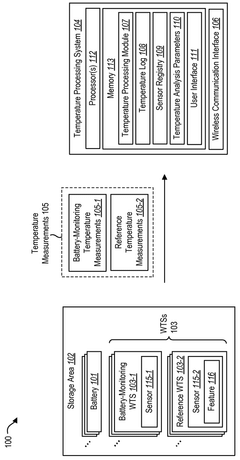

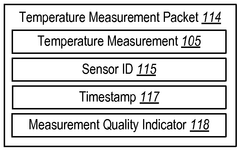

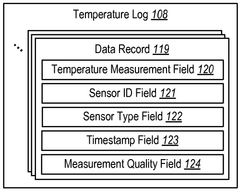

Wireless sensor networks can be deployed to monitor battery systems for early signs of thermal runaway. These networks consist of multiple sensors that communicate wirelessly to a central monitoring system, allowing for real-time data collection and analysis. The sensors can detect temperature changes, gas emissions, and other parameters indicative of potential thermal runaway conditions, enabling timely intervention to prevent catastrophic failures.- Wireless sensor networks for thermal runaway detection: Wireless sensor networks can be deployed to monitor battery systems for thermal runaway conditions. These networks consist of multiple sensors that communicate wirelessly to a central monitoring system, allowing for real-time detection of temperature anomalies across battery arrays. The wireless nature enables flexible installation in various battery configurations without complex wiring, while providing continuous monitoring capabilities for early detection of potential thermal events.

- IoT-based monitoring systems with cloud integration: Internet of Things (IoT) platforms integrated with thermal sensors enable comprehensive monitoring of battery systems with cloud-based data analytics. These systems collect temperature and other relevant parameters from battery cells, transmit the data wirelessly to cloud servers, and employ advanced algorithms to analyze patterns indicating potential thermal runaway. The cloud integration allows for remote access to monitoring data, automated alerts, and historical performance analysis to identify degradation trends before critical failures occur.

- Multi-parameter sensing technologies for early warning: Advanced thermal runaway detection systems incorporate multiple sensing parameters beyond temperature, such as gas detection, pressure monitoring, and voltage/current analysis. These multi-parameter sensors work together to provide a more comprehensive assessment of battery health, enabling earlier detection of thermal runaway precursors. The combined data from different sensor types is transmitted wirelessly to monitoring systems that use fusion algorithms to improve detection accuracy and reduce false alarms.

- Energy-efficient wireless communication protocols: Specialized low-power wireless communication protocols are implemented in thermal runaway monitoring systems to extend battery life of the sensors themselves. These protocols optimize data transmission frequency based on detected risk levels, using techniques such as adaptive sampling rates and sleep modes during normal operation. The energy efficiency enables long-term deployment of wireless sensors without frequent maintenance, while still ensuring reliable communication during critical events.

- AI-enhanced predictive analytics for thermal event prevention: Artificial intelligence and machine learning algorithms are integrated with wireless monitoring systems to predict thermal runaway events before they occur. These systems analyze patterns in sensor data over time to identify subtle indicators of battery degradation or impending failure. The predictive capabilities allow for preventive maintenance and intervention before critical thermal events develop, while continuous learning improves detection accuracy as more data is collected from the wireless sensor network.

02 IoT-based monitoring systems for battery safety

Internet of Things (IoT) technology enables comprehensive monitoring of battery systems through wireless connectivity. These systems integrate various sensors with cloud-based platforms for data storage, analysis, and remote access. IoT-based monitoring solutions provide real-time alerts and notifications when abnormal conditions are detected, allowing for predictive maintenance and enhanced safety measures. The wireless capabilities enable monitoring of battery systems in diverse locations and environments.Expand Specific Solutions03 Advanced sensor technologies for early thermal runaway detection

Advanced sensor technologies have been developed specifically for early detection of thermal runaway conditions. These include temperature sensors, gas sensors, voltage monitors, and impedance measurement devices that can detect subtle changes indicating potential battery failure. The sensors are designed to be highly sensitive and capable of detecting precursor events before thermal runaway occurs, providing critical time for preventive actions. These technologies can be integrated into wireless monitoring systems for comprehensive battery safety management.Expand Specific Solutions04 Battery management systems with wireless communication capabilities

Battery management systems (BMS) with integrated wireless communication capabilities provide comprehensive monitoring and control of battery systems. These systems continuously monitor parameters such as temperature, voltage, and current, and can wirelessly transmit this data to control centers or mobile devices. The wireless functionality enables remote diagnostics, firmware updates, and system configuration without physical access to the battery installation, enhancing operational efficiency and safety management.Expand Specific Solutions05 Energy-efficient wireless monitoring solutions for long-term deployment

Energy-efficient wireless monitoring solutions have been developed for long-term deployment in battery systems. These solutions utilize low-power wireless communication protocols and intelligent power management techniques to extend battery life of the monitoring devices themselves. Advanced algorithms optimize data transmission frequency based on detected risk levels, reducing power consumption during normal operation while ensuring rapid response during potential thermal runaway events. These energy-efficient designs enable continuous monitoring without frequent maintenance or battery replacement.Expand Specific Solutions

Key Industry Players in Wireless Thermal Monitoring Solutions

The thermal runaway sensor market with wireless monitoring capabilities is in a growth phase, driven by increasing electric vehicle adoption and energy storage system deployments. The market is expanding rapidly with an estimated value exceeding $1 billion by 2025. Leading players include established industrial giants like Bosch, Honeywell, and Renesas Electronics, alongside battery specialists such as CATL and Samsung SDI. Tesla and automotive manufacturers including Mercedes-Benz and Volvo are integrating these technologies into their vehicles. State Grid Corporation of China and NARI Technology are advancing grid-scale applications, while research institutions like Johns Hopkins University contribute to technological innovation. The technology is maturing quickly, with companies developing increasingly sophisticated sensors featuring real-time monitoring, predictive analytics, and wireless communication capabilities to prevent catastrophic battery failures.

Tesla, Inc.

Technical Solution: Tesla has pioneered a comprehensive thermal runaway detection system that combines multiple sensing technologies with wireless monitoring capabilities. Their approach utilizes a distributed network of thermistors, voltage sensors, and gas detectors embedded throughout the battery pack. These sensors communicate wirelessly via a proprietary low-energy protocol to Tesla's Battery Management System (BMS). The system employs predictive analytics to identify thermal anomalies before they escalate to critical levels, with claimed detection capabilities up to 5-7 minutes before visible thermal events occur. Tesla's wireless monitoring architecture incorporates redundant communication pathways and operates on multiple frequency bands to ensure reliability. The system is integrated with Tesla's over-the-air update infrastructure, allowing for continuous improvement of detection algorithms based on fleet-wide data collection. Tesla has also developed specialized sensor fusion techniques that combine temperature readings with voltage fluctuations and gas detection to minimize false positives while maximizing early detection capabilities.

Strengths: Comprehensive integration with vehicle systems allowing for automated emergency responses, extensive real-world validation across millions of miles of driving data, and continuous improvement through over-the-air updates. Weaknesses: Closed ecosystem that limits interoperability with third-party safety systems, relatively high component costs, and potential for communication latency in areas with electromagnetic interference.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed an innovative thermal runaway detection system called "Cell Sentinel" that incorporates wireless monitoring capabilities specifically designed for high-energy density battery applications. The system employs a network of miniaturized temperature sensors and gas detectors embedded at the cell level, connected through a proprietary wireless mesh network operating on the 2.4GHz band. Samsung's approach features ultra-low-power sensor nodes that can operate for the entire battery lifetime without requiring separate power sources, drawing minimal current from the cells they monitor. The wireless architecture utilizes a time-synchronized channel hopping protocol to ensure reliable communication even in electromagnetically noisy environments. Samsung's system incorporates advanced thermal modeling algorithms that can predict thermal runaway events up to 8 minutes before critical temperature thresholds are reached. The Cell Sentinel technology integrates with Samsung's battery management system to enable automated safety responses, including circuit isolation, emergency cooling activation, and controlled discharge procedures when potential thermal events are detected.

Strengths: Extremely long sensor operational life without maintenance, sophisticated predictive algorithms with high accuracy rates, and minimal impact on battery energy density. Weaknesses: Limited compatibility with non-Samsung battery management systems, higher initial cost compared to conventional thermal monitoring solutions, and potential for wireless interference in densely packed battery installations.

Core Sensing Technologies and Communication Protocols Analysis

Passive detection of thermal runaway using acoustic waves

PatentPendingEP4517915A1

Innovation

- A computer system utilizing processing circuitry to receive sensing data from sensors detecting sound waves emitted from electrical energy storage cells, applying a machine learning algorithm to predict thermal runaway events by analyzing acoustic waves generated from gas bubbles.

Systems and methods for monitoring thermal conditions of batteries in a storage area

PatentWO2025125710A1

Innovation

- The implementation of wireless temperature sensors (WTS) to monitor the thermal conditions of batteries in real-time, with a system that compares battery-monitoring temperature measurements to reference and previous measurements to initiate preventive actions when thresholds are exceeded.

Safety Standards and Regulatory Compliance Requirements

The regulatory landscape for thermal runaway sensors with wireless monitoring capabilities is governed by a complex framework of international, regional, and industry-specific standards. IEC 62133 and UL 1642 serve as foundational standards for battery safety, establishing baseline requirements for thermal management systems including sensor integration. These standards mandate specific temperature thresholds and response times that wireless thermal runaway detection systems must meet to achieve certification.

For wireless communication aspects, compliance with electromagnetic compatibility standards such as IEC 61000 series is essential, particularly addressing potential interference issues in critical environments like electric vehicles and energy storage facilities. The FCC regulations in the United States and CE marking requirements in Europe impose additional constraints on wireless transmission frequencies, power levels, and data security protocols for these monitoring systems.

UN 38.3 testing requirements for lithium battery transportation have recently been updated to specifically address thermal runaway monitoring capabilities, requiring demonstration of early detection functionality under simulated transport conditions. This has significant implications for sensor design and integration, particularly for systems intended for global distribution.

Industry-specific standards introduce further complexity, with automotive applications governed by ISO 26262 functional safety requirements and UL 2580 for electric vehicle batteries. These standards increasingly emphasize real-time monitoring capabilities with specific performance metrics for wireless communication reliability under thermal stress conditions. The energy storage sector follows IEC 62619 and NFPA 855, which have been revised to incorporate specific provisions for remote thermal monitoring systems.

Emerging regulatory trends indicate a move toward mandatory implementation of thermal runaway detection with wireless alert capabilities in certain high-risk applications. China's GB/T 36276 standard has pioneered this approach, requiring all large-scale energy storage installations to incorporate remote thermal monitoring with specific performance parameters. Similar requirements are under consideration in the European Union's Battery Directive revision and California's energy storage system regulations.

Compliance testing methodologies are evolving to address the unique challenges of wireless monitoring systems, with particular focus on communication reliability under extreme temperature conditions and electromagnetic interference scenarios. Test protocols increasingly evaluate not only sensor accuracy but also data transmission integrity during simulated thermal events, creating new validation challenges for manufacturers.

For wireless communication aspects, compliance with electromagnetic compatibility standards such as IEC 61000 series is essential, particularly addressing potential interference issues in critical environments like electric vehicles and energy storage facilities. The FCC regulations in the United States and CE marking requirements in Europe impose additional constraints on wireless transmission frequencies, power levels, and data security protocols for these monitoring systems.

UN 38.3 testing requirements for lithium battery transportation have recently been updated to specifically address thermal runaway monitoring capabilities, requiring demonstration of early detection functionality under simulated transport conditions. This has significant implications for sensor design and integration, particularly for systems intended for global distribution.

Industry-specific standards introduce further complexity, with automotive applications governed by ISO 26262 functional safety requirements and UL 2580 for electric vehicle batteries. These standards increasingly emphasize real-time monitoring capabilities with specific performance metrics for wireless communication reliability under thermal stress conditions. The energy storage sector follows IEC 62619 and NFPA 855, which have been revised to incorporate specific provisions for remote thermal monitoring systems.

Emerging regulatory trends indicate a move toward mandatory implementation of thermal runaway detection with wireless alert capabilities in certain high-risk applications. China's GB/T 36276 standard has pioneered this approach, requiring all large-scale energy storage installations to incorporate remote thermal monitoring with specific performance parameters. Similar requirements are under consideration in the European Union's Battery Directive revision and California's energy storage system regulations.

Compliance testing methodologies are evolving to address the unique challenges of wireless monitoring systems, with particular focus on communication reliability under extreme temperature conditions and electromagnetic interference scenarios. Test protocols increasingly evaluate not only sensor accuracy but also data transmission integrity during simulated thermal events, creating new validation challenges for manufacturers.

Energy Storage Integration and System Reliability Assessment

The integration of thermal runaway sensors with wireless monitoring capabilities into energy storage systems represents a critical advancement in ensuring the safety and reliability of these increasingly vital infrastructures. Battery energy storage systems (BESS) are being deployed at unprecedented scales across utility, commercial, and residential applications, making their safe operation paramount. Thermal runaway events, while rare, pose catastrophic risks including fire, explosion, and toxic gas release that can result in significant property damage, environmental contamination, and potential loss of life.

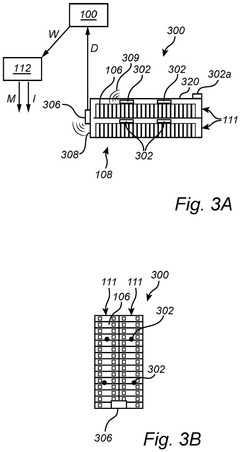

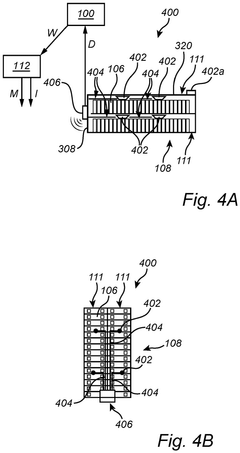

Wireless thermal runaway sensors can be strategically integrated at multiple levels within energy storage systems. At the cell level, these sensors provide the earliest possible detection of anomalous temperature increases, allowing for intervention before propagation occurs. Module-level integration offers a balance between granular monitoring and system complexity, while pack-level deployment provides overall thermal profile monitoring with reduced implementation costs.

System reliability assessment methodologies must evolve to incorporate these wireless monitoring capabilities into their frameworks. Traditional reliability metrics such as Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) can be significantly improved through real-time wireless monitoring data. Predictive reliability models can leverage continuous temperature data streams to forecast potential failure points before they manifest as critical issues.

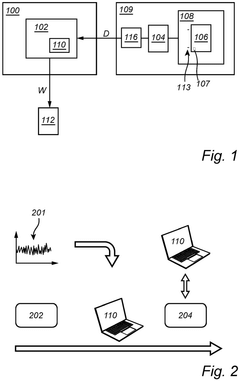

The integration architecture typically involves a multi-tiered approach where wireless sensors communicate with local gateways, which then relay data to centralized monitoring systems. This architecture must be designed with redundancy pathways to ensure monitoring continues even if primary communication channels fail. Power considerations for wireless sensors remain challenging, with options ranging from long-life batteries to energy harvesting technologies that capture ambient vibration or thermal gradient energy.

Reliability assessment must also consider the sensors themselves as potential points of failure. False positives can trigger unnecessary emergency responses and system shutdowns, while false negatives could allow dangerous conditions to develop undetected. Therefore, comprehensive system reliability assessment must include sensor validation protocols, regular calibration schedules, and degradation monitoring of the sensors over their operational lifetime.

The economic impact of integrating wireless thermal runaway monitoring must be evaluated against the risk mitigation benefits. While adding monitoring capabilities increases initial capital expenditure, the long-term operational benefits include extended system lifetime, reduced insurance premiums, and most importantly, prevention of catastrophic failures that could otherwise result in substantial financial losses and reputational damage.

Wireless thermal runaway sensors can be strategically integrated at multiple levels within energy storage systems. At the cell level, these sensors provide the earliest possible detection of anomalous temperature increases, allowing for intervention before propagation occurs. Module-level integration offers a balance between granular monitoring and system complexity, while pack-level deployment provides overall thermal profile monitoring with reduced implementation costs.

System reliability assessment methodologies must evolve to incorporate these wireless monitoring capabilities into their frameworks. Traditional reliability metrics such as Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) can be significantly improved through real-time wireless monitoring data. Predictive reliability models can leverage continuous temperature data streams to forecast potential failure points before they manifest as critical issues.

The integration architecture typically involves a multi-tiered approach where wireless sensors communicate with local gateways, which then relay data to centralized monitoring systems. This architecture must be designed with redundancy pathways to ensure monitoring continues even if primary communication channels fail. Power considerations for wireless sensors remain challenging, with options ranging from long-life batteries to energy harvesting technologies that capture ambient vibration or thermal gradient energy.

Reliability assessment must also consider the sensors themselves as potential points of failure. False positives can trigger unnecessary emergency responses and system shutdowns, while false negatives could allow dangerous conditions to develop undetected. Therefore, comprehensive system reliability assessment must include sensor validation protocols, regular calibration schedules, and degradation monitoring of the sensors over their operational lifetime.

The economic impact of integrating wireless thermal runaway monitoring must be evaluated against the risk mitigation benefits. While adding monitoring capabilities increases initial capital expenditure, the long-term operational benefits include extended system lifetime, reduced insurance premiums, and most importantly, prevention of catastrophic failures that could otherwise result in substantial financial losses and reputational damage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!