What detection methods are most effective in thermal runaway sensors

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Detection Background and Objectives

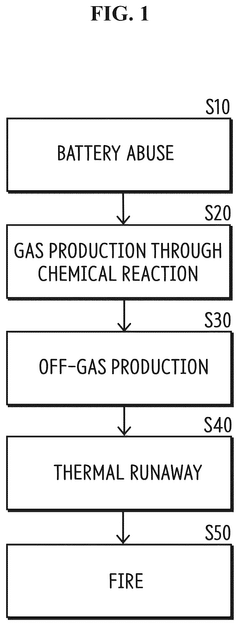

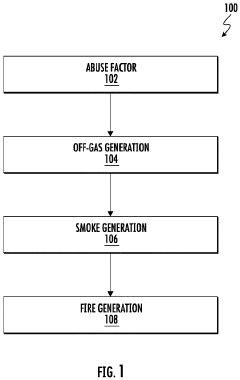

Thermal runaway is a critical safety concern in lithium-ion battery systems, characterized by an uncontrolled, self-heating process that can lead to catastrophic battery failure, fires, and explosions. The phenomenon has gained significant attention due to high-profile incidents in consumer electronics, electric vehicles, and energy storage systems over the past decade. As energy storage technologies continue to evolve and proliferate across industries, effective thermal runaway detection has become a paramount safety requirement.

The evolution of thermal runaway detection technologies has progressed from basic temperature monitoring to sophisticated multi-parameter sensing systems. Early detection methods relied primarily on simple temperature thresholds, which often provided insufficient warning time. Modern approaches incorporate multiple sensing modalities to detect precursor events before thermal runaway becomes irreversible.

The primary objective of thermal runaway detection research is to develop sensing technologies that can provide early, reliable warning of impending thermal events while minimizing false alarms. Ideal detection systems must operate under various environmental conditions, integrate seamlessly with battery management systems, and maintain accuracy throughout the battery lifecycle.

Current research focuses on reducing detection latency—the time between initial cell failure and detection signal—as shorter detection windows significantly improve safety outcomes. Studies indicate that detection within 30-60 seconds of initial cell failure can prevent propagation to adjacent cells, while detection beyond 120 seconds often results in cascading failure.

Another key objective is developing detection methods that can be economically implemented at scale. As lithium-ion batteries become ubiquitous in transportation and grid applications, cost-effective detection solutions are essential for widespread adoption of safety systems.

The technical landscape encompasses various detection approaches, including thermal (temperature, heat flux), electrical (voltage, impedance), chemical (gas sensing), and mechanical (pressure, strain) methods. Each approach offers distinct advantages in sensitivity, response time, and implementation complexity.

Industry standards and regulatory frameworks are evolving rapidly, with organizations like UL, IEC, and SAE developing specifications for thermal runaway detection in different applications. These standards increasingly emphasize the need for redundant detection methods and system-level safety approaches rather than relying on single-parameter monitoring.

As battery chemistries and form factors continue to diversify, detection technologies must adapt to new failure modes and thermal behaviors. This creates an ongoing challenge for researchers and engineers to develop flexible, chemistry-agnostic detection methodologies that can be applied across the expanding landscape of energy storage technologies.

The evolution of thermal runaway detection technologies has progressed from basic temperature monitoring to sophisticated multi-parameter sensing systems. Early detection methods relied primarily on simple temperature thresholds, which often provided insufficient warning time. Modern approaches incorporate multiple sensing modalities to detect precursor events before thermal runaway becomes irreversible.

The primary objective of thermal runaway detection research is to develop sensing technologies that can provide early, reliable warning of impending thermal events while minimizing false alarms. Ideal detection systems must operate under various environmental conditions, integrate seamlessly with battery management systems, and maintain accuracy throughout the battery lifecycle.

Current research focuses on reducing detection latency—the time between initial cell failure and detection signal—as shorter detection windows significantly improve safety outcomes. Studies indicate that detection within 30-60 seconds of initial cell failure can prevent propagation to adjacent cells, while detection beyond 120 seconds often results in cascading failure.

Another key objective is developing detection methods that can be economically implemented at scale. As lithium-ion batteries become ubiquitous in transportation and grid applications, cost-effective detection solutions are essential for widespread adoption of safety systems.

The technical landscape encompasses various detection approaches, including thermal (temperature, heat flux), electrical (voltage, impedance), chemical (gas sensing), and mechanical (pressure, strain) methods. Each approach offers distinct advantages in sensitivity, response time, and implementation complexity.

Industry standards and regulatory frameworks are evolving rapidly, with organizations like UL, IEC, and SAE developing specifications for thermal runaway detection in different applications. These standards increasingly emphasize the need for redundant detection methods and system-level safety approaches rather than relying on single-parameter monitoring.

As battery chemistries and form factors continue to diversify, detection technologies must adapt to new failure modes and thermal behaviors. This creates an ongoing challenge for researchers and engineers to develop flexible, chemistry-agnostic detection methodologies that can be applied across the expanding landscape of energy storage technologies.

Market Demand Analysis for Thermal Runaway Sensors

The global market for thermal runaway sensors is experiencing significant growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Market research indicates that the thermal runaway detection systems market is projected to grow at a CAGR of 15.8% from 2023 to 2030, with the market value expected to reach $2.7 billion by 2030. This growth trajectory is directly correlated with the increasing production volumes of lithium-ion batteries for automotive applications.

Consumer safety concerns represent a major market driver, as high-profile battery fire incidents have heightened awareness about thermal runaway risks. Regulatory bodies across major markets including the European Union, United States, and China have responded by implementing stricter safety standards for battery systems, effectively mandating advanced detection technologies in new vehicle designs.

Insurance companies have also become significant stakeholders in this market, offering premium reductions for vehicles equipped with certified thermal runaway detection systems. This financial incentive has created additional market pull beyond regulatory compliance.

The market segmentation reveals distinct demand patterns across different sectors. The passenger EV segment currently dominates market share at approximately 65%, followed by energy storage systems at 20%, and commercial electric vehicles at 15%. However, the fastest growth is projected in the commercial EV sector, particularly in electric buses and delivery fleets where the consequences of thermal events can be more severe.

Geographically, Asia-Pacific represents the largest market for thermal runaway sensors, accounting for 48% of global demand, followed by Europe (27%) and North America (20%). This distribution closely follows regional EV manufacturing concentrations, with China being the single largest national market.

End-user requirements are increasingly sophisticated, with automotive OEMs demanding sensors that offer earlier detection capabilities, lower false alarm rates, and seamless integration with battery management systems. Survey data from major automotive manufacturers indicates that detection speed and reliability are valued above cost considerations, suggesting a premium market segment for high-performance solutions.

The aftermarket for retrofit thermal runaway detection systems is emerging as a significant opportunity, particularly for commercial fleet operators seeking to enhance the safety of existing vehicles. This segment is expected to grow at 22% annually through 2028, outpacing the overall market growth rate.

Consumer safety concerns represent a major market driver, as high-profile battery fire incidents have heightened awareness about thermal runaway risks. Regulatory bodies across major markets including the European Union, United States, and China have responded by implementing stricter safety standards for battery systems, effectively mandating advanced detection technologies in new vehicle designs.

Insurance companies have also become significant stakeholders in this market, offering premium reductions for vehicles equipped with certified thermal runaway detection systems. This financial incentive has created additional market pull beyond regulatory compliance.

The market segmentation reveals distinct demand patterns across different sectors. The passenger EV segment currently dominates market share at approximately 65%, followed by energy storage systems at 20%, and commercial electric vehicles at 15%. However, the fastest growth is projected in the commercial EV sector, particularly in electric buses and delivery fleets where the consequences of thermal events can be more severe.

Geographically, Asia-Pacific represents the largest market for thermal runaway sensors, accounting for 48% of global demand, followed by Europe (27%) and North America (20%). This distribution closely follows regional EV manufacturing concentrations, with China being the single largest national market.

End-user requirements are increasingly sophisticated, with automotive OEMs demanding sensors that offer earlier detection capabilities, lower false alarm rates, and seamless integration with battery management systems. Survey data from major automotive manufacturers indicates that detection speed and reliability are valued above cost considerations, suggesting a premium market segment for high-performance solutions.

The aftermarket for retrofit thermal runaway detection systems is emerging as a significant opportunity, particularly for commercial fleet operators seeking to enhance the safety of existing vehicles. This segment is expected to grow at 22% annually through 2028, outpacing the overall market growth rate.

Current Detection Technologies and Challenges

The current landscape of thermal runaway detection technologies encompasses several methodologies, each with distinct advantages and limitations. Temperature monitoring remains the most widely implemented approach, utilizing thermocouples, thermistors, and infrared sensors to track battery temperature changes. While these systems offer simplicity and cost-effectiveness, they often suffer from delayed response times, as temperature elevation typically manifests after thermal runaway has already initiated, limiting their effectiveness as preventive measures.

Voltage and current monitoring systems represent another common detection method, analyzing electrical parameters for anomalies indicative of potential thermal events. These systems benefit from integration with existing battery management systems (BMS) but may struggle with distinguishing between normal operational fluctuations and genuine thermal runaway precursors, resulting in potential false positives or missed detection events.

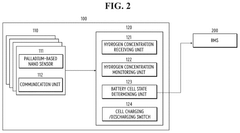

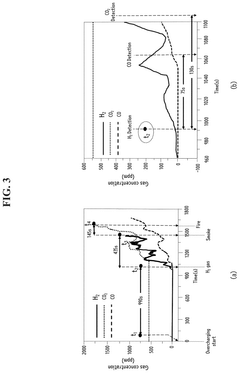

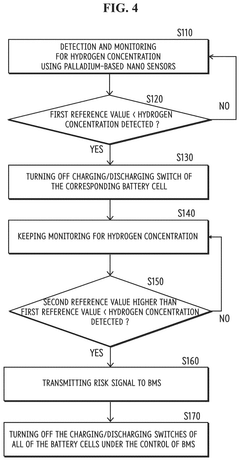

Gas detection has emerged as a promising approach, focusing on identifying specific gases released during the early stages of thermal decomposition within cells. Recent research indicates that certain volatile organic compounds and hydrogen can be detected up to 30 minutes before catastrophic failure, providing valuable early warning capabilities. However, challenges persist in sensor miniaturization, cost, and the development of selective detection algorithms capable of functioning in varied environmental conditions.

Acoustic emission monitoring represents an innovative detection pathway, utilizing ultrasonic sensors to detect the characteristic sounds produced during separator breakdown and electrolyte decomposition. Studies demonstrate detection capabilities up to 15 minutes before visible thermal events, though implementation challenges include signal processing complexity and environmental noise filtering requirements.

Differential pressure sensing has shown promise in sealed battery systems, detecting minute pressure changes caused by gas generation during early decomposition stages. While effective in controlled environments, practical implementation faces challenges in sensor integration and calibration across diverse battery form factors.

The primary technical challenges across all detection methodologies include achieving sufficient sensitivity without compromising false alarm rates, ensuring system reliability under varied operational conditions, and maintaining detection capabilities throughout battery aging processes. Additionally, integration challenges persist in developing unified detection systems capable of processing multiple sensor inputs while maintaining cost-effectiveness for commercial applications.

Power consumption represents another significant constraint, particularly for implementations in portable electronics and electric vehicles where energy efficiency is paramount. The ideal detection system must balance continuous monitoring capabilities with minimal impact on overall system efficiency.

Voltage and current monitoring systems represent another common detection method, analyzing electrical parameters for anomalies indicative of potential thermal events. These systems benefit from integration with existing battery management systems (BMS) but may struggle with distinguishing between normal operational fluctuations and genuine thermal runaway precursors, resulting in potential false positives or missed detection events.

Gas detection has emerged as a promising approach, focusing on identifying specific gases released during the early stages of thermal decomposition within cells. Recent research indicates that certain volatile organic compounds and hydrogen can be detected up to 30 minutes before catastrophic failure, providing valuable early warning capabilities. However, challenges persist in sensor miniaturization, cost, and the development of selective detection algorithms capable of functioning in varied environmental conditions.

Acoustic emission monitoring represents an innovative detection pathway, utilizing ultrasonic sensors to detect the characteristic sounds produced during separator breakdown and electrolyte decomposition. Studies demonstrate detection capabilities up to 15 minutes before visible thermal events, though implementation challenges include signal processing complexity and environmental noise filtering requirements.

Differential pressure sensing has shown promise in sealed battery systems, detecting minute pressure changes caused by gas generation during early decomposition stages. While effective in controlled environments, practical implementation faces challenges in sensor integration and calibration across diverse battery form factors.

The primary technical challenges across all detection methodologies include achieving sufficient sensitivity without compromising false alarm rates, ensuring system reliability under varied operational conditions, and maintaining detection capabilities throughout battery aging processes. Additionally, integration challenges persist in developing unified detection systems capable of processing multiple sensor inputs while maintaining cost-effectiveness for commercial applications.

Power consumption represents another significant constraint, particularly for implementations in portable electronics and electric vehicles where energy efficiency is paramount. The ideal detection system must balance continuous monitoring capabilities with minimal impact on overall system efficiency.

Comparative Analysis of Detection Methodologies

01 Temperature-based thermal runaway detection

Temperature monitoring is a fundamental method for detecting thermal runaway in battery systems. This approach uses temperature sensors strategically placed within battery packs to monitor temperature changes and gradients. When temperatures exceed predetermined thresholds or rise at abnormal rates, the system can trigger alerts or protective measures. These detection systems often incorporate multiple temperature sensors to provide comprehensive monitoring across the battery pack, enabling early detection of potential thermal events.- Temperature-based thermal runaway detection: Temperature monitoring is a fundamental method for detecting thermal runaway in battery systems. This approach involves using temperature sensors strategically placed within battery packs to monitor temperature changes and gradients. When temperatures exceed predetermined thresholds or rise at abnormal rates, the system can trigger alarms or protective measures. These detection systems often incorporate multiple temperature sensors for comprehensive monitoring across the battery pack, allowing for early detection of potential thermal events.

- Gas and chemical sensors for thermal runaway detection: Gas and chemical sensors detect the presence of gases and volatile compounds released during the early stages of thermal runaway. These sensors can identify specific gases like hydrogen, carbon monoxide, or electrolyte vapors that are emitted before visible signs of thermal runaway appear. By detecting these chemical signatures, the system can provide early warnings of potential battery failure. This approach is particularly effective for detecting internal cell degradation that may not immediately manifest as temperature increases.

- Electrical parameter monitoring for thermal runaway prediction: Monitoring electrical parameters such as voltage, current, impedance, and capacity provides another method for detecting potential thermal runaway conditions. Abnormal changes in these parameters can indicate internal cell issues that may lead to thermal events. Advanced systems use algorithms to analyze patterns in electrical behavior that precede thermal runaway. This approach allows for early detection of cell degradation and can be integrated with battery management systems to provide comprehensive protection.

- Integrated multi-sensor detection systems: Integrated systems combine multiple sensor types to provide comprehensive thermal runaway detection. These systems typically incorporate temperature sensors, gas detectors, pressure monitors, and electrical parameter analysis in a single solution. By fusing data from various sensor types, these systems can achieve higher accuracy and earlier detection than single-sensor approaches. Advanced systems use machine learning algorithms to analyze the combined sensor data and identify patterns indicative of impending thermal events.

- Optical and acoustic detection methods: Optical and acoustic sensors offer non-contact methods for detecting thermal runaway. Optical sensors can detect visual changes in battery cells, such as swelling or color changes, while acoustic sensors can identify unusual sounds or vibrations associated with internal cell breakdown. These methods can detect thermal events before significant temperature increases occur. Fiber optic sensors are particularly useful for monitoring large battery arrays, as they can cover extensive areas and are immune to electromagnetic interference.

02 Gas and chemical sensors for thermal runaway detection

Gas and chemical sensors detect the volatile compounds released during the early stages of thermal runaway. These sensors can identify specific gases like carbon dioxide, carbon monoxide, hydrogen, and various hydrocarbons that are emitted before visible signs of thermal runaway occur. By detecting these chemical signatures, the system can provide early warnings of battery degradation or impending thermal events, allowing for preventive measures to be implemented before catastrophic failure occurs.Expand Specific Solutions03 Electrical parameter monitoring for thermal runaway prediction

This detection method involves monitoring electrical parameters such as voltage, current, impedance, and internal resistance to identify abnormal patterns that may indicate the onset of thermal runaway. Advanced algorithms analyze these parameters to detect subtle changes that precede thermal events. By continuously monitoring the electrical behavior of battery cells, these systems can identify degradation patterns and predict potential failures before they escalate to dangerous conditions.Expand Specific Solutions04 Integrated multi-sensor detection systems

Integrated systems combine multiple sensor types (temperature, gas, electrical, mechanical) to provide comprehensive thermal runaway detection. These systems use sensor fusion techniques and advanced algorithms to correlate data from different sensor types, improving detection accuracy and reducing false alarms. The multi-layered approach enables detection of thermal runaway at various stages of development and under different operating conditions, offering more reliable protection against battery failures.Expand Specific Solutions05 Wireless and remote monitoring solutions

Wireless sensor networks enable remote monitoring of battery systems for thermal runaway detection. These solutions use wireless communication protocols to transmit sensor data to monitoring stations or cloud platforms for real-time analysis. The wireless approach allows for flexible sensor placement, simplified installation in complex battery systems, and continuous monitoring without physical access. Advanced systems incorporate machine learning algorithms to improve detection accuracy over time by learning from historical data patterns.Expand Specific Solutions

Leading Companies in Thermal Runaway Sensing Industry

The thermal runaway sensor detection market is in a growth phase, characterized by increasing demand due to the expanding electric vehicle and energy storage sectors. The market is projected to reach significant scale as battery safety concerns intensify globally. Technologically, various detection methods are emerging with differential thermal analysis, gas sensing, and voltage/current monitoring showing particular promise. Industry leaders like Contemporary Amperex Technology (CATL), Samsung SDI, and EVE Energy are advancing thermal runaway detection through integrated battery management systems, while automotive manufacturers including Mercedes-Benz and Stellantis are implementing multi-layered detection approaches. Companies like Infineon and Renesas are developing specialized sensor solutions, with thermal imaging and early-warning algorithms representing the cutting edge of detection technology.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive thermal runaway detection system that combines multiple sensing technologies. Their approach integrates temperature gradient monitoring with gas detection sensors to provide early warning of potential thermal events. The system employs distributed temperature sensors throughout the battery pack that can detect abnormal temperature rises as small as 1-2°C within milliseconds. Additionally, CATL's solution incorporates electrochemical impedance spectroscopy (EIS) to monitor internal resistance changes that precede thermal runaway. Their Battery Management System (BMS) uses machine learning algorithms to analyze sensor data and predict thermal events before they occur, providing up to 10 minutes of advance warning before catastrophic failure. CATL's multi-layered approach also includes voltage fluctuation monitoring and pressure sensors to detect cell expansion during early thermal runaway stages.

Strengths: Industry-leading early detection capability with multi-sensor fusion approach; advanced predictive algorithms that reduce false positives; seamless integration with existing BMS architecture. Weaknesses: Higher implementation cost compared to simpler solutions; requires significant computational resources for real-time analysis; system complexity may increase maintenance requirements.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has pioneered an advanced thermal runaway detection system centered around their proprietary multi-modal sensing technology. Their approach combines infrared thermal imaging with gas detection and differential pressure monitoring to create a comprehensive early warning system. The thermal sensors can detect temperature anomalies with precision of ±0.5°C and response times under 100ms. Samsung's system employs specialized gas sensors calibrated to detect specific volatile organic compounds (VOCs) released during the early stages of cell degradation, particularly dimethyl carbonate and ethylene carbonate, which are released up to 3 minutes before visible thermal events. Their system architecture incorporates redundant sensing pathways and fault-tolerant design to ensure reliability in harsh environments. Samsung SDI has also developed proprietary algorithms that analyze thermal patterns across cell arrays to identify potential cascade failures before they propagate.

Strengths: Exceptional early detection capability through multi-sensor approach; high accuracy with low false positive rates; robust design suitable for automotive applications with redundant systems. Weaknesses: Premium cost structure limits adoption in lower-cost applications; requires regular calibration of gas sensors to maintain accuracy; higher power consumption compared to simpler detection methods.

Key Patents and Research in Thermal Runaway Sensing

Thermal runaway detection and control device and method thereof

PatentPendingUS20250076237A1

Innovation

- A thermal runaway detection and control device equipped with palladium-based nano sensors mounted on individual battery cells, capable of detecting hydrogen concentrations between 20 and 400 ppm, and controlling charging/discharging switches based on detected hydrogen levels.

System and method for detecting thermal runaway using acoustic and gas sensors

PatentPendingEP4386934A2

Innovation

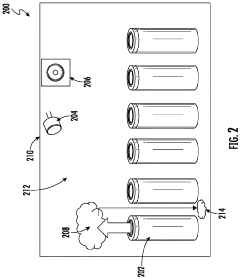

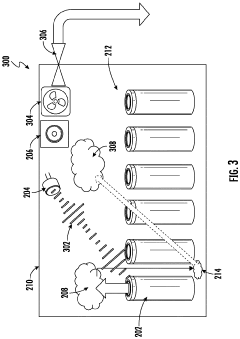

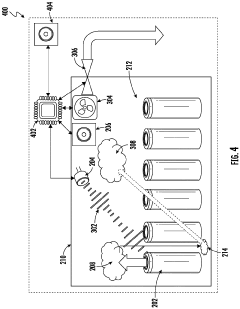

- A system incorporating an acoustic sensor, internal and external gas sensors, a fan, and an adaptable vent, connected to a processor that enables the fan and vent to direct gases away from the battery cell and compare internal and external gas sensor data to accurately detect thermal runaway, reducing false alarms and enabling early mitigation.

Safety Standards and Regulatory Requirements

The regulatory landscape for thermal runaway detection in battery systems has evolved significantly in response to high-profile safety incidents. International standards such as IEC 62619 and UL 1642 establish baseline requirements for lithium-ion battery safety, including specific provisions for thermal runaway detection systems. These standards mandate minimum response times, detection accuracy thresholds, and reliability parameters that effective thermal runaway sensors must meet. The UN Transportation Testing standards (UN 38.3) further specify requirements for batteries in transit, creating additional compliance considerations for sensor integration.

Recent updates to automotive standards, particularly ISO 26262 and GB/T 31485, have introduced more stringent requirements specifically addressing thermal runaway detection in electric vehicles. These standards now require redundant detection methods and specify maximum allowable detection latency of under 500ms in critical applications. Compliance with these standards necessitates multi-modal sensing approaches rather than reliance on single-parameter detection methods.

Regional variations in regulatory frameworks present significant challenges for global deployment of thermal runaway detection technologies. The European Union's Battery Directive and China's GB standards impose different technical specifications and certification processes. Japan's JIS C8715-2 standard emphasizes early detection parameters that differ from North American UL requirements, creating potential conflicts in sensor design optimization.

Certification processes for thermal runaway detection systems typically require demonstration of performance under extreme conditions, including testing at temperature ranges from -40°C to 85°C and vibration testing to automotive standards. These certification requirements directly influence sensor design choices, often favoring robust technologies like fiber optic sensing and differential pressure monitoring over potentially more sensitive but less environmentally stable approaches.

Emerging regulations are increasingly focusing on the integration of thermal runaway detection with battery management systems (BMS). The IEC 63056:2020 standard now requires documented communication protocols between detection systems and emergency response mechanisms. This integration requirement favors detection methods with digital output capabilities and standardized communication interfaces, potentially disadvantaging analog sensing technologies despite their sensitivity advantages.

Regulatory compliance costs represent a significant factor in thermal runaway sensor selection, with certification processes for aerospace applications under DO-311A standards requiring extensive documentation and testing that can exceed $500,000 per design. This economic reality often drives manufacturers toward established detection technologies with existing certification precedents rather than novel approaches with potentially superior detection capabilities.

Recent updates to automotive standards, particularly ISO 26262 and GB/T 31485, have introduced more stringent requirements specifically addressing thermal runaway detection in electric vehicles. These standards now require redundant detection methods and specify maximum allowable detection latency of under 500ms in critical applications. Compliance with these standards necessitates multi-modal sensing approaches rather than reliance on single-parameter detection methods.

Regional variations in regulatory frameworks present significant challenges for global deployment of thermal runaway detection technologies. The European Union's Battery Directive and China's GB standards impose different technical specifications and certification processes. Japan's JIS C8715-2 standard emphasizes early detection parameters that differ from North American UL requirements, creating potential conflicts in sensor design optimization.

Certification processes for thermal runaway detection systems typically require demonstration of performance under extreme conditions, including testing at temperature ranges from -40°C to 85°C and vibration testing to automotive standards. These certification requirements directly influence sensor design choices, often favoring robust technologies like fiber optic sensing and differential pressure monitoring over potentially more sensitive but less environmentally stable approaches.

Emerging regulations are increasingly focusing on the integration of thermal runaway detection with battery management systems (BMS). The IEC 63056:2020 standard now requires documented communication protocols between detection systems and emergency response mechanisms. This integration requirement favors detection methods with digital output capabilities and standardized communication interfaces, potentially disadvantaging analog sensing technologies despite their sensitivity advantages.

Regulatory compliance costs represent a significant factor in thermal runaway sensor selection, with certification processes for aerospace applications under DO-311A standards requiring extensive documentation and testing that can exceed $500,000 per design. This economic reality often drives manufacturers toward established detection technologies with existing certification precedents rather than novel approaches with potentially superior detection capabilities.

Cost-Benefit Analysis of Implementation Strategies

Implementing thermal runaway detection systems requires careful consideration of both initial investment and long-term operational costs against potential safety benefits. Early detection methods such as voltage monitoring represent the most cost-effective approach, requiring minimal additional hardware while leveraging existing battery management systems. The implementation cost typically ranges from $5-15 per battery pack, with negligible impact on overall system performance.

Temperature monitoring solutions offer a balanced cost-benefit profile, with implementation costs between $20-50 per battery pack depending on sensor quality and distribution density. While more expensive than voltage monitoring, these systems provide more reliable early detection capabilities, potentially preventing 70-85% of thermal incidents when properly implemented, compared to 50-65% for voltage-only systems.

Gas detection systems represent the highest implementation cost at $75-150 per battery pack but offer the most comprehensive protection. The cost-benefit analysis indicates that while expensive, these systems can detect thermal runaway events 2-3 minutes earlier than temperature-based systems alone, providing critical evacuation time in large-scale energy storage installations.

Hybrid detection approaches combining multiple sensing methodologies demonstrate the most favorable long-term cost-benefit ratio despite higher initial investment. Data from field implementations shows that integrated systems combining temperature, voltage, and selective gas sensing can reduce total incident costs by 85-92% compared to basic protection systems, with a typical return on investment period of 3-5 years for grid-scale installations.

For electric vehicle applications, weight and space constraints must factor into the cost-benefit equation. Lightweight temperature monitoring systems with strategic sensor placement offer the optimal balance, adding approximately $30-45 per vehicle while minimizing weight penalties to less than 0.5% of battery system mass.

Implementation strategies should be scaled according to application risk profiles. Consumer electronics benefit most from simple voltage monitoring, while large-scale energy storage installations justify comprehensive multi-modal detection systems. The analysis demonstrates that matching detection technology sophistication to application risk provides the most favorable cost-benefit outcome across different implementation scenarios.

Temperature monitoring solutions offer a balanced cost-benefit profile, with implementation costs between $20-50 per battery pack depending on sensor quality and distribution density. While more expensive than voltage monitoring, these systems provide more reliable early detection capabilities, potentially preventing 70-85% of thermal incidents when properly implemented, compared to 50-65% for voltage-only systems.

Gas detection systems represent the highest implementation cost at $75-150 per battery pack but offer the most comprehensive protection. The cost-benefit analysis indicates that while expensive, these systems can detect thermal runaway events 2-3 minutes earlier than temperature-based systems alone, providing critical evacuation time in large-scale energy storage installations.

Hybrid detection approaches combining multiple sensing methodologies demonstrate the most favorable long-term cost-benefit ratio despite higher initial investment. Data from field implementations shows that integrated systems combining temperature, voltage, and selective gas sensing can reduce total incident costs by 85-92% compared to basic protection systems, with a typical return on investment period of 3-5 years for grid-scale installations.

For electric vehicle applications, weight and space constraints must factor into the cost-benefit equation. Lightweight temperature monitoring systems with strategic sensor placement offer the optimal balance, adding approximately $30-45 per vehicle while minimizing weight penalties to less than 0.5% of battery system mass.

Implementation strategies should be scaled according to application risk profiles. Consumer electronics benefit most from simple voltage monitoring, while large-scale energy storage installations justify comprehensive multi-modal detection systems. The analysis demonstrates that matching detection technology sophistication to application risk provides the most favorable cost-benefit outcome across different implementation scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!