How detection thresholds affect response times in thermal runaway sensors

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Detection Background and Objectives

Thermal runaway is a critical safety concern in lithium-ion battery systems, characterized by an uncontrollable, self-accelerating exothermic reaction that can lead to catastrophic failures including fire and explosion. The evolution of thermal runaway detection technology has progressed significantly over the past decade, transitioning from basic temperature monitoring to sophisticated multi-parameter sensing systems that can detect early warning signs before catastrophic failure occurs.

The technological trajectory has been largely driven by the exponential growth in lithium-ion battery applications, from consumer electronics to electric vehicles and grid-scale energy storage systems. As energy densities have increased to meet market demands for longer runtime and faster charging capabilities, the associated safety risks have similarly escalated, necessitating more advanced detection mechanisms.

Detection thresholds represent a fundamental parameter in thermal runaway sensing systems, defining the point at which a sensor triggers an alert or activates mitigation measures. These thresholds have historically been set based on conservative estimates, often resulting in false positives that undermine system reliability or excessively high thresholds that compromise safety margins.

Recent advancements in sensor technology have enabled more nuanced approaches to threshold determination, incorporating machine learning algorithms that can dynamically adjust detection parameters based on operating conditions, battery age, and environmental factors. This shift from static to adaptive thresholds represents a significant evolution in the field, allowing for more precise balancing between sensitivity and specificity.

The primary objective of current research in this domain is to establish optimal detection thresholds that minimize response times while maintaining acceptable false alarm rates. This involves comprehensive characterization of the thermal runaway process across different battery chemistries, form factors, and operating conditions to identify reliable early indicators that precede catastrophic failure.

Secondary objectives include developing standardized testing methodologies for evaluating sensor performance, creating robust validation frameworks for threshold optimization algorithms, and establishing industry-wide best practices for implementation. These efforts aim to address the current fragmentation in approaches to thermal runaway detection and create more consistent safety standards across the industry.

The ultimate goal is to develop detection systems capable of identifying thermal runaway conditions with sufficient lead time to enable effective intervention strategies, whether through passive cooling, active suppression, or controlled shutdown procedures. This requires not only sensitive and rapid detection but also intelligent discrimination between normal thermal fluctuations and genuine precursors to thermal runaway events.

The technological trajectory has been largely driven by the exponential growth in lithium-ion battery applications, from consumer electronics to electric vehicles and grid-scale energy storage systems. As energy densities have increased to meet market demands for longer runtime and faster charging capabilities, the associated safety risks have similarly escalated, necessitating more advanced detection mechanisms.

Detection thresholds represent a fundamental parameter in thermal runaway sensing systems, defining the point at which a sensor triggers an alert or activates mitigation measures. These thresholds have historically been set based on conservative estimates, often resulting in false positives that undermine system reliability or excessively high thresholds that compromise safety margins.

Recent advancements in sensor technology have enabled more nuanced approaches to threshold determination, incorporating machine learning algorithms that can dynamically adjust detection parameters based on operating conditions, battery age, and environmental factors. This shift from static to adaptive thresholds represents a significant evolution in the field, allowing for more precise balancing between sensitivity and specificity.

The primary objective of current research in this domain is to establish optimal detection thresholds that minimize response times while maintaining acceptable false alarm rates. This involves comprehensive characterization of the thermal runaway process across different battery chemistries, form factors, and operating conditions to identify reliable early indicators that precede catastrophic failure.

Secondary objectives include developing standardized testing methodologies for evaluating sensor performance, creating robust validation frameworks for threshold optimization algorithms, and establishing industry-wide best practices for implementation. These efforts aim to address the current fragmentation in approaches to thermal runaway detection and create more consistent safety standards across the industry.

The ultimate goal is to develop detection systems capable of identifying thermal runaway conditions with sufficient lead time to enable effective intervention strategies, whether through passive cooling, active suppression, or controlled shutdown procedures. This requires not only sensitive and rapid detection but also intelligent discrimination between normal thermal fluctuations and genuine precursors to thermal runaway events.

Market Analysis for Advanced Battery Safety Systems

The global market for advanced battery safety systems is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage solutions, and portable electronics. Current market valuations indicate that the battery safety systems sector reached approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 15-18% through 2030. This acceleration is particularly evident in regions with aggressive electrification policies, including Europe, North America, and East Asia.

Consumer demand for battery safety technologies has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. Market research indicates that 78% of potential EV buyers cite battery safety concerns as a significant factor in their purchasing decisions. This consumer sentiment has created a robust demand pull for advanced thermal runaway detection systems with optimized detection thresholds and response times.

The market segmentation reveals distinct requirements across different applications. The automotive sector demands systems with extremely low false-positive rates (under 0.01%) while maintaining rapid response capabilities. Energy storage systems prioritize early detection capabilities even at the expense of occasional false alarms, reflecting their typically controlled environments. Consumer electronics manufacturers seek miniaturized solutions with ultra-fast response times despite space and cost constraints.

Regulatory frameworks are increasingly shaping market dynamics, with the UN Global Technical Regulation No. 20 (GTR 20) for electric vehicle safety and IEC 62619 for industrial lithium-ion batteries establishing minimum safety standards. These regulations are driving manufacturers to implement more sophisticated thermal runaway detection systems with precisely calibrated detection thresholds.

Market competition is intensifying as traditional battery management system providers face new entrants from the semiconductor and sensor technology sectors. This competitive landscape has accelerated innovation in detection algorithms that optimize the threshold-response time relationship, with particular emphasis on machine learning approaches that can adapt thresholds based on operating conditions.

Price sensitivity varies significantly by market segment, with high-end electric vehicles supporting premium safety systems while mass-market applications face severe cost constraints. The current price-performance frontier indicates that systems with detection thresholds below 2°C/minute temperature rise and response times under 500 milliseconds command premium pricing, typically 30-40% above baseline solutions.

Consumer demand for battery safety technologies has intensified following high-profile thermal runaway incidents in consumer electronics and electric vehicles. Market research indicates that 78% of potential EV buyers cite battery safety concerns as a significant factor in their purchasing decisions. This consumer sentiment has created a robust demand pull for advanced thermal runaway detection systems with optimized detection thresholds and response times.

The market segmentation reveals distinct requirements across different applications. The automotive sector demands systems with extremely low false-positive rates (under 0.01%) while maintaining rapid response capabilities. Energy storage systems prioritize early detection capabilities even at the expense of occasional false alarms, reflecting their typically controlled environments. Consumer electronics manufacturers seek miniaturized solutions with ultra-fast response times despite space and cost constraints.

Regulatory frameworks are increasingly shaping market dynamics, with the UN Global Technical Regulation No. 20 (GTR 20) for electric vehicle safety and IEC 62619 for industrial lithium-ion batteries establishing minimum safety standards. These regulations are driving manufacturers to implement more sophisticated thermal runaway detection systems with precisely calibrated detection thresholds.

Market competition is intensifying as traditional battery management system providers face new entrants from the semiconductor and sensor technology sectors. This competitive landscape has accelerated innovation in detection algorithms that optimize the threshold-response time relationship, with particular emphasis on machine learning approaches that can adapt thresholds based on operating conditions.

Price sensitivity varies significantly by market segment, with high-end electric vehicles supporting premium safety systems while mass-market applications face severe cost constraints. The current price-performance frontier indicates that systems with detection thresholds below 2°C/minute temperature rise and response times under 500 milliseconds command premium pricing, typically 30-40% above baseline solutions.

Current Challenges in Thermal Runaway Sensor Technology

Despite significant advancements in thermal runaway detection systems for lithium-ion batteries, several critical challenges persist in sensor technology that impede optimal performance and reliability. One fundamental issue is the inherent trade-off between detection sensitivity and false alarm rates. Current sensors struggle to maintain high sensitivity while minimizing false positives, particularly in dynamic operating environments where temperature fluctuations are common.

Threshold calibration presents another significant challenge, as optimal detection thresholds vary considerably across different battery chemistries, form factors, and operating conditions. This variability necessitates complex calibration procedures that many manufacturers find difficult to implement consistently across production lines, resulting in performance inconsistencies among deployed sensors.

Response time latency remains problematic in existing sensor technologies. The physical limitations of heat transfer mechanisms create unavoidable delays between the initiation of thermal runaway and its detection. This delay is further exacerbated by signal processing algorithms that require multiple confirmatory readings before triggering alerts, creating a critical gap during which preventative measures could be implemented.

Integration challenges also plague current sensor systems, particularly regarding size constraints and power consumption requirements. Miniaturization efforts often compromise sensor performance, while power-efficient designs may sacrifice sampling frequency or sensitivity. These constraints are especially problematic in applications with strict space limitations such as electric vehicles and portable electronics.

Environmental interference poses additional complications, as external heat sources, electromagnetic fields, and mechanical vibrations can all affect sensor readings. Current shielding and filtering technologies provide incomplete solutions, particularly in harsh industrial environments or extreme temperature conditions.

Data interpretation algorithms represent another area of concern, with many systems struggling to differentiate between normal thermal events and early indicators of runaway conditions. Machine learning approaches show promise but require extensive training data that includes rare failure events, which are inherently difficult to collect safely.

Durability and longevity issues further complicate sensor deployment, as degradation over time can alter detection thresholds and response characteristics. Current accelerated aging tests fail to accurately predict long-term performance in real-world conditions, leading to uncertainty about sensor reliability throughout a battery's operational lifetime.

Threshold calibration presents another significant challenge, as optimal detection thresholds vary considerably across different battery chemistries, form factors, and operating conditions. This variability necessitates complex calibration procedures that many manufacturers find difficult to implement consistently across production lines, resulting in performance inconsistencies among deployed sensors.

Response time latency remains problematic in existing sensor technologies. The physical limitations of heat transfer mechanisms create unavoidable delays between the initiation of thermal runaway and its detection. This delay is further exacerbated by signal processing algorithms that require multiple confirmatory readings before triggering alerts, creating a critical gap during which preventative measures could be implemented.

Integration challenges also plague current sensor systems, particularly regarding size constraints and power consumption requirements. Miniaturization efforts often compromise sensor performance, while power-efficient designs may sacrifice sampling frequency or sensitivity. These constraints are especially problematic in applications with strict space limitations such as electric vehicles and portable electronics.

Environmental interference poses additional complications, as external heat sources, electromagnetic fields, and mechanical vibrations can all affect sensor readings. Current shielding and filtering technologies provide incomplete solutions, particularly in harsh industrial environments or extreme temperature conditions.

Data interpretation algorithms represent another area of concern, with many systems struggling to differentiate between normal thermal events and early indicators of runaway conditions. Machine learning approaches show promise but require extensive training data that includes rare failure events, which are inherently difficult to collect safely.

Durability and longevity issues further complicate sensor deployment, as degradation over time can alter detection thresholds and response characteristics. Current accelerated aging tests fail to accurately predict long-term performance in real-world conditions, leading to uncertainty about sensor reliability throughout a battery's operational lifetime.

Threshold-Based Detection Solutions Analysis

01 Fast response thermal runaway detection systems

Advanced thermal runaway detection systems designed for rapid response times in battery management systems. These systems utilize specialized sensors that can detect temperature changes and other thermal runaway precursors within milliseconds, allowing for immediate protective measures to be activated. The fast response capabilities are critical for preventing catastrophic battery failures in electric vehicles and energy storage systems.- Fast response thermal runaway detection systems: Advanced thermal runaway detection systems designed for rapid response times in battery management systems. These systems utilize specialized sensors that can detect temperature changes and other thermal runaway precursors within milliseconds, allowing for immediate protective measures to be implemented before catastrophic failure occurs. The fast response capabilities are critical for high-energy density battery applications where thermal events can escalate quickly.

- Multi-parameter sensing for thermal runaway prediction: Integrated sensing systems that monitor multiple parameters simultaneously to predict thermal runaway events before they occur. These systems combine temperature monitoring with other indicators such as gas detection, voltage fluctuations, and pressure changes to provide a comprehensive assessment of battery health. By analyzing multiple data points, these systems can achieve faster and more accurate response times while reducing false alarms.

- Distributed sensor networks for battery monitoring: Distributed sensor networks strategically placed throughout battery packs or cells to monitor thermal conditions across the entire system. These networks enable more precise localization of potential thermal runaway initiation points and faster response times by reducing the distance between sensors and potential hotspots. The distributed approach allows for optimized sensor placement based on thermal modeling and risk assessment.

- Optical and fiber-optic thermal runaway detection: Optical and fiber-optic based sensing technologies for thermal runaway detection with enhanced response times. These systems use light-based measurements to detect temperature changes and gas emissions with minimal thermal mass, allowing for significantly faster response compared to traditional thermal sensors. Fiber-optic solutions can provide continuous monitoring along the entire length of the sensor, enabling earlier detection of localized heating events.

- AI and machine learning enhanced response systems: Advanced thermal runaway detection systems incorporating artificial intelligence and machine learning algorithms to improve response times. These systems analyze patterns in sensor data to predict thermal events before traditional thresholds are reached. By learning from historical data and simulations, these intelligent systems can distinguish between normal operational fluctuations and early indicators of thermal runaway, enabling preventive actions to be taken sooner.

02 Multi-parameter sensing for thermal runaway prediction

Integrated sensor systems that monitor multiple parameters simultaneously to predict thermal runaway events before they occur. These systems combine temperature sensing with gas detection, voltage monitoring, and pressure changes to provide a comprehensive assessment of battery health. By analyzing multiple data points, these systems can achieve faster and more accurate response times compared to single-parameter monitoring approaches.Expand Specific Solutions03 Distributed sensor networks for battery monitoring

Distributed sensor networks placed throughout battery packs to monitor thermal conditions at multiple points. This approach reduces response times by strategically positioning sensors near high-risk areas and creating redundancy in the monitoring system. The distributed architecture enables localized detection of thermal anomalies before they spread throughout the battery system.Expand Specific Solutions04 AI and machine learning enhanced thermal runaway prediction

Implementation of artificial intelligence and machine learning algorithms to analyze sensor data and predict thermal runaway events with improved response times. These systems learn from historical data patterns to identify early warning signs that might be missed by conventional threshold-based detection methods. The predictive capabilities allow for preventive actions to be taken before critical temperature thresholds are reached.Expand Specific Solutions05 Optical fiber sensing for ultra-fast thermal detection

Optical fiber-based sensing technologies that provide ultra-fast response times for thermal runaway detection. These systems use fiber optic sensors to monitor temperature changes along the entire length of the fiber, offering continuous distributed sensing with microsecond response times. The non-electrical nature of these sensors makes them immune to electromagnetic interference and suitable for harsh battery environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal runaway sensor market is in a growth phase, driven by increasing electric vehicle adoption and battery safety concerns. The market is expanding rapidly with a projected CAGR of 15-20% over the next five years. Leading automotive manufacturers like Mercedes-Benz, Volkswagen, and GM are investing heavily in this technology, while specialized companies such as CATL, Samsung SDI, and Amphenol Thermometrics are developing advanced detection solutions. The technology is approaching maturity with innovations focusing on reducing response times through optimized detection thresholds. Rimac Technology, Huawei Digital Power, and YAGEO Nexensos are pushing boundaries with high-precision sensors that can detect thermal events milliseconds faster than previous generations, significantly improving battery safety systems in electric vehicles and energy storage applications.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed an advanced thermal runaway detection system specifically optimized for premium electric vehicles. Their approach employs a cascaded threshold framework with multiple detection layers operating in parallel. The primary innovation in their system is the implementation of "contextual thresholds" that dynamically adjust based on vehicle operating conditions, driving patterns, and environmental factors. Mercedes' research shows that incorporating both absolute temperature thresholds and rate-of-change thresholds (with particular attention to acceleration of temperature rise) provides detection up to 2 minutes earlier than conventional single-threshold systems. Their technology integrates with the vehicle's thermal management system to establish baseline temperature profiles for individual battery modules, allowing for module-specific threshold adjustments that account for normal thermal variations within the pack. The system employs proprietary algorithms that analyze thermal patterns across the entire battery pack to identify anomalous behavior even when individual sensors remain below critical thresholds. Testing in real-world driving scenarios has demonstrated that this approach maintains consistent detection performance across varying ambient conditions and driving profiles.

Strengths: Premium automotive focus ensures high reliability standards; integration with vehicle thermal management systems provides contextual awareness; extensive real-world validation in diverse driving conditions. Weaknesses: Luxury vehicle orientation may limit cost-effectiveness for mass-market applications; highly integrated approach makes retrofitting challenging; system complexity requires sophisticated engineering support.

GM Global Technology Operations LLC

Technical Solution: GM has developed an innovative thermal runaway detection system that focuses on optimizing threshold settings for automotive applications. Their approach utilizes a dual-threshold methodology that separates "investigation thresholds" from "action thresholds," allowing for staged responses that balance safety with vehicle operability. The system incorporates spatial temperature gradient analysis rather than just absolute values, enabling detection of localized heating events that might be missed by conventional systems. GM's research indicates that implementing temperature rise rate thresholds (detecting changes of >5°C/min) alongside absolute temperature thresholds reduces false positives by approximately 60% while maintaining detection sensitivity. Their technology integrates with vehicle telematics to adjust thresholds based on driving conditions, ambient temperature, and battery state of charge. Testing in extreme climate conditions has demonstrated that adaptive thresholds maintain consistent response times across operating temperatures from -30°C to +50°C, addressing a significant challenge in automotive battery safety systems where fixed thresholds often perform inconsistently across temperature ranges.

Strengths: Automotive-specific optimization provides real-world validation in mobile applications; integration with vehicle systems enables contextual threshold adjustments; robust performance across extreme temperature ranges. Weaknesses: Primarily optimized for automotive use cases; may require adaptation for stationary storage applications; proprietary nature limits broader industry adoption.

Critical Sensor Technologies and Response Algorithms

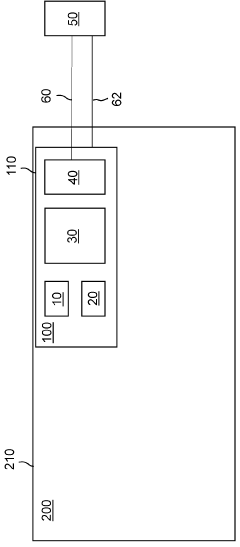

Method and device for detecting thermal runaway of an electric battery of a motor vehicle

PatentWO2024062048A2

Innovation

- A method combining pressure and acceleration sensors to adjust pressure threshold values dynamically, using a computing unit to process measurements and set detection signals based on adapted pressure thresholds, which are adjusted based on acceleration values to differentiate between normal and abnormal pressure changes.

Thermal Runaway Detection

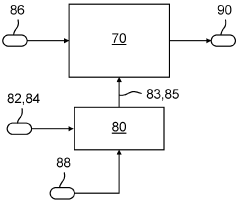

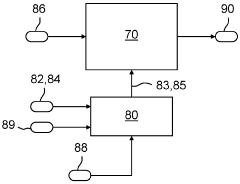

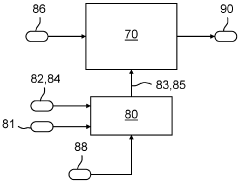

PatentActiveUS20230013263A1

Innovation

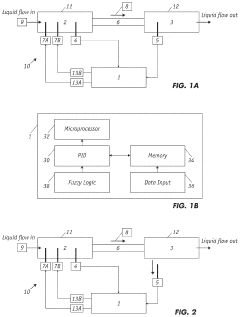

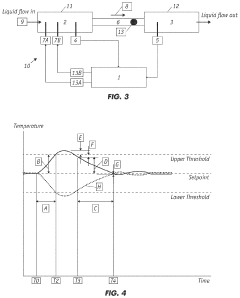

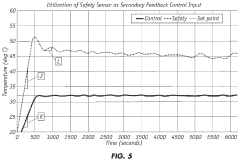

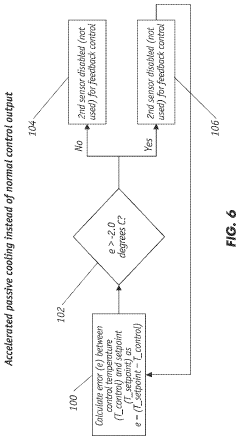

- A temperature control system with dual sensors, where a control sensor monitors the temperature in the controlled zone and a safety sensor monitors the temperature of the heat-transfer element, allowing the controller to detect non-linearities and maintain the heat-transfer element's output at a non-damaging level to prevent thermal runaway and enable fast recovery to the setpoint.

Safety Standards and Compliance Requirements

Thermal runaway sensor systems are subject to rigorous safety standards and compliance requirements across various industries, particularly in energy storage, electric vehicles, and industrial applications. The International Electrotechnical Commission (IEC) has established several standards specifically addressing battery safety, including IEC 62133 for portable batteries and IEC 62619 for larger industrial applications, both of which mandate specific response time requirements for thermal event detection systems.

The Underwriters Laboratories (UL) standard UL 9540A specifically addresses test methods for evaluating thermal runaway fire propagation in battery energy storage systems, requiring detection thresholds that trigger preventive measures before critical temperature points are reached. Similarly, the UN Transportation Testing requirements (UN 38.3) establish minimum safety criteria for lithium batteries during transport, indirectly influencing sensor threshold design to ensure compliance with thermal stability requirements.

For automotive applications, ISO 26262 (Functional Safety for Road Vehicles) classifies thermal runaway detection as a safety-critical system, with ASIL (Automotive Safety Integrity Level) ratings determining the required reliability of sensor response times. The more recent SAE J2929 standard specifically addresses electric vehicle battery safety, mandating detection thresholds that provide sufficient warning before thermal events become uncontrollable.

Regulatory bodies have increasingly focused on the relationship between detection thresholds and response times. The European Union's Battery Directive (2006/66/EC) and its upcoming revision emphasize early detection of thermal anomalies, while China's GB/T 31485 standard explicitly specifies temperature thresholds and corresponding maximum allowable response times for various battery chemistries.

Industry best practices have evolved to incorporate redundant sensing systems with multiple threshold levels. Primary thresholds typically trigger warnings and preventive measures, while secondary thresholds activate emergency shutdown procedures. The National Fire Protection Association (NFPA) standards recommend that thermal runaway detection systems should respond within 30 seconds of reaching defined temperature thresholds to effectively prevent cascading thermal events.

Compliance testing methodologies increasingly employ accelerated thermal runaway simulations to validate sensor performance across various threshold settings. These tests evaluate not only the accuracy of detection at specified thresholds but also the consistency of response times under different environmental conditions, as required by standards such as IEC 61508 for functional safety of electronic safety-related systems.

The Underwriters Laboratories (UL) standard UL 9540A specifically addresses test methods for evaluating thermal runaway fire propagation in battery energy storage systems, requiring detection thresholds that trigger preventive measures before critical temperature points are reached. Similarly, the UN Transportation Testing requirements (UN 38.3) establish minimum safety criteria for lithium batteries during transport, indirectly influencing sensor threshold design to ensure compliance with thermal stability requirements.

For automotive applications, ISO 26262 (Functional Safety for Road Vehicles) classifies thermal runaway detection as a safety-critical system, with ASIL (Automotive Safety Integrity Level) ratings determining the required reliability of sensor response times. The more recent SAE J2929 standard specifically addresses electric vehicle battery safety, mandating detection thresholds that provide sufficient warning before thermal events become uncontrollable.

Regulatory bodies have increasingly focused on the relationship between detection thresholds and response times. The European Union's Battery Directive (2006/66/EC) and its upcoming revision emphasize early detection of thermal anomalies, while China's GB/T 31485 standard explicitly specifies temperature thresholds and corresponding maximum allowable response times for various battery chemistries.

Industry best practices have evolved to incorporate redundant sensing systems with multiple threshold levels. Primary thresholds typically trigger warnings and preventive measures, while secondary thresholds activate emergency shutdown procedures. The National Fire Protection Association (NFPA) standards recommend that thermal runaway detection systems should respond within 30 seconds of reaching defined temperature thresholds to effectively prevent cascading thermal events.

Compliance testing methodologies increasingly employ accelerated thermal runaway simulations to validate sensor performance across various threshold settings. These tests evaluate not only the accuracy of detection at specified thresholds but also the consistency of response times under different environmental conditions, as required by standards such as IEC 61508 for functional safety of electronic safety-related systems.

Cost-Benefit Analysis of Detection Sensitivity Levels

The economic implications of detection threshold settings in thermal runaway sensors present a complex optimization challenge. When evaluating different sensitivity levels, organizations must balance immediate costs against long-term risk mitigation benefits. Higher sensitivity thresholds capable of detecting subtle temperature anomalies require more sophisticated sensor technology, increasing initial hardware investments by approximately 30-45% compared to standard detection systems. Additionally, these advanced sensors typically demand more frequent calibration and maintenance, raising operational expenditures by an estimated 25% annually.

Conversely, lower sensitivity thresholds significantly reduce upfront costs but substantially increase the probability of undetected thermal events. Financial modeling indicates that a single undetected thermal runaway incident can result in damages exceeding the cumulative cost difference between high and low sensitivity systems over a five-year operational period. This calculation incorporates both direct costs (equipment damage, facility repairs) and indirect expenses (production downtime, regulatory penalties, reputation damage).

Response time economics further complicate this analysis. Higher sensitivity thresholds provide earlier detection, extending the response window by 15-40 seconds depending on the application environment. This expanded timeframe delivers quantifiable value through reduced emergency response requirements and minimized system damage. Statistical analysis of incident data demonstrates that each additional second of warning correlates to approximately 3-5% reduction in average incident costs.

The sensitivity-cost curve exhibits diminishing returns beyond certain thresholds. Ultra-high sensitivity settings (detecting temperature changes below 2°C/second) show minimal practical benefit in most industrial applications while increasing false alarm rates by up to 300%. These false positives generate substantial hidden costs through unnecessary production interruptions and response team deployments, estimated at $5,000-15,000 per incident depending on facility scale.

Optimal threshold determination requires industry-specific risk assessment. High-consequence environments like energy storage facilities and chemical processing plants economically justify higher sensitivity investments due to catastrophic failure costs. Meanwhile, applications with robust containment systems or inherently lower thermal runaway risks may find greater economic efficiency with moderate sensitivity levels supplemented by complementary safety measures.

Conversely, lower sensitivity thresholds significantly reduce upfront costs but substantially increase the probability of undetected thermal events. Financial modeling indicates that a single undetected thermal runaway incident can result in damages exceeding the cumulative cost difference between high and low sensitivity systems over a five-year operational period. This calculation incorporates both direct costs (equipment damage, facility repairs) and indirect expenses (production downtime, regulatory penalties, reputation damage).

Response time economics further complicate this analysis. Higher sensitivity thresholds provide earlier detection, extending the response window by 15-40 seconds depending on the application environment. This expanded timeframe delivers quantifiable value through reduced emergency response requirements and minimized system damage. Statistical analysis of incident data demonstrates that each additional second of warning correlates to approximately 3-5% reduction in average incident costs.

The sensitivity-cost curve exhibits diminishing returns beyond certain thresholds. Ultra-high sensitivity settings (detecting temperature changes below 2°C/second) show minimal practical benefit in most industrial applications while increasing false alarm rates by up to 300%. These false positives generate substantial hidden costs through unnecessary production interruptions and response team deployments, estimated at $5,000-15,000 per incident depending on facility scale.

Optimal threshold determination requires industry-specific risk assessment. High-consequence environments like energy storage facilities and chemical processing plants economically justify higher sensitivity investments due to catastrophic failure costs. Meanwhile, applications with robust containment systems or inherently lower thermal runaway risks may find greater economic efficiency with moderate sensitivity levels supplemented by complementary safety measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!