Thermal runaway sensors integrated with smart battery packs

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Runaway Detection Background and Objectives

Thermal runaway in lithium-ion batteries represents one of the most critical safety challenges in modern energy storage systems. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to fire, explosion, and catastrophic failure of the entire battery system. The evolution of thermal runaway detection technology has progressed from basic temperature monitoring to sophisticated multi-parameter sensing systems integrated directly within battery packs.

The historical development of thermal runaway detection began with external temperature sensors in the early 2000s, which provided limited warning capabilities due to their delayed response to internal battery events. By the mid-2010s, the integration of multiple sensing modalities emerged, incorporating gas detection, voltage monitoring, and impedance tracking alongside temperature sensing. Recent advancements have focused on embedding sensors directly within cells and developing predictive algorithms capable of identifying precursor events before thermal runaway occurs.

Current technological trends point toward miniaturized, cost-effective sensor arrays that can be integrated during battery manufacturing processes without compromising energy density or adding significant cost. These systems increasingly leverage machine learning algorithms to distinguish between normal operational fluctuations and genuine thermal runaway precursors, dramatically reducing false alarms while improving early detection capabilities.

The primary objective of thermal runaway sensor research is to develop detection systems that can identify potential failure events at the earliest possible stage, providing sufficient time for preventive measures to be implemented. Specifically, the goal is to achieve detection at least 5-10 minutes before catastrophic failure, allowing for isolation of affected cells, emergency cooling activation, or safe system shutdown.

Secondary objectives include developing sensors that maintain accuracy across the entire battery lifecycle, operate reliably in diverse environmental conditions, and integrate seamlessly with battery management systems. Cost-effectiveness remains a critical consideration, with targets suggesting that advanced thermal runaway detection should add no more than 2-3% to overall battery pack costs to achieve widespread adoption.

The integration of these sensors with smart battery packs represents a paradigm shift from reactive to predictive safety systems. By combining real-time sensor data with sophisticated algorithms, next-generation battery systems aim to not only detect thermal events but actively prevent them through adaptive control strategies. This approach aligns with broader industry goals of improving battery safety while simultaneously extending operational lifetimes and enhancing performance characteristics.

The historical development of thermal runaway detection began with external temperature sensors in the early 2000s, which provided limited warning capabilities due to their delayed response to internal battery events. By the mid-2010s, the integration of multiple sensing modalities emerged, incorporating gas detection, voltage monitoring, and impedance tracking alongside temperature sensing. Recent advancements have focused on embedding sensors directly within cells and developing predictive algorithms capable of identifying precursor events before thermal runaway occurs.

Current technological trends point toward miniaturized, cost-effective sensor arrays that can be integrated during battery manufacturing processes without compromising energy density or adding significant cost. These systems increasingly leverage machine learning algorithms to distinguish between normal operational fluctuations and genuine thermal runaway precursors, dramatically reducing false alarms while improving early detection capabilities.

The primary objective of thermal runaway sensor research is to develop detection systems that can identify potential failure events at the earliest possible stage, providing sufficient time for preventive measures to be implemented. Specifically, the goal is to achieve detection at least 5-10 minutes before catastrophic failure, allowing for isolation of affected cells, emergency cooling activation, or safe system shutdown.

Secondary objectives include developing sensors that maintain accuracy across the entire battery lifecycle, operate reliably in diverse environmental conditions, and integrate seamlessly with battery management systems. Cost-effectiveness remains a critical consideration, with targets suggesting that advanced thermal runaway detection should add no more than 2-3% to overall battery pack costs to achieve widespread adoption.

The integration of these sensors with smart battery packs represents a paradigm shift from reactive to predictive safety systems. By combining real-time sensor data with sophisticated algorithms, next-generation battery systems aim to not only detect thermal events but actively prevent them through adaptive control strategies. This approach aligns with broader industry goals of improving battery safety while simultaneously extending operational lifetimes and enhancing performance characteristics.

Market Analysis for Smart Battery Safety Solutions

The global market for smart battery safety solutions is experiencing significant growth, driven primarily by the increasing adoption of lithium-ion batteries across multiple industries. The market size for battery safety systems was valued at approximately $2.3 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate (CAGR) of 16.4%. This growth trajectory is particularly pronounced in the electric vehicle sector, where battery safety concerns have become paramount following several high-profile thermal runaway incidents.

Consumer electronics represents another substantial market segment, with smartphone and laptop manufacturers increasingly integrating advanced battery management systems that include thermal runaway detection capabilities. This segment accounts for roughly 28% of the total market share, with annual growth rates exceeding 12% since 2020.

The industrial and energy storage sectors are emerging as significant growth areas, particularly as grid-scale battery installations become more common. These applications demand highly reliable safety systems due to the scale of potential failures, driving innovation in integrated sensor technologies. Market analysis indicates that this segment will grow at a CAGR of 19.2% through 2028, outpacing the overall market average.

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea where major battery manufacturers and electronics companies are concentrated. North America follows with 27% market share, while Europe accounts for 22% with particularly strong growth in countries with aggressive electric mobility initiatives.

Market demand is increasingly shifting toward integrated solutions that combine multiple sensing modalities with artificial intelligence for predictive failure detection. Systems that can detect thermal runaway precursors rather than just responding to events are commanding premium prices, with customers willing to pay 30-40% more for advanced predictive capabilities.

Regulatory factors are significantly influencing market dynamics, with new safety standards being implemented across major markets. The UN Regulation No. 100 for EV battery safety, China's GB/T 31485 standard, and the IEC 62619 international standard are creating consistent demand for more sophisticated safety solutions. These regulations are expected to tighten further, creating barriers to entry but also premium opportunities for companies with advanced technological capabilities.

Customer willingness to pay for safety features varies by segment, with automotive OEMs demonstrating the highest price tolerance due to liability concerns and brand protection considerations. Consumer electronics manufacturers are more price-sensitive but increasingly recognize safety as a differentiating feature in premium devices.

Consumer electronics represents another substantial market segment, with smartphone and laptop manufacturers increasingly integrating advanced battery management systems that include thermal runaway detection capabilities. This segment accounts for roughly 28% of the total market share, with annual growth rates exceeding 12% since 2020.

The industrial and energy storage sectors are emerging as significant growth areas, particularly as grid-scale battery installations become more common. These applications demand highly reliable safety systems due to the scale of potential failures, driving innovation in integrated sensor technologies. Market analysis indicates that this segment will grow at a CAGR of 19.2% through 2028, outpacing the overall market average.

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea where major battery manufacturers and electronics companies are concentrated. North America follows with 27% market share, while Europe accounts for 22% with particularly strong growth in countries with aggressive electric mobility initiatives.

Market demand is increasingly shifting toward integrated solutions that combine multiple sensing modalities with artificial intelligence for predictive failure detection. Systems that can detect thermal runaway precursors rather than just responding to events are commanding premium prices, with customers willing to pay 30-40% more for advanced predictive capabilities.

Regulatory factors are significantly influencing market dynamics, with new safety standards being implemented across major markets. The UN Regulation No. 100 for EV battery safety, China's GB/T 31485 standard, and the IEC 62619 international standard are creating consistent demand for more sophisticated safety solutions. These regulations are expected to tighten further, creating barriers to entry but also premium opportunities for companies with advanced technological capabilities.

Customer willingness to pay for safety features varies by segment, with automotive OEMs demonstrating the highest price tolerance due to liability concerns and brand protection considerations. Consumer electronics manufacturers are more price-sensitive but increasingly recognize safety as a differentiating feature in premium devices.

Current Thermal Runaway Sensing Technologies and Challenges

The current landscape of thermal runaway sensing technologies in smart battery packs encompasses various detection methods, each with distinct advantages and limitations. Temperature monitoring remains the most widely implemented approach, utilizing thermistors or thermocouples strategically placed within battery packs to detect abnormal temperature rises. While cost-effective and relatively simple to integrate, these sensors often suffer from delayed response times, as they can only detect thermal events after significant heat generation has occurred.

Gas detection sensors represent another critical technology category, designed to identify volatile gases released during the early stages of thermal decomposition. These sensors can detect gases such as carbon dioxide, carbon monoxide, and various hydrocarbons that precede visible thermal runaway events. Though offering earlier detection capabilities than temperature sensors alone, gas sensors face challenges related to selectivity, calibration drift, and potential contamination in real-world environments.

Voltage and impedance monitoring systems analyze electrical characteristics to identify internal short circuits or abnormal electrochemical behaviors. These methods leverage existing battery management system infrastructure but require sophisticated algorithms to differentiate between normal operational fluctuations and genuine thermal runaway precursors. The computational demands of these approaches can strain processing resources in compact battery systems.

Differential pressure sensors detect the buildup of gases within sealed battery enclosures, providing another early warning mechanism. However, their effectiveness depends heavily on enclosure design and may be compromised in systems with pressure relief mechanisms or in batteries with slow gas generation profiles.

Optical sensing technologies, including fiber optic sensors and infrared imaging, offer promising alternatives with rapid response times and immunity to electromagnetic interference. Despite these advantages, their widespread adoption faces barriers related to cost, complexity, and challenges in miniaturization for integration within compact battery assemblies.

A significant challenge across all sensing technologies is achieving the optimal balance between sensitivity and false alarm rates. Overly sensitive systems may trigger unnecessary shutdowns and user inconvenience, while less sensitive approaches risk missing critical thermal events until they become uncontrollable. This balance becomes particularly challenging in dynamic operating environments with varying ambient conditions.

Integration challenges further complicate implementation, as sensors must withstand harsh electrochemical environments while maintaining long-term reliability throughout the battery's operational life. Power consumption represents another critical constraint, especially in portable applications where energy efficiency directly impacts device runtime.

Gas detection sensors represent another critical technology category, designed to identify volatile gases released during the early stages of thermal decomposition. These sensors can detect gases such as carbon dioxide, carbon monoxide, and various hydrocarbons that precede visible thermal runaway events. Though offering earlier detection capabilities than temperature sensors alone, gas sensors face challenges related to selectivity, calibration drift, and potential contamination in real-world environments.

Voltage and impedance monitoring systems analyze electrical characteristics to identify internal short circuits or abnormal electrochemical behaviors. These methods leverage existing battery management system infrastructure but require sophisticated algorithms to differentiate between normal operational fluctuations and genuine thermal runaway precursors. The computational demands of these approaches can strain processing resources in compact battery systems.

Differential pressure sensors detect the buildup of gases within sealed battery enclosures, providing another early warning mechanism. However, their effectiveness depends heavily on enclosure design and may be compromised in systems with pressure relief mechanisms or in batteries with slow gas generation profiles.

Optical sensing technologies, including fiber optic sensors and infrared imaging, offer promising alternatives with rapid response times and immunity to electromagnetic interference. Despite these advantages, their widespread adoption faces barriers related to cost, complexity, and challenges in miniaturization for integration within compact battery assemblies.

A significant challenge across all sensing technologies is achieving the optimal balance between sensitivity and false alarm rates. Overly sensitive systems may trigger unnecessary shutdowns and user inconvenience, while less sensitive approaches risk missing critical thermal events until they become uncontrollable. This balance becomes particularly challenging in dynamic operating environments with varying ambient conditions.

Integration challenges further complicate implementation, as sensors must withstand harsh electrochemical environments while maintaining long-term reliability throughout the battery's operational life. Power consumption represents another critical constraint, especially in portable applications where energy efficiency directly impacts device runtime.

Existing Thermal Runaway Detection Integration Methods

01 Temperature monitoring systems for battery thermal runaway detection

Temperature monitoring systems are essential for early detection of thermal runaway in batteries. These systems utilize various temperature sensors strategically placed within battery packs to continuously monitor temperature changes. When abnormal temperature rises are detected, the system can trigger alarms or activate safety mechanisms to prevent catastrophic failures. Advanced systems may incorporate predictive algorithms to identify potential thermal runaway conditions before they become critical.- Temperature monitoring systems for battery thermal runaway detection: Temperature monitoring systems are essential for early detection of thermal runaway in batteries. These systems utilize various temperature sensors strategically placed within battery packs to continuously monitor temperature changes. When abnormal temperature rises are detected, the system can trigger alarms or activate safety mechanisms to prevent catastrophic failures. Advanced systems may incorporate predictive algorithms to identify potential thermal runaway conditions before they fully develop.

- Gas detection sensors for thermal runaway prevention: Gas detection sensors provide an alternative approach to thermal runaway detection by monitoring the presence of gases released during the early stages of battery degradation. These sensors can detect specific gases like carbon monoxide, hydrogen, and volatile organic compounds that are emitted before visible signs of thermal runaway occur. By identifying these precursor gases, safety systems can intervene earlier than temperature-based detection alone, providing additional time for preventive measures.

- Integrated multi-sensor systems for comprehensive thermal runaway protection: Integrated multi-sensor systems combine different sensor types to create a more robust thermal runaway detection framework. These systems typically incorporate temperature sensors, gas detectors, voltage monitors, and current sensors to provide comprehensive monitoring of battery health. By analyzing data from multiple sensor types simultaneously, these systems can more accurately distinguish between normal operation and potential thermal runaway conditions, reducing false alarms while improving safety.

- Wireless sensor networks for thermal runaway monitoring in large battery installations: Wireless sensor networks enable efficient monitoring of large-scale battery installations by eliminating the need for extensive wiring. These networks consist of distributed sensor nodes that communicate wirelessly with central monitoring systems. Each node can contain multiple sensor types and operate independently, providing redundancy and improved coverage. Wireless systems are particularly valuable in applications like grid storage and electric vehicle fleets where numerous batteries must be monitored simultaneously across large areas.

- Artificial intelligence and machine learning for predictive thermal runaway detection: Advanced thermal runaway detection systems incorporate artificial intelligence and machine learning algorithms to analyze sensor data and predict potential failures before they occur. These systems learn from historical data patterns to identify subtle indicators of battery degradation that might precede thermal runaway. By continuously improving their predictive models through machine learning, these systems can detect anomalies earlier and with greater accuracy than traditional threshold-based approaches, potentially preventing thermal runaway incidents entirely.

02 Gas detection sensors for thermal runaway prevention

Gas detection sensors are used to identify the release of specific gases that occur during the early stages of thermal runaway. These sensors can detect volatile organic compounds, hydrogen, carbon monoxide, and other gases emitted when battery cells begin to degrade thermally. By detecting these gases before significant temperature increases occur, safety systems can be activated earlier, providing more time for preventive measures and potentially avoiding thermal runaway progression.Expand Specific Solutions03 Integrated multi-parameter sensing systems for comprehensive thermal runaway monitoring

Integrated sensing systems combine multiple sensor types to provide comprehensive monitoring of thermal runaway conditions. These systems may incorporate temperature sensors, gas detectors, voltage monitors, and current sensors to create a holistic view of battery health. By analyzing data from multiple parameters simultaneously, these systems can more accurately identify the early signs of thermal runaway and distinguish between normal operational fluctuations and potentially dangerous conditions.Expand Specific Solutions04 Optical fiber sensors for distributed thermal runaway detection

Optical fiber sensors provide distributed temperature sensing capabilities across battery systems. These sensors can detect temperature changes along their entire length, allowing for precise localization of hotspots within large battery packs. Fiber optic technology offers advantages including immunity to electromagnetic interference, ability to function in harsh environments, and capability to monitor multiple points simultaneously. This technology enables early detection of thermal runaway conditions even in complex battery configurations.Expand Specific Solutions05 Artificial intelligence and machine learning for predictive thermal runaway detection

Advanced thermal runaway detection systems incorporate artificial intelligence and machine learning algorithms to predict potential failure conditions before they occur. These systems analyze patterns in sensor data to identify subtle indicators of developing thermal issues. By learning from historical data and continuously improving their predictive models, these systems can distinguish between normal operational variations and early warning signs of thermal runaway, enabling preventive actions before critical conditions develop.Expand Specific Solutions

Leading Companies in Battery Safety Sensor Development

The thermal runaway sensor market for smart battery packs is currently in a growth phase, with increasing demand driven by electric vehicle proliferation and energy storage applications. Market size is expanding rapidly, projected to reach significant value as battery safety concerns become paramount. Technologically, industry leaders like Tesla, CATL, and LG Energy Solution are at the forefront, having developed advanced thermal runaway detection systems with varying degrees of maturity. Companies including Samsung SDI, Rimac Technology, and NIO are investing heavily in proprietary sensor technologies, while newer entrants like Global Battery Solutions and Viridi Parente are focusing on specialized applications. University collaborations with Newcastle University and Beijing Institute of Technology are accelerating innovation in early detection methodologies, pushing the technology toward greater reliability and integration capabilities.

Tesla, Inc.

Technical Solution: Tesla has developed an advanced thermal runaway detection system that integrates multiple sensor types within their battery packs. Their approach combines temperature sensors, gas detection sensors, and voltage monitoring in a distributed network throughout the battery pack. Tesla's system utilizes machine learning algorithms to analyze sensor data patterns and predict potential thermal events before they become critical. Their Battery Management System (BMS) incorporates predictive analytics that can detect subtle changes in cell behavior that might indicate the early stages of thermal runaway. Tesla has also implemented a proprietary cooling system that works in conjunction with these sensors to actively manage thermal conditions. The company's thermal runaway prevention strategy includes both hardware and software components, with redundant safety mechanisms that can isolate affected modules to prevent propagation across the entire battery pack.

Strengths: Tesla's integrated approach combines multiple sensor types with advanced analytics, providing early detection capabilities. Their system benefits from vast real-world data collection across their vehicle fleet, enabling continuous improvement of detection algorithms. Weaknesses: The complexity of Tesla's system requires significant computational resources and may be costly to implement in lower-priced vehicles. Their proprietary nature also limits adoption by other manufacturers.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive thermal runaway detection system called "Safety Reinforced Separator" (SRS) technology integrated with smart battery management. Their approach focuses on early detection through a multi-layered sensing network embedded directly within battery cells. The system incorporates specialized thermal sensors placed strategically between cells and modules to monitor temperature gradients and detect anomalies. LG's innovation includes ceramic-coated separators that act as both physical barriers and sensing elements, providing an additional layer of protection against thermal propagation. Their smart battery packs feature real-time monitoring capabilities that track individual cell performance metrics including temperature, voltage, and internal resistance. When potential thermal issues are detected, the system can automatically trigger protective measures such as current limitation, load disconnection, or emergency cooling activation. LG has also implemented gas detection sensors that can identify the presence of volatile organic compounds released during the early stages of thermal decomposition.

Strengths: LG's system features multi-layer protection with sensors integrated at the cell level, providing highly localized detection capabilities. Their ceramic-coated separators offer both sensing and physical protection functions. Weaknesses: The complex manufacturing process for integrating sensors at the cell level increases production costs and may impact energy density. The system requires sophisticated calibration to avoid false alarms.

Critical Patents in Smart Battery Thermal Management

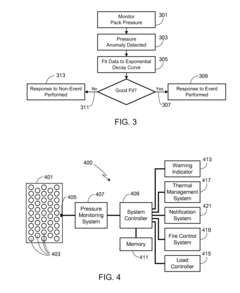

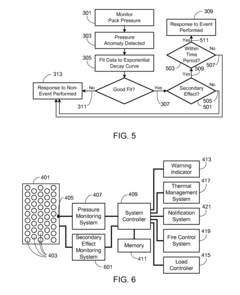

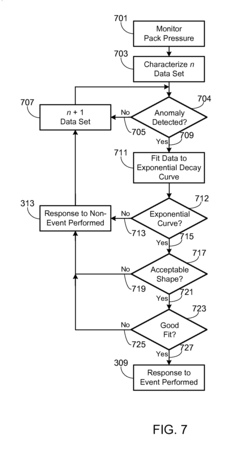

Battery Pack Pressure Monitoring System for Thermal Event Detection

PatentActiveUS20130260192A1

Innovation

- A system utilizing pressure sensors and a system controller to analyze pressure data, fitting curves to identify exponential decay patterns, and triggering responses based on preset criteria to detect thermal events, including secondary effect monitoring to corroborate detections.

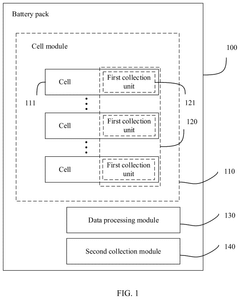

Battery pack, electric apparatus, detection method of battery pack, and computer storage medium

PatentPendingUS20250046894A1

Innovation

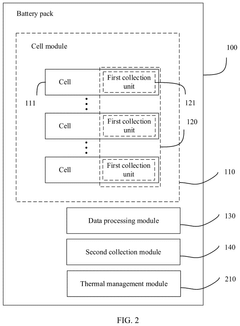

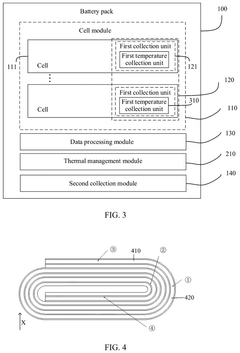

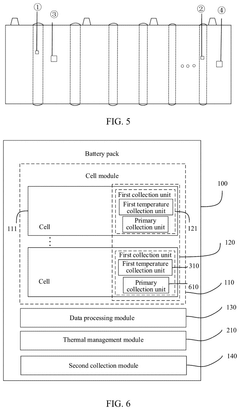

- A battery pack design that includes a cell module with internal first collection units for direct data collection, a data processing module for thermal runaway detection, and an external second collection module activated only when a thermal risk is detected, performing secondary detection to improve accuracy.

Regulatory Standards for Battery Safety Systems

The regulatory landscape for battery safety systems has evolved significantly in response to increasing concerns about thermal runaway incidents in lithium-ion batteries. Key international standards such as IEC 62133, UL 1642, and UN 38.3 establish baseline requirements for battery safety, with specific provisions for thermal management and runaway prevention. These standards mandate various testing protocols including thermal abuse tests, overcharge protection, and short circuit resilience.

In the automotive sector, regulations have become particularly stringent following high-profile electric vehicle battery fires. ISO 26262 addresses functional safety requirements for automotive electrical systems, while SAE J2464 and J2929 specifically target electric vehicle battery safety. These standards increasingly require sophisticated thermal monitoring systems with early detection capabilities for thermal anomalies.

Consumer electronics face similar regulatory scrutiny, with IEC 61960 and IEEE 1625/1725 providing guidelines for portable battery safety. These standards are progressively incorporating requirements for integrated thermal sensors and intelligent battery management systems that can detect precursors to thermal runaway events.

The aviation industry maintains some of the most demanding standards through RTCA DO-311A and EUROCAE ED-179B, which establish rigorous requirements for batteries used in aircraft systems. These standards emphasize redundant safety mechanisms and real-time monitoring capabilities to prevent catastrophic failures during flight operations.

Recent regulatory trends show a clear shift toward mandating smart battery management systems with integrated thermal runaway sensors. The European Union's Battery Directive revision and China's GB/T 31485 standard now explicitly reference advanced thermal monitoring technologies. Similarly, the International Civil Aviation Organization (ICAO) has updated its Technical Instructions to address lithium battery risks through enhanced detection requirements.

Compliance with these evolving standards presents significant challenges for manufacturers. The integration of thermal runaway sensors must be accomplished without compromising battery performance or increasing costs prohibitively. Additionally, there is growing regulatory emphasis on standardized communication protocols for battery safety systems to ensure interoperability across different platforms and applications.

Future regulatory developments are likely to focus on establishing more precise thresholds for early thermal event detection and standardizing sensor response characteristics. This trend will drive further innovation in integrated sensor technologies that can reliably identify thermal runaway precursors while minimizing false alarms that could undermine user confidence in battery-powered systems.

In the automotive sector, regulations have become particularly stringent following high-profile electric vehicle battery fires. ISO 26262 addresses functional safety requirements for automotive electrical systems, while SAE J2464 and J2929 specifically target electric vehicle battery safety. These standards increasingly require sophisticated thermal monitoring systems with early detection capabilities for thermal anomalies.

Consumer electronics face similar regulatory scrutiny, with IEC 61960 and IEEE 1625/1725 providing guidelines for portable battery safety. These standards are progressively incorporating requirements for integrated thermal sensors and intelligent battery management systems that can detect precursors to thermal runaway events.

The aviation industry maintains some of the most demanding standards through RTCA DO-311A and EUROCAE ED-179B, which establish rigorous requirements for batteries used in aircraft systems. These standards emphasize redundant safety mechanisms and real-time monitoring capabilities to prevent catastrophic failures during flight operations.

Recent regulatory trends show a clear shift toward mandating smart battery management systems with integrated thermal runaway sensors. The European Union's Battery Directive revision and China's GB/T 31485 standard now explicitly reference advanced thermal monitoring technologies. Similarly, the International Civil Aviation Organization (ICAO) has updated its Technical Instructions to address lithium battery risks through enhanced detection requirements.

Compliance with these evolving standards presents significant challenges for manufacturers. The integration of thermal runaway sensors must be accomplished without compromising battery performance or increasing costs prohibitively. Additionally, there is growing regulatory emphasis on standardized communication protocols for battery safety systems to ensure interoperability across different platforms and applications.

Future regulatory developments are likely to focus on establishing more precise thresholds for early thermal event detection and standardizing sensor response characteristics. This trend will drive further innovation in integrated sensor technologies that can reliably identify thermal runaway precursors while minimizing false alarms that could undermine user confidence in battery-powered systems.

Cost-Benefit Analysis of Integrated Sensor Solutions

The integration of thermal runaway sensors with smart battery packs represents a significant investment for manufacturers. This analysis examines the economic implications of such integration, balancing implementation costs against potential benefits and risk mitigation value.

Initial implementation costs for integrated sensor solutions typically range from $5-15 per battery pack, depending on sensor type and complexity. Gas sensors generally command premium pricing ($8-15) compared to temperature-based solutions ($5-8). These costs include not only the physical sensors but also the necessary signal processing circuitry, firmware development, and integration testing.

Manufacturing process modifications represent another substantial cost factor. Production lines require reconfiguration to accommodate sensor placement, calibration stations, and additional quality control steps. Companies report one-time setup costs between $100,000-500,000 depending on production volume and existing infrastructure.

Maintenance considerations must also factor into the cost equation. While modern solid-state sensors demonstrate impressive longevity (5-7 years), periodic calibration and potential replacement add to the total cost of ownership. Cloud connectivity features for remote monitoring further increase both initial and operational expenses by approximately 15-20%.

Against these costs, significant benefits emerge. Insurance premium reductions represent a quantifiable advantage, with manufacturers reporting 10-25% decreases in product liability coverage costs when implementing comprehensive thermal runaway detection systems. This can translate to annual savings of $50,000-250,000 for mid-sized battery manufacturers.

Warranty claim reductions constitute another major benefit. Field data indicates a 30-40% decrease in catastrophic battery failure claims following sensor integration, representing potential savings of millions annually for large-scale producers. Early detection capabilities enable controlled shutdown before cascading cell failures occur.

Brand protection value, while more difficult to quantify precisely, may represent the most significant long-term benefit. Consumer electronics manufacturers estimate that a single high-profile thermal incident can depress sales by 5-15% for multiple quarters. The reputational damage from safety incidents frequently exceeds direct recall costs by factors of 3-5.

Regulatory compliance positioning provides another advantage. As safety standards evolve globally, manufacturers with integrated sensing solutions gain competitive advantages through faster certification processes and reduced compliance costs, estimated at $75,000-150,000 annually.

Initial implementation costs for integrated sensor solutions typically range from $5-15 per battery pack, depending on sensor type and complexity. Gas sensors generally command premium pricing ($8-15) compared to temperature-based solutions ($5-8). These costs include not only the physical sensors but also the necessary signal processing circuitry, firmware development, and integration testing.

Manufacturing process modifications represent another substantial cost factor. Production lines require reconfiguration to accommodate sensor placement, calibration stations, and additional quality control steps. Companies report one-time setup costs between $100,000-500,000 depending on production volume and existing infrastructure.

Maintenance considerations must also factor into the cost equation. While modern solid-state sensors demonstrate impressive longevity (5-7 years), periodic calibration and potential replacement add to the total cost of ownership. Cloud connectivity features for remote monitoring further increase both initial and operational expenses by approximately 15-20%.

Against these costs, significant benefits emerge. Insurance premium reductions represent a quantifiable advantage, with manufacturers reporting 10-25% decreases in product liability coverage costs when implementing comprehensive thermal runaway detection systems. This can translate to annual savings of $50,000-250,000 for mid-sized battery manufacturers.

Warranty claim reductions constitute another major benefit. Field data indicates a 30-40% decrease in catastrophic battery failure claims following sensor integration, representing potential savings of millions annually for large-scale producers. Early detection capabilities enable controlled shutdown before cascading cell failures occur.

Brand protection value, while more difficult to quantify precisely, may represent the most significant long-term benefit. Consumer electronics manufacturers estimate that a single high-profile thermal incident can depress sales by 5-15% for multiple quarters. The reputational damage from safety incidents frequently exceeds direct recall costs by factors of 3-5.

Regulatory compliance positioning provides another advantage. As safety standards evolve globally, manufacturers with integrated sensing solutions gain competitive advantages through faster certification processes and reduced compliance costs, estimated at $75,000-150,000 annually.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!