Analysis of Surface Coating Effects on Fluoride Cathode Lifetime

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoride Cathode Coating Technology Background and Objectives

Fluoride-based cathode materials have emerged as promising candidates for next-generation energy storage systems due to their high theoretical energy densities and potential cost advantages. The evolution of fluoride cathode technology can be traced back to the early 2000s when researchers began exploring alternatives to traditional lithium-ion battery materials. Initial research focused primarily on simple metal fluorides such as FeF₃, CoF₃, and CuF₂, which demonstrated impressive theoretical capacities but suffered from severe practical limitations.

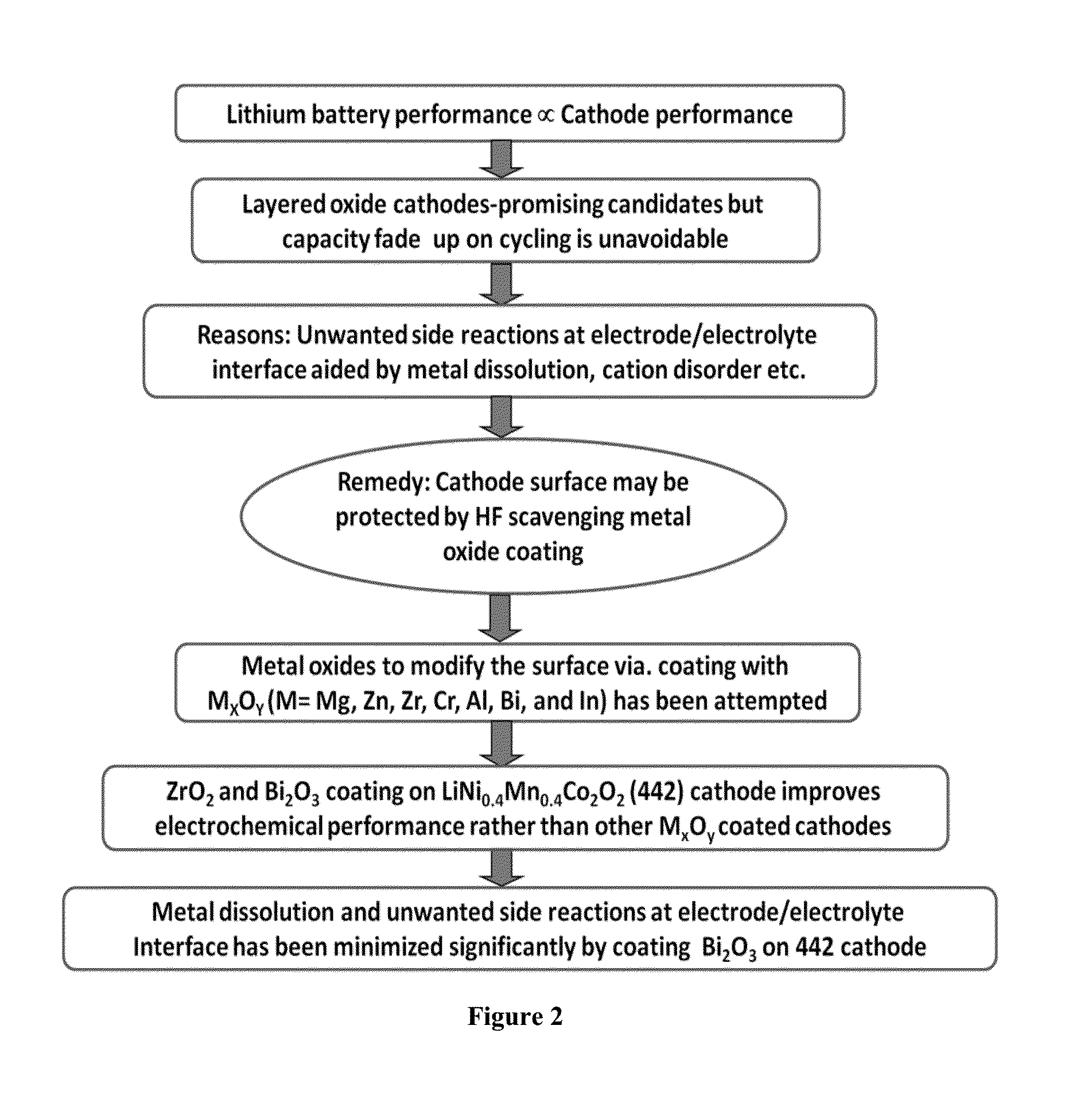

The technological trajectory has since shifted toward addressing the fundamental challenges inherent to fluoride cathodes, particularly their poor electronic conductivity, structural instability during cycling, and susceptibility to side reactions with electrolytes. Surface coating technologies have emerged as a critical intervention strategy, with significant advancements occurring between 2015 and 2023. These coating innovations aim to create protective barriers that prevent direct contact between the cathode active material and the electrolyte while enhancing electron transport properties.

Current research objectives in fluoride cathode coating technology are multifaceted and ambitious. Primary goals include extending cycle life by at least 300% compared to uncoated materials, mitigating capacity fade to less than 0.05% per cycle, and maintaining structural integrity under high-rate charging conditions. Additionally, researchers aim to develop coating methodologies that are scalable for industrial production while remaining environmentally sustainable and cost-effective.

The field is witnessing a convergence of materials science, electrochemistry, and manufacturing engineering to overcome persistent challenges. Advanced coating materials under investigation include carbon-based composites, metal oxides, phosphates, and novel polymer-ceramic hybrids. Each coating type offers distinct advantages in terms of ionic conductivity, mechanical properties, and chemical stability.

Looking forward, the technology roadmap for fluoride cathode coatings includes the development of multi-functional coatings that simultaneously address multiple failure mechanisms, atomic-level precision in coating deposition, and in-situ formation techniques that adapt to changing conditions during battery operation. The ultimate technological objective is to enable fluoride-based batteries that can deliver energy densities exceeding 500 Wh/kg while maintaining stable performance over 1,000+ cycles – a benchmark that would revolutionize applications ranging from portable electronics to electric vehicles and grid-scale energy storage.

The technological trajectory has since shifted toward addressing the fundamental challenges inherent to fluoride cathodes, particularly their poor electronic conductivity, structural instability during cycling, and susceptibility to side reactions with electrolytes. Surface coating technologies have emerged as a critical intervention strategy, with significant advancements occurring between 2015 and 2023. These coating innovations aim to create protective barriers that prevent direct contact between the cathode active material and the electrolyte while enhancing electron transport properties.

Current research objectives in fluoride cathode coating technology are multifaceted and ambitious. Primary goals include extending cycle life by at least 300% compared to uncoated materials, mitigating capacity fade to less than 0.05% per cycle, and maintaining structural integrity under high-rate charging conditions. Additionally, researchers aim to develop coating methodologies that are scalable for industrial production while remaining environmentally sustainable and cost-effective.

The field is witnessing a convergence of materials science, electrochemistry, and manufacturing engineering to overcome persistent challenges. Advanced coating materials under investigation include carbon-based composites, metal oxides, phosphates, and novel polymer-ceramic hybrids. Each coating type offers distinct advantages in terms of ionic conductivity, mechanical properties, and chemical stability.

Looking forward, the technology roadmap for fluoride cathode coatings includes the development of multi-functional coatings that simultaneously address multiple failure mechanisms, atomic-level precision in coating deposition, and in-situ formation techniques that adapt to changing conditions during battery operation. The ultimate technological objective is to enable fluoride-based batteries that can deliver energy densities exceeding 500 Wh/kg while maintaining stable performance over 1,000+ cycles – a benchmark that would revolutionize applications ranging from portable electronics to electric vehicles and grid-scale energy storage.

Market Analysis of Advanced Battery Materials

The advanced battery materials market is experiencing unprecedented growth, driven by the global shift towards electrification and renewable energy storage solutions. Currently valued at approximately $8.3 billion in 2023, this market is projected to reach $15.1 billion by 2028, representing a compound annual growth rate (CAGR) of 12.7%. Surface coating technologies for fluoride cathodes represent a particularly promising segment within this expanding market.

Demand for high-performance batteries with extended lifetimes is intensifying across multiple sectors. The electric vehicle industry remains the primary driver, with global EV sales exceeding 10 million units in 2022 and expected to reach 27 million by 2030. This trajectory creates substantial pull for advanced cathode materials that can withstand numerous charge-discharge cycles while maintaining capacity.

Consumer electronics manufacturers constitute another significant market segment, increasingly prioritizing battery longevity as a key differentiator in their products. The renewable energy storage sector also presents substantial growth opportunities, with grid-scale storage installations growing at 27% annually, necessitating batteries with enhanced cycle life and stability.

Fluoride-based cathode materials have garnered significant attention due to their theoretical energy density advantages over conventional lithium-ion cathodes. However, their commercial adoption has been hindered by stability issues and rapid capacity fading. Surface coating technologies have emerged as a critical solution pathway, with the market for specialized cathode coatings growing at 15.3% annually.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity for advanced battery materials, accounting for 67% of global production. China leads with substantial investments in fluoride cathode research and manufacturing infrastructure. North America and Europe are rapidly expanding their domestic production capabilities through strategic initiatives like the U.S. Inflation Reduction Act and the European Battery Alliance, which collectively aim to establish regional supply chains.

Customer requirements are evolving toward more stringent performance metrics, with OEMs increasingly specifying minimum cycle life requirements of 2,000+ cycles for automotive applications and demanding warranties of 8-10 years. This trend directly benefits technologies that can extend cathode lifetime through protective surface modifications.

Market barriers include high processing costs for specialized coating technologies and intellectual property concentration among a small number of materials technology companies. However, the potential value proposition of extended battery lifetime presents compelling economic incentives for continued investment and innovation in this space.

Demand for high-performance batteries with extended lifetimes is intensifying across multiple sectors. The electric vehicle industry remains the primary driver, with global EV sales exceeding 10 million units in 2022 and expected to reach 27 million by 2030. This trajectory creates substantial pull for advanced cathode materials that can withstand numerous charge-discharge cycles while maintaining capacity.

Consumer electronics manufacturers constitute another significant market segment, increasingly prioritizing battery longevity as a key differentiator in their products. The renewable energy storage sector also presents substantial growth opportunities, with grid-scale storage installations growing at 27% annually, necessitating batteries with enhanced cycle life and stability.

Fluoride-based cathode materials have garnered significant attention due to their theoretical energy density advantages over conventional lithium-ion cathodes. However, their commercial adoption has been hindered by stability issues and rapid capacity fading. Surface coating technologies have emerged as a critical solution pathway, with the market for specialized cathode coatings growing at 15.3% annually.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity for advanced battery materials, accounting for 67% of global production. China leads with substantial investments in fluoride cathode research and manufacturing infrastructure. North America and Europe are rapidly expanding their domestic production capabilities through strategic initiatives like the U.S. Inflation Reduction Act and the European Battery Alliance, which collectively aim to establish regional supply chains.

Customer requirements are evolving toward more stringent performance metrics, with OEMs increasingly specifying minimum cycle life requirements of 2,000+ cycles for automotive applications and demanding warranties of 8-10 years. This trend directly benefits technologies that can extend cathode lifetime through protective surface modifications.

Market barriers include high processing costs for specialized coating technologies and intellectual property concentration among a small number of materials technology companies. However, the potential value proposition of extended battery lifetime presents compelling economic incentives for continued investment and innovation in this space.

Current Challenges in Fluoride Cathode Surface Coating

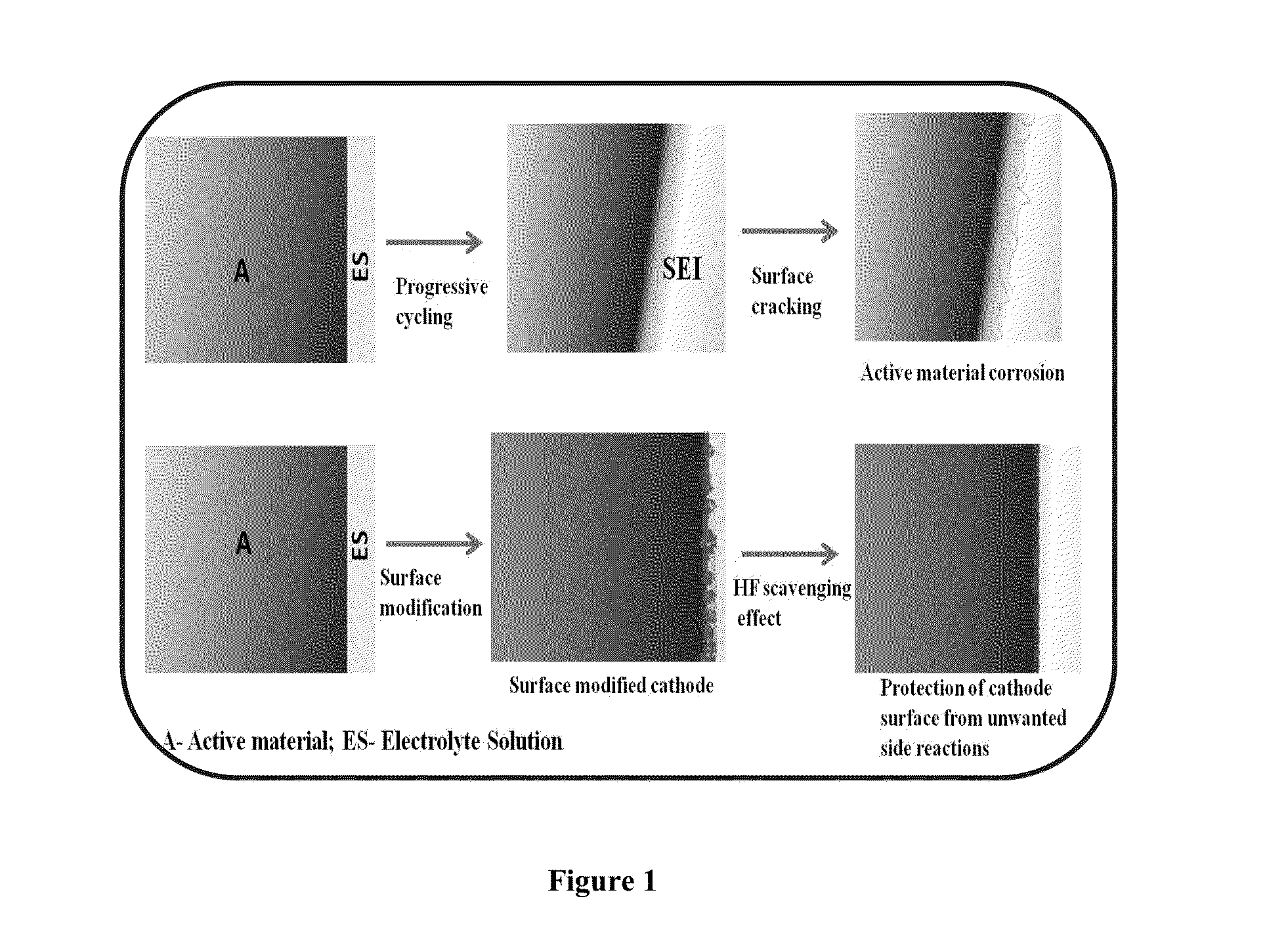

Despite significant advancements in fluoride cathode technology, several critical challenges persist in surface coating applications that directly impact cathode lifetime and performance. The interface between the coating layer and the active cathode material represents a primary concern, as chemical and mechanical incompatibilities often lead to delamination during charge-discharge cycles. This degradation accelerates particularly under high current densities and elevated temperatures, creating pathways for electrolyte penetration and subsequent cathode deterioration.

Uniformity in coating thickness presents another substantial challenge. Current deposition techniques, including atomic layer deposition (ALD) and chemical vapor deposition (CVD), struggle to achieve consistent nanometer-scale coatings across complex cathode particle geometries. This non-uniformity creates localized areas of over-protection that impede ion transport and under-protected regions vulnerable to electrolyte attack, both compromising overall performance.

The trade-off between protective capability and ionic conductivity remains unresolved. While thicker coatings provide enhanced protection against electrolyte corrosion, they simultaneously increase internal resistance and impede fluoride ion transport. Conversely, ultrathin coatings offer minimal transport resistance but provide insufficient protection against chemical degradation mechanisms, particularly in aggressive fluoride-containing electrolytes.

Long-term stability of coating materials in fluoride environments poses significant difficulties. Many conventional coating materials that perform adequately in lithium-ion systems undergo gradual dissolution or structural transformation when exposed to fluoride ions, especially at elevated potentials. This degradation compromises the intended protective function and can introduce dissolved species that catalyze side reactions within the cell.

Manufacturing scalability represents a substantial industrial challenge. Laboratory-scale coating processes that demonstrate excellent performance often prove difficult to scale to commercial production volumes while maintaining quality and cost-effectiveness. Techniques requiring high vacuum, precise temperature control, or extended processing times face particular barriers to industrial implementation.

Cost considerations further complicate coating selection and application. High-performance coating materials like artificial solid electrolyte interphases often incorporate expensive rare earth elements or require complex synthesis procedures, driving up production costs. Finding economically viable alternatives that maintain performance standards remains an ongoing challenge for commercial viability of fluoride cathode technologies.

Uniformity in coating thickness presents another substantial challenge. Current deposition techniques, including atomic layer deposition (ALD) and chemical vapor deposition (CVD), struggle to achieve consistent nanometer-scale coatings across complex cathode particle geometries. This non-uniformity creates localized areas of over-protection that impede ion transport and under-protected regions vulnerable to electrolyte attack, both compromising overall performance.

The trade-off between protective capability and ionic conductivity remains unresolved. While thicker coatings provide enhanced protection against electrolyte corrosion, they simultaneously increase internal resistance and impede fluoride ion transport. Conversely, ultrathin coatings offer minimal transport resistance but provide insufficient protection against chemical degradation mechanisms, particularly in aggressive fluoride-containing electrolytes.

Long-term stability of coating materials in fluoride environments poses significant difficulties. Many conventional coating materials that perform adequately in lithium-ion systems undergo gradual dissolution or structural transformation when exposed to fluoride ions, especially at elevated potentials. This degradation compromises the intended protective function and can introduce dissolved species that catalyze side reactions within the cell.

Manufacturing scalability represents a substantial industrial challenge. Laboratory-scale coating processes that demonstrate excellent performance often prove difficult to scale to commercial production volumes while maintaining quality and cost-effectiveness. Techniques requiring high vacuum, precise temperature control, or extended processing times face particular barriers to industrial implementation.

Cost considerations further complicate coating selection and application. High-performance coating materials like artificial solid electrolyte interphases often incorporate expensive rare earth elements or require complex synthesis procedures, driving up production costs. Finding economically viable alternatives that maintain performance standards remains an ongoing challenge for commercial viability of fluoride cathode technologies.

Current Surface Coating Solutions for Fluoride Cathodes

01 Protective fluoride coatings for cathode materials

Fluoride-based protective coatings can be applied to cathode surfaces to enhance their stability and extend lifetime. These coatings form a barrier that prevents direct contact between the cathode active material and the electrolyte, reducing unwanted side reactions. The fluoride layer helps maintain structural integrity during charge-discharge cycles, leading to improved capacity retention and extended battery life.- Fluoride-based protective coatings for cathode surfaces: Fluoride-based coatings can be applied to cathode surfaces to protect them from degradation and extend their lifetime. These coatings form a protective layer that prevents direct contact between the cathode active material and the electrolyte, reducing unwanted side reactions. The fluoride coating helps maintain the structural integrity of the cathode during charge-discharge cycles, leading to improved battery performance and longevity.

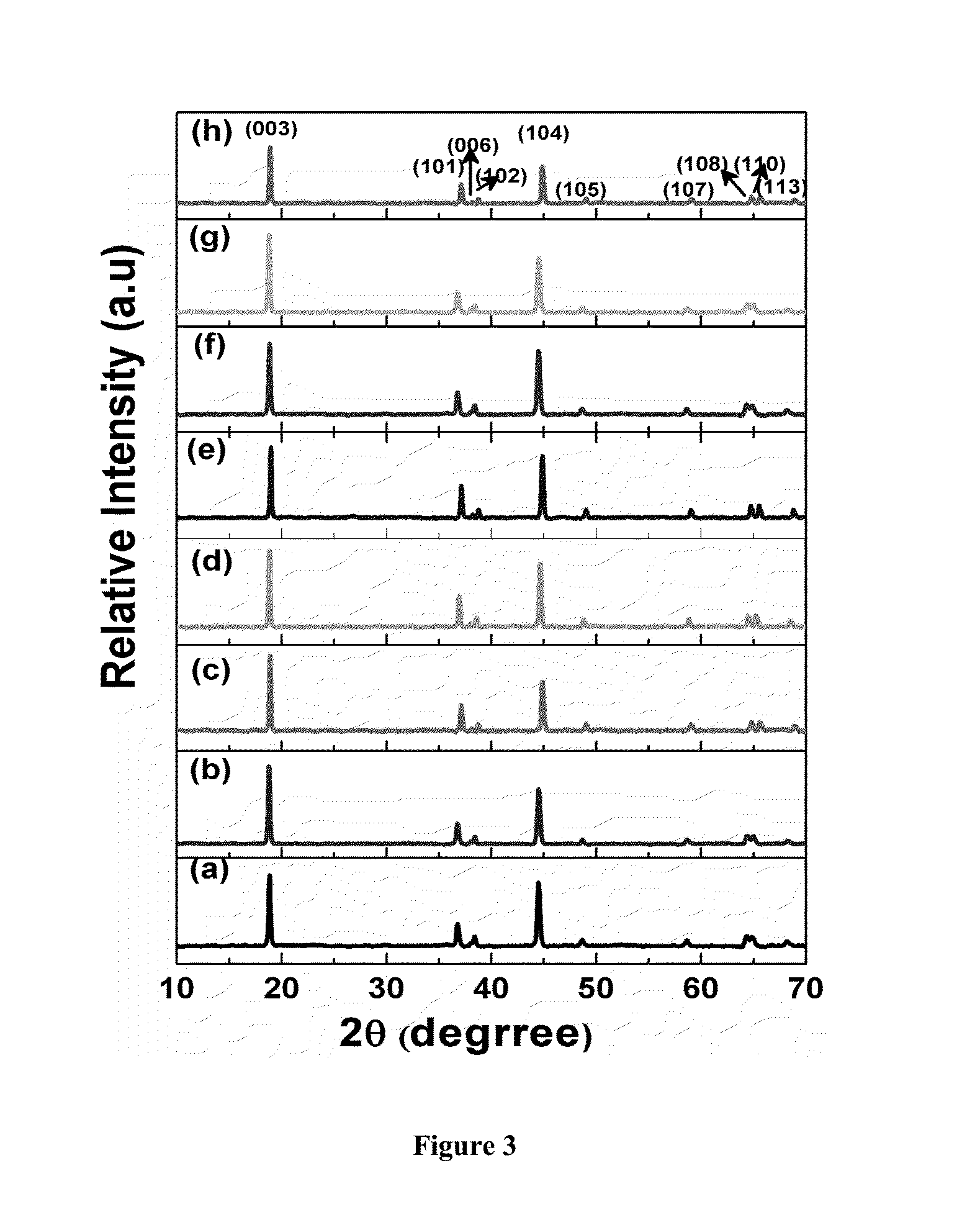

- Surface modification techniques for fluoride cathodes: Various surface modification techniques can be employed to enhance the stability and lifetime of fluoride cathodes. These include atomic layer deposition, solution-based coating methods, and vapor deposition processes. Surface modifications can create uniform and conformal coatings that effectively protect the cathode material from electrolyte attack while maintaining good ionic conductivity. These techniques can be optimized to control coating thickness and composition for maximum effectiveness.

- Composite coatings with fluoride components: Composite coatings that incorporate fluoride components along with other materials can provide enhanced protection for cathode surfaces. These multi-component coatings can combine the benefits of fluoride's stability with other materials' properties such as improved conductivity or mechanical strength. The synergistic effects between different coating components can address multiple degradation mechanisms simultaneously, resulting in significantly extended cathode lifetime and improved cycling performance.

- Monitoring and analysis of fluoride cathode coating performance: Advanced monitoring and analytical techniques can be used to evaluate the performance and degradation of fluoride cathode coatings over time. These methods include electrochemical impedance spectroscopy, surface analysis techniques, and computational modeling. By understanding the degradation mechanisms and failure modes of fluoride coatings, researchers can develop improved coating formulations and application methods that extend cathode lifetime under various operating conditions.

- Novel fluoride compounds for enhanced cathode protection: Research into novel fluoride compounds has led to the development of advanced materials for cathode surface protection. These include metal fluorides, complex fluoride structures, and fluoride-containing polymers. These innovative materials can offer superior protection against electrolyte attack, prevent transition metal dissolution, and maintain structural stability during cycling. The incorporation of these novel fluoride compounds into cathode coatings can significantly extend battery lifetime and improve overall performance.

02 Surface modification techniques for fluoride cathodes

Various surface modification techniques can be employed to apply fluoride coatings on cathode materials. These include atomic layer deposition, sol-gel methods, wet chemical processes, and physical vapor deposition. The coating thickness and uniformity can be precisely controlled to optimize the protective effect while maintaining good ionic conductivity. These techniques allow for tailored surface properties that enhance the electrochemical performance and lifetime of cathode materials.Expand Specific Solutions03 Composite fluoride coatings for enhanced lifetime

Composite fluoride coatings that combine multiple materials can provide superior protection for cathode surfaces. These composite structures may include combinations of metal fluorides with other compounds such as oxides or phosphates. The synergistic effect of these materials can address multiple degradation mechanisms simultaneously, resulting in significantly improved cathode lifetime and performance under various operating conditions.Expand Specific Solutions04 Monitoring and characterization of fluoride cathode coatings

Advanced analytical techniques are essential for monitoring the condition and effectiveness of fluoride coatings on cathode surfaces. Methods such as X-ray photoelectron spectroscopy, scanning electron microscopy, and electrochemical impedance spectroscopy can be used to characterize coating integrity, thickness, and chemical composition. These monitoring approaches enable the assessment of coating degradation mechanisms and lifetime prediction, facilitating the development of improved coating formulations.Expand Specific Solutions05 Self-healing fluoride coating systems

Self-healing fluoride coating systems represent an innovative approach to extending cathode lifetime. These coatings contain components that can repair damage automatically during battery operation. When cracks or defects form in the protective layer, reactive components in the coating or electrolyte migrate to the damaged areas and form new protective compounds. This self-repair mechanism maintains the integrity of the protective layer throughout the battery lifetime, significantly extending the operational life of fluoride-based cathode materials.Expand Specific Solutions

Leading Companies in Fluoride Battery Materials

The surface coating technology for fluoride cathodes is in a growth phase, with increasing market demand driven by the need for longer-lasting battery solutions. The global market is expanding rapidly as energy storage applications proliferate across industries. Technologically, the field shows moderate maturity with significant ongoing innovation. Key players demonstrate varying approaches: Arkema and DAIKIN focus on fluorochemical expertise; LG Energy Solution and Panasonic Energy leverage their battery manufacturing capabilities; while research institutions like Northwestern University and Technical University of Denmark contribute fundamental breakthroughs. Applied Materials and 3M Innovative Properties bring advanced coating technologies, while specialized players like Beijing Easpring and BTR Nano Tech develop tailored solutions for fluoride cathode protection, indicating a competitive landscape with diverse technical approaches.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed advanced atomic layer deposition (ALD) techniques for fluoride cathode coatings that significantly enhance electrochemical performance. Their approach involves creating ultrathin conformal coatings (typically 2-5 nm) of metal oxides like Al2O3 and ZrO2 that act as artificial solid electrolyte interphases. These coatings effectively suppress the dissolution of active materials and prevent HF attack on the cathode surface. Argonne's research demonstrates that optimized ALD coatings can extend fluoride cathode cycle life by up to 300% compared to uncoated materials, while maintaining high capacity retention (>85% after 500 cycles). Their technology also incorporates fluoride-scavenging additives within the coating matrix to neutralize HF formed during cycling, creating a self-healing mechanism that continuously protects the cathode surface throughout battery operation.

Strengths: Exceptional conformality and thickness control at nanometer scale; demonstrated significant cycle life improvements; established expertise in battery materials. Weaknesses: ALD processes can be relatively slow and expensive for large-scale manufacturing; some coating materials may reduce initial capacity or rate capability due to increased resistance.

3M Innovative Properties Co.

Technical Solution: 3M has developed an advanced fluoropolymer-based protective coating system specifically engineered for high-voltage fluoride cathode materials. Their proprietary "F-Bond" technology utilizes a thin (3-7 nm) fluorinated polymer coating that creates a chemical gradient interface between the cathode and electrolyte. The coating is applied through a vapor deposition process that ensures uniform coverage even on complex particle morphologies. The fluoropolymer structure is designed with selective permeability, allowing lithium-ion transport while blocking larger solvent molecules and scavenging HF. 3M's research demonstrates that their coated fluoride cathodes show significantly reduced transition metal dissolution (>90% reduction) and minimal surface structural degradation after extended cycling. The technology incorporates self-healing properties through mobile fluorine species within the coating that can repair defects formed during cycling. In full cell testing, 3M's coated cathodes maintained 87% capacity retention after 1000 cycles at C/2 rate, with notably improved performance at elevated temperatures (45-60°C) where fluoride stability issues typically accelerate.

Strengths: Exceptional chemical stability in aggressive electrolyte environments; excellent HF scavenging capability; proprietary vapor deposition process ensures uniform coverage. Weaknesses: Potential for increased interfacial resistance affecting rate capability; vapor deposition process may have throughput limitations for mass production; possible trade-off between protection and lithium-ion conductivity.

Key Coating Mechanisms and Performance Impact Analysis

Surface modified cathode with improved lithium intercalation behavior

PatentActiveUS20160043387A1

Innovation

- Surface modification of the LiNi0.4Mn0.4Co0.2O2 cathode with MxOy type metal oxides such as Al2O3, Bi2O3, In2O3, Cr2O3, ZrO2, and MgO, which impart a hydrofluoric acid scavenging effect, suppress phase transitions, and block active sites for electrolyte decomposition, thereby enhancing electrochemical properties.

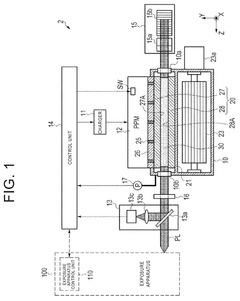

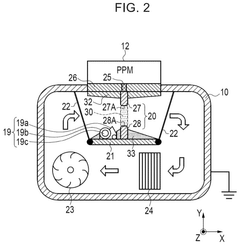

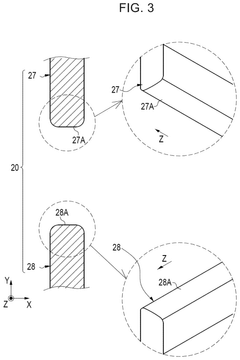

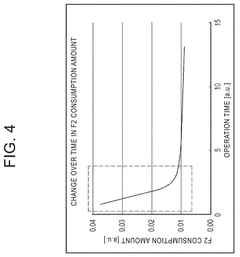

Discharge electrode, manufacturing method for discharge electrode, and manufacturing method for electronic device

PatentPendingUS20250233379A1

Innovation

- The cathode discharge surface is engineered with a large number of recesses and a coating layer on these recesses, while the anode discharge surface remains smooth to disperse discharge and reduce wear, thereby stabilizing the discharge process.

Environmental Impact of Fluoride Battery Materials

The environmental implications of fluoride battery materials represent a critical dimension in evaluating their sustainability and long-term viability. Fluoride-based cathode materials, while promising for high-energy density applications, introduce specific environmental concerns throughout their lifecycle that warrant careful consideration.

The extraction and processing of raw materials for fluoride cathodes often involve mining operations that can lead to habitat disruption, soil erosion, and water contamination. Particularly concerning is the extraction of rare earth elements frequently used in advanced battery formulations, which typically generates substantial quantities of toxic waste and radioactive byproducts.

Surface coating technologies applied to fluoride cathodes, while enhancing performance and longevity, introduce additional environmental complexities. Many coating materials utilize synthetic polymers, metal oxides, or composite materials that may present end-of-life disposal challenges. The manufacturing processes for these coatings frequently require energy-intensive conditions and specialized solvents, some of which have significant global warming potential or ozone depletion capabilities.

During the operational phase, fluoride batteries with enhanced surface coatings demonstrate improved environmental profiles through extended cycle life, effectively reducing the frequency of replacement and associated waste generation. However, the potential for fluoride leaching from degraded cathodes remains a concern, particularly in improperly managed waste streams, as fluoride compounds can persist in ecosystems and potentially contaminate groundwater resources.

End-of-life management presents perhaps the most significant environmental challenge. Current recycling infrastructure is inadequately equipped to handle fluoride-based battery components, particularly those with complex surface coating formulations. The chemical stability that makes these coatings effective during operation simultaneously complicates their separation and recovery during recycling processes.

Comparative lifecycle assessments indicate that fluoride batteries with advanced surface coatings may offer reduced environmental impact compared to conventional lithium-ion technologies when accounting for extended service life. However, this advantage is contingent upon the development of specialized recycling pathways capable of recovering both the fluoride compounds and the coating materials with high efficiency.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with particular emphasis on recyclability requirements and restrictions on hazardous materials. Future development of fluoride cathode coatings will likely need to balance performance enhancements against environmental compatibility, potentially driving innovation toward bio-based coating alternatives and design-for-recycling approaches.

The extraction and processing of raw materials for fluoride cathodes often involve mining operations that can lead to habitat disruption, soil erosion, and water contamination. Particularly concerning is the extraction of rare earth elements frequently used in advanced battery formulations, which typically generates substantial quantities of toxic waste and radioactive byproducts.

Surface coating technologies applied to fluoride cathodes, while enhancing performance and longevity, introduce additional environmental complexities. Many coating materials utilize synthetic polymers, metal oxides, or composite materials that may present end-of-life disposal challenges. The manufacturing processes for these coatings frequently require energy-intensive conditions and specialized solvents, some of which have significant global warming potential or ozone depletion capabilities.

During the operational phase, fluoride batteries with enhanced surface coatings demonstrate improved environmental profiles through extended cycle life, effectively reducing the frequency of replacement and associated waste generation. However, the potential for fluoride leaching from degraded cathodes remains a concern, particularly in improperly managed waste streams, as fluoride compounds can persist in ecosystems and potentially contaminate groundwater resources.

End-of-life management presents perhaps the most significant environmental challenge. Current recycling infrastructure is inadequately equipped to handle fluoride-based battery components, particularly those with complex surface coating formulations. The chemical stability that makes these coatings effective during operation simultaneously complicates their separation and recovery during recycling processes.

Comparative lifecycle assessments indicate that fluoride batteries with advanced surface coatings may offer reduced environmental impact compared to conventional lithium-ion technologies when accounting for extended service life. However, this advantage is contingent upon the development of specialized recycling pathways capable of recovering both the fluoride compounds and the coating materials with high efficiency.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns, with particular emphasis on recyclability requirements and restrictions on hazardous materials. Future development of fluoride cathode coatings will likely need to balance performance enhancements against environmental compatibility, potentially driving innovation toward bio-based coating alternatives and design-for-recycling approaches.

Scalability and Manufacturing Considerations

The scalability of surface coating technologies for fluoride cathodes represents a critical factor in their commercial viability. Current laboratory-scale coating methods, including atomic layer deposition (ALD) and sol-gel processes, demonstrate excellent performance in enhancing cathode lifetime but face significant challenges when transitioning to mass production environments. The capital expenditure required for industrial-scale ALD equipment can exceed $5-10 million per production line, creating substantial barriers to entry for smaller manufacturers.

Manufacturing throughput presents another significant challenge, as conventional coating processes often operate at rates incompatible with high-volume battery production. For instance, traditional ALD processes typically deposit material at 1-2 nm per hour, which becomes prohibitively slow when considering the production volumes required for commercial battery applications. Recent advancements in spatial ALD and roll-to-roll processing have improved throughput by 10-15 times, though further optimization remains necessary.

Quality control and coating uniformity across large surface areas represent persistent manufacturing challenges. Statistical analysis indicates that coating thickness variations exceeding 5% can significantly compromise the protective benefits, leading to inconsistent battery performance and reduced lifetime. Advanced in-line monitoring techniques, including optical emission spectroscopy and ellipsometry, are being integrated into production lines to ensure coating consistency.

Cost considerations remain paramount, with current estimates placing the additional manufacturing cost for high-quality protective coatings at $15-25 per kWh of battery capacity. This represents a 10-15% increase in overall cell production costs, which must be offset by the extended lifetime and improved performance to justify implementation. Material selection plays a crucial role in this equation, with aluminum oxide and lithium phosphate coatings offering the most promising balance between performance and cost-effectiveness.

Environmental and safety considerations in the coating process must also be addressed for large-scale manufacturing. Several common precursors used in ALD and chemical vapor deposition processes are pyrophoric or toxic, requiring specialized handling equipment and safety protocols. Water-based coating alternatives are emerging as environmentally friendly options, though they currently lag behind in performance metrics compared to traditional methods.

Manufacturing throughput presents another significant challenge, as conventional coating processes often operate at rates incompatible with high-volume battery production. For instance, traditional ALD processes typically deposit material at 1-2 nm per hour, which becomes prohibitively slow when considering the production volumes required for commercial battery applications. Recent advancements in spatial ALD and roll-to-roll processing have improved throughput by 10-15 times, though further optimization remains necessary.

Quality control and coating uniformity across large surface areas represent persistent manufacturing challenges. Statistical analysis indicates that coating thickness variations exceeding 5% can significantly compromise the protective benefits, leading to inconsistent battery performance and reduced lifetime. Advanced in-line monitoring techniques, including optical emission spectroscopy and ellipsometry, are being integrated into production lines to ensure coating consistency.

Cost considerations remain paramount, with current estimates placing the additional manufacturing cost for high-quality protective coatings at $15-25 per kWh of battery capacity. This represents a 10-15% increase in overall cell production costs, which must be offset by the extended lifetime and improved performance to justify implementation. Material selection plays a crucial role in this equation, with aluminum oxide and lithium phosphate coatings offering the most promising balance between performance and cost-effectiveness.

Environmental and safety considerations in the coating process must also be addressed for large-scale manufacturing. Several common precursors used in ALD and chemical vapor deposition processes are pyrophoric or toxic, requiring specialized handling equipment and safety protocols. Water-based coating alternatives are emerging as environmentally friendly options, though they currently lag behind in performance metrics compared to traditional methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!