Thermal runaway sensors with fiber optic sensing technology

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fiber Optic Thermal Runaway Detection Background and Objectives

Fiber optic sensing technology has emerged as a revolutionary approach for thermal runaway detection in energy storage systems, particularly lithium-ion batteries. The evolution of this technology spans over three decades, beginning with basic fiber optic temperature sensing in the 1990s and advancing to sophisticated distributed sensing systems capable of real-time monitoring across multiple parameters today. This technological progression has been driven by the exponential growth in energy storage applications and the critical need for enhanced safety measures in battery systems.

The fundamental principle behind fiber optic thermal runaway detection leverages the sensitivity of light transmission through optical fibers to temperature changes. When a battery cell begins to experience thermal instability, the optical properties of the fiber are altered, creating measurable changes in parameters such as wavelength, intensity, or phase of the transmitted light. This enables early detection of potential thermal events before they escalate to catastrophic failure.

Current technological trends in this field are moving toward multi-parameter sensing systems that can simultaneously monitor temperature, strain, and acoustic emissions. These integrated approaches provide a more comprehensive picture of battery health and potential failure modes. Additionally, there is significant development in miniaturization and cost reduction of fiber optic sensing components, making widespread implementation more feasible across various energy storage applications.

The primary objective of fiber optic thermal runaway detection technology is to provide an early warning system that can identify precursors to thermal runaway events with sufficient lead time to enable preventive actions. Specific technical goals include achieving temperature sensitivity below 0.1°C, spatial resolution under 10mm, response times under 1 second, and system durability for operational lifetimes exceeding 10 years in harsh battery environments.

Secondary objectives include developing systems that are immune to electromagnetic interference, intrinsically safe in explosive environments, and capable of being retrofitted to existing battery installations. The technology aims to address the limitations of conventional sensing methods such as thermocouples and thermistors, which often suffer from delayed response, limited spatial coverage, and vulnerability to electromagnetic noise in battery systems.

The long-term vision for this technology extends beyond mere fault detection to predictive analytics, where fiber optic sensing data combined with machine learning algorithms can forecast potential thermal events hours or days before they occur, fundamentally transforming battery safety management paradigms across electric vehicles, grid storage, and consumer electronics applications.

The fundamental principle behind fiber optic thermal runaway detection leverages the sensitivity of light transmission through optical fibers to temperature changes. When a battery cell begins to experience thermal instability, the optical properties of the fiber are altered, creating measurable changes in parameters such as wavelength, intensity, or phase of the transmitted light. This enables early detection of potential thermal events before they escalate to catastrophic failure.

Current technological trends in this field are moving toward multi-parameter sensing systems that can simultaneously monitor temperature, strain, and acoustic emissions. These integrated approaches provide a more comprehensive picture of battery health and potential failure modes. Additionally, there is significant development in miniaturization and cost reduction of fiber optic sensing components, making widespread implementation more feasible across various energy storage applications.

The primary objective of fiber optic thermal runaway detection technology is to provide an early warning system that can identify precursors to thermal runaway events with sufficient lead time to enable preventive actions. Specific technical goals include achieving temperature sensitivity below 0.1°C, spatial resolution under 10mm, response times under 1 second, and system durability for operational lifetimes exceeding 10 years in harsh battery environments.

Secondary objectives include developing systems that are immune to electromagnetic interference, intrinsically safe in explosive environments, and capable of being retrofitted to existing battery installations. The technology aims to address the limitations of conventional sensing methods such as thermocouples and thermistors, which often suffer from delayed response, limited spatial coverage, and vulnerability to electromagnetic noise in battery systems.

The long-term vision for this technology extends beyond mere fault detection to predictive analytics, where fiber optic sensing data combined with machine learning algorithms can forecast potential thermal events hours or days before they occur, fundamentally transforming battery safety management paradigms across electric vehicles, grid storage, and consumer electronics applications.

Market Analysis for Advanced Battery Safety Solutions

The global market for advanced battery safety solutions is experiencing significant growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. The market value for battery safety technologies reached approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 15.7% through 2030, potentially reaching $7.8 billion by the end of the forecast period.

Fiber optic sensing technology for thermal runaway detection represents a particularly promising segment within this market. This technology currently accounts for about 8% of the total battery safety solutions market, but is expected to grow at an accelerated rate of 22.3% annually due to its superior performance characteristics compared to traditional sensing methods.

The EV sector dominates demand for advanced battery safety solutions, representing 56% of the total market. This is unsurprising given the average electric vehicle contains between 2,000 and 8,000 individual battery cells, each presenting a potential thermal runaway risk. The stationary energy storage sector follows at 27%, with consumer electronics accounting for 12% and industrial applications comprising the remaining 5%.

Regionally, Asia-Pacific leads the market with 45% share, driven by China's dominant position in both EV manufacturing and battery production. North America and Europe follow with 28% and 22% respectively, with both regions implementing increasingly stringent safety regulations that favor advanced detection technologies like fiber optic sensing.

The market is characterized by a growing preference for preventative rather than reactive safety systems. Traditional thermal management systems that activate after detecting high temperatures are increasingly being replaced by predictive systems capable of identifying precursors to thermal events. Fiber optic sensing technology excels in this area, capable of detecting temperature anomalies with millisecond response times and spatial resolution of less than 1cm.

Customer willingness to pay for premium safety solutions varies by sector. EV manufacturers demonstrate the highest price tolerance, with safety systems typically representing 3-5% of total battery system costs. This percentage is expected to increase as manufacturers compete on safety credentials and as insurance companies begin offering premium discounts for vehicles equipped with advanced thermal runaway prevention systems.

Market barriers include integration challenges with existing battery management systems, cost concerns in price-sensitive segments, and the need for standardized testing protocols to validate performance claims. Despite these challenges, the trajectory remains strongly positive as regulatory requirements tighten and consumer awareness of battery safety issues grows.

Fiber optic sensing technology for thermal runaway detection represents a particularly promising segment within this market. This technology currently accounts for about 8% of the total battery safety solutions market, but is expected to grow at an accelerated rate of 22.3% annually due to its superior performance characteristics compared to traditional sensing methods.

The EV sector dominates demand for advanced battery safety solutions, representing 56% of the total market. This is unsurprising given the average electric vehicle contains between 2,000 and 8,000 individual battery cells, each presenting a potential thermal runaway risk. The stationary energy storage sector follows at 27%, with consumer electronics accounting for 12% and industrial applications comprising the remaining 5%.

Regionally, Asia-Pacific leads the market with 45% share, driven by China's dominant position in both EV manufacturing and battery production. North America and Europe follow with 28% and 22% respectively, with both regions implementing increasingly stringent safety regulations that favor advanced detection technologies like fiber optic sensing.

The market is characterized by a growing preference for preventative rather than reactive safety systems. Traditional thermal management systems that activate after detecting high temperatures are increasingly being replaced by predictive systems capable of identifying precursors to thermal events. Fiber optic sensing technology excels in this area, capable of detecting temperature anomalies with millisecond response times and spatial resolution of less than 1cm.

Customer willingness to pay for premium safety solutions varies by sector. EV manufacturers demonstrate the highest price tolerance, with safety systems typically representing 3-5% of total battery system costs. This percentage is expected to increase as manufacturers compete on safety credentials and as insurance companies begin offering premium discounts for vehicles equipped with advanced thermal runaway prevention systems.

Market barriers include integration challenges with existing battery management systems, cost concerns in price-sensitive segments, and the need for standardized testing protocols to validate performance claims. Despite these challenges, the trajectory remains strongly positive as regulatory requirements tighten and consumer awareness of battery safety issues grows.

Current Challenges in Thermal Runaway Detection Technologies

Despite significant advancements in thermal runaway detection technologies, several critical challenges persist that limit their widespread implementation and effectiveness in battery safety systems. The current generation of thermal runaway detection methods faces substantial technical hurdles that require innovative solutions, particularly when considering fiber optic sensing technology integration.

Temperature threshold determination remains a fundamental challenge, as establishing the optimal trigger point that balances early detection with false alarm prevention continues to elude researchers. Too sensitive settings result in unnecessary system shutdowns, while conservative thresholds may detect thermal events too late to prevent catastrophic failure. This challenge is compounded by the diverse thermal behaviors exhibited across different battery chemistries and form factors.

Response time limitations present another significant obstacle. Even when thermal anomalies are detected, the window between detection and full thermal runaway can be extremely narrow—sometimes mere seconds—leaving insufficient time for intervention. This is particularly problematic in large-scale battery systems where thermal propagation can accelerate rapidly once initiated.

Signal processing complexity introduces additional difficulties, as distinguishing between normal operational temperature fluctuations and early indicators of thermal runaway requires sophisticated algorithms. Environmental noise, electromagnetic interference, and thermal gradients within battery packs further complicate accurate signal interpretation.

Integration challenges with battery management systems (BMS) create compatibility issues, as many existing BMS architectures were not designed to accommodate advanced sensing technologies. This results in communication protocol mismatches and data processing bottlenecks that impede real-time response capabilities.

Cost-effectiveness remains a significant barrier to widespread adoption, particularly for fiber optic sensing solutions which typically require specialized equipment and expertise. The economic justification becomes especially challenging for consumer electronics and entry-level electric vehicles where price sensitivity is high.

Durability and reliability concerns persist throughout the battery lifecycle. Sensors must maintain calibration and functionality despite exposure to harsh chemical environments, mechanical stress, and thermal cycling. Current solutions often demonstrate performance degradation over time, reducing their effectiveness precisely when aging batteries become more vulnerable to thermal events.

Miniaturization limitations restrict implementation in space-constrained applications, as many detection systems remain too bulky for integration into densely packed battery assemblies. This is particularly relevant for fiber optic systems that require minimum bend radii and protective conduits.

Temperature threshold determination remains a fundamental challenge, as establishing the optimal trigger point that balances early detection with false alarm prevention continues to elude researchers. Too sensitive settings result in unnecessary system shutdowns, while conservative thresholds may detect thermal events too late to prevent catastrophic failure. This challenge is compounded by the diverse thermal behaviors exhibited across different battery chemistries and form factors.

Response time limitations present another significant obstacle. Even when thermal anomalies are detected, the window between detection and full thermal runaway can be extremely narrow—sometimes mere seconds—leaving insufficient time for intervention. This is particularly problematic in large-scale battery systems where thermal propagation can accelerate rapidly once initiated.

Signal processing complexity introduces additional difficulties, as distinguishing between normal operational temperature fluctuations and early indicators of thermal runaway requires sophisticated algorithms. Environmental noise, electromagnetic interference, and thermal gradients within battery packs further complicate accurate signal interpretation.

Integration challenges with battery management systems (BMS) create compatibility issues, as many existing BMS architectures were not designed to accommodate advanced sensing technologies. This results in communication protocol mismatches and data processing bottlenecks that impede real-time response capabilities.

Cost-effectiveness remains a significant barrier to widespread adoption, particularly for fiber optic sensing solutions which typically require specialized equipment and expertise. The economic justification becomes especially challenging for consumer electronics and entry-level electric vehicles where price sensitivity is high.

Durability and reliability concerns persist throughout the battery lifecycle. Sensors must maintain calibration and functionality despite exposure to harsh chemical environments, mechanical stress, and thermal cycling. Current solutions often demonstrate performance degradation over time, reducing their effectiveness precisely when aging batteries become more vulnerable to thermal events.

Miniaturization limitations restrict implementation in space-constrained applications, as many detection systems remain too bulky for integration into densely packed battery assemblies. This is particularly relevant for fiber optic systems that require minimum bend radii and protective conduits.

Existing Fiber Optic Sensor Implementation Approaches

01 Distributed fiber optic sensing for thermal runaway detection

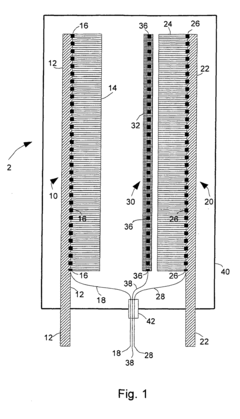

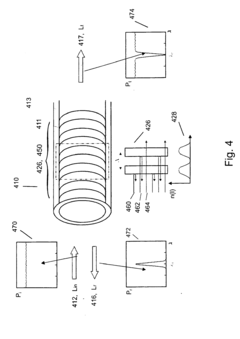

Distributed fiber optic sensing systems can be deployed to monitor temperature changes across battery systems for early thermal runaway detection. These systems use optical fibers as continuous sensors that can detect temperature variations along their entire length, providing real-time monitoring capabilities. The technology relies on analyzing backscattered light signals that change with temperature, enabling precise localization of hotspots that may indicate the onset of thermal runaway conditions in battery systems.- Distributed fiber optic sensing for battery thermal monitoring: Distributed fiber optic sensing systems can be integrated with battery systems to detect thermal runaway conditions. These systems use optical fibers embedded in or around battery cells to continuously monitor temperature distributions across the entire battery pack. The fiber optic sensors can detect temperature anomalies and early signs of thermal runaway by measuring changes in light properties as they travel through the fiber, providing real-time monitoring with high spatial resolution.

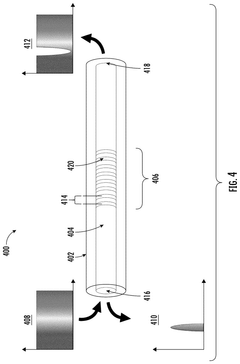

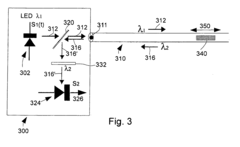

- Fiber Bragg Grating (FBG) sensors for thermal event detection: Fiber Bragg Grating sensors offer precise temperature and strain measurements for thermal runaway detection in battery systems. These specialized optical fibers contain periodic variations in their refractive index that reflect specific wavelengths of light. When temperature changes occur during thermal events, the reflected wavelength shifts, allowing for accurate temperature monitoring. FBG sensors provide immunity to electromagnetic interference, multiplexing capabilities, and can be strategically placed to monitor critical areas within battery systems.

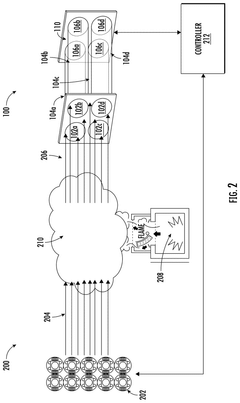

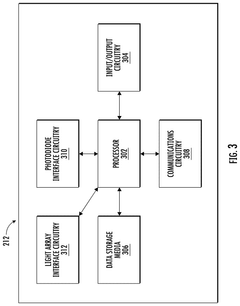

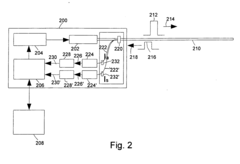

- Integration of fiber optic sensors with battery management systems: Advanced battery management systems incorporate fiber optic sensing technology to enhance thermal runaway detection capabilities. These integrated systems combine fiber optic temperature measurements with other battery parameters like voltage and current to provide comprehensive monitoring. The fiber optic data is processed through specialized algorithms that can identify thermal anomalies, predict potential failures, and trigger appropriate safety responses. This integration enables more effective early warning systems and improved battery safety protocols.

- Novel fiber optic sensor designs for enhanced thermal sensitivity: Innovative fiber optic sensor designs have been developed specifically for improved thermal runaway detection. These include specialized coating materials that enhance temperature sensitivity, multi-parameter sensing fibers that can simultaneously detect temperature and mechanical deformation, and novel fiber structures optimized for rapid response to thermal events. Some designs incorporate luminescent materials or specialized dopants within the fiber core to provide enhanced temperature resolution and faster response times in battery monitoring applications.

- Fiber optic sensing networks for large-scale battery installations: Fiber optic sensing networks enable comprehensive thermal monitoring across large-scale battery installations such as grid storage systems and electric vehicle fleets. These networks utilize multiplexed fiber optic sensors connected to centralized interrogation units that can monitor hundreds of measurement points simultaneously. The systems incorporate advanced data processing techniques to handle the large volumes of temperature data, identify patterns indicative of thermal issues, and provide spatial mapping of temperature distributions across the entire battery installation.

02 Fiber Bragg Grating (FBG) sensors for battery monitoring

Fiber Bragg Grating sensors offer a specialized approach to thermal runaway detection by measuring strain and temperature changes in battery systems. These sensors contain periodic variations in the refractive index of the fiber core that reflect specific wavelengths of light. When temperature changes occur during thermal events, the grating period changes, shifting the reflected wavelength. This technology enables high-precision temperature monitoring with immunity to electromagnetic interference, making it particularly suitable for battery management systems where early detection of thermal anomalies is critical.Expand Specific Solutions03 Integration of fiber optic sensors with battery management systems

Advanced battery management systems incorporate fiber optic sensing technology to enhance thermal runaway detection capabilities. These integrated systems combine temperature data from fiber optic sensors with other battery parameters to create comprehensive monitoring solutions. The integration enables automated safety responses such as circuit disconnection, cooling system activation, or emergency shutdown when thermal anomalies are detected. This approach provides a multi-layered safety strategy that can significantly reduce the risk of catastrophic battery failures in electric vehicles, energy storage systems, and other high-capacity battery applications.Expand Specific Solutions04 Novel fiber optic sensor designs for improved sensitivity

Innovative fiber optic sensor designs have been developed to enhance sensitivity and response time for thermal runaway detection. These include specialized coating materials that amplify temperature-dependent signal changes, multi-parameter sensing fibers that can simultaneously monitor temperature and strain, and miniaturized sensor configurations that can be embedded directly within battery cells. Some designs incorporate luminescent materials or phase-change materials that provide distinct optical signatures during temperature excursions, enabling more reliable early warning of potential thermal events.Expand Specific Solutions05 Communication systems for fiber optic thermal monitoring

Specialized communication systems have been developed to transmit and process data from fiber optic thermal runaway detection networks. These systems include optical interrogators that analyze the backscattered light signals, data processing algorithms that filter noise and identify thermal anomalies, and communication protocols that ensure reliable data transmission even in harsh electromagnetic environments. Some systems incorporate wireless transmission capabilities to relay thermal monitoring data to remote monitoring stations, while others integrate with cloud-based analytics platforms for advanced pattern recognition and predictive maintenance applications.Expand Specific Solutions

Leading Companies in Fiber Optic Sensing Industry

The thermal runaway sensing market using fiber optic technology is in its growth phase, with increasing adoption driven by battery safety concerns in electric vehicles and energy storage systems. The market is projected to expand significantly as EV adoption accelerates globally. Leading players include established industrial giants like Honeywell International and Renesas Electronics, alongside battery technology specialists such as CATL and Samsung SDI. Tesla and automotive manufacturers (Hyundai, GM) are integrating these sensors into their battery management systems. Research institutions like Naval Research Laboratory and universities (Chongqing, Beihang) are advancing the fundamental technology, while specialized companies are developing commercial applications. The technology is approaching maturity with deployable solutions, though continuous refinement for cost reduction and reliability improvement remains ongoing.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced fiber optic sensing technology for thermal runaway detection in battery systems. Their solution integrates distributed temperature sensing (DTS) fiber optic cables directly into battery modules to provide real-time temperature monitoring across the entire battery surface. The system uses Rayleigh backscattering principles to detect temperature changes with high spatial resolution (as fine as 1mm) and can identify hotspots before they trigger thermal runaway events. Honeywell's implementation includes specialized signal processing algorithms that filter out ambient noise and can detect temperature anomalies as small as 0.5°C. The system is designed with redundant optical channels to ensure reliability in harsh automotive and industrial environments, with response times under 100ms to enable rapid intervention when thermal events begin to develop.

Strengths: Superior spatial resolution allowing precise localization of hotspots; immune to electromagnetic interference; intrinsically safe in hazardous environments; no electrical components within battery enclosure. Weaknesses: Higher initial implementation cost compared to traditional sensors; requires specialized expertise for installation and maintenance; potential vulnerability of fiber cables to physical damage during battery assembly.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered an integrated fiber optic sensing network for thermal runaway prevention in their latest generation of lithium-ion battery systems. Their proprietary solution embeds fiber Bragg grating (FBG) sensors throughout the battery pack, creating a comprehensive monitoring mesh that can detect temperature variations with ±0.1°C accuracy. The system employs wavelength division multiplexing to monitor hundreds of sensing points simultaneously through a single fiber, significantly reducing system complexity. CATL's approach incorporates predictive analytics that leverage machine learning algorithms trained on extensive thermal runaway test data to identify precursor patterns before critical temperature thresholds are reached. Their implementation includes specialized coating materials for the optical fibers that enhance durability in the high-temperature, chemically aggressive battery environment while maintaining sensitivity. The system integrates directly with battery management systems to enable automatic shutdown protocols when abnormal thermal patterns are detected.

Strengths: Highly scalable solution suitable for large battery packs; predictive capabilities that identify potential failures before they occur; seamless integration with existing BMS architecture; minimal additional weight impact. Weaknesses: Requires specialized manufacturing processes to incorporate fibers during battery production; higher component cost compared to traditional thermal monitoring; limited field performance data for long-term reliability assessment.

Key Technical Innovations in Distributed Temperature Sensing

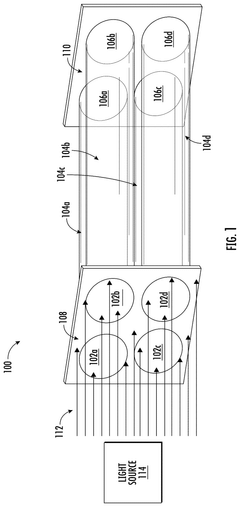

System, method, and computer program product for utilizing a fiber bragg grating to detect a gas indicating the onset of thermal runaway

PatentPendingUS20240288364A1

Innovation

- A system utilizing a light source emitting a spectrum of wavelengths and optical fibers with filtering mechanisms, such as fiber Bragg gratings, to detect gases like ethylene carbonate, diethyl carbonate, and dimethyl carbonate released during battery decay, enabling early detection of thermal runaway through spectral signature analysis.

Electrical device operating using galvanic principles such as a lithium ion rechargeable battery, with a temperature sensor

PatentInactiveEP2187472A2

Innovation

- Incorporating glass fibers as temperature sensors within the battery, allowing for real-time temperature monitoring and data transmission optically, enabling precise detection of temperature changes and reducing interference from electrical or electromagnetic influences, while also serving as a carrier material for the separator device.

Integration Strategies with Battery Management Systems

The integration of fiber optic thermal runaway sensors with Battery Management Systems (BMS) represents a critical advancement in battery safety technology. Effective integration strategies must address both hardware and software interfaces to ensure seamless data flow and rapid response capabilities. At the hardware level, fiber optic sensors require specialized connection points within the battery pack architecture, necessitating redesigned BMS boards that incorporate optical signal processing components alongside traditional electrical monitoring circuits.

Signal processing algorithms must be developed to interpret the distributed temperature data from fiber optic sensors and translate it into actionable intelligence for the BMS. These algorithms need to distinguish between normal thermal gradients and early indicators of thermal runaway events, requiring sophisticated pattern recognition capabilities. The integration architecture typically follows either a parallel monitoring approach, where fiber optic systems operate alongside conventional sensors, or a fully integrated solution where fiber optic data becomes a primary input for BMS decision-making.

Communication protocols between fiber optic sensing systems and BMS controllers require standardization to ensure compatibility across different battery designs. Current approaches include dedicated optical-to-digital converters that transform light-based measurements into digital signals compatible with standard BMS communication buses such as CAN, LIN, or FlexRay. The data transmission rates must be optimized to balance between comprehensive monitoring and system resource utilization.

Power management considerations are particularly important, as fiber optic interrogation systems traditionally consume more power than conventional sensor networks. Integration strategies must include power optimization techniques such as adaptive sampling rates and sleep modes during vehicle inactivity periods to minimize parasitic drain on the battery system being monitored.

Fault tolerance mechanisms represent another crucial aspect of integration. Redundancy designs typically incorporate both conventional and fiber optic sensing technologies to ensure system reliability even if one monitoring method fails. This hybrid approach provides comprehensive coverage while maintaining backward compatibility with existing safety systems.

Calibration and maintenance protocols must be established for integrated systems, addressing the unique requirements of fiber optic components. These protocols should include procedures for periodic verification of sensor accuracy and methods for detecting degradation in optical fiber performance over time. Software update pathways must also be defined to allow for refinement of detection algorithms as more field data becomes available.

Signal processing algorithms must be developed to interpret the distributed temperature data from fiber optic sensors and translate it into actionable intelligence for the BMS. These algorithms need to distinguish between normal thermal gradients and early indicators of thermal runaway events, requiring sophisticated pattern recognition capabilities. The integration architecture typically follows either a parallel monitoring approach, where fiber optic systems operate alongside conventional sensors, or a fully integrated solution where fiber optic data becomes a primary input for BMS decision-making.

Communication protocols between fiber optic sensing systems and BMS controllers require standardization to ensure compatibility across different battery designs. Current approaches include dedicated optical-to-digital converters that transform light-based measurements into digital signals compatible with standard BMS communication buses such as CAN, LIN, or FlexRay. The data transmission rates must be optimized to balance between comprehensive monitoring and system resource utilization.

Power management considerations are particularly important, as fiber optic interrogation systems traditionally consume more power than conventional sensor networks. Integration strategies must include power optimization techniques such as adaptive sampling rates and sleep modes during vehicle inactivity periods to minimize parasitic drain on the battery system being monitored.

Fault tolerance mechanisms represent another crucial aspect of integration. Redundancy designs typically incorporate both conventional and fiber optic sensing technologies to ensure system reliability even if one monitoring method fails. This hybrid approach provides comprehensive coverage while maintaining backward compatibility with existing safety systems.

Calibration and maintenance protocols must be established for integrated systems, addressing the unique requirements of fiber optic components. These protocols should include procedures for periodic verification of sensor accuracy and methods for detecting degradation in optical fiber performance over time. Software update pathways must also be defined to allow for refinement of detection algorithms as more field data becomes available.

Safety Standards and Certification Requirements

The integration of fiber optic sensing technology for thermal runaway detection in battery systems necessitates adherence to rigorous safety standards and certification requirements. Currently, the International Electrotechnical Commission (IEC) has established several standards specifically addressing battery safety, including IEC 62133 for portable batteries and IEC 62619 for industrial applications. These standards outline baseline requirements for thermal management systems but have not yet fully incorporated specific provisions for advanced sensing technologies like fiber optic thermal runaway detection.

The Underwriters Laboratories (UL) has developed UL 9540A, which specifically addresses test methods for evaluating thermal runaway fire propagation in battery energy storage systems. This standard is increasingly being referenced when evaluating new sensing technologies for early thermal event detection. Additionally, UL 1973 for batteries used in light electric rail and stationary applications provides guidelines that manufacturers of fiber optic sensing systems must consider.

In the automotive sector, ISO 26262 (functional safety for road vehicles) and UN/ECE-R100 (safety requirements for electric powertrains) establish critical frameworks that fiber optic thermal runaway sensors must comply with. These standards emphasize the need for redundancy, reliability, and rapid response times in safety-critical sensing systems.

For certification purposes, fiber optic sensing systems must demonstrate compliance with electromagnetic compatibility standards (EMC) such as IEC 61000 series, as these systems often operate in environments with significant electromagnetic interference. The sensors must maintain accuracy and reliability under these challenging conditions to receive certification.

Regional variations in certification requirements present additional challenges. While European markets follow the CE marking process requiring compliance with applicable directives like the Low Voltage Directive (2014/35/EU), North American markets typically require UL or CSA certification. Asian markets, particularly China and Japan, have established their own certification pathways through CCC and JIS standards respectively.

Emerging standards specifically addressing battery monitoring systems, such as the developing IEC 63056 for secondary lithium-ion cells for stationary energy storage, are beginning to include provisions for advanced sensing technologies. These standards are expected to evolve rapidly as fiber optic sensing technology gains wider adoption in thermal runaway prevention systems.

Manufacturers seeking global deployment of fiber optic thermal runaway sensors must navigate this complex regulatory landscape, often requiring multiple certifications and continuous monitoring of evolving standards to ensure compliance across different markets and applications.

The Underwriters Laboratories (UL) has developed UL 9540A, which specifically addresses test methods for evaluating thermal runaway fire propagation in battery energy storage systems. This standard is increasingly being referenced when evaluating new sensing technologies for early thermal event detection. Additionally, UL 1973 for batteries used in light electric rail and stationary applications provides guidelines that manufacturers of fiber optic sensing systems must consider.

In the automotive sector, ISO 26262 (functional safety for road vehicles) and UN/ECE-R100 (safety requirements for electric powertrains) establish critical frameworks that fiber optic thermal runaway sensors must comply with. These standards emphasize the need for redundancy, reliability, and rapid response times in safety-critical sensing systems.

For certification purposes, fiber optic sensing systems must demonstrate compliance with electromagnetic compatibility standards (EMC) such as IEC 61000 series, as these systems often operate in environments with significant electromagnetic interference. The sensors must maintain accuracy and reliability under these challenging conditions to receive certification.

Regional variations in certification requirements present additional challenges. While European markets follow the CE marking process requiring compliance with applicable directives like the Low Voltage Directive (2014/35/EU), North American markets typically require UL or CSA certification. Asian markets, particularly China and Japan, have established their own certification pathways through CCC and JIS standards respectively.

Emerging standards specifically addressing battery monitoring systems, such as the developing IEC 63056 for secondary lithium-ion cells for stationary energy storage, are beginning to include provisions for advanced sensing technologies. These standards are expected to evolve rapidly as fiber optic sensing technology gains wider adoption in thermal runaway prevention systems.

Manufacturers seeking global deployment of fiber optic thermal runaway sensors must navigate this complex regulatory landscape, often requiring multiple certifications and continuous monitoring of evolving standards to ensure compliance across different markets and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!