Thermal runaway sensors using acoustic emission detection methods

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Detection Background and Objectives

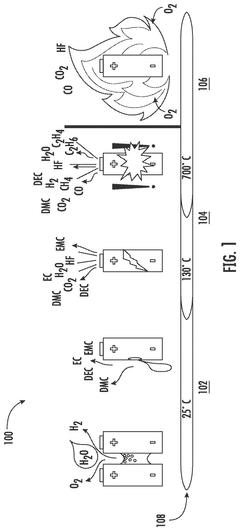

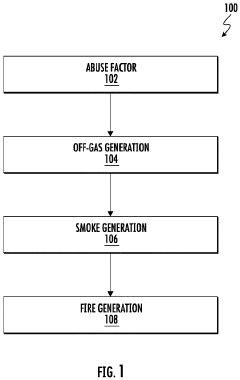

Thermal runaway is a critical safety concern in lithium-ion battery systems, characterized by an uncontrolled, self-accelerating exothermic reaction that can lead to catastrophic battery failure, fires, and explosions. The detection of thermal runaway events before they reach critical stages has become increasingly important as lithium-ion batteries find widespread application in electric vehicles, grid storage systems, consumer electronics, and aerospace applications.

The evolution of thermal runaway detection technologies has progressed significantly over the past two decades. Early detection methods relied primarily on temperature monitoring, which often provided warnings too late in the thermal runaway process. Voltage and current monitoring followed, offering slightly improved early detection capabilities but still suffering from reliability issues and false positives. The industry has since moved toward more sophisticated multi-parameter detection systems that integrate various sensing modalities.

Acoustic emission (AE) detection represents a promising frontier in thermal runaway sensing technology. This approach leverages the fact that during the initial stages of thermal runaway, microscopic structural changes within battery cells generate distinctive acoustic signatures that can be detected before significant temperature increases occur. These acoustic emissions typically manifest in frequency ranges from 10 kHz to 1 MHz, providing a potential early warning mechanism that precedes traditional thermal indicators by critical minutes.

The primary objective of acoustic emission-based thermal runaway detection is to identify precursor events that occur during the initiation phase of thermal runaway, particularly gas generation and separator breakdown, which produce characteristic acoustic patterns. By detecting these early-stage events, safety systems can be activated before thermal runaway progresses to dangerous levels, potentially preventing catastrophic failures.

Current research aims to overcome several technical challenges in AE detection, including signal-to-noise ratio optimization in noisy operational environments, development of robust pattern recognition algorithms for distinguishing normal operational sounds from thermal runaway precursors, and integration of AE sensors into battery management systems without compromising battery performance or adding significant cost or weight.

The technology trajectory suggests a convergence toward hybrid sensing approaches that combine acoustic emission detection with other complementary methods such as gas sensing, impedance tracking, and thermal monitoring to create comprehensive early warning systems. These integrated solutions aim to achieve near-zero false alarm rates while maintaining high sensitivity to genuine thermal runaway events.

As regulatory frameworks increasingly emphasize battery safety, particularly in electric vehicle and energy storage applications, the development of reliable thermal runaway detection systems has become not just a technical objective but a regulatory necessity, driving significant investment in this field across major markets including North America, Europe, and Asia.

The evolution of thermal runaway detection technologies has progressed significantly over the past two decades. Early detection methods relied primarily on temperature monitoring, which often provided warnings too late in the thermal runaway process. Voltage and current monitoring followed, offering slightly improved early detection capabilities but still suffering from reliability issues and false positives. The industry has since moved toward more sophisticated multi-parameter detection systems that integrate various sensing modalities.

Acoustic emission (AE) detection represents a promising frontier in thermal runaway sensing technology. This approach leverages the fact that during the initial stages of thermal runaway, microscopic structural changes within battery cells generate distinctive acoustic signatures that can be detected before significant temperature increases occur. These acoustic emissions typically manifest in frequency ranges from 10 kHz to 1 MHz, providing a potential early warning mechanism that precedes traditional thermal indicators by critical minutes.

The primary objective of acoustic emission-based thermal runaway detection is to identify precursor events that occur during the initiation phase of thermal runaway, particularly gas generation and separator breakdown, which produce characteristic acoustic patterns. By detecting these early-stage events, safety systems can be activated before thermal runaway progresses to dangerous levels, potentially preventing catastrophic failures.

Current research aims to overcome several technical challenges in AE detection, including signal-to-noise ratio optimization in noisy operational environments, development of robust pattern recognition algorithms for distinguishing normal operational sounds from thermal runaway precursors, and integration of AE sensors into battery management systems without compromising battery performance or adding significant cost or weight.

The technology trajectory suggests a convergence toward hybrid sensing approaches that combine acoustic emission detection with other complementary methods such as gas sensing, impedance tracking, and thermal monitoring to create comprehensive early warning systems. These integrated solutions aim to achieve near-zero false alarm rates while maintaining high sensitivity to genuine thermal runaway events.

As regulatory frameworks increasingly emphasize battery safety, particularly in electric vehicle and energy storage applications, the development of reliable thermal runaway detection systems has become not just a technical objective but a regulatory necessity, driving significant investment in this field across major markets including North America, Europe, and Asia.

Market Demand for Battery Safety Monitoring Solutions

The global market for battery safety monitoring solutions has witnessed significant growth in recent years, driven primarily by the widespread adoption of lithium-ion batteries across various industries. With the electric vehicle (EV) market expanding at an unprecedented rate, the demand for reliable battery safety systems has become paramount. According to industry reports, the global battery safety monitoring market was valued at approximately $2.3 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 16.4%.

The automotive sector constitutes the largest market segment for battery safety monitoring solutions, accounting for nearly 45% of the total market share. This dominance is attributed to stringent safety regulations imposed by governments worldwide and increasing consumer awareness regarding battery-related hazards. Major automotive manufacturers are increasingly incorporating advanced battery monitoring systems into their electric vehicles to prevent thermal runaway incidents, which can lead to catastrophic failures.

Consumer electronics represents another significant market segment, driven by the growing adoption of high-density batteries in smartphones, laptops, and wearable devices. Manufacturers are under pressure to ensure battery safety while maintaining compact form factors, creating a substantial demand for miniaturized yet effective monitoring solutions. The consumer electronics segment is expected to grow at a CAGR of 14.8% through 2028.

Energy storage systems (ESS) for grid applications and renewable energy integration have emerged as a rapidly growing market for battery safety monitoring. As utility companies and renewable energy providers deploy large-scale battery storage facilities, the potential consequences of thermal runaway events become more severe, necessitating sophisticated monitoring systems. This segment is projected to witness the fastest growth rate of 19.2% over the forecast period.

Geographically, Asia-Pacific dominates the market, accounting for approximately 42% of global demand, followed by North America (28%) and Europe (23%). China, Japan, and South Korea are the key contributors in the Asia-Pacific region, driven by their robust manufacturing capabilities in battery production and electronic devices.

The market demand is increasingly shifting toward predictive monitoring solutions that can detect potential failures before they occur. Acoustic emission detection methods have gained significant attention due to their ability to identify precursors to thermal runaway events with higher accuracy and earlier warning times compared to traditional temperature-based monitoring systems. End-users are willing to pay premium prices for solutions that offer real-time monitoring capabilities, remote diagnostics, and integration with battery management systems.

The automotive sector constitutes the largest market segment for battery safety monitoring solutions, accounting for nearly 45% of the total market share. This dominance is attributed to stringent safety regulations imposed by governments worldwide and increasing consumer awareness regarding battery-related hazards. Major automotive manufacturers are increasingly incorporating advanced battery monitoring systems into their electric vehicles to prevent thermal runaway incidents, which can lead to catastrophic failures.

Consumer electronics represents another significant market segment, driven by the growing adoption of high-density batteries in smartphones, laptops, and wearable devices. Manufacturers are under pressure to ensure battery safety while maintaining compact form factors, creating a substantial demand for miniaturized yet effective monitoring solutions. The consumer electronics segment is expected to grow at a CAGR of 14.8% through 2028.

Energy storage systems (ESS) for grid applications and renewable energy integration have emerged as a rapidly growing market for battery safety monitoring. As utility companies and renewable energy providers deploy large-scale battery storage facilities, the potential consequences of thermal runaway events become more severe, necessitating sophisticated monitoring systems. This segment is projected to witness the fastest growth rate of 19.2% over the forecast period.

Geographically, Asia-Pacific dominates the market, accounting for approximately 42% of global demand, followed by North America (28%) and Europe (23%). China, Japan, and South Korea are the key contributors in the Asia-Pacific region, driven by their robust manufacturing capabilities in battery production and electronic devices.

The market demand is increasingly shifting toward predictive monitoring solutions that can detect potential failures before they occur. Acoustic emission detection methods have gained significant attention due to their ability to identify precursors to thermal runaway events with higher accuracy and earlier warning times compared to traditional temperature-based monitoring systems. End-users are willing to pay premium prices for solutions that offer real-time monitoring capabilities, remote diagnostics, and integration with battery management systems.

Acoustic Emission Detection Technology Status and Challenges

Acoustic Emission (AE) detection technology for thermal runaway monitoring in batteries has seen significant advancements globally, yet faces several critical challenges. Current state-of-the-art systems employ piezoelectric sensors, fiber optic sensors, and MEMS-based solutions to detect the characteristic acoustic signatures generated during battery failure events. These technologies have demonstrated promising results in laboratory settings, achieving detection rates of up to 95% for early-stage thermal runaway events.

The primary technical challenge remains signal-to-noise ratio optimization in real-world environments. Battery systems in electric vehicles, grid storage, and consumer electronics operate in acoustically complex settings where ambient noise can mask critical thermal runaway signatures. Current filtering algorithms struggle to differentiate between normal operational sounds and anomalous acoustic events, particularly in the 50-300 kHz frequency range most relevant to thermal runaway detection.

Sensor placement presents another significant hurdle. Research indicates that optimal detection requires strategic sensor positioning relative to battery cells, with sensitivity decreasing exponentially with distance. This creates a complex engineering trade-off between comprehensive coverage and system cost/complexity. Leading implementations currently require approximately one sensor per 8-10 cells for reliable detection, creating scalability challenges for large battery arrays.

Miniaturization constraints further complicate implementation. The most sensitive piezoelectric sensors remain relatively bulky (typically 5-15mm in diameter), limiting integration options in space-constrained battery packs. Recent developments in MEMS acoustic sensors show promise but currently sacrifice sensitivity for size reduction.

Geographically, research leadership in this field is distributed across several regions. North American institutions lead in fundamental acoustic characterization of battery failure modes, while Asian manufacturers (particularly in Japan and South Korea) dominate in sensor miniaturization and integration technologies. European research centers have made significant contributions to signal processing algorithms and system-level implementations.

Temperature sensitivity represents another critical challenge, as most acoustic sensors exhibit performance drift across the wide operating temperature ranges (-20°C to 60°C) typical of battery applications. Current compensation algorithms provide only partial correction, with detection reliability decreasing at temperature extremes.

Data processing requirements pose implementation barriers, particularly for real-time monitoring. Current algorithms require significant computational resources to process acoustic data streams, creating power consumption challenges for battery-powered devices where energy efficiency is paramount.

The primary technical challenge remains signal-to-noise ratio optimization in real-world environments. Battery systems in electric vehicles, grid storage, and consumer electronics operate in acoustically complex settings where ambient noise can mask critical thermal runaway signatures. Current filtering algorithms struggle to differentiate between normal operational sounds and anomalous acoustic events, particularly in the 50-300 kHz frequency range most relevant to thermal runaway detection.

Sensor placement presents another significant hurdle. Research indicates that optimal detection requires strategic sensor positioning relative to battery cells, with sensitivity decreasing exponentially with distance. This creates a complex engineering trade-off between comprehensive coverage and system cost/complexity. Leading implementations currently require approximately one sensor per 8-10 cells for reliable detection, creating scalability challenges for large battery arrays.

Miniaturization constraints further complicate implementation. The most sensitive piezoelectric sensors remain relatively bulky (typically 5-15mm in diameter), limiting integration options in space-constrained battery packs. Recent developments in MEMS acoustic sensors show promise but currently sacrifice sensitivity for size reduction.

Geographically, research leadership in this field is distributed across several regions. North American institutions lead in fundamental acoustic characterization of battery failure modes, while Asian manufacturers (particularly in Japan and South Korea) dominate in sensor miniaturization and integration technologies. European research centers have made significant contributions to signal processing algorithms and system-level implementations.

Temperature sensitivity represents another critical challenge, as most acoustic sensors exhibit performance drift across the wide operating temperature ranges (-20°C to 60°C) typical of battery applications. Current compensation algorithms provide only partial correction, with detection reliability decreasing at temperature extremes.

Data processing requirements pose implementation barriers, particularly for real-time monitoring. Current algorithms require significant computational resources to process acoustic data streams, creating power consumption challenges for battery-powered devices where energy efficiency is paramount.

Current Acoustic Emission Detection Implementation Methods

01 Acoustic emission sensors for battery thermal runaway detection

Acoustic emission sensors can be used to detect thermal runaway in batteries by monitoring the sound waves generated during the early stages of thermal events. These sensors capture the characteristic acoustic signatures produced by gas evolution, electrolyte decomposition, and structural changes that precede catastrophic failure. By analyzing these acoustic patterns, the system can provide early warning of potential thermal runaway conditions, allowing for preventive measures to be taken before the situation becomes critical.- Acoustic emission sensors for battery thermal runaway detection: Acoustic emission sensors can be used to detect thermal runaway in batteries by monitoring the sound waves generated during abnormal battery conditions. These sensors capture the acoustic signals emitted during the early stages of thermal runaway, allowing for early detection before catastrophic failure occurs. The acoustic emission detection systems can be integrated with battery management systems to provide real-time monitoring and safety alerts.

- Multi-sensor integration for comprehensive thermal runaway detection: Combining acoustic emission sensors with other sensing technologies such as temperature, voltage, and gas sensors creates a more robust thermal runaway detection system. This multi-sensor approach provides redundancy and improves the accuracy of thermal runaway prediction by analyzing multiple parameters simultaneously. The integrated system can better distinguish between normal battery operation and potential failure conditions, reducing false alarms while enhancing safety.

- Signal processing algorithms for acoustic emission analysis: Advanced signal processing algorithms are essential for interpreting acoustic emission data from battery systems. These algorithms filter out background noise, identify specific acoustic signatures associated with thermal runaway, and analyze frequency patterns to determine the severity and progression of battery failure events. Machine learning techniques can be employed to improve detection accuracy by learning from historical acoustic emission patterns associated with various battery failure modes.

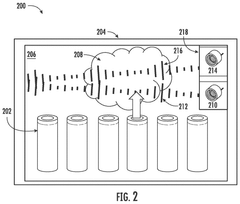

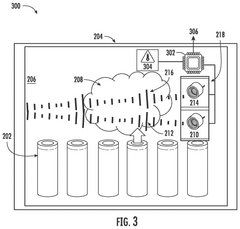

- Acoustic sensor placement and configuration optimization: The effectiveness of acoustic emission detection systems depends significantly on sensor placement and configuration. Strategic positioning of acoustic sensors on battery packs or cells maximizes signal capture while minimizing interference. Various mounting techniques and sensor array configurations can be employed to improve detection sensitivity and coverage area. Waveguide structures may be used to channel acoustic signals from hard-to-reach areas to sensor locations.

- Early warning systems and safety response integration: Acoustic emission detection systems can be integrated with battery management systems to trigger appropriate safety responses when thermal runaway is detected. These early warning systems can initiate cooling mechanisms, electrical isolation, or emergency shutdown procedures based on the severity of the detected acoustic signals. The integration enables graduated response protocols that match the intervention to the level of risk, potentially preventing catastrophic battery failures and enhancing overall system safety.

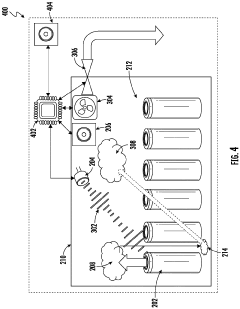

02 Integration of acoustic sensors in battery management systems

Acoustic emission detection technology can be integrated into comprehensive battery management systems to enhance safety monitoring capabilities. These integrated systems combine acoustic sensors with temperature, voltage, and current monitoring to create a multi-parameter approach to thermal runaway detection. The acoustic component provides an additional layer of safety by detecting subtle changes in battery behavior that might not be captured by conventional sensors, enabling more robust protection against thermal events in energy storage systems.Expand Specific Solutions03 Advanced signal processing for acoustic emission detection

Advanced signal processing techniques are employed to analyze acoustic emissions from battery cells for reliable thermal runaway detection. These methods include machine learning algorithms, pattern recognition, and frequency domain analysis to distinguish between normal operational sounds and those indicating potential failure. By filtering out background noise and identifying specific acoustic signatures associated with thermal runaway precursors, these processing techniques significantly improve detection accuracy and reduce false alarms in battery monitoring systems.Expand Specific Solutions04 Distributed acoustic sensing networks for large battery systems

Distributed acoustic sensing networks can be deployed across large-scale battery installations to provide comprehensive thermal runaway monitoring. These networks consist of multiple acoustic sensors strategically placed throughout battery packs or energy storage facilities. The distributed approach allows for precise localization of potential thermal events within complex battery systems, enabling targeted intervention and minimizing damage to adjacent cells. This architecture is particularly valuable for grid-scale energy storage, electric vehicle fleets, and industrial applications where battery arrays cover significant physical space.Expand Specific Solutions05 Combined acoustic and thermal sensing technologies

Hybrid sensing approaches that combine acoustic emission detection with thermal imaging or temperature sensing provide enhanced reliability for thermal runaway detection. These multi-modal systems leverage the complementary strengths of different sensing technologies to create a more robust detection framework. While acoustic sensors can detect the earliest signs of thermal runaway, thermal sensors confirm temperature anomalies, creating a verification mechanism that reduces false positives. This combined approach is particularly effective in high-reliability applications where the consequences of undetected thermal runaway would be severe.Expand Specific Solutions

Leading Companies in Acoustic Emission Sensing Industry

The thermal runaway sensors market using acoustic emission detection methods is in an early growth stage, characterized by increasing adoption as battery safety concerns rise in electric vehicles and energy storage systems. The market is expanding rapidly, driven by stringent safety regulations and growing EV adoption, with projections indicating substantial growth over the next decade. Technologically, the field is evolving from experimental to commercial applications, with companies at varying maturity levels. Industry leaders like Tesla, CATL, and Samsung SDI are advancing proprietary solutions, while automotive manufacturers (Mercedes-Benz, Hyundai, Kia) are integrating these technologies into their battery management systems. Research institutions like Beijing Institute of Technology and Harbin Institute of Technology are contributing fundamental research, while specialized companies such as Honeywell and Infineon are developing sensor components and systems for early thermal runaway detection.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an advanced acoustic emission-based thermal runaway detection system primarily targeting industrial energy storage installations and electric vehicle applications. Their solution employs specialized acoustic sensors with high sensitivity in the 50-500 kHz frequency range, strategically positioned to monitor battery cells for the distinctive acoustic signatures that precede thermal events. Honeywell's system incorporates proprietary signal processing algorithms that filter environmental noise and isolate the specific acoustic patterns associated with internal battery degradation mechanisms. The technology features adaptive thresholding that automatically adjusts detection parameters based on ambient conditions and battery operational state, significantly reducing false alarms while maintaining detection sensitivity. Honeywell's implementation includes a centralized monitoring unit that processes data from multiple acoustic sensors, correlating acoustic information with temperature measurements to provide comprehensive thermal event prediction. Their system can detect thermal runaway precursors approximately 4-8 minutes before conventional temperature sensors would register critical values[6], allowing sufficient time for preventative measures including emergency shutdown, isolation of affected modules, and activation of fire suppression systems.

Strengths: Industrial-grade reliability with proven performance in harsh environments, seamless integration with existing building management and safety systems, and comprehensive alert management capabilities. Weaknesses: Higher initial implementation cost compared to basic thermal monitoring solutions, and requires periodic system validation to ensure continued detection accuracy.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a sophisticated acoustic emission monitoring system for thermal runaway detection in their electric vehicle battery packs. Their approach utilizes an array of specialized acoustic sensors positioned strategically throughout the battery enclosure to detect the characteristic ultrasonic signatures (150-400 kHz range) that precede thermal events. The Mercedes system employs advanced digital signal processing with adaptive filtering to isolate thermal runaway acoustic patterns from vehicle operational noise and road vibrations. Their implementation features a two-stage detection algorithm: the first stage continuously monitors for anomalous acoustic patterns, while the second stage performs detailed spectral analysis to confirm potential thermal events before triggering safety protocols. Mercedes has integrated this acoustic monitoring with their proprietary Battery Management System (BMS) to create a comprehensive safety architecture that can detect thermal runaway up to 3-7 minutes before conventional temperature sensors would register critical values[5]. The system is designed with redundancy, utilizing multiple sensor types and detection methods to ensure reliability in diverse operating conditions.

Strengths: Exceptional noise rejection capabilities in automotive environments, seamless integration with vehicle safety systems, and proven reliability across various driving conditions. Weaknesses: Higher system complexity requiring specialized installation procedures and periodic calibration to maintain detection accuracy over vehicle lifetime.

Key Patents and Research in Thermal Runaway Acoustic Sensing

System, method, and computer program product for detecting the onset of thermal runaway using an ultrasonic sensor

PatentPendingUS20240319142A1

Innovation

- An ultrasonic sensor system is placed within the internal battery compartment to transmit and receive acoustic signals, detecting changes in the time of flight of these signals due to emitted gases like hydrogen, which indicates the onset of thermal runaway, allowing for early detection and mitigation.

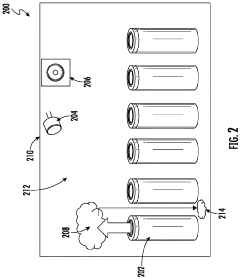

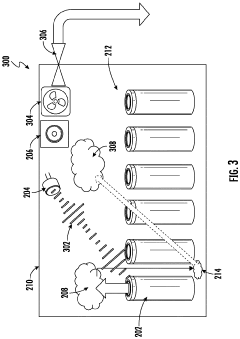

System and method for detecting thermal runaway using acoustic and gas sensors

PatentPendingEP4386934A2

Innovation

- A system incorporating an acoustic sensor, internal and external gas sensors, a fan, and an adaptable vent, connected to a processor that enables the fan and vent to direct gases away from the battery cell and compare internal and external gas sensor data to accurately detect thermal runaway, reducing false alarms and enabling early mitigation.

Integration Strategies with Battery Management Systems

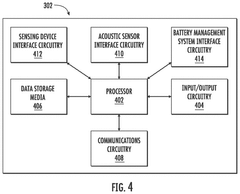

The integration of acoustic emission (AE) detection systems with Battery Management Systems (BMS) represents a critical advancement in battery safety technology. Effective integration strategies must address both hardware and software interfaces to ensure seamless operation while maintaining the primary BMS functions of monitoring, protection, and optimization. At the hardware level, AE sensors require dedicated signal processing channels that must be incorporated into existing BMS architectures without compromising system reliability or introducing electromagnetic interference. This typically involves designing custom interface boards or utilizing existing expansion capabilities within modern BMS platforms.

Data integration presents another significant challenge, as AE detection systems generate high-frequency acoustic data that must be processed and analyzed in real-time alongside traditional battery parameters. Advanced signal processing algorithms must be implemented within the BMS computational framework to extract meaningful thermal runaway precursor signals from background noise. This necessitates careful consideration of computational resources and may require dedicated digital signal processors or field-programmable gate arrays to handle the intensive processing requirements without impacting core BMS functions.

Communication protocols between AE subsystems and the main BMS controller must be optimized for minimal latency, as early detection of thermal events is time-critical. Industry standards such as CAN, SPI, or I²C are commonly employed, with custom protocol extensions to accommodate the unique data characteristics of acoustic emission signals. Redundancy in communication pathways ensures that critical safety information is reliably transmitted even under adverse conditions.

Power management strategies must also be considered, particularly for large-scale battery systems where continuous AE monitoring could impose significant energy demands. Intelligent power scheduling algorithms can activate full AE monitoring during high-risk operations (rapid charging, high-power discharge) while maintaining reduced monitoring during normal operation. This approach optimizes the balance between safety coverage and system efficiency.

The integration architecture should support hierarchical decision-making processes where AE detection data contributes to a comprehensive battery health assessment alongside traditional parameters like voltage, current, and temperature. This multi-modal approach significantly enhances the accuracy of thermal runaway prediction compared to single-parameter monitoring systems. Machine learning algorithms can be implemented to continuously improve detection accuracy by correlating acoustic signatures with other battery health indicators and operational conditions.

Standardization efforts are emerging to facilitate smoother integration of advanced sensing technologies like AE detection into commercial BMS platforms. Organizations such as IEEE and IEC are developing reference architectures and interface specifications that will enable plug-and-play compatibility between different vendors' components, accelerating industry adoption of these critical safety technologies.

Data integration presents another significant challenge, as AE detection systems generate high-frequency acoustic data that must be processed and analyzed in real-time alongside traditional battery parameters. Advanced signal processing algorithms must be implemented within the BMS computational framework to extract meaningful thermal runaway precursor signals from background noise. This necessitates careful consideration of computational resources and may require dedicated digital signal processors or field-programmable gate arrays to handle the intensive processing requirements without impacting core BMS functions.

Communication protocols between AE subsystems and the main BMS controller must be optimized for minimal latency, as early detection of thermal events is time-critical. Industry standards such as CAN, SPI, or I²C are commonly employed, with custom protocol extensions to accommodate the unique data characteristics of acoustic emission signals. Redundancy in communication pathways ensures that critical safety information is reliably transmitted even under adverse conditions.

Power management strategies must also be considered, particularly for large-scale battery systems where continuous AE monitoring could impose significant energy demands. Intelligent power scheduling algorithms can activate full AE monitoring during high-risk operations (rapid charging, high-power discharge) while maintaining reduced monitoring during normal operation. This approach optimizes the balance between safety coverage and system efficiency.

The integration architecture should support hierarchical decision-making processes where AE detection data contributes to a comprehensive battery health assessment alongside traditional parameters like voltage, current, and temperature. This multi-modal approach significantly enhances the accuracy of thermal runaway prediction compared to single-parameter monitoring systems. Machine learning algorithms can be implemented to continuously improve detection accuracy by correlating acoustic signatures with other battery health indicators and operational conditions.

Standardization efforts are emerging to facilitate smoother integration of advanced sensing technologies like AE detection into commercial BMS platforms. Organizations such as IEEE and IEC are developing reference architectures and interface specifications that will enable plug-and-play compatibility between different vendors' components, accelerating industry adoption of these critical safety technologies.

Safety Standards and Certification Requirements

The implementation of acoustic emission detection methods for thermal runaway sensors must comply with various safety standards and certification requirements to ensure reliable operation in critical applications. Currently, the International Electrotechnical Commission (IEC) has established several standards specifically addressing battery safety monitoring systems, including IEC 62133 for secondary cells and batteries and IEC 62619 for industrial applications. These standards outline minimum requirements for acoustic monitoring systems, including sensitivity thresholds, response times, and integration with battery management systems.

UL 2580 (Batteries for Use in Electric Vehicles) and UL 1642 (Lithium Batteries) have recently updated their guidelines to include provisions for early detection systems, with acoustic emission monitoring now recognized as a viable safety technology. Manufacturers seeking certification must demonstrate that their acoustic sensors can detect thermal events at least 120 seconds before thermal runaway becomes irreversible, with a false positive rate below 0.01%.

The automotive industry has developed more stringent requirements through ISO 26262 (Functional Safety for Road Vehicles), which classifies battery monitoring systems as ASIL-D components—the highest safety integrity level. Acoustic emission sensors for EV applications must undergo extensive validation testing, including vibration resistance, electromagnetic compatibility, and performance verification across temperature ranges from -40°C to 85°C.

Regional variations in certification requirements present challenges for global deployment. While European standards (EN standards) closely align with IEC frameworks, China's GB/T standards impose additional testing protocols specifically for acoustic emission sensitivity in high-humidity environments. The United States NFPA 855 standard for stationary energy storage systems now explicitly references acoustic monitoring as a recommended detection method for large-scale installations.

Certification testing protocols typically require acoustic emission sensors to demonstrate detection capability across multiple failure modes, including gas generation, electrode delamination, and electrolyte decomposition. The testing must verify that sensors can distinguish between normal operational sounds and anomalous acoustic signatures with at least 95% accuracy under varying environmental conditions.

Emerging standards from organizations like IEEE and ASTM are currently developing specific test methods for acoustic emission monitoring systems, with draft standards expected to be finalized within the next 18-24 months. These upcoming standards will likely establish more precise performance benchmarks and standardized testing methodologies specifically tailored to acoustic emission detection technologies.

UL 2580 (Batteries for Use in Electric Vehicles) and UL 1642 (Lithium Batteries) have recently updated their guidelines to include provisions for early detection systems, with acoustic emission monitoring now recognized as a viable safety technology. Manufacturers seeking certification must demonstrate that their acoustic sensors can detect thermal events at least 120 seconds before thermal runaway becomes irreversible, with a false positive rate below 0.01%.

The automotive industry has developed more stringent requirements through ISO 26262 (Functional Safety for Road Vehicles), which classifies battery monitoring systems as ASIL-D components—the highest safety integrity level. Acoustic emission sensors for EV applications must undergo extensive validation testing, including vibration resistance, electromagnetic compatibility, and performance verification across temperature ranges from -40°C to 85°C.

Regional variations in certification requirements present challenges for global deployment. While European standards (EN standards) closely align with IEC frameworks, China's GB/T standards impose additional testing protocols specifically for acoustic emission sensitivity in high-humidity environments. The United States NFPA 855 standard for stationary energy storage systems now explicitly references acoustic monitoring as a recommended detection method for large-scale installations.

Certification testing protocols typically require acoustic emission sensors to demonstrate detection capability across multiple failure modes, including gas generation, electrode delamination, and electrolyte decomposition. The testing must verify that sensors can distinguish between normal operational sounds and anomalous acoustic signatures with at least 95% accuracy under varying environmental conditions.

Emerging standards from organizations like IEEE and ASTM are currently developing specific test methods for acoustic emission monitoring systems, with draft standards expected to be finalized within the next 18-24 months. These upcoming standards will likely establish more precise performance benchmarks and standardized testing methodologies specifically tailored to acoustic emission detection technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!