Comparative evaluation of thermal runaway sensors in stationary storage systems

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Sensor Technology Background and Objectives

Thermal runaway in stationary energy storage systems represents one of the most critical safety challenges facing the energy storage industry today. The phenomenon, characterized by an uncontrolled self-heating process that can lead to fire, explosion, and toxic gas emissions, has been documented across various battery chemistries but is particularly concerning in lithium-ion based systems due to their high energy density and widespread deployment.

The evolution of thermal runaway sensor technology has progressed significantly over the past decade, moving from basic temperature monitoring to sophisticated multi-parameter detection systems. Early detection methods relied primarily on simple thermocouples and resistance temperature detectors (RTDs) that could only identify temperature increases after significant heat generation had already occurred, often too late for effective intervention.

Current technological trends are moving toward integrated sensing approaches that combine multiple detection modalities including gas sensing, voltage monitoring, impedance tracking, and advanced temperature gradient analysis. This multi-signal approach allows for earlier detection of precursor events that occur before catastrophic failure, potentially providing critical minutes or hours of warning time.

The primary objective of thermal runaway sensor technology development is to create detection systems capable of identifying battery failure conditions at the earliest possible stage while minimizing false positives that could unnecessarily trigger mitigation systems or system shutdowns. This balance between sensitivity and specificity represents a fundamental engineering challenge in the field.

Another key goal is the development of sensors that can operate reliably in the harsh environmental conditions typical of energy storage installations, including wide temperature ranges, high electromagnetic interference environments, and potentially corrosive atmospheres. Sensor robustness and longevity must match or exceed the expected 10-20 year lifespan of modern stationary storage systems.

Cost-effectiveness remains a critical consideration, as sensors must be economically viable for widespread deployment across large-scale energy storage installations that may contain thousands of individual cells or modules. The industry is actively pursuing solutions that provide comprehensive protection while maintaining reasonable implementation costs.

Standardization efforts are also emerging as a significant objective, with organizations like UL, IEC, and NFPA working to establish testing protocols and performance requirements for thermal runaway detection systems. These standards aim to provide consistent evaluation metrics and minimum safety thresholds across the industry, facilitating broader adoption of effective sensing technologies.

The evolution of thermal runaway sensor technology has progressed significantly over the past decade, moving from basic temperature monitoring to sophisticated multi-parameter detection systems. Early detection methods relied primarily on simple thermocouples and resistance temperature detectors (RTDs) that could only identify temperature increases after significant heat generation had already occurred, often too late for effective intervention.

Current technological trends are moving toward integrated sensing approaches that combine multiple detection modalities including gas sensing, voltage monitoring, impedance tracking, and advanced temperature gradient analysis. This multi-signal approach allows for earlier detection of precursor events that occur before catastrophic failure, potentially providing critical minutes or hours of warning time.

The primary objective of thermal runaway sensor technology development is to create detection systems capable of identifying battery failure conditions at the earliest possible stage while minimizing false positives that could unnecessarily trigger mitigation systems or system shutdowns. This balance between sensitivity and specificity represents a fundamental engineering challenge in the field.

Another key goal is the development of sensors that can operate reliably in the harsh environmental conditions typical of energy storage installations, including wide temperature ranges, high electromagnetic interference environments, and potentially corrosive atmospheres. Sensor robustness and longevity must match or exceed the expected 10-20 year lifespan of modern stationary storage systems.

Cost-effectiveness remains a critical consideration, as sensors must be economically viable for widespread deployment across large-scale energy storage installations that may contain thousands of individual cells or modules. The industry is actively pursuing solutions that provide comprehensive protection while maintaining reasonable implementation costs.

Standardization efforts are also emerging as a significant objective, with organizations like UL, IEC, and NFPA working to establish testing protocols and performance requirements for thermal runaway detection systems. These standards aim to provide consistent evaluation metrics and minimum safety thresholds across the industry, facilitating broader adoption of effective sensing technologies.

Market Demand Analysis for Energy Storage Safety Solutions

The global energy storage safety solutions market is experiencing unprecedented growth, driven by the rapid expansion of stationary energy storage systems (ESS) across utility, commercial, and residential sectors. Current market valuations indicate the thermal runaway detection and prevention segment reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 18-20% through 2030. This acceleration is primarily fueled by increasing safety concerns following several high-profile battery energy storage system (BESS) fire incidents worldwide.

Regulatory bodies across North America, Europe, and Asia-Pacific regions have responded by implementing stricter safety standards, creating substantial market pull for advanced thermal runaway detection technologies. The UL9540A test method and NFPA 855 standards in the United States, along with similar frameworks being developed in the EU and China, have established minimum safety requirements that are driving demand for sophisticated sensor systems.

Insurance providers have emerged as significant market influencers, with many now requiring comprehensive thermal runaway detection systems before underwriting large-scale energy storage projects. This requirement has transformed advanced safety solutions from optional features to essential components, particularly for utility-scale installations where financial exposure is greatest.

Market segmentation reveals distinct demand patterns across different application sectors. Utility-scale storage deployments, representing approximately 65% of the total market value, prioritize early detection systems with remote monitoring capabilities and integration with fire suppression systems. Commercial and industrial applications, accounting for roughly 25% of market demand, focus on cost-effective solutions that can be retrofitted to existing installations while meeting increasingly stringent building safety codes.

Customer needs analysis indicates five primary market requirements: early detection capability (detecting thermal events 15-30 minutes before critical failure), system reliability with minimal false alarms, integration capability with battery management systems, cost-effectiveness relative to total system value, and compliance with evolving international standards.

The market landscape is further shaped by the transition from lithium-ion to next-generation battery chemistries, including solid-state technologies. This evolution creates demand for sensor systems capable of addressing the unique thermal runaway characteristics of emerging battery technologies, representing a significant growth opportunity for adaptive and chemistry-agnostic detection solutions.

Regional analysis shows Asia-Pacific leading market growth at 22% annually, driven by China's massive energy storage deployment initiatives, while North America and Europe follow at 19% and 17% respectively, with their growth primarily policy and safety-standard driven.

Regulatory bodies across North America, Europe, and Asia-Pacific regions have responded by implementing stricter safety standards, creating substantial market pull for advanced thermal runaway detection technologies. The UL9540A test method and NFPA 855 standards in the United States, along with similar frameworks being developed in the EU and China, have established minimum safety requirements that are driving demand for sophisticated sensor systems.

Insurance providers have emerged as significant market influencers, with many now requiring comprehensive thermal runaway detection systems before underwriting large-scale energy storage projects. This requirement has transformed advanced safety solutions from optional features to essential components, particularly for utility-scale installations where financial exposure is greatest.

Market segmentation reveals distinct demand patterns across different application sectors. Utility-scale storage deployments, representing approximately 65% of the total market value, prioritize early detection systems with remote monitoring capabilities and integration with fire suppression systems. Commercial and industrial applications, accounting for roughly 25% of market demand, focus on cost-effective solutions that can be retrofitted to existing installations while meeting increasingly stringent building safety codes.

Customer needs analysis indicates five primary market requirements: early detection capability (detecting thermal events 15-30 minutes before critical failure), system reliability with minimal false alarms, integration capability with battery management systems, cost-effectiveness relative to total system value, and compliance with evolving international standards.

The market landscape is further shaped by the transition from lithium-ion to next-generation battery chemistries, including solid-state technologies. This evolution creates demand for sensor systems capable of addressing the unique thermal runaway characteristics of emerging battery technologies, representing a significant growth opportunity for adaptive and chemistry-agnostic detection solutions.

Regional analysis shows Asia-Pacific leading market growth at 22% annually, driven by China's massive energy storage deployment initiatives, while North America and Europe follow at 19% and 17% respectively, with their growth primarily policy and safety-standard driven.

Current State and Challenges in Thermal Runaway Detection

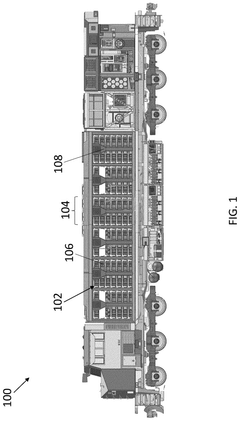

The global stationary energy storage market has witnessed significant growth, with lithium-ion batteries dominating due to their high energy density and decreasing costs. However, thermal runaway incidents in these systems pose serious safety concerns, highlighting the critical need for effective detection technologies. Current thermal runaway detection in stationary storage systems primarily relies on four sensor types: temperature sensors, gas sensors, voltage/current monitoring systems, and optical sensors.

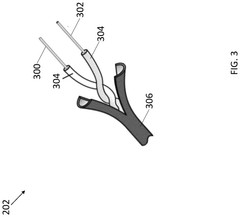

Temperature sensors remain the most widely implemented detection method, utilizing thermocouples, thermistors, and resistance temperature detectors (RTDs) strategically placed throughout battery modules. While these sensors offer reliability and cost-effectiveness, they often detect thermal events only after significant heat generation has occurred, limiting early intervention capabilities. Recent advancements include distributed temperature sensing using fiber optic technology, enabling more comprehensive thermal mapping across large-scale installations.

Gas sensors have emerged as promising early detection tools by identifying volatile organic compounds and gases released during the initial stages of thermal decomposition. Commercial implementations include metal oxide semiconductor sensors, electrochemical sensors, and non-dispersive infrared sensors. These technologies can detect thermal events up to 30 minutes earlier than temperature sensors alone, though they face challenges with sensor drift and calibration requirements in diverse environmental conditions.

Voltage and current monitoring systems analyze electrical parameters to identify anomalies indicative of potential thermal issues. Advanced battery management systems (BMS) incorporate algorithms that track impedance changes, voltage fluctuations, and current irregularities. While these systems integrate seamlessly with existing battery infrastructure, their effectiveness varies with battery chemistry and operating conditions, sometimes yielding false positives during normal operational fluctuations.

Optical sensing technologies, including infrared cameras and specialized fiber optic systems, represent the cutting edge in thermal runaway detection. These systems can detect minute temperature changes across large battery arrays without direct contact. However, widespread implementation remains limited by high costs and integration complexities, particularly in retrofitting existing installations.

The primary challenges in thermal runaway detection include achieving sufficient early warning without false alarms, maintaining sensor reliability throughout the 10-15 year lifespan of stationary systems, and developing cost-effective solutions suitable for large-scale deployments. Additionally, the industry lacks standardized testing protocols for evaluating sensor performance across different battery chemistries and system configurations, complicating comparative assessments of detection technologies.

Temperature sensors remain the most widely implemented detection method, utilizing thermocouples, thermistors, and resistance temperature detectors (RTDs) strategically placed throughout battery modules. While these sensors offer reliability and cost-effectiveness, they often detect thermal events only after significant heat generation has occurred, limiting early intervention capabilities. Recent advancements include distributed temperature sensing using fiber optic technology, enabling more comprehensive thermal mapping across large-scale installations.

Gas sensors have emerged as promising early detection tools by identifying volatile organic compounds and gases released during the initial stages of thermal decomposition. Commercial implementations include metal oxide semiconductor sensors, electrochemical sensors, and non-dispersive infrared sensors. These technologies can detect thermal events up to 30 minutes earlier than temperature sensors alone, though they face challenges with sensor drift and calibration requirements in diverse environmental conditions.

Voltage and current monitoring systems analyze electrical parameters to identify anomalies indicative of potential thermal issues. Advanced battery management systems (BMS) incorporate algorithms that track impedance changes, voltage fluctuations, and current irregularities. While these systems integrate seamlessly with existing battery infrastructure, their effectiveness varies with battery chemistry and operating conditions, sometimes yielding false positives during normal operational fluctuations.

Optical sensing technologies, including infrared cameras and specialized fiber optic systems, represent the cutting edge in thermal runaway detection. These systems can detect minute temperature changes across large battery arrays without direct contact. However, widespread implementation remains limited by high costs and integration complexities, particularly in retrofitting existing installations.

The primary challenges in thermal runaway detection include achieving sufficient early warning without false alarms, maintaining sensor reliability throughout the 10-15 year lifespan of stationary systems, and developing cost-effective solutions suitable for large-scale deployments. Additionally, the industry lacks standardized testing protocols for evaluating sensor performance across different battery chemistries and system configurations, complicating comparative assessments of detection technologies.

Existing Thermal Runaway Detection Solutions Comparison

01 Temperature-based thermal runaway detection sensors

These sensors monitor temperature changes in battery systems to detect early signs of thermal runaway. They utilize various temperature sensing technologies to measure and track temperature fluctuations, triggering alerts or protective measures when abnormal temperature rises are detected. This approach allows for early intervention before a full thermal runaway event occurs, enhancing battery safety systems in electric vehicles and energy storage applications.- Temperature sensing technologies for thermal runaway detection: Various temperature sensing technologies are employed for detecting thermal runaway in battery systems. These include thermistors, thermocouples, fiber optic sensors, and infrared sensors that monitor temperature changes in real-time. These sensors can detect abnormal temperature rises that may indicate the onset of thermal runaway, allowing for early intervention. The sensitivity, response time, and placement of these sensors are critical factors in their effectiveness for thermal runaway prevention.

- Gas detection and analysis systems for early warning: Gas detection systems analyze the composition and concentration of gases released during the early stages of thermal runaway. These systems can detect volatile organic compounds, hydrogen, carbon monoxide, and other gases that are emitted before visible signs of thermal runaway appear. By monitoring these gas signatures, the systems provide early warning of potential battery failure, allowing for preventive measures to be implemented before catastrophic failure occurs.

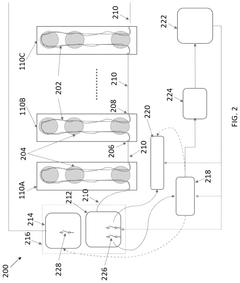

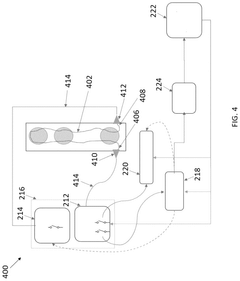

- Integrated multi-parameter monitoring systems: Advanced thermal runaway detection systems integrate multiple sensor types to monitor various parameters simultaneously. These systems combine temperature sensors, voltage monitors, current sensors, and gas detectors to provide comprehensive monitoring of battery health. By analyzing the correlation between different parameters, these integrated systems can more accurately identify the early signs of thermal runaway and reduce false alarms. Machine learning algorithms are often employed to improve detection accuracy by recognizing patterns indicative of impending thermal events.

- Wireless and remote monitoring solutions: Wireless sensor networks enable remote monitoring of battery systems for thermal runaway detection. These solutions utilize Bluetooth, Wi-Fi, or cellular connectivity to transmit sensor data to monitoring stations or cloud platforms. This allows for real-time monitoring of battery systems in various applications, including electric vehicles, energy storage systems, and portable electronics. Remote monitoring solutions can provide alerts and notifications to operators when abnormal conditions are detected, enabling prompt response to potential thermal runaway events.

- Comparative performance metrics and evaluation methodologies: Standardized testing protocols and performance metrics have been developed to evaluate and compare different thermal runaway detection systems. These evaluation methodologies assess factors such as detection speed, accuracy, reliability, false alarm rate, and durability under various operating conditions. Comparative studies analyze the strengths and limitations of different sensor technologies in detecting thermal runaway across different battery chemistries, form factors, and use cases. These evaluations help in selecting the most appropriate detection system for specific applications based on their performance characteristics.

02 Gas detection sensors for thermal runaway prevention

Gas detection sensors identify specific gases released during the early stages of battery degradation and thermal runaway. These sensors can detect volatile organic compounds, hydrogen, carbon monoxide, and other gases that indicate cell failure before significant temperature increases occur. This early detection capability provides additional response time for safety systems to activate cooling mechanisms or disconnect affected battery modules.Expand Specific Solutions03 Integrated multi-parameter sensing systems

Advanced thermal runaway detection systems combine multiple sensing technologies to improve accuracy and reduce false alarms. These integrated systems simultaneously monitor temperature, voltage, current, gas emissions, and physical deformation to provide comprehensive battery health assessment. By correlating data from different sensor types, these systems can distinguish between normal operational variations and genuine thermal runaway precursors, enabling more reliable early warning capabilities.Expand Specific Solutions04 Wireless and distributed sensor networks

Wireless sensor networks distribute multiple sensing nodes throughout battery packs to provide comprehensive monitoring coverage. These systems use wireless communication protocols to transmit real-time data to central monitoring systems, eliminating the need for extensive wiring. Distributed sensing architectures improve detection reliability by providing redundancy and enabling precise localization of potential thermal events within large battery arrays.Expand Specific Solutions05 Comparative evaluation methodologies for thermal runaway sensors

Standardized testing and evaluation frameworks have been developed to assess and compare the performance of different thermal runaway detection technologies. These methodologies evaluate sensors based on detection speed, accuracy, reliability under various conditions, false alarm rates, and integration capabilities. Comparative evaluations help battery manufacturers and system integrators select appropriate sensing technologies based on specific application requirements and safety standards.Expand Specific Solutions

Key Industry Players in Stationary Storage Safety Systems

The thermal runaway sensor market for stationary storage systems is in a growth phase, driven by increasing safety concerns in energy storage applications. The market is expanding rapidly with the global energy storage sector, projected to reach significant value by 2030. Technologically, the field shows varying maturity levels, with established automotive players like Mercedes-Benz, Volvo, and Schaeffler bringing advanced sensing expertise, while battery manufacturers such as CATL and energy specialists like Huawei Digital Power and Fluence Energy focus on integration solutions. Companies like Infineon and Renesas lead in semiconductor-based detection technologies. Research institutions including Shandong University and Indian Institute of Science are advancing next-generation sensing methods, indicating the field remains dynamic with substantial innovation potential across thermal, electrical, and gas-based detection approaches.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive thermal runaway detection system for stationary storage applications that combines multiple sensor types for early detection. Their solution integrates fiber optic temperature sensors distributed throughout battery modules with gas detection sensors that can identify specific gases released during early thermal events. The system employs a hierarchical monitoring approach where temperature gradients and rates of change are continuously analyzed alongside gas concentration measurements. CATL's system features proprietary algorithms that can distinguish between normal operational fluctuations and actual thermal runaway precursors, reducing false alarms while maintaining high sensitivity. Their technology includes redundant communication channels to ensure data transmission even during emergency conditions, and integrates with automated fire suppression systems for immediate response. The system is designed with a modular architecture allowing for easy scaling across different sizes of energy storage installations.

Strengths: Industry-leading early detection capabilities with multi-parameter monitoring; highly scalable for various installation sizes; proven reliability in commercial deployments. Weaknesses: Higher implementation cost compared to simpler solutions; requires more complex integration with existing BMS systems; proprietary nature may limit compatibility with third-party components.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed an advanced thermal runaway detection system for stationary storage applications leveraging their automotive battery expertise. Their approach utilizes a multi-layered sensor network that combines traditional temperature monitoring with differential pressure sensors to detect the earliest stages of thermal events. The system incorporates specialized voltage monitoring algorithms that can identify minute changes in cell impedance—often a precursor to thermal issues. Mercedes' solution features proprietary machine learning algorithms trained on extensive test data from controlled thermal runaway events, enabling pattern recognition that can distinguish between normal operational fluctuations and actual thermal anomalies. Their system includes dedicated microcontrollers for each battery module that perform local processing before transmitting data to a central management system, reducing communication latency during critical events. The technology also incorporates automated isolation mechanisms that can electrically disconnect compromised battery sections within milliseconds of detecting a thermal event.

Strengths: Exceptional early detection capabilities derived from automotive safety expertise; robust hardware with redundant monitoring paths; sophisticated AI-based anomaly detection. Weaknesses: Higher cost implementation due to premium components; system complexity requires specialized maintenance personnel; primarily optimized for their own battery chemistry and configurations.

Critical Sensor Technologies for Early Thermal Event Detection

Passive detection of thermal runaway using acoustic waves

PatentPendingEP4517915A1

Innovation

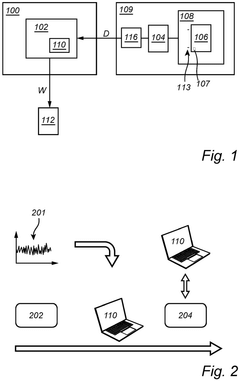

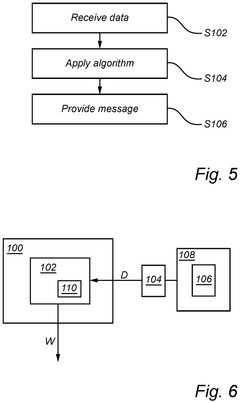

- A computer system utilizing processing circuitry to receive sensing data from sensors detecting sound waves emitted from electrical energy storage cells, applying a machine learning algorithm to predict thermal runaway events by analyzing acoustic waves generated from gas bubbles.

Thermal sensor system

PatentPendingUS20250198852A1

Innovation

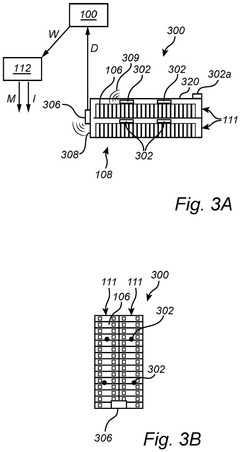

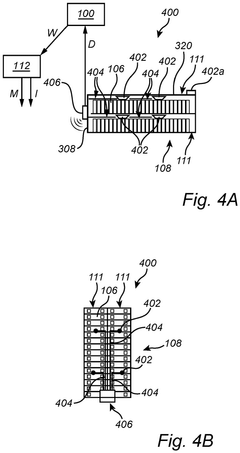

- A sensor system that employs elongated sensors, which can be threaded through various locations within a powered system, including energy storage device enclosures and exhaust chimneys. These sensors generate an electrical short or change light attenuation in response to temperature changes, allowing for early detection of thermal runaway events without the need for complex communication systems.

Safety Standards and Compliance Requirements

The regulatory landscape for stationary energy storage systems (ESS) has evolved significantly in response to thermal runaway incidents. IEC 62933-5-2 and UL 9540A have emerged as the primary international standards addressing thermal runaway detection in stationary storage systems. These standards establish rigorous testing protocols for evaluating sensor performance under various thermal conditions and mandate specific response times for detection systems. Notably, UL 9540A requires thermal runaway detection systems to identify abnormal temperature rises at least 60 seconds before thermal propagation occurs.

National Fire Protection Association (NFPA) standards, particularly NFPA 855, complement these international frameworks by specifying installation requirements for thermal runaway detection systems in stationary applications. The standard mandates that sensors must be capable of detecting temperature anomalies across the entire battery system and trigger appropriate mitigation measures when predefined thresholds are exceeded.

Regional variations in compliance requirements present significant challenges for global manufacturers. European regulations under EN IEC 63056 emphasize early detection capabilities and integration with battery management systems, while Asian markets, particularly China's GB/T 36276, focus on sensor durability under extreme environmental conditions. North American regulations through UL 1973 and CSA C22.2 place greater emphasis on sensor redundancy and fail-safe operation.

Recent regulatory developments have introduced more stringent certification processes for thermal runaway sensors. These include accelerated life testing requirements to verify long-term reliability and performance validation under simulated fault conditions. Certification now typically requires sensors to demonstrate consistent detection capabilities across the battery system's entire operational temperature range while maintaining false alarm rates below industry-accepted thresholds.

Compliance with these evolving standards necessitates comprehensive documentation of sensor specifications, installation procedures, and maintenance protocols. Manufacturers must provide detailed evidence of sensor calibration methodologies and verification procedures to ensure consistent performance throughout the system's operational lifetime. Additionally, many jurisdictions now require regular recertification of installed sensors to verify ongoing compliance with updated safety standards.

Insurance requirements have become increasingly aligned with these regulatory frameworks, with many insurers requiring certified thermal runaway detection systems as a prerequisite for coverage of large-scale stationary storage installations. This market-driven enforcement mechanism has accelerated the adoption of advanced sensor technologies beyond what is strictly mandated by regulatory bodies.

National Fire Protection Association (NFPA) standards, particularly NFPA 855, complement these international frameworks by specifying installation requirements for thermal runaway detection systems in stationary applications. The standard mandates that sensors must be capable of detecting temperature anomalies across the entire battery system and trigger appropriate mitigation measures when predefined thresholds are exceeded.

Regional variations in compliance requirements present significant challenges for global manufacturers. European regulations under EN IEC 63056 emphasize early detection capabilities and integration with battery management systems, while Asian markets, particularly China's GB/T 36276, focus on sensor durability under extreme environmental conditions. North American regulations through UL 1973 and CSA C22.2 place greater emphasis on sensor redundancy and fail-safe operation.

Recent regulatory developments have introduced more stringent certification processes for thermal runaway sensors. These include accelerated life testing requirements to verify long-term reliability and performance validation under simulated fault conditions. Certification now typically requires sensors to demonstrate consistent detection capabilities across the battery system's entire operational temperature range while maintaining false alarm rates below industry-accepted thresholds.

Compliance with these evolving standards necessitates comprehensive documentation of sensor specifications, installation procedures, and maintenance protocols. Manufacturers must provide detailed evidence of sensor calibration methodologies and verification procedures to ensure consistent performance throughout the system's operational lifetime. Additionally, many jurisdictions now require regular recertification of installed sensors to verify ongoing compliance with updated safety standards.

Insurance requirements have become increasingly aligned with these regulatory frameworks, with many insurers requiring certified thermal runaway detection systems as a prerequisite for coverage of large-scale stationary storage installations. This market-driven enforcement mechanism has accelerated the adoption of advanced sensor technologies beyond what is strictly mandated by regulatory bodies.

Cost-Benefit Analysis of Advanced Detection Systems

The implementation of advanced thermal runaway detection systems in stationary energy storage installations represents a significant investment decision that requires thorough cost-benefit analysis. Initial deployment costs for comprehensive sensor networks range from $50,000 to $150,000 per megawatt-hour of storage capacity, depending on the technology selection and integration complexity. These systems typically include combinations of gas sensors, temperature monitoring arrays, and voltage anomaly detection mechanisms.

When evaluating return on investment, the primary benefit stems from potential damage prevention. Historical data indicates that thermal runaway events in large-scale storage systems can result in damages exceeding $1-2 million per incident, not including business interruption costs which may reach $10,000-$30,000 per day of downtime. Advanced detection systems demonstrating early warning capabilities of 10-15 minutes before critical failure provide sufficient intervention time, reducing incident severity by approximately 60-80%.

Insurance premium reductions represent another quantifiable benefit, with providers offering 15-25% discounts for facilities implementing multi-layered detection systems. This translates to annual savings of $20,000-$75,000 for utility-scale installations, creating a potential payback period of 2-4 years solely from insurance benefits.

Operational efficiency improvements must also factor into the analysis. Remote monitoring capabilities reduce routine inspection requirements by 30-40%, saving approximately $15,000-$25,000 annually in labor costs for medium-sized facilities. Additionally, predictive maintenance enabled by these systems extends battery life by 10-15%, representing significant value preservation in assets with 10+ year lifespans.

The cost-effectiveness varies considerably across detection technologies. Gas detection systems offer the highest sensitivity-to-cost ratio for early-stage thermal events, while thermal imaging provides superior coverage but at 2-3 times the implementation cost. Hybrid systems combining multiple detection methodologies demonstrate the most favorable long-term economics despite higher initial investment.

Regulatory compliance benefits, though difficult to quantify directly, include avoidance of potential fines and operational restrictions. As energy storage safety standards evolve globally, facilities with advanced detection capabilities maintain operational flexibility worth an estimated $50,000-$100,000 annually in avoided compliance retrofitting costs and operational continuity.

When evaluating return on investment, the primary benefit stems from potential damage prevention. Historical data indicates that thermal runaway events in large-scale storage systems can result in damages exceeding $1-2 million per incident, not including business interruption costs which may reach $10,000-$30,000 per day of downtime. Advanced detection systems demonstrating early warning capabilities of 10-15 minutes before critical failure provide sufficient intervention time, reducing incident severity by approximately 60-80%.

Insurance premium reductions represent another quantifiable benefit, with providers offering 15-25% discounts for facilities implementing multi-layered detection systems. This translates to annual savings of $20,000-$75,000 for utility-scale installations, creating a potential payback period of 2-4 years solely from insurance benefits.

Operational efficiency improvements must also factor into the analysis. Remote monitoring capabilities reduce routine inspection requirements by 30-40%, saving approximately $15,000-$25,000 annually in labor costs for medium-sized facilities. Additionally, predictive maintenance enabled by these systems extends battery life by 10-15%, representing significant value preservation in assets with 10+ year lifespans.

The cost-effectiveness varies considerably across detection technologies. Gas detection systems offer the highest sensitivity-to-cost ratio for early-stage thermal events, while thermal imaging provides superior coverage but at 2-3 times the implementation cost. Hybrid systems combining multiple detection methodologies demonstrate the most favorable long-term economics despite higher initial investment.

Regulatory compliance benefits, though difficult to quantify directly, include avoidance of potential fines and operational restrictions. As energy storage safety standards evolve globally, facilities with advanced detection capabilities maintain operational flexibility worth an estimated $50,000-$100,000 annually in avoided compliance retrofitting costs and operational continuity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!