Research on multiparameter detection in thermal runaway sensors

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Sensor Technology Background and Objectives

Thermal runaway in lithium-ion batteries represents one of the most significant safety challenges in modern energy storage systems. This phenomenon, characterized by an uncontrolled increase in battery temperature leading to potential fire or explosion, has been documented across various applications from consumer electronics to electric vehicles and grid-scale energy storage. The evolution of thermal runaway sensor technology has progressed significantly over the past decade, transitioning from simple temperature monitoring to sophisticated multi-parameter detection systems.

Historically, thermal runaway detection relied primarily on single-parameter monitoring, typically temperature or voltage. However, research has demonstrated that thermal runaway is a complex cascade of electrochemical reactions that manifests through multiple physical and chemical indicators. This understanding has driven the technological evolution toward integrated sensing approaches that can detect precursor signals well before catastrophic failure occurs.

The current technological trajectory focuses on developing sensors capable of simultaneously monitoring multiple parameters including temperature gradients, gas emissions, pressure changes, and electrochemical impedance. This multi-parameter approach provides a more comprehensive picture of battery health and significantly improves early warning capabilities. Recent advancements in materials science and miniaturization have enabled the integration of multiple sensing modalities into compact form factors suitable for implementation in commercial battery systems.

Market demands for safer energy storage solutions, coupled with increasingly stringent regulatory requirements, have accelerated research in this field. The electric vehicle industry, in particular, has emerged as a primary driver for innovation, as thermal runaway events in high-capacity automotive batteries present substantial safety risks and potential liability concerns. Additionally, the growing deployment of stationary energy storage systems in residential and commercial settings has further emphasized the need for reliable thermal runaway detection.

The primary technical objective in this field is to develop sensor systems that can detect thermal runaway precursors with sufficient lead time to enable preventive measures. This includes creating sensors with high sensitivity, rapid response times, and minimal false positives. Secondary objectives include developing sensors that are cost-effective for mass production, physically robust for integration into battery packs, and capable of operating reliably throughout the battery lifecycle.

Looking forward, the field is moving toward predictive analytics that combine real-time multi-parameter sensor data with machine learning algorithms to forecast potential thermal runaway events before traditional warning signs appear. This predictive capability represents the next frontier in battery safety technology, potentially enabling proactive intervention strategies that could fundamentally transform battery safety management.

Historically, thermal runaway detection relied primarily on single-parameter monitoring, typically temperature or voltage. However, research has demonstrated that thermal runaway is a complex cascade of electrochemical reactions that manifests through multiple physical and chemical indicators. This understanding has driven the technological evolution toward integrated sensing approaches that can detect precursor signals well before catastrophic failure occurs.

The current technological trajectory focuses on developing sensors capable of simultaneously monitoring multiple parameters including temperature gradients, gas emissions, pressure changes, and electrochemical impedance. This multi-parameter approach provides a more comprehensive picture of battery health and significantly improves early warning capabilities. Recent advancements in materials science and miniaturization have enabled the integration of multiple sensing modalities into compact form factors suitable for implementation in commercial battery systems.

Market demands for safer energy storage solutions, coupled with increasingly stringent regulatory requirements, have accelerated research in this field. The electric vehicle industry, in particular, has emerged as a primary driver for innovation, as thermal runaway events in high-capacity automotive batteries present substantial safety risks and potential liability concerns. Additionally, the growing deployment of stationary energy storage systems in residential and commercial settings has further emphasized the need for reliable thermal runaway detection.

The primary technical objective in this field is to develop sensor systems that can detect thermal runaway precursors with sufficient lead time to enable preventive measures. This includes creating sensors with high sensitivity, rapid response times, and minimal false positives. Secondary objectives include developing sensors that are cost-effective for mass production, physically robust for integration into battery packs, and capable of operating reliably throughout the battery lifecycle.

Looking forward, the field is moving toward predictive analytics that combine real-time multi-parameter sensor data with machine learning algorithms to forecast potential thermal runaway events before traditional warning signs appear. This predictive capability represents the next frontier in battery safety technology, potentially enabling proactive intervention strategies that could fundamentally transform battery safety management.

Market Demand Analysis for Multiparameter Detection Systems

The global market for multiparameter detection systems in thermal runaway sensors is experiencing robust growth, driven primarily by the rapid expansion of electric vehicle (EV) production and energy storage systems. Current market estimates value this segment at approximately 2.3 billion USD in 2023, with projections indicating a compound annual growth rate of 18.7% through 2030. This accelerated growth reflects the increasing recognition of battery safety as a critical concern across multiple industries.

The automotive sector represents the largest market segment, accounting for nearly 45% of the total demand. This is directly correlated with the exponential growth in EV adoption worldwide, where early detection of thermal events has become a non-negotiable safety requirement. Major automotive manufacturers are increasingly specifying advanced multiparameter detection systems as standard components in their battery management systems.

Energy storage systems constitute the second-largest market segment, representing approximately 30% of current demand. As grid-scale and residential energy storage deployments continue to expand globally, the need for comprehensive safety monitoring systems has intensified. Regulatory bodies in North America, Europe, and Asia have begun implementing stricter safety standards, further driving market demand.

Consumer electronics applications account for approximately 15% of the market, with the remaining 10% distributed across aerospace, medical devices, and industrial applications. Each of these sectors demonstrates unique requirements for multiparameter detection capabilities, creating opportunities for specialized solutions.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 48% of global demand, followed by Europe (27%) and North America (20%). This distribution closely mirrors global battery production capacity, with China maintaining its position as the leading manufacturer of lithium-ion batteries and associated safety systems.

Market research indicates that customers increasingly prioritize integration capabilities, reliability under extreme conditions, and early detection accuracy when selecting multiparameter detection systems. The ability to simultaneously monitor multiple parameters—including temperature gradients, gas emissions, pressure changes, and voltage fluctuations—represents a significant competitive advantage in the marketplace.

Emerging market trends include the integration of artificial intelligence for predictive analytics, miniaturization of sensor arrays, and the development of wireless monitoring capabilities. These innovations are expected to expand the addressable market by enabling implementation in previously constrained applications where size, weight, or connectivity limitations existed.

The automotive sector represents the largest market segment, accounting for nearly 45% of the total demand. This is directly correlated with the exponential growth in EV adoption worldwide, where early detection of thermal events has become a non-negotiable safety requirement. Major automotive manufacturers are increasingly specifying advanced multiparameter detection systems as standard components in their battery management systems.

Energy storage systems constitute the second-largest market segment, representing approximately 30% of current demand. As grid-scale and residential energy storage deployments continue to expand globally, the need for comprehensive safety monitoring systems has intensified. Regulatory bodies in North America, Europe, and Asia have begun implementing stricter safety standards, further driving market demand.

Consumer electronics applications account for approximately 15% of the market, with the remaining 10% distributed across aerospace, medical devices, and industrial applications. Each of these sectors demonstrates unique requirements for multiparameter detection capabilities, creating opportunities for specialized solutions.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for 48% of global demand, followed by Europe (27%) and North America (20%). This distribution closely mirrors global battery production capacity, with China maintaining its position as the leading manufacturer of lithium-ion batteries and associated safety systems.

Market research indicates that customers increasingly prioritize integration capabilities, reliability under extreme conditions, and early detection accuracy when selecting multiparameter detection systems. The ability to simultaneously monitor multiple parameters—including temperature gradients, gas emissions, pressure changes, and voltage fluctuations—represents a significant competitive advantage in the marketplace.

Emerging market trends include the integration of artificial intelligence for predictive analytics, miniaturization of sensor arrays, and the development of wireless monitoring capabilities. These innovations are expected to expand the addressable market by enabling implementation in previously constrained applications where size, weight, or connectivity limitations existed.

Current Technical Challenges in Thermal Runaway Monitoring

Despite significant advancements in thermal runaway detection technologies, several critical challenges persist that impede the development of robust, reliable, and commercially viable multiparameter detection systems for battery safety applications. The primary technical hurdle remains the integration of multiple sensing modalities within a single compact device while maintaining accuracy across all parameters.

Signal processing complexity presents a formidable challenge, as different physical parameters (temperature, pressure, gas composition, voltage fluctuations) generate signals with varying characteristics and response times. Developing algorithms capable of real-time data fusion and interpretation from heterogeneous sensors requires sophisticated computational approaches that must operate within the power and processing constraints of battery management systems.

Sensor durability under extreme conditions constitutes another significant obstacle. Thermal runaway events can produce temperatures exceeding 600°C, generate corrosive gases, and cause rapid pressure changes. Sensors must maintain functionality and accuracy throughout these harsh conditions, yet current materials often degrade or fail when exposed to such extreme environments, particularly in the critical moments when detection is most needed.

Miniaturization while preserving sensitivity represents a persistent engineering challenge. As battery designs become more energy-dense and compact, the available space for sensing equipment diminishes. Developing multiparameter sensors that can fit within the constrained geometry of modern battery packs without compromising detection capabilities requires innovations in both materials science and manufacturing techniques.

False alarm management continues to plague current systems. The complex electrochemical processes within batteries can produce signal patterns that mimic early-stage thermal runaway indicators, leading to unnecessary shutdowns and reduced user confidence. Distinguishing between normal operational fluctuations and genuine safety concerns demands more sophisticated pattern recognition and machine learning approaches than currently deployed.

Power consumption optimization remains problematic for continuous monitoring systems. Effective multiparameter detection requires constant vigilance, yet parasitic power drain from sensors can significantly impact overall battery performance. Current technologies struggle to balance comprehensive monitoring with minimal energy consumption, particularly in applications where battery efficiency is paramount.

Response time optimization presents another critical challenge. The rapid progression of thermal runaway events—often evolving from initial triggers to catastrophic failure within seconds—demands extremely fast detection and response mechanisms. Current multiparameter systems frequently exhibit latency issues when processing inputs from multiple sensors simultaneously, potentially missing the critical intervention window.

AI and Machine Learning integration, while promising, faces implementation barriers in real-world battery systems. Training models requires extensive datasets of actual thermal runaway events, which are inherently dangerous and costly to produce. Synthetic data generation approaches have not yet achieved the fidelity needed for reliable algorithm development.

Signal processing complexity presents a formidable challenge, as different physical parameters (temperature, pressure, gas composition, voltage fluctuations) generate signals with varying characteristics and response times. Developing algorithms capable of real-time data fusion and interpretation from heterogeneous sensors requires sophisticated computational approaches that must operate within the power and processing constraints of battery management systems.

Sensor durability under extreme conditions constitutes another significant obstacle. Thermal runaway events can produce temperatures exceeding 600°C, generate corrosive gases, and cause rapid pressure changes. Sensors must maintain functionality and accuracy throughout these harsh conditions, yet current materials often degrade or fail when exposed to such extreme environments, particularly in the critical moments when detection is most needed.

Miniaturization while preserving sensitivity represents a persistent engineering challenge. As battery designs become more energy-dense and compact, the available space for sensing equipment diminishes. Developing multiparameter sensors that can fit within the constrained geometry of modern battery packs without compromising detection capabilities requires innovations in both materials science and manufacturing techniques.

False alarm management continues to plague current systems. The complex electrochemical processes within batteries can produce signal patterns that mimic early-stage thermal runaway indicators, leading to unnecessary shutdowns and reduced user confidence. Distinguishing between normal operational fluctuations and genuine safety concerns demands more sophisticated pattern recognition and machine learning approaches than currently deployed.

Power consumption optimization remains problematic for continuous monitoring systems. Effective multiparameter detection requires constant vigilance, yet parasitic power drain from sensors can significantly impact overall battery performance. Current technologies struggle to balance comprehensive monitoring with minimal energy consumption, particularly in applications where battery efficiency is paramount.

Response time optimization presents another critical challenge. The rapid progression of thermal runaway events—often evolving from initial triggers to catastrophic failure within seconds—demands extremely fast detection and response mechanisms. Current multiparameter systems frequently exhibit latency issues when processing inputs from multiple sensors simultaneously, potentially missing the critical intervention window.

AI and Machine Learning integration, while promising, faces implementation barriers in real-world battery systems. Training models requires extensive datasets of actual thermal runaway events, which are inherently dangerous and costly to produce. Synthetic data generation approaches have not yet achieved the fidelity needed for reliable algorithm development.

Current Multiparameter Detection Solutions and Implementations

01 Multi-parameter detection systems for thermal runaway prevention

Advanced sensor systems that monitor multiple parameters simultaneously to detect early signs of thermal runaway in battery systems. These systems integrate various sensing technologies to measure temperature, voltage, current, pressure, and gas emissions. By analyzing multiple parameters together, these systems can provide more accurate and earlier detection of potential thermal runaway conditions, allowing for preventive measures to be implemented before catastrophic failure occurs.- Temperature and voltage monitoring systems: These systems integrate temperature and voltage sensors to detect early signs of thermal runaway in batteries. By monitoring both parameters simultaneously, the system can identify abnormal patterns that precede thermal events. The monitoring typically involves strategically placed sensors throughout battery packs that continuously measure temperature gradients and voltage fluctuations, with algorithms that can distinguish between normal operational variations and dangerous conditions.

- Gas detection and analysis for battery safety: This approach focuses on detecting gases released during the early stages of battery degradation and thermal events. Specialized sensors can identify specific gases like hydrogen, carbon monoxide, and volatile organic compounds that indicate cell breakdown before visible thermal runaway occurs. These systems often employ multiple gas sensors with different detection principles to improve accuracy and reduce false alarms, providing an additional layer of safety monitoring beyond traditional temperature measurements.

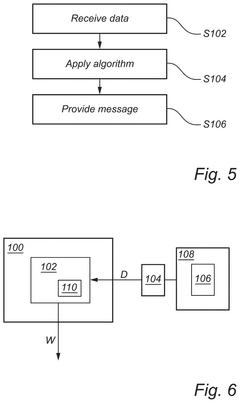

- Integrated multiparameter detection systems: These comprehensive systems combine multiple sensor types including temperature, voltage, current, pressure, and gas sensors to provide holistic monitoring of battery conditions. By correlating data from different sensor types, these systems can detect subtle patterns indicating potential thermal runaway with greater accuracy than single-parameter approaches. Advanced algorithms process the multi-sensor data to distinguish between normal operational variations and dangerous conditions, enabling earlier intervention before thermal runaway becomes catastrophic.

- Optical and acoustic sensing technologies: These innovative detection methods use optical sensors and acoustic monitoring to detect early signs of thermal runaway. Optical sensors can detect subtle color changes, smoke, or particulate emissions that precede thermal events, while acoustic sensors monitor sound patterns within battery cells that change during degradation. These non-contact sensing methods can detect thermal issues without requiring direct physical connection to battery components, offering advantages in certain applications where traditional sensor placement is challenging.

- AI-enhanced predictive thermal runaway detection: These systems leverage artificial intelligence and machine learning algorithms to analyze complex patterns from multiple sensor inputs to predict thermal runaway before it occurs. By training on historical data of battery failures, these systems can identify subtle precursor patterns that human operators might miss. The AI systems continuously improve their detection accuracy through ongoing learning from operational data, adapting to different battery chemistries and usage patterns to provide increasingly reliable early warnings of potential thermal events.

02 Gas detection sensors for battery safety monitoring

Specialized sensors designed to detect gases emitted during the early stages of thermal runaway. These sensors can identify specific gas signatures that precede thermal events, such as hydrogen, carbon monoxide, and various volatile organic compounds. The gas detection approach provides an additional layer of safety monitoring that can detect thermal issues before significant temperature increases occur, enabling earlier intervention and potentially preventing thermal runaway progression.Expand Specific Solutions03 Integrated battery management systems with thermal runaway detection

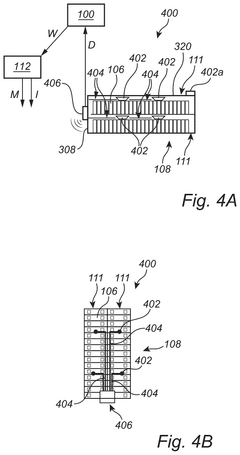

Comprehensive battery management systems that incorporate thermal runaway detection capabilities alongside traditional battery monitoring functions. These systems combine temperature monitoring with electrical parameter analysis to create a holistic approach to battery safety. By integrating thermal runaway detection directly into the battery management architecture, these systems enable immediate protective responses such as circuit disconnection, cooling activation, or emergency shutdown when abnormal conditions are detected.Expand Specific Solutions04 Distributed sensor networks for large battery systems

Networks of interconnected sensors strategically placed throughout large battery systems to provide comprehensive monitoring coverage. These distributed networks enable more precise localization of potential thermal issues within battery packs or arrays. The systems typically employ multiple sensor types at various locations, creating redundancy and allowing for differential analysis between sensors. This approach is particularly valuable for electric vehicle battery packs, grid storage systems, and other large-scale battery installations.Expand Specific Solutions05 AI and machine learning enhanced thermal runaway prediction

Advanced systems that utilize artificial intelligence and machine learning algorithms to analyze sensor data and predict thermal runaway events before they occur. These systems process historical and real-time data from multiple parameters to identify patterns and anomalies that may indicate developing battery issues. By continuously learning from operational data, these predictive systems can improve their accuracy over time and potentially detect subtle precursors to thermal runaway that might be missed by threshold-based detection methods.Expand Specific Solutions

Key Industry Players in Thermal Runaway Sensor Development

The thermal runaway sensor multiparameter detection market is currently in a growth phase, with increasing adoption driven by battery safety concerns in electric vehicles and energy storage systems. The global market size is expanding rapidly, projected to reach significant value as battery technologies proliferate across industries. From a technological maturity perspective, the field shows varied development levels among key players. Industry leaders like Tesla, CATL, and Samsung SDI have advanced multiparameter detection capabilities, while automotive manufacturers including Hyundai, Mercedes-Benz, and Honda are integrating these technologies into their EV platforms. Specialized sensor companies such as Sensirion and component manufacturers like ROHM and Renesas are developing innovative detection solutions. Honeywell and Huawei Digital Power represent the industrial and energy storage segments with growing technological investments in this critical safety domain.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced thermal runaway detection systems that integrate multiple sensing parameters including temperature, gas, pressure, and voltage fluctuations. Their solution employs a distributed sensor network architecture with proprietary algorithms to detect early warning signs of thermal events in battery systems. The technology utilizes micro-electromechanical systems (MEMS) sensors combined with machine learning algorithms to analyze thermal patterns and detect anomalies before catastrophic failure occurs. Honeywell's system incorporates redundant sensing mechanisms and cross-validation between different parameter measurements to minimize false alarms while maintaining high detection sensitivity. Their latest generation sensors can detect temperature changes as small as 0.1°C and gas emissions at parts-per-million levels, providing crucial early warning capabilities for battery management systems.

Strengths: Industry-leading detection accuracy with multi-parameter fusion algorithms; extensive experience in safety-critical systems; robust false-alarm prevention. Weaknesses: Higher implementation cost compared to simpler solutions; requires more complex integration with existing battery management systems; proprietary nature of algorithms may limit customization options.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has pioneered a comprehensive thermal runaway detection system that integrates multiple sensing parameters across their battery cell and pack designs. Their approach combines traditional temperature monitoring with innovative gas detection sensors that can identify specific volatile organic compounds released during early-stage thermal events. Samsung's technology employs a network of miniaturized sensors distributed throughout the battery pack, connected to a central processing unit that runs proprietary pattern recognition algorithms. The system monitors not only absolute values but also rates of change across parameters, enabling detection of thermal anomalies before they reach critical thresholds. Samsung has incorporated optical sensing technology that detects subtle changes in cell expansion, providing an additional early warning parameter. Their latest generation systems can detect thermal events up to 5 minutes before traditional temperature-only systems, giving critical time for mitigation measures.

Strengths: Highly integrated approach with sensors designed specifically for their battery chemistry; extensive real-world validation data; seamless integration with battery management systems. Weaknesses: Solution is primarily optimized for Samsung's own battery technology; relatively high cost per sensing point; requires specialized manufacturing processes.

Critical Patents and Research in Thermal Runaway Sensing

Thermal Runaway Detection

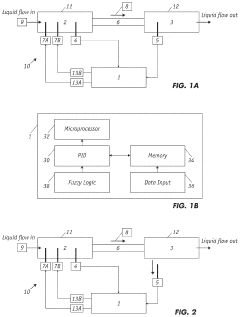

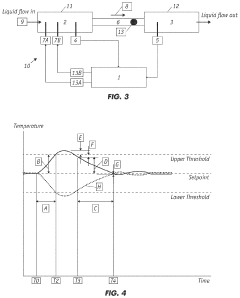

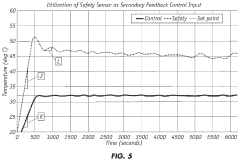

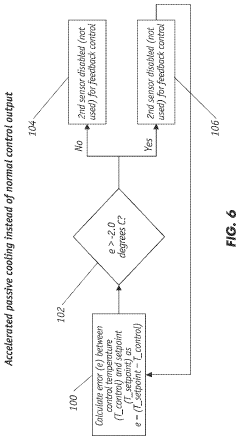

PatentActiveUS20230013263A1

Innovation

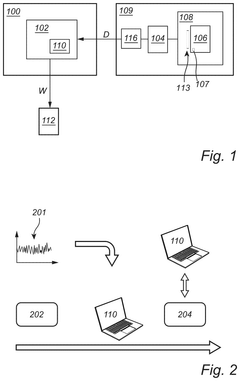

- A temperature control system with dual sensors, where a control sensor monitors the temperature in the controlled zone and a safety sensor monitors the temperature of the heat-transfer element, allowing the controller to detect non-linearities and maintain the heat-transfer element's output at a non-damaging level to prevent thermal runaway and enable fast recovery to the setpoint.

Passive detection of thermal runaway using acoustic waves

PatentPendingUS20250076387A1

Innovation

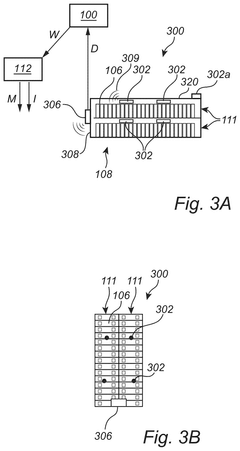

- A computer system utilizing processing circuitry to receive sensing data from sensors detecting sound waves emitted from electrical energy storage cells, applying a machine learning algorithm to predict thermal runaway events by analyzing acoustic waves generated from gas bubbles.

Safety Standards and Regulatory Requirements

The regulatory landscape for thermal runaway sensors in battery systems has evolved significantly in response to high-profile safety incidents across various industries. International standards such as IEC 62619 and UL 1642 establish baseline requirements for lithium-ion battery safety, with specific provisions for thermal management systems and early detection mechanisms. These standards mandate minimum performance criteria for thermal runaway detection, including response time thresholds, accuracy parameters, and reliability metrics under various environmental conditions.

Recent updates to automotive standards, particularly UN ECE R100 and ISO 6469, have introduced more stringent requirements for electric vehicle battery monitoring systems. These regulations now explicitly require multiparameter detection approaches rather than single-parameter monitoring, acknowledging the complex nature of thermal runaway events. Manufacturers must demonstrate compliance through rigorous testing protocols that simulate various failure modes and environmental stressors.

In the consumer electronics sector, IEC 62133 and UL 2054 have been revised to address emerging risks associated with higher energy density batteries. These standards now specify more comprehensive testing methodologies for thermal runaway detection systems, including accelerated aging tests and performance verification under extreme temperature conditions. Notably, recent amendments emphasize the need for redundant detection mechanisms that monitor multiple parameters simultaneously.

Regional variations in regulatory requirements present significant challenges for global manufacturers. The European Union's Battery Directive and China's GB/T 31485 standard impose different technical specifications and certification processes. Japan's JIS C8715 standard places particular emphasis on early detection capabilities through multiparameter monitoring, requiring sensors to detect subtle precursor events before thermal runaway becomes irreversible.

Emerging regulations are increasingly focusing on system-level integration rather than component-level compliance. This shift recognizes that effective thermal runaway prevention requires coordinated responses across battery management systems. Future regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety outcomes. This approach will likely accelerate the adoption of advanced multiparameter detection technologies that can adapt to different battery chemistries and form factors.

Compliance with these evolving standards requires manufacturers to implement comprehensive testing programs that validate sensor performance across diverse operating conditions. Documentation requirements have also expanded, with regulatory bodies now demanding detailed evidence of detection algorithm validation and failure mode analysis specific to multiparameter monitoring systems.

Recent updates to automotive standards, particularly UN ECE R100 and ISO 6469, have introduced more stringent requirements for electric vehicle battery monitoring systems. These regulations now explicitly require multiparameter detection approaches rather than single-parameter monitoring, acknowledging the complex nature of thermal runaway events. Manufacturers must demonstrate compliance through rigorous testing protocols that simulate various failure modes and environmental stressors.

In the consumer electronics sector, IEC 62133 and UL 2054 have been revised to address emerging risks associated with higher energy density batteries. These standards now specify more comprehensive testing methodologies for thermal runaway detection systems, including accelerated aging tests and performance verification under extreme temperature conditions. Notably, recent amendments emphasize the need for redundant detection mechanisms that monitor multiple parameters simultaneously.

Regional variations in regulatory requirements present significant challenges for global manufacturers. The European Union's Battery Directive and China's GB/T 31485 standard impose different technical specifications and certification processes. Japan's JIS C8715 standard places particular emphasis on early detection capabilities through multiparameter monitoring, requiring sensors to detect subtle precursor events before thermal runaway becomes irreversible.

Emerging regulations are increasingly focusing on system-level integration rather than component-level compliance. This shift recognizes that effective thermal runaway prevention requires coordinated responses across battery management systems. Future regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, allowing for innovation while maintaining safety outcomes. This approach will likely accelerate the adoption of advanced multiparameter detection technologies that can adapt to different battery chemistries and form factors.

Compliance with these evolving standards requires manufacturers to implement comprehensive testing programs that validate sensor performance across diverse operating conditions. Documentation requirements have also expanded, with regulatory bodies now demanding detailed evidence of detection algorithm validation and failure mode analysis specific to multiparameter monitoring systems.

Integration Strategies with Battery Management Systems

The integration of thermal runaway sensors with Battery Management Systems (BMS) represents a critical advancement in battery safety technology. Effective integration strategies must address both hardware and software interfaces to ensure seamless communication between sensor arrays and the BMS control architecture. Current integration approaches typically follow three primary models: direct integration, modular integration, and distributed integration, each with distinct advantages for different battery system configurations.

Direct integration embeds thermal runaway detection capabilities directly within the BMS hardware, minimizing communication latency and reducing component count. This approach is particularly effective for smaller battery systems where space constraints are significant. However, it may limit flexibility for sensor upgrades and increases the complexity of the primary BMS circuit design.

Modular integration employs dedicated sensor modules that communicate with the BMS through standardized protocols such as CAN, I2C, or SPI. This architecture provides greater flexibility for sensor replacement and upgrades while maintaining system reliability. Companies like Tesla and LG Energy Solution have adopted variations of this approach, implementing dedicated thermal monitoring subsystems that interface with their main BMS.

Distributed integration represents the most advanced approach, utilizing intelligent sensor nodes with local processing capabilities distributed throughout the battery pack. Each node can perform preliminary data analysis and anomaly detection before transmitting processed information to the central BMS. This reduces communication bandwidth requirements and enables more sophisticated real-time response strategies.

Communication protocols play a decisive role in integration effectiveness. Low-latency protocols are essential for time-critical thermal event detection, with response times under 100ms generally considered necessary for effective intervention. Recent developments in wireless sensor networks have also enabled reduced wiring complexity, though reliability concerns persist in high-interference environments.

Data fusion algorithms represent another critical integration component, combining inputs from multiple sensor types (temperature, gas, pressure, voltage) to improve detection accuracy and reduce false positives. Machine learning approaches have demonstrated particular promise, with neural network models achieving up to 95% accuracy in early thermal event prediction when trained on comprehensive multiparameter datasets.

Regulatory frameworks increasingly mandate specific integration requirements, with standards such as UL 1973 and IEC 62619 establishing minimum safety monitoring capabilities. These standards are driving the adoption of more sophisticated integration strategies across the industry, particularly in electric vehicle and grid storage applications where failure consequences are most severe.

Direct integration embeds thermal runaway detection capabilities directly within the BMS hardware, minimizing communication latency and reducing component count. This approach is particularly effective for smaller battery systems where space constraints are significant. However, it may limit flexibility for sensor upgrades and increases the complexity of the primary BMS circuit design.

Modular integration employs dedicated sensor modules that communicate with the BMS through standardized protocols such as CAN, I2C, or SPI. This architecture provides greater flexibility for sensor replacement and upgrades while maintaining system reliability. Companies like Tesla and LG Energy Solution have adopted variations of this approach, implementing dedicated thermal monitoring subsystems that interface with their main BMS.

Distributed integration represents the most advanced approach, utilizing intelligent sensor nodes with local processing capabilities distributed throughout the battery pack. Each node can perform preliminary data analysis and anomaly detection before transmitting processed information to the central BMS. This reduces communication bandwidth requirements and enables more sophisticated real-time response strategies.

Communication protocols play a decisive role in integration effectiveness. Low-latency protocols are essential for time-critical thermal event detection, with response times under 100ms generally considered necessary for effective intervention. Recent developments in wireless sensor networks have also enabled reduced wiring complexity, though reliability concerns persist in high-interference environments.

Data fusion algorithms represent another critical integration component, combining inputs from multiple sensor types (temperature, gas, pressure, voltage) to improve detection accuracy and reduce false positives. Machine learning approaches have demonstrated particular promise, with neural network models achieving up to 95% accuracy in early thermal event prediction when trained on comprehensive multiparameter datasets.

Regulatory frameworks increasingly mandate specific integration requirements, with standards such as UL 1973 and IEC 62619 establishing minimum safety monitoring capabilities. These standards are driving the adoption of more sophisticated integration strategies across the industry, particularly in electric vehicle and grid storage applications where failure consequences are most severe.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!