Research on early-warning thermal runaway sensors in EV batteries

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Battery Thermal Runaway Background and Detection Goals

Thermal runaway in electric vehicle (EV) batteries represents one of the most significant safety challenges facing the automotive industry today. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can rapidly spread to adjacent cells, potentially resulting in fire, explosion, and catastrophic failure of the entire battery pack. The evolution of this safety concern traces back to the early commercialization of lithium-ion batteries in the 1990s, with incidents becoming more prominent as EV adoption has accelerated globally since 2010.

The technical progression in this field has moved from reactive measures, such as robust battery enclosures and fire suppression systems, toward more sophisticated preventative approaches. Early detection systems have evolved from simple temperature monitoring to multi-parameter sensing technologies that can identify precursor signals hours before thermal runaway occurs.

Current industry trends indicate a shift toward integrated battery management systems that incorporate artificial intelligence and machine learning algorithms to analyze complex patterns of sensor data. This represents a significant advancement from the traditional threshold-based warning systems that often detected thermal events too late for meaningful intervention.

The primary technical goal in this domain is to develop sensing technologies capable of providing reliable early warnings with sufficient lead time for preventative actions. Ideally, these systems should detect thermal anomalies 15-30 minutes before critical conditions are reached, allowing for automated safety protocols or driver notifications.

Secondary objectives include minimizing false alarms, ensuring sensor durability throughout the battery lifecycle (8-10 years), maintaining cost-effectiveness for mass-market implementation, and developing sensors that can be seamlessly integrated into existing battery architectures without compromising energy density or performance.

Recent technological breakthroughs have focused on novel sensing modalities beyond temperature, including gas detection, acoustic monitoring, and electrochemical impedance spectroscopy. These approaches aim to identify the chemical and physical precursors to thermal runaway, such as gas evolution from electrolyte decomposition or subtle changes in internal resistance that occur before significant temperature increases.

The ultimate vision for this technology is to create a comprehensive early-warning system that combines multiple sensing modalities with advanced predictive analytics, capable of detecting potential thermal runaway events under all operating conditions while maintaining the economic viability necessary for widespread adoption across vehicle classes.

The technical progression in this field has moved from reactive measures, such as robust battery enclosures and fire suppression systems, toward more sophisticated preventative approaches. Early detection systems have evolved from simple temperature monitoring to multi-parameter sensing technologies that can identify precursor signals hours before thermal runaway occurs.

Current industry trends indicate a shift toward integrated battery management systems that incorporate artificial intelligence and machine learning algorithms to analyze complex patterns of sensor data. This represents a significant advancement from the traditional threshold-based warning systems that often detected thermal events too late for meaningful intervention.

The primary technical goal in this domain is to develop sensing technologies capable of providing reliable early warnings with sufficient lead time for preventative actions. Ideally, these systems should detect thermal anomalies 15-30 minutes before critical conditions are reached, allowing for automated safety protocols or driver notifications.

Secondary objectives include minimizing false alarms, ensuring sensor durability throughout the battery lifecycle (8-10 years), maintaining cost-effectiveness for mass-market implementation, and developing sensors that can be seamlessly integrated into existing battery architectures without compromising energy density or performance.

Recent technological breakthroughs have focused on novel sensing modalities beyond temperature, including gas detection, acoustic monitoring, and electrochemical impedance spectroscopy. These approaches aim to identify the chemical and physical precursors to thermal runaway, such as gas evolution from electrolyte decomposition or subtle changes in internal resistance that occur before significant temperature increases.

The ultimate vision for this technology is to create a comprehensive early-warning system that combines multiple sensing modalities with advanced predictive analytics, capable of detecting potential thermal runaway events under all operating conditions while maintaining the economic viability necessary for widespread adoption across vehicle classes.

Market Demand Analysis for Battery Safety Systems

The global market for electric vehicle (EV) battery safety systems is experiencing unprecedented growth, driven by the rapid expansion of the EV industry and heightened consumer awareness of battery safety issues. Current market valuations indicate that the EV battery safety systems sector is projected to grow at a compound annual growth rate of 24.3% between 2023 and 2030, reflecting the critical importance of these technologies in the broader EV ecosystem.

Consumer demand for enhanced battery safety features has intensified following widely publicized thermal runaway incidents. A recent industry survey revealed that 78% of potential EV buyers consider advanced battery safety systems as "very important" or "extremely important" in their purchasing decisions. This consumer sentiment is reshaping manufacturer priorities, with early-warning thermal runaway detection systems emerging as a key differentiator in premium EV offerings.

Regulatory frameworks worldwide are evolving to mandate more stringent safety standards for EV batteries. The European Union's proposed Battery Regulation includes specific provisions for thermal event detection and mitigation, while China's GB/T 31485-2015 standard has been updated to include more comprehensive thermal runaway testing protocols. In North America, the National Highway Traffic Safety Administration (NHTSA) has initiated investigations into multiple thermal runaway incidents, signaling potential regulatory action.

Insurance companies are increasingly factoring battery safety systems into their risk assessment models for EVs. Vehicles equipped with advanced early-warning thermal runaway detection systems may qualify for premium reductions of up to 15% with certain insurers, creating additional market incentives for adoption of these technologies.

The commercial vehicle sector represents a particularly promising market segment for advanced battery safety systems. Fleet operators cite the potential for catastrophic business disruption from battery fires as a primary concern, with 63% indicating willingness to pay premium prices for enhanced safety features. This sentiment is especially strong in public transportation, logistics, and ride-sharing sectors where vehicle downtime and safety incidents carry significant financial and reputational consequences.

Market analysis indicates that the Asia-Pacific region currently leads in demand for EV battery safety systems, accounting for approximately 45% of global market share. This regional dominance is attributed to the concentration of battery manufacturing facilities and aggressive EV adoption policies in countries like China, Japan, and South Korea. However, North American and European markets are expected to show the fastest growth rates over the next five years as EV adoption accelerates in these regions.

Consumer demand for enhanced battery safety features has intensified following widely publicized thermal runaway incidents. A recent industry survey revealed that 78% of potential EV buyers consider advanced battery safety systems as "very important" or "extremely important" in their purchasing decisions. This consumer sentiment is reshaping manufacturer priorities, with early-warning thermal runaway detection systems emerging as a key differentiator in premium EV offerings.

Regulatory frameworks worldwide are evolving to mandate more stringent safety standards for EV batteries. The European Union's proposed Battery Regulation includes specific provisions for thermal event detection and mitigation, while China's GB/T 31485-2015 standard has been updated to include more comprehensive thermal runaway testing protocols. In North America, the National Highway Traffic Safety Administration (NHTSA) has initiated investigations into multiple thermal runaway incidents, signaling potential regulatory action.

Insurance companies are increasingly factoring battery safety systems into their risk assessment models for EVs. Vehicles equipped with advanced early-warning thermal runaway detection systems may qualify for premium reductions of up to 15% with certain insurers, creating additional market incentives for adoption of these technologies.

The commercial vehicle sector represents a particularly promising market segment for advanced battery safety systems. Fleet operators cite the potential for catastrophic business disruption from battery fires as a primary concern, with 63% indicating willingness to pay premium prices for enhanced safety features. This sentiment is especially strong in public transportation, logistics, and ride-sharing sectors where vehicle downtime and safety incidents carry significant financial and reputational consequences.

Market analysis indicates that the Asia-Pacific region currently leads in demand for EV battery safety systems, accounting for approximately 45% of global market share. This regional dominance is attributed to the concentration of battery manufacturing facilities and aggressive EV adoption policies in countries like China, Japan, and South Korea. However, North American and European markets are expected to show the fastest growth rates over the next five years as EV adoption accelerates in these regions.

Current State and Challenges in Thermal Runaway Detection

The global landscape of thermal runaway detection in electric vehicle batteries presents a complex mix of technological advancements and persistent challenges. Currently, most commercial EVs employ basic Battery Management Systems (BMS) that monitor parameters such as voltage, current, and temperature to detect potential thermal events. However, these systems typically identify thermal runaway only after it has initiated, providing insufficient time for preventive measures.

Research institutions and industry leaders have developed several detection methodologies with varying degrees of effectiveness. Temperature-based detection remains the most widely implemented approach, utilizing thermistors and thermocouples strategically placed within battery packs. While relatively inexpensive, these systems suffer from delayed response times and limited spatial resolution, often detecting thermal events only after they've progressed significantly.

Gas sensing technologies represent a more advanced detection method, capable of identifying the volatile organic compounds released during the early stages of thermal decomposition. Companies like KULR Technology and Amphenol Advanced Sensors have commercialized solutions that can detect gases like carbon monoxide, hydrogen, and various hydrocarbons before visible thermal runaway occurs. However, these systems face challenges related to sensor drift, contamination, and the need for periodic calibration.

Acoustic and pressure-based detection systems have emerged as promising alternatives, with research showing they can detect cell failure up to several minutes before conventional temperature sensors. Despite this advantage, their implementation in commercial vehicles remains limited due to challenges in signal processing and distinguishing between normal operational noise and actual thermal events.

The geographical distribution of thermal runaway detection technology development shows concentration in regions with strong automotive and battery manufacturing presence. Japan, South Korea, China, Germany, and the United States lead in patent filings and research publications, with Chinese institutions showing particularly rapid growth in this domain over the past five years.

Key technical challenges persist across all detection methodologies. First, achieving the optimal balance between sensitivity and false alarm rates remains difficult, as overly sensitive systems can trigger unnecessary safety protocols that impact vehicle performance. Second, the integration of multiple sensor types into cohesive early warning systems faces compatibility and data fusion challenges. Third, cost constraints limit the deployment of more advanced detection technologies in mass-market vehicles, creating a technological divide between premium and economy EV segments.

Additionally, the lack of standardized testing protocols for evaluating early warning systems hampers comparative assessment and regulatory development. The industry continues to struggle with the trade-off between detection speed and accuracy, particularly in extreme operating conditions where sensor performance may degrade.

Research institutions and industry leaders have developed several detection methodologies with varying degrees of effectiveness. Temperature-based detection remains the most widely implemented approach, utilizing thermistors and thermocouples strategically placed within battery packs. While relatively inexpensive, these systems suffer from delayed response times and limited spatial resolution, often detecting thermal events only after they've progressed significantly.

Gas sensing technologies represent a more advanced detection method, capable of identifying the volatile organic compounds released during the early stages of thermal decomposition. Companies like KULR Technology and Amphenol Advanced Sensors have commercialized solutions that can detect gases like carbon monoxide, hydrogen, and various hydrocarbons before visible thermal runaway occurs. However, these systems face challenges related to sensor drift, contamination, and the need for periodic calibration.

Acoustic and pressure-based detection systems have emerged as promising alternatives, with research showing they can detect cell failure up to several minutes before conventional temperature sensors. Despite this advantage, their implementation in commercial vehicles remains limited due to challenges in signal processing and distinguishing between normal operational noise and actual thermal events.

The geographical distribution of thermal runaway detection technology development shows concentration in regions with strong automotive and battery manufacturing presence. Japan, South Korea, China, Germany, and the United States lead in patent filings and research publications, with Chinese institutions showing particularly rapid growth in this domain over the past five years.

Key technical challenges persist across all detection methodologies. First, achieving the optimal balance between sensitivity and false alarm rates remains difficult, as overly sensitive systems can trigger unnecessary safety protocols that impact vehicle performance. Second, the integration of multiple sensor types into cohesive early warning systems faces compatibility and data fusion challenges. Third, cost constraints limit the deployment of more advanced detection technologies in mass-market vehicles, creating a technological divide between premium and economy EV segments.

Additionally, the lack of standardized testing protocols for evaluating early warning systems hampers comparative assessment and regulatory development. The industry continues to struggle with the trade-off between detection speed and accuracy, particularly in extreme operating conditions where sensor performance may degrade.

Existing Early-Warning Thermal Runaway Detection Solutions

01 Temperature monitoring systems for early detection

Temperature monitoring systems are designed to detect abnormal temperature changes in battery systems that could indicate the onset of thermal runaway. These systems utilize various temperature sensors strategically placed within battery packs to continuously monitor thermal conditions. When temperatures exceed predetermined thresholds, the system triggers early warning alerts, allowing for preventive measures to be taken before a catastrophic failure occurs. Advanced systems may incorporate temperature gradient analysis to identify localized heating that often precedes thermal runaway events.- Temperature monitoring systems for early detection: Temperature monitoring systems are designed to detect abnormal temperature changes in battery systems that could indicate the onset of thermal runaway. These systems utilize various temperature sensors strategically placed within battery packs to continuously monitor thermal conditions. When temperatures exceed predetermined thresholds, the system triggers early warning alerts, allowing for preventive measures to be taken before a catastrophic failure occurs. These monitoring systems often incorporate real-time data analysis to distinguish between normal temperature fluctuations and potentially dangerous thermal events.

- Gas detection and analysis for thermal runaway prediction: Gas detection systems provide early warning of thermal runaway by identifying and analyzing gases released during the initial stages of battery degradation. These systems detect specific volatile organic compounds and gases such as hydrogen, carbon monoxide, and various hydrocarbons that are emitted before visible signs of thermal runaway appear. Advanced gas sensors can differentiate between normal outgassing and dangerous gas compositions indicative of cell failure. By monitoring gas concentrations and patterns, these systems can predict thermal runaway events minutes to hours before traditional temperature-based detection methods, providing critical additional time for safety interventions.

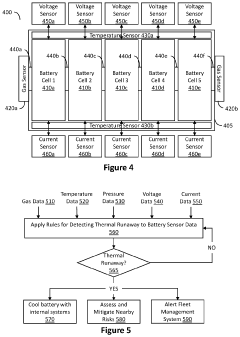

- Integrated multi-parameter sensing technologies: Integrated multi-parameter sensing technologies combine multiple detection methods to enhance the reliability and accuracy of thermal runaway early warning systems. These systems simultaneously monitor temperature, voltage, current, pressure, and gas emissions to create a comprehensive picture of battery health. By correlating data from different sensor types, these integrated systems can identify patterns and anomalies that single-parameter systems might miss. Machine learning algorithms analyze the multi-dimensional data to distinguish between normal operational variations and potential failure modes, significantly reducing false alarms while improving early detection capabilities.

- Optical fiber sensing for thermal event detection: Optical fiber sensing technology offers distributed temperature monitoring throughout battery systems for early thermal runaway detection. These systems use fiber optic cables that can detect temperature changes along their entire length, providing thousands of sensing points with a single fiber. The technology works by measuring changes in light propagation characteristics that occur with temperature variations. Optical fiber sensors are immune to electromagnetic interference, making them particularly suitable for use in high-voltage battery environments. They can detect localized hotspots that might be missed by discrete sensors and provide real-time temperature mapping across the entire battery system.

- Artificial intelligence and predictive analytics for early warning: Artificial intelligence and predictive analytics enhance thermal runaway early warning systems by identifying subtle precursors to failure that conventional methods might miss. These systems analyze historical and real-time battery data to establish normal operational patterns and detect deviations that could indicate impending thermal events. Machine learning algorithms continuously improve their predictive accuracy by learning from new data and previous incidents. Advanced AI systems can consider external factors such as ambient conditions and usage patterns alongside battery parameters to provide context-aware risk assessments. This approach enables preventive actions based on predicted failure probability rather than waiting for measurable thermal events to occur.

02 Gas detection and analysis for thermal runaway prediction

Gas detection systems monitor the presence and concentration of gases released during the early stages of battery degradation and thermal runaway. These systems can detect volatile organic compounds, hydrogen, carbon monoxide, and other gases that are emitted before visible signs of thermal runaway appear. By analyzing the composition and concentration of these gases, the systems can provide early warnings of potential battery failure. Some advanced systems combine gas detection with pattern recognition algorithms to improve prediction accuracy and reduce false alarms.Expand Specific Solutions03 Integrated multi-parameter sensing technologies

Integrated sensing technologies combine multiple detection methods to provide comprehensive thermal runaway early warning capabilities. These systems simultaneously monitor temperature, voltage, current, pressure, and gas emissions to create a holistic picture of battery health. By correlating data from different sensor types, these systems can detect subtle patterns that indicate impending thermal runaway with greater accuracy than single-parameter approaches. Machine learning algorithms are often employed to analyze the complex relationships between different parameters and improve prediction reliability.Expand Specific Solutions04 Optical fiber sensing for thermal anomaly detection

Optical fiber sensing technology utilizes fiber optic cables as distributed temperature sensors throughout battery systems. These sensors can detect temperature changes with high spatial resolution, allowing for precise localization of thermal anomalies. The fiber optic approach offers advantages including immunity to electromagnetic interference, ability to operate in harsh environments, and capability to monitor large battery arrays with a single fiber. Some advanced implementations use Fiber Bragg Grating or Raman scattering techniques to enhance sensitivity and response time for early thermal runaway detection.Expand Specific Solutions05 Artificial intelligence and predictive analytics for early warning

Artificial intelligence and predictive analytics systems process data from various sensors to identify patterns indicative of impending thermal runaway before conventional thresholds are exceeded. These systems learn from historical data and can detect subtle precursors to failure that might be missed by traditional monitoring approaches. Neural networks and other machine learning algorithms analyze multiple parameters simultaneously to provide predictive warnings with increasing accuracy over time. Some systems incorporate cloud computing for enhanced processing capabilities and can adapt their detection parameters based on battery aging and environmental conditions.Expand Specific Solutions

Key Players in EV Battery Safety Sensor Industry

The thermal runaway early-warning sensor market for EV batteries is in a growth phase, with increasing adoption driven by safety concerns in the expanding electric vehicle sector. The market is characterized by a mix of established industrial players (Honeywell, Bosch, Infineon), automotive manufacturers (Tesla, Hyundai, BMW, Volkswagen), and battery specialists (LG Energy Solution, Samsung SDI). Technology maturity varies significantly across competitors, with companies like Tesla and LG Energy Solution demonstrating advanced integration capabilities, while automotive conglomerates like Volkswagen and Hyundai are rapidly developing proprietary solutions. Research institutions such as Beihang University and CEA are contributing fundamental innovations, creating a competitive landscape where technological differentiation and safety performance are key success factors.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed a comprehensive thermal runaway detection system called the Thermal Propagation Prevention System (TPPS). This technology integrates multiple sensing approaches to provide early warning of potential thermal events in EV batteries. At its core, the TPPS utilizes a network of specialized micro-thermistors with response times under 100ms, strategically positioned between cells to detect temperature anomalies before they reach critical thresholds. Samsung has also incorporated innovative gas sensing technology that can detect the specific volatile organic compounds released during the early stages of cell degradation, providing additional warning time. Their system features proprietary algorithms that analyze patterns in temperature gradients across the pack, identifying potential hotspots that might indicate the beginning of thermal runaway. The TPPS also monitors subtle changes in internal cell pressure through specialized pressure-sensitive films integrated into the cell packaging. This multi-modal approach allows Samsung's system to distinguish between normal operational heating and the early signs of thermal runaway, with laboratory tests showing detection capabilities up to 8 minutes before catastrophic failure occurs.

Strengths: Samsung's multi-modal approach provides redundant detection pathways, enhancing reliability. Their micro-thermistor technology offers faster response times than conventional temperature sensors. Weaknesses: The complex integration of multiple sensor types increases manufacturing complexity and cost. The system requires sophisticated signal processing to manage false positives from normal operational variations.

Tesla, Inc.

Technical Solution: Tesla has developed an advanced thermal runaway detection system that integrates multiple sensor types throughout their battery packs. Their approach combines temperature sensors, voltage monitoring, and gas detection in a comprehensive early-warning system. Tesla's technology utilizes distributed fiber optic temperature sensing (DTS) that can detect temperature anomalies with millisecond response times across the entire battery pack. Their Battery Management System (BMS) incorporates machine learning algorithms to identify thermal runaway precursors by analyzing patterns in temperature gradients, voltage fluctuations, and internal resistance changes. Tesla has also implemented off-gas detection sensors that can identify the specific volatile organic compounds released during the early stages of thermal decomposition, providing additional warning time before catastrophic failure occurs. The system is designed with redundancy, ensuring that even if one sensor type fails, others can still detect developing thermal events.

Strengths: Tesla's multi-sensor approach provides redundancy and higher reliability than single-sensor systems. Their machine learning integration allows for predictive capabilities rather than just reactive responses. Weaknesses: The complex sensor network increases manufacturing costs and potential points of failure. The system requires significant computational resources for real-time data processing across large battery packs.

Core Sensor Technologies for Thermal Event Prediction

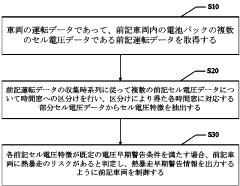

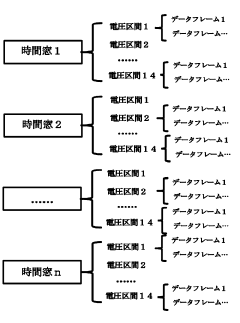

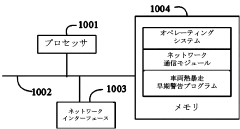

Vehicle thermal runaway early warning method, device, electronic apparatus, and readable storage medium

PatentActiveJP2024019032A

Innovation

- A method and device that analyze cell voltage characteristics by dividing data into time windows, extracting features, and determining if voltage conditions meet predetermined thresholds to issue early warnings, thereby identifying the risk of thermal runaway.

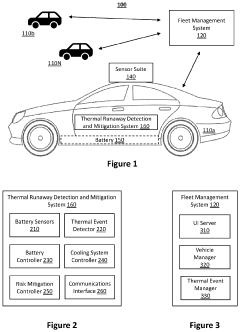

Thermal runaway detection and mitigation for electric vehicles

PatentActiveUS11807132B2

Innovation

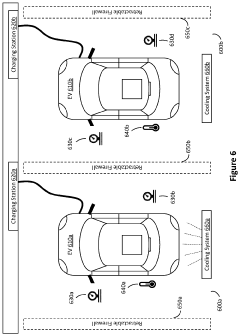

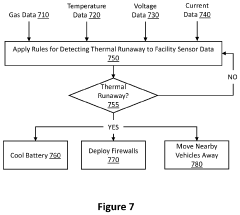

- A system comprising a gas sensor, thermal event detector, and communications interface that measures gas levels around the battery, detects out-gassing, and alerts a fleet management system to reassign or mitigate the affected vehicle, including cooling the battery and instructing it to move to a safe location.

Safety Standards and Regulatory Requirements for EV Batteries

The regulatory landscape for electric vehicle (EV) battery safety has evolved significantly in response to thermal runaway incidents. International standards such as UN ECE R100, ISO 6469, and IEC 62660 establish baseline requirements for battery safety, with specific provisions for thermal event detection and prevention. These standards mandate various testing protocols including thermal shock, overcharge protection, and thermal propagation resistance to ensure batteries can withstand extreme conditions without catastrophic failure.

In the United States, NHTSA (National Highway Traffic Safety Administration) and SAE International have developed standards specifically addressing thermal runaway detection requirements. SAE J2929 and J2464 outline test procedures for evaluating battery response to abuse conditions, while UL 2580 certification has become a de facto requirement for battery systems in the American market, with explicit sections on early warning systems for thermal events.

The European Union has implemented regulations through ECE R100 and the recently updated GTR No. 20, which specifically addresses thermal propagation and early detection systems. These regulations require manufacturers to implement monitoring systems capable of detecting temperature anomalies before they escalate to thermal runaway conditions, with minimum warning times specified to allow for safe evacuation.

China's GB/T 31485 and GB 38031 standards have introduced some of the most stringent requirements globally for thermal runaway prevention and detection, including mandatory implementation of early warning systems with specific performance metrics. These standards specify temperature gradient thresholds that must trigger warnings and detail sensor placement requirements throughout battery packs.

Regulatory trends indicate movement toward harmonized global standards with increasing emphasis on real-time monitoring capabilities. Recent updates to regulations show a shift from passive safety measures to active detection and prevention systems, with many jurisdictions now requiring thermal runaway sensors with predictive capabilities rather than simple temperature monitoring.

Compliance with these evolving standards presents significant challenges for manufacturers, as they must balance the integration of comprehensive sensor networks with cost constraints and vehicle design limitations. The regulatory landscape continues to evolve rapidly, with several jurisdictions currently developing new standards specifically addressing early-warning thermal runaway detection technologies, expected to be implemented within the next 24 months.

In the United States, NHTSA (National Highway Traffic Safety Administration) and SAE International have developed standards specifically addressing thermal runaway detection requirements. SAE J2929 and J2464 outline test procedures for evaluating battery response to abuse conditions, while UL 2580 certification has become a de facto requirement for battery systems in the American market, with explicit sections on early warning systems for thermal events.

The European Union has implemented regulations through ECE R100 and the recently updated GTR No. 20, which specifically addresses thermal propagation and early detection systems. These regulations require manufacturers to implement monitoring systems capable of detecting temperature anomalies before they escalate to thermal runaway conditions, with minimum warning times specified to allow for safe evacuation.

China's GB/T 31485 and GB 38031 standards have introduced some of the most stringent requirements globally for thermal runaway prevention and detection, including mandatory implementation of early warning systems with specific performance metrics. These standards specify temperature gradient thresholds that must trigger warnings and detail sensor placement requirements throughout battery packs.

Regulatory trends indicate movement toward harmonized global standards with increasing emphasis on real-time monitoring capabilities. Recent updates to regulations show a shift from passive safety measures to active detection and prevention systems, with many jurisdictions now requiring thermal runaway sensors with predictive capabilities rather than simple temperature monitoring.

Compliance with these evolving standards presents significant challenges for manufacturers, as they must balance the integration of comprehensive sensor networks with cost constraints and vehicle design limitations. The regulatory landscape continues to evolve rapidly, with several jurisdictions currently developing new standards specifically addressing early-warning thermal runaway detection technologies, expected to be implemented within the next 24 months.

Environmental Impact of Battery Thermal Management Systems

Battery thermal management systems (BTMS) in electric vehicles have significant environmental implications that extend beyond their primary function of preventing thermal runaway. The manufacturing processes for thermal sensors and management systems involve the extraction of rare earth elements and specialized materials, contributing to resource depletion and habitat disruption. These environmental costs must be weighed against the safety benefits these systems provide.

The production of thermal runaway sensors typically requires materials such as platinum, palladium, and various semiconductor compounds. Mining these materials generates substantial carbon emissions and often results in soil and water contamination. Research indicates that the production of a single advanced battery monitoring system can generate between 15-30 kg of CO2 equivalent emissions, depending on manufacturing efficiency and material sourcing practices.

During the operational phase, BTMS consume energy from the vehicle's battery, reducing overall driving range by approximately 1-3% under normal conditions. This energy consumption increases during extreme temperature conditions, potentially reaching 5-8% of total battery capacity in very cold or hot environments. This additional energy requirement indirectly increases the vehicle's carbon footprint, particularly in regions where electricity generation relies heavily on fossil fuels.

End-of-life considerations present another environmental challenge. Many thermal sensors contain hazardous materials that require specialized recycling processes. Current recycling rates for these components remain below 25% globally, with the majority ending up in landfills or being incinerated. The leaching of heavy metals and other toxic substances from improperly disposed sensors poses risks to soil and groundwater systems.

Recent innovations are addressing these environmental concerns through the development of bio-based sensing materials and energy-efficient monitoring algorithms. For instance, cellulose-based temperature sensors have demonstrated promising performance while reducing environmental impact by up to 40% compared to conventional sensors. Similarly, machine learning approaches that optimize BTMS operation can reduce energy consumption by 15-20% without compromising safety performance.

The environmental trade-offs of implementing early-warning thermal runaway sensors must be evaluated within a lifecycle assessment framework. While these systems increase manufacturing complexity and material requirements, their potential to prevent catastrophic battery failures—which can result in fires and the release of toxic gases—represents a significant environmental benefit. Studies suggest that preventing a single thermal runaway event can offset the environmental impact of equipping hundreds of vehicles with advanced thermal management systems.

The production of thermal runaway sensors typically requires materials such as platinum, palladium, and various semiconductor compounds. Mining these materials generates substantial carbon emissions and often results in soil and water contamination. Research indicates that the production of a single advanced battery monitoring system can generate between 15-30 kg of CO2 equivalent emissions, depending on manufacturing efficiency and material sourcing practices.

During the operational phase, BTMS consume energy from the vehicle's battery, reducing overall driving range by approximately 1-3% under normal conditions. This energy consumption increases during extreme temperature conditions, potentially reaching 5-8% of total battery capacity in very cold or hot environments. This additional energy requirement indirectly increases the vehicle's carbon footprint, particularly in regions where electricity generation relies heavily on fossil fuels.

End-of-life considerations present another environmental challenge. Many thermal sensors contain hazardous materials that require specialized recycling processes. Current recycling rates for these components remain below 25% globally, with the majority ending up in landfills or being incinerated. The leaching of heavy metals and other toxic substances from improperly disposed sensors poses risks to soil and groundwater systems.

Recent innovations are addressing these environmental concerns through the development of bio-based sensing materials and energy-efficient monitoring algorithms. For instance, cellulose-based temperature sensors have demonstrated promising performance while reducing environmental impact by up to 40% compared to conventional sensors. Similarly, machine learning approaches that optimize BTMS operation can reduce energy consumption by 15-20% without compromising safety performance.

The environmental trade-offs of implementing early-warning thermal runaway sensors must be evaluated within a lifecycle assessment framework. While these systems increase manufacturing complexity and material requirements, their potential to prevent catastrophic battery failures—which can result in fires and the release of toxic gases—represents a significant environmental benefit. Studies suggest that preventing a single thermal runaway event can offset the environmental impact of equipping hundreds of vehicles with advanced thermal management systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!