Research on calibration protocols for thermal runaway sensors

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Sensor Calibration Background and Objectives

Thermal runaway is a critical safety concern in lithium-ion battery systems, characterized by an uncontrollable, self-accelerating exothermic reaction that can lead to catastrophic battery failure, fires, and explosions. As energy storage technologies continue to proliferate across industries from electric vehicles to grid-scale applications, the need for reliable early detection systems has become paramount. Thermal runaway sensors represent a specialized class of monitoring devices designed to detect precursor conditions before a full thermal event occurs, providing crucial time for intervention or controlled shutdown.

The evolution of thermal runaway detection technology has progressed from basic temperature monitoring to sophisticated multi-parameter sensing systems. Early approaches relied primarily on simple thermistors or thermocouples to monitor cell temperature, offering limited predictive capability. Modern systems incorporate multiple sensing modalities including gas detection, pressure monitoring, and impedance tracking to create a more comprehensive picture of battery health and potential failure modes.

The primary objective of calibration protocol research is to establish standardized, reliable methods for ensuring sensor accuracy across varying operational conditions and battery chemistries. This includes developing procedures that account for sensor drift over time, environmental variations, and the unique thermal profiles of different battery designs. Without proper calibration, sensors may produce false positives that trigger unnecessary shutdowns or, more dangerously, false negatives that fail to detect imminent thermal events.

Current calibration approaches face significant challenges due to the complex, non-linear behavior of battery systems during thermal runaway initiation. The rapid temperature acceleration characteristic of these events makes traditional static calibration methods insufficient. Additionally, the destructive nature of thermal runaway testing complicates the development of repeatable calibration standards.

Research goals in this field include developing dynamic calibration methodologies that can accurately characterize sensor response across the entire thermal profile of a runaway event, from early detection thresholds to extreme temperature conditions. This requires innovative approaches to simulate pre-runaway conditions without triggering actual destructive events.

Another key objective is establishing industry-wide calibration standards that enable consistent performance evaluation across different sensor technologies and manufacturers. This standardization is essential for regulatory compliance and ensuring minimum safety performance levels across the energy storage industry. The development of accelerated aging protocols for sensors is also critical to understand how calibration requirements may change throughout a battery system's operational lifetime.

The evolution of thermal runaway detection technology has progressed from basic temperature monitoring to sophisticated multi-parameter sensing systems. Early approaches relied primarily on simple thermistors or thermocouples to monitor cell temperature, offering limited predictive capability. Modern systems incorporate multiple sensing modalities including gas detection, pressure monitoring, and impedance tracking to create a more comprehensive picture of battery health and potential failure modes.

The primary objective of calibration protocol research is to establish standardized, reliable methods for ensuring sensor accuracy across varying operational conditions and battery chemistries. This includes developing procedures that account for sensor drift over time, environmental variations, and the unique thermal profiles of different battery designs. Without proper calibration, sensors may produce false positives that trigger unnecessary shutdowns or, more dangerously, false negatives that fail to detect imminent thermal events.

Current calibration approaches face significant challenges due to the complex, non-linear behavior of battery systems during thermal runaway initiation. The rapid temperature acceleration characteristic of these events makes traditional static calibration methods insufficient. Additionally, the destructive nature of thermal runaway testing complicates the development of repeatable calibration standards.

Research goals in this field include developing dynamic calibration methodologies that can accurately characterize sensor response across the entire thermal profile of a runaway event, from early detection thresholds to extreme temperature conditions. This requires innovative approaches to simulate pre-runaway conditions without triggering actual destructive events.

Another key objective is establishing industry-wide calibration standards that enable consistent performance evaluation across different sensor technologies and manufacturers. This standardization is essential for regulatory compliance and ensuring minimum safety performance levels across the energy storage industry. The development of accelerated aging protocols for sensors is also critical to understand how calibration requirements may change throughout a battery system's operational lifetime.

Market Demand Analysis for Reliable Thermal Runaway Detection

The global market for thermal runaway detection systems is experiencing significant growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption and energy storage systems (ESS). Market research indicates that the thermal runaway detection market is projected to grow at a CAGR of 25% between 2023 and 2030, with the market value expected to reach $5.2 billion by 2030. This growth trajectory is directly correlated with the increasing concerns about battery safety across multiple industries.

Consumer demand for reliable thermal runaway detection is primarily fueled by high-profile battery failure incidents that have resulted in property damage, injuries, and in some cases, fatalities. These incidents have heightened awareness among consumers, manufacturers, and regulatory bodies about the critical importance of early detection systems. A recent survey of EV owners revealed that 78% consider battery safety features as "extremely important" in their purchasing decisions, highlighting the market pull for advanced detection technologies.

The automotive sector represents the largest market segment, accounting for approximately 45% of the total demand for thermal runaway detection systems. This is followed by consumer electronics (22%), grid-scale energy storage (18%), and industrial applications (15%). Regional analysis shows that Asia-Pacific currently leads the market with a 42% share, followed by North America (30%) and Europe (25%), with the remaining 3% distributed across other regions.

Regulatory frameworks are increasingly mandating enhanced safety measures for lithium-ion battery systems. The UN Global Technical Regulation No. 20 (GTR 20), European Union Battery Directive, and various national standards are driving manufacturers to implement more sophisticated thermal runaway detection systems. These regulatory pressures are expected to accelerate market growth by 30% over the next five years.

Industry stakeholders have identified several key market requirements for thermal runaway sensors, including high accuracy (false alarm rates below 0.1%), rapid response times (under 30 seconds), durability (operational life of 10+ years), cost-effectiveness, and seamless integration with battery management systems. The calibration protocols for these sensors represent a critical market need, as they directly impact the reliability and effectiveness of detection systems.

Market analysis reveals a growing demand for standardized calibration protocols that can ensure consistent performance across different operating conditions. Currently, the lack of universally accepted calibration standards is identified as a significant market gap, with 67% of battery manufacturers citing it as a major challenge in implementing effective thermal runaway detection systems.

Consumer demand for reliable thermal runaway detection is primarily fueled by high-profile battery failure incidents that have resulted in property damage, injuries, and in some cases, fatalities. These incidents have heightened awareness among consumers, manufacturers, and regulatory bodies about the critical importance of early detection systems. A recent survey of EV owners revealed that 78% consider battery safety features as "extremely important" in their purchasing decisions, highlighting the market pull for advanced detection technologies.

The automotive sector represents the largest market segment, accounting for approximately 45% of the total demand for thermal runaway detection systems. This is followed by consumer electronics (22%), grid-scale energy storage (18%), and industrial applications (15%). Regional analysis shows that Asia-Pacific currently leads the market with a 42% share, followed by North America (30%) and Europe (25%), with the remaining 3% distributed across other regions.

Regulatory frameworks are increasingly mandating enhanced safety measures for lithium-ion battery systems. The UN Global Technical Regulation No. 20 (GTR 20), European Union Battery Directive, and various national standards are driving manufacturers to implement more sophisticated thermal runaway detection systems. These regulatory pressures are expected to accelerate market growth by 30% over the next five years.

Industry stakeholders have identified several key market requirements for thermal runaway sensors, including high accuracy (false alarm rates below 0.1%), rapid response times (under 30 seconds), durability (operational life of 10+ years), cost-effectiveness, and seamless integration with battery management systems. The calibration protocols for these sensors represent a critical market need, as they directly impact the reliability and effectiveness of detection systems.

Market analysis reveals a growing demand for standardized calibration protocols that can ensure consistent performance across different operating conditions. Currently, the lack of universally accepted calibration standards is identified as a significant market gap, with 67% of battery manufacturers citing it as a major challenge in implementing effective thermal runaway detection systems.

Current Challenges in Thermal Sensor Calibration Technologies

Despite significant advancements in thermal runaway sensor technology, the calibration of these critical safety devices faces numerous challenges that impede their reliability and widespread implementation. The primary challenge lies in the extreme temperature conditions under which these sensors must operate. Thermal runaway events in lithium-ion batteries can rapidly escalate from ambient temperature to over 600°C within seconds, making it exceptionally difficult to develop calibration protocols that remain accurate across such a wide and dynamic temperature range.

The lack of standardized calibration methodologies presents another significant obstacle. Currently, different manufacturers employ varied calibration approaches, resulting in inconsistent performance metrics across the industry. This absence of standardization complicates the comparison of sensor performance and hinders the establishment of universal safety benchmarks for thermal runaway detection systems.

Environmental factors introduce additional complexities to the calibration process. Humidity, pressure, and electromagnetic interference can significantly affect sensor readings, yet developing calibration protocols that account for these variables simultaneously remains challenging. Moreover, these environmental conditions may fluctuate during actual thermal runaway events, further complicating the development of robust calibration methods.

The time-dependent degradation of sensor performance represents a persistent challenge. Thermal sensors often experience drift over time, necessitating recalibration procedures. However, current protocols rarely address long-term stability issues adequately, leading to potential false positives or missed detection events as sensors age in field applications.

Miniaturization requirements for modern battery systems create additional calibration difficulties. As sensors become smaller to accommodate compact battery designs, their thermal mass decreases, potentially affecting their response characteristics and calibration stability. Developing protocols that account for these size-dependent variations while maintaining accuracy presents a significant technical hurdle.

Cross-sensitivity issues further complicate calibration efforts. Thermal runaway sensors must distinguish between actual thermal events and other heat-generating processes within battery systems. Current calibration methods struggle to address this selectivity requirement effectively, particularly in complex battery pack configurations where thermal gradients naturally occur during normal operation.

The cost and time constraints associated with comprehensive calibration procedures present practical implementation challenges. High-precision calibration equipment is expensive, and thorough calibration processes can be time-consuming, creating economic barriers to the widespread adoption of properly calibrated thermal runaway detection systems, especially in cost-sensitive applications like consumer electronics and entry-level electric vehicles.

The lack of standardized calibration methodologies presents another significant obstacle. Currently, different manufacturers employ varied calibration approaches, resulting in inconsistent performance metrics across the industry. This absence of standardization complicates the comparison of sensor performance and hinders the establishment of universal safety benchmarks for thermal runaway detection systems.

Environmental factors introduce additional complexities to the calibration process. Humidity, pressure, and electromagnetic interference can significantly affect sensor readings, yet developing calibration protocols that account for these variables simultaneously remains challenging. Moreover, these environmental conditions may fluctuate during actual thermal runaway events, further complicating the development of robust calibration methods.

The time-dependent degradation of sensor performance represents a persistent challenge. Thermal sensors often experience drift over time, necessitating recalibration procedures. However, current protocols rarely address long-term stability issues adequately, leading to potential false positives or missed detection events as sensors age in field applications.

Miniaturization requirements for modern battery systems create additional calibration difficulties. As sensors become smaller to accommodate compact battery designs, their thermal mass decreases, potentially affecting their response characteristics and calibration stability. Developing protocols that account for these size-dependent variations while maintaining accuracy presents a significant technical hurdle.

Cross-sensitivity issues further complicate calibration efforts. Thermal runaway sensors must distinguish between actual thermal events and other heat-generating processes within battery systems. Current calibration methods struggle to address this selectivity requirement effectively, particularly in complex battery pack configurations where thermal gradients naturally occur during normal operation.

The cost and time constraints associated with comprehensive calibration procedures present practical implementation challenges. High-precision calibration equipment is expensive, and thorough calibration processes can be time-consuming, creating economic barriers to the widespread adoption of properly calibrated thermal runaway detection systems, especially in cost-sensitive applications like consumer electronics and entry-level electric vehicles.

Existing Calibration Protocol Solutions and Implementations

01 Temperature sensor calibration methods for thermal runaway detection

Various calibration methods are employed for temperature sensors used in thermal runaway detection systems. These methods include multi-point calibration techniques, reference temperature comparison, and automated calibration procedures that ensure accurate temperature readings across operational ranges. Proper calibration of these sensors is critical for early detection of thermal anomalies that could lead to runaway conditions in battery systems and other thermal-sensitive applications.- Temperature sensor calibration methods for thermal runaway detection: Calibration protocols for temperature sensors used in thermal runaway detection systems involve precise measurement techniques to ensure accuracy across operating ranges. These methods include multi-point calibration procedures that compare sensor readings against reference standards under controlled conditions. Proper calibration ensures that thermal runaway detection systems can accurately identify temperature anomalies that might indicate the onset of thermal runaway in battery systems or other critical components.

- Real-time calibration verification systems for battery monitoring: Real-time calibration verification systems continuously monitor sensor performance in battery management systems. These protocols include automated diagnostic routines that periodically verify sensor calibration accuracy during operation without requiring system shutdown. Such systems can detect calibration drift and compensate for environmental factors that might affect sensor readings, ensuring reliable thermal runaway detection even under changing operating conditions.

- Environmental compensation techniques for thermal sensors: Environmental compensation techniques adjust calibration parameters based on ambient conditions that might affect sensor readings. These protocols account for factors such as humidity, pressure, and electromagnetic interference that can impact the accuracy of thermal runaway sensors. By implementing environmental compensation algorithms during calibration, these systems maintain detection accuracy across diverse operating environments and reduce false alarms caused by environmental factors.

- Machine learning approaches for adaptive sensor calibration: Advanced calibration protocols incorporate machine learning algorithms that continuously refine calibration parameters based on operational data. These systems analyze patterns in sensor readings to identify and compensate for systematic errors or aging effects. The adaptive calibration approach improves detection accuracy over time by learning from historical data and adjusting sensitivity thresholds accordingly, which is particularly valuable for long-term deployment of thermal runaway detection systems.

- Multi-sensor fusion calibration for enhanced detection reliability: Multi-sensor fusion calibration protocols integrate data from different sensor types to improve thermal runaway detection reliability. These methods calibrate complementary sensors (temperature, gas, pressure, voltage) in relation to each other, creating a more robust detection system. The calibration process establishes correlation parameters between different sensor readings, enabling the system to distinguish between normal operational variations and actual thermal runaway conditions through cross-validation of multiple sensor inputs.

02 Real-time calibration protocols for battery monitoring systems

Real-time calibration protocols are implemented in battery monitoring systems to continuously adjust sensor parameters during operation. These protocols include dynamic baseline adjustments, drift compensation algorithms, and periodic self-calibration routines that maintain measurement accuracy over time. Such real-time calibration is essential for maintaining the reliability of thermal runaway detection in changing environmental conditions and throughout battery aging processes.Expand Specific Solutions03 Integration of multiple sensor types in calibration systems

Advanced calibration protocols incorporate data from multiple sensor types to improve accuracy and reliability. These systems integrate temperature sensors with voltage, current, pressure, and gas sensors in a comprehensive calibration framework. Cross-validation between different sensor types helps eliminate measurement errors and provides redundancy in thermal runaway detection systems, enhancing overall safety and reliability.Expand Specific Solutions04 Machine learning approaches for sensor calibration

Machine learning algorithms are increasingly used to optimize sensor calibration for thermal runaway detection. These approaches include neural networks that adapt to sensor behavior over time, predictive models that compensate for environmental factors, and pattern recognition systems that identify calibration drift. Machine learning enables more sophisticated calibration that can account for complex interdependencies between various parameters affecting sensor performance.Expand Specific Solutions05 Environmental compensation in calibration protocols

Calibration protocols incorporate environmental compensation techniques to maintain accuracy across varying conditions. These methods adjust for factors such as ambient temperature fluctuations, humidity variations, and pressure changes that can affect sensor readings. Compensation algorithms apply correction factors based on environmental measurements to ensure consistent thermal runaway detection performance regardless of external conditions, which is particularly important for applications in extreme or variable environments.Expand Specific Solutions

Key Industry Players in Thermal Runaway Detection Systems

The thermal runaway sensor calibration protocol market is in a growth phase, characterized by increasing demand due to the expanding electric vehicle and energy storage sectors. Market size is projected to grow significantly as battery safety concerns drive regulatory requirements. Technologically, the field shows varying maturity levels across players. Leading companies like Tesla, BYD, and Contemporary Amperex Technology are advancing proprietary calibration methods, while Mercedes-Benz, Honda, and Continental Automotive are developing integrated safety systems. Academic institutions like Tsinghua University contribute fundamental research. Specialized sensor manufacturers including Innovative Sensor Technology and Renesas Electronics provide enabling technologies, creating a competitive landscape where collaboration between battery manufacturers, automotive OEMs, and sensor specialists is increasingly common to establish standardized protocols.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed an advanced thermal runaway sensor calibration protocol as part of their Electric Vehicle Architecture (EVA) platform. Their approach centers on a hierarchical sensor network with primary and secondary verification points throughout the battery pack. The Mercedes calibration protocol incorporates precision temperature mapping during manufacturing, where each sensor undergoes a multi-point calibration against NIST-traceable temperature standards. Their system features dynamic threshold adjustment based on battery state-of-charge, ambient conditions, and vehicle operation mode. Mercedes employs a unique "thermal signature recognition" algorithm that requires sensors to be calibrated not just for absolute temperature values but also for rate-of-change patterns that indicate impending thermal events. The calibration process includes deliberate introduction of controlled thermal gradients to verify sensor response linearity across their operating range. Mercedes has implemented a continuous validation protocol where sensors periodically cross-check against redundant sensors to detect drift, with automatic recalibration or fault notification if discrepancies exceed predetermined thresholds.

Strengths: Extremely high precision with calibrated accuracy of ±0.3°C across the full operating temperature range, enabling highly reliable early detection. The hierarchical approach with redundancy provides exceptional fault tolerance and system reliability. Weaknesses: The sophisticated calibration process adds significant time to manufacturing and increases production costs. The system requires substantial computational resources for the continuous validation algorithms.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei Digital Power has developed a comprehensive thermal runaway sensor calibration protocol for their energy storage systems and EV battery technologies. Their approach utilizes a distributed fiber optic sensing network combined with traditional thermistor arrays to create a high-density measurement grid throughout battery packs. Huawei's calibration protocol employs a reference temperature bath methodology where sensors are calibrated against platinum resistance thermometers with NIST traceability. Their system features an innovative "thermal fingerprinting" process during manufacturing where each battery cell's normal thermal behavior is characterized across multiple charge/discharge cycles and environmental conditions. This baseline is then used to create individualized detection thresholds. Huawei implements a two-stage calibration process: initial precision calibration during manufacturing and an adaptive field calibration that continuously refines detection parameters based on operational data. Their protocol incorporates cross-validation between optical and electronic sensors to eliminate mode-specific detection errors and ensure system reliability despite potential single-sensor failures.

Strengths: Exceptional spatial resolution with their fiber optic network detecting temperature variations as small as 0.1°C across distances of less than 1cm, enabling precise localization of potential thermal events. The dual-technology approach provides redundancy and cross-verification capabilities. Weaknesses: The fiber optic sensing technology increases system complexity and cost compared to traditional approaches. The calibration process requires specialized equipment and expertise, potentially limiting deployment in some manufacturing environments.

Critical Patents and Research in Sensor Calibration Techniques

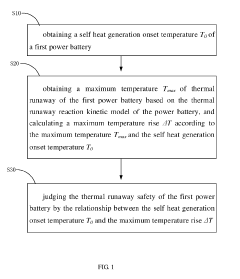

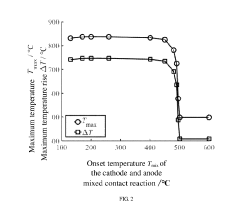

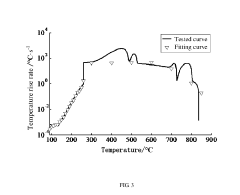

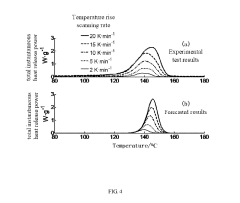

Method and device for forecasting thermal runaway safety of power battery, and a method for making power battery

PatentActiveUS20190243931A1

Innovation

- A method and device using a thermal runaway reaction kinetic model to forecast the thermal runaway safety of full batteries by calculating the self heat generation onset temperature and maximum temperature rise of a half cell battery, allowing for the prediction of thermal runaway safety without assembling a full battery, utilizing a computer system with a processor and memory to execute instructions for forecasting thermal runaway safety based on a thermal runaway reaction kinetic model.

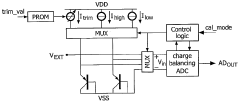

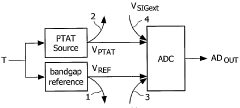

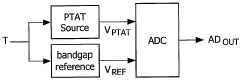

Digital temperature sensors and calibration thereof

PatentWO2006030374A2

Innovation

- A method for calibrating digital temperature sensors by measuring and adjusting the internal reference voltage source, using direct or indirect measurement techniques, allowing for electrical voltage mode calibration that can be performed post-packaging and without additional device pins, focusing on reducing the error of the bandgap reference voltage.

Safety Standards and Compliance Requirements

The regulatory landscape for thermal runaway sensors in battery systems is governed by a comprehensive framework of international, regional, and industry-specific standards. IEC 62619 and UL 1642 stand as foundational standards addressing lithium-ion battery safety requirements, with specific provisions for thermal event detection and management systems. These standards mandate minimum performance criteria for thermal sensors, including temperature range specifications, response time requirements, and accuracy thresholds across varying environmental conditions.

ISO 26262, originally developed for automotive functional safety, has been adapted to include specific requirements for battery thermal management systems, particularly in electric vehicles where thermal runaway presents significant safety risks. The standard establishes a systematic framework for sensor calibration verification and validation processes, requiring documented evidence of sensor reliability throughout the expected operational lifetime.

UN/ECE Regulation No. 100 specifically addresses the safety requirements for rechargeable energy storage systems in vehicles, mandating thermal monitoring capabilities with calibrated warning systems. This regulation requires manufacturers to demonstrate sensor calibration protocols that maintain accuracy under vibration, temperature cycling, and electromagnetic interference conditions typical in automotive environments.

For stationary energy storage applications, NFPA 855 and IEC 62933 provide comprehensive safety guidelines, including specific requirements for thermal monitoring systems. These standards emphasize the need for regular recalibration procedures and define acceptable drift parameters for thermal sensors over time, typically requiring accuracy maintenance within ±2°C over the sensor's operational lifetime.

Emerging standards from organizations like IEEE and ASTM are developing more specific calibration protocols for thermal runaway detection systems. IEEE P2686, currently under development, aims to standardize test methods for thermal runaway propagation in battery systems, including sensor calibration methodologies. This standard is expected to establish uniform procedures for sensor verification against known thermal profiles characteristic of incipient thermal runaway events.

Compliance with these standards typically requires manufacturers to implement documented calibration procedures, maintain calibration records, and perform periodic verification testing. Many jurisdictions now require third-party certification of thermal management systems, including verification of sensor calibration protocols against traceable reference standards. This certification process often involves demonstrating sensor performance under accelerated aging conditions to validate long-term calibration stability.

ISO 26262, originally developed for automotive functional safety, has been adapted to include specific requirements for battery thermal management systems, particularly in electric vehicles where thermal runaway presents significant safety risks. The standard establishes a systematic framework for sensor calibration verification and validation processes, requiring documented evidence of sensor reliability throughout the expected operational lifetime.

UN/ECE Regulation No. 100 specifically addresses the safety requirements for rechargeable energy storage systems in vehicles, mandating thermal monitoring capabilities with calibrated warning systems. This regulation requires manufacturers to demonstrate sensor calibration protocols that maintain accuracy under vibration, temperature cycling, and electromagnetic interference conditions typical in automotive environments.

For stationary energy storage applications, NFPA 855 and IEC 62933 provide comprehensive safety guidelines, including specific requirements for thermal monitoring systems. These standards emphasize the need for regular recalibration procedures and define acceptable drift parameters for thermal sensors over time, typically requiring accuracy maintenance within ±2°C over the sensor's operational lifetime.

Emerging standards from organizations like IEEE and ASTM are developing more specific calibration protocols for thermal runaway detection systems. IEEE P2686, currently under development, aims to standardize test methods for thermal runaway propagation in battery systems, including sensor calibration methodologies. This standard is expected to establish uniform procedures for sensor verification against known thermal profiles characteristic of incipient thermal runaway events.

Compliance with these standards typically requires manufacturers to implement documented calibration procedures, maintain calibration records, and perform periodic verification testing. Many jurisdictions now require third-party certification of thermal management systems, including verification of sensor calibration protocols against traceable reference standards. This certification process often involves demonstrating sensor performance under accelerated aging conditions to validate long-term calibration stability.

Cross-Industry Applications and Use Cases

Thermal runaway sensors have demonstrated remarkable versatility across multiple industries beyond their primary applications in battery systems. In automotive manufacturing, these sensors are increasingly integrated into electric vehicle production lines, where they serve dual purposes: ensuring worker safety during assembly and enabling quality control through early detection of potential battery defects. The calibration protocols developed for automotive applications have been adapted to meet the stringent safety requirements of this high-volume manufacturing environment.

The aerospace industry has adopted thermal runaway sensing technologies with specialized calibration approaches that account for extreme temperature variations and altitude changes. Commercial aircraft manufacturers now incorporate these sensors in cargo holds and passenger electronic device storage areas, with calibration protocols designed to minimize false alarms while maintaining detection sensitivity in pressurized environments.

Energy storage facilities represent another critical application domain, where grid-scale battery installations require comprehensive monitoring systems. The calibration protocols in this sector focus on long-term stability and environmental adaptability, allowing sensors to maintain accuracy despite seasonal temperature fluctuations and varying operational loads. These protocols typically incorporate regular recalibration schedules based on installation-specific environmental factors.

Consumer electronics manufacturers have begun implementing miniaturized thermal runaway sensors in high-performance devices, with calibration approaches that balance power consumption constraints with detection reliability. The protocols developed for this sector emphasize rapid calibration procedures suitable for high-volume production environments while maintaining detection accuracy in compact form factors.

Industrial robotics and automated manufacturing systems represent an emerging application area, where thermal runaway sensors monitor both battery systems and critical mechanical components. Calibration protocols in this domain address the challenges of vibration interference and electromagnetic noise present in factory environments, often incorporating machine learning algorithms to distinguish between normal operational heating and potential thermal runaway conditions.

Medical device applications present unique calibration challenges, particularly for implantable or wearable technologies powered by lithium batteries. The protocols developed for this sector emphasize biocompatibility considerations and ultra-low power consumption while maintaining detection reliability. Regulatory requirements in this domain have driven the development of standardized calibration verification procedures that can be documented for compliance purposes.

The aerospace industry has adopted thermal runaway sensing technologies with specialized calibration approaches that account for extreme temperature variations and altitude changes. Commercial aircraft manufacturers now incorporate these sensors in cargo holds and passenger electronic device storage areas, with calibration protocols designed to minimize false alarms while maintaining detection sensitivity in pressurized environments.

Energy storage facilities represent another critical application domain, where grid-scale battery installations require comprehensive monitoring systems. The calibration protocols in this sector focus on long-term stability and environmental adaptability, allowing sensors to maintain accuracy despite seasonal temperature fluctuations and varying operational loads. These protocols typically incorporate regular recalibration schedules based on installation-specific environmental factors.

Consumer electronics manufacturers have begun implementing miniaturized thermal runaway sensors in high-performance devices, with calibration approaches that balance power consumption constraints with detection reliability. The protocols developed for this sector emphasize rapid calibration procedures suitable for high-volume production environments while maintaining detection accuracy in compact form factors.

Industrial robotics and automated manufacturing systems represent an emerging application area, where thermal runaway sensors monitor both battery systems and critical mechanical components. Calibration protocols in this domain address the challenges of vibration interference and electromagnetic noise present in factory environments, often incorporating machine learning algorithms to distinguish between normal operational heating and potential thermal runaway conditions.

Medical device applications present unique calibration challenges, particularly for implantable or wearable technologies powered by lithium batteries. The protocols developed for this sector emphasize biocompatibility considerations and ultra-low power consumption while maintaining detection reliability. Regulatory requirements in this domain have driven the development of standardized calibration verification procedures that can be documented for compliance purposes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!