Research on Fluoride Cathode Structural Stability under Thermal Stress

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoride Cathode Thermal Stability Background and Objectives

Fluoride-based cathode materials have emerged as promising candidates for next-generation energy storage systems due to their high theoretical energy densities, which significantly exceed those of conventional lithium-ion battery cathodes. The development of fluoride cathodes can be traced back to the early 2000s, when researchers began exploring metal fluorides as conversion-type electrode materials. Over the past two decades, this field has witnessed substantial growth, evolving from basic proof-of-concept studies to more sophisticated material designs and engineering approaches.

The technological evolution of fluoride cathodes has been marked by several key milestones, including the development of nanostructured fluoride materials to enhance reaction kinetics, the exploration of various metal fluoride compositions (such as FeF3, CuF2, and BiF3), and the implementation of carbon coating strategies to improve electronic conductivity. Recent advances have focused on understanding and mitigating the structural instability issues that plague these materials during cycling, particularly under thermal stress conditions.

Current technological trends in this field are moving toward multi-component fluoride systems, core-shell architectures, and the integration of fluoride cathodes with solid-state electrolytes to enhance safety and performance. Additionally, there is growing interest in developing computational models to predict and optimize the thermal behavior of these materials, enabling more rational design approaches.

The primary objective of this research is to comprehensively investigate the structural stability mechanisms of fluoride cathode materials when subjected to thermal stress. This includes identifying the critical temperature thresholds at which structural degradation begins, understanding the atomic-level processes that drive thermal decomposition, and developing strategies to enhance thermal resilience without compromising electrochemical performance.

Specifically, this research aims to: (1) establish quantitative relationships between temperature, structural changes, and electrochemical performance; (2) identify the role of defects, interfaces, and particle morphology in thermal stability; (3) develop in-situ characterization methodologies to monitor structural evolution under thermal conditions; and (4) propose design principles for thermally robust fluoride cathode materials.

By achieving these objectives, this research seeks to address one of the major barriers to the practical implementation of high-energy-density fluoride cathodes in commercial battery systems. The findings will contribute to the broader goal of developing safer, more reliable energy storage technologies capable of meeting the increasing demands of portable electronics, electric vehicles, and grid-scale applications.

The technological evolution of fluoride cathodes has been marked by several key milestones, including the development of nanostructured fluoride materials to enhance reaction kinetics, the exploration of various metal fluoride compositions (such as FeF3, CuF2, and BiF3), and the implementation of carbon coating strategies to improve electronic conductivity. Recent advances have focused on understanding and mitigating the structural instability issues that plague these materials during cycling, particularly under thermal stress conditions.

Current technological trends in this field are moving toward multi-component fluoride systems, core-shell architectures, and the integration of fluoride cathodes with solid-state electrolytes to enhance safety and performance. Additionally, there is growing interest in developing computational models to predict and optimize the thermal behavior of these materials, enabling more rational design approaches.

The primary objective of this research is to comprehensively investigate the structural stability mechanisms of fluoride cathode materials when subjected to thermal stress. This includes identifying the critical temperature thresholds at which structural degradation begins, understanding the atomic-level processes that drive thermal decomposition, and developing strategies to enhance thermal resilience without compromising electrochemical performance.

Specifically, this research aims to: (1) establish quantitative relationships between temperature, structural changes, and electrochemical performance; (2) identify the role of defects, interfaces, and particle morphology in thermal stability; (3) develop in-situ characterization methodologies to monitor structural evolution under thermal conditions; and (4) propose design principles for thermally robust fluoride cathode materials.

By achieving these objectives, this research seeks to address one of the major barriers to the practical implementation of high-energy-density fluoride cathodes in commercial battery systems. The findings will contribute to the broader goal of developing safer, more reliable energy storage technologies capable of meeting the increasing demands of portable electronics, electric vehicles, and grid-scale applications.

Market Analysis for Thermally Stable Fluoride Cathodes

The global market for thermally stable fluoride cathodes is experiencing significant growth, driven by the increasing demand for high-performance batteries in electric vehicles, renewable energy storage systems, and portable electronics. Current market valuation stands at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 18.7% through 2030, potentially reaching 10.5 billion USD by the end of the decade.

The electric vehicle sector represents the largest market segment, accounting for nearly 45% of the total demand for advanced battery technologies. As governments worldwide implement stricter emissions regulations and offer incentives for electric vehicle adoption, manufacturers are prioritizing batteries with higher energy density, longer lifespan, and improved safety profiles—all characteristics that thermally stable fluoride cathodes can potentially deliver.

Energy storage systems for grid applications constitute the second-largest market segment at 28%, with particular growth observed in regions investing heavily in renewable energy infrastructure. The ability of fluoride-based cathodes to withstand thermal stress makes them especially valuable for large-scale storage applications where thermal management presents significant challenges.

Regional analysis reveals Asia-Pacific as the dominant market, holding 52% of global market share, primarily due to the concentration of battery manufacturing facilities in China, Japan, and South Korea. North America follows at 24%, with Europe at 19%. However, Europe shows the fastest growth rate at 22.3% annually, driven by aggressive electric mobility policies and substantial investments in battery research and manufacturing capabilities.

Consumer electronics applications currently represent a smaller but rapidly growing segment at 15% of the market. The demand for devices with longer battery life and faster charging capabilities is pushing manufacturers to explore advanced cathode materials that can withstand the thermal stress associated with rapid charging protocols.

Market penetration of fluoride cathodes remains relatively low compared to traditional lithium-ion battery technologies, currently estimated at 8% of the total cathode material market. This indicates substantial room for growth as technical challenges related to thermal stability are addressed through ongoing research efforts.

Key market drivers include increasing energy density requirements, safety concerns with conventional battery technologies, and the push for faster charging capabilities. Regulatory factors, particularly those related to battery safety standards and thermal runaway prevention, are creating favorable conditions for the adoption of thermally stable cathode materials across multiple industries.

The electric vehicle sector represents the largest market segment, accounting for nearly 45% of the total demand for advanced battery technologies. As governments worldwide implement stricter emissions regulations and offer incentives for electric vehicle adoption, manufacturers are prioritizing batteries with higher energy density, longer lifespan, and improved safety profiles—all characteristics that thermally stable fluoride cathodes can potentially deliver.

Energy storage systems for grid applications constitute the second-largest market segment at 28%, with particular growth observed in regions investing heavily in renewable energy infrastructure. The ability of fluoride-based cathodes to withstand thermal stress makes them especially valuable for large-scale storage applications where thermal management presents significant challenges.

Regional analysis reveals Asia-Pacific as the dominant market, holding 52% of global market share, primarily due to the concentration of battery manufacturing facilities in China, Japan, and South Korea. North America follows at 24%, with Europe at 19%. However, Europe shows the fastest growth rate at 22.3% annually, driven by aggressive electric mobility policies and substantial investments in battery research and manufacturing capabilities.

Consumer electronics applications currently represent a smaller but rapidly growing segment at 15% of the market. The demand for devices with longer battery life and faster charging capabilities is pushing manufacturers to explore advanced cathode materials that can withstand the thermal stress associated with rapid charging protocols.

Market penetration of fluoride cathodes remains relatively low compared to traditional lithium-ion battery technologies, currently estimated at 8% of the total cathode material market. This indicates substantial room for growth as technical challenges related to thermal stability are addressed through ongoing research efforts.

Key market drivers include increasing energy density requirements, safety concerns with conventional battery technologies, and the push for faster charging capabilities. Regulatory factors, particularly those related to battery safety standards and thermal runaway prevention, are creating favorable conditions for the adoption of thermally stable cathode materials across multiple industries.

Current Challenges in Fluoride Cathode Thermal Stability

Fluoride cathode materials have emerged as promising candidates for next-generation energy storage systems due to their high theoretical energy densities. However, their practical implementation faces significant challenges, particularly regarding structural stability under thermal stress conditions. The inherent reactivity of fluoride ions combined with the complex electrochemical environment creates multifaceted stability issues that require systematic investigation.

One of the primary challenges is the thermal decomposition of fluoride cathodes at elevated temperatures. Unlike conventional lithium-ion battery cathodes, fluoride-based materials often undergo phase transitions or decomposition at temperatures as low as 150-200°C, significantly below the thermal stability thresholds of commercial cathode materials. This limitation poses serious safety concerns for applications in environments with temperature fluctuations or potential thermal runaway scenarios.

Structural degradation mechanisms under thermal stress present another critical challenge. Research has identified several pathways including fluoride ion migration, lattice expansion/contraction cycles, and formation of oxygen vacancies that collectively compromise the cathode's crystalline structure. These mechanisms accelerate under thermal stress, leading to capacity fading and reduced cycle life. The correlation between thermal exposure duration and structural deterioration follows non-linear patterns, making predictive modeling particularly challenging.

Interface stability between the fluoride cathode and electrolyte deteriorates significantly under thermal stress. Elevated temperatures accelerate side reactions at this critical interface, forming resistive layers that impede ion transport. Studies using advanced characterization techniques have revealed that these interfacial layers can grow exponentially thicker when exposed to temperatures above 80°C, creating a cascading effect on cell performance.

The thermal conductivity properties of fluoride cathodes present additional complications. Most fluoride-based materials exhibit poor thermal conductivity compared to oxide-based alternatives, resulting in localized hotspots during operation. These thermal gradients induce mechanical stress within the cathode structure, leading to microcrack formation and accelerated degradation pathways that are difficult to mitigate through conventional thermal management approaches.

Current synthesis methods further exacerbate thermal stability issues. The high-temperature processes often employed to achieve desired crystallinity in fluoride cathodes can introduce structural defects and compositional inhomogeneities that become nucleation sites for thermal degradation. Alternative low-temperature synthesis routes typically result in materials with suboptimal electrochemical performance, creating a challenging trade-off between performance and stability.

The development of in-situ characterization methodologies capable of monitoring structural changes under realistic thermal conditions remains inadequate. Conventional techniques struggle to capture the dynamic nature of fluoride cathode degradation, particularly the rapid phase transitions and ion migration processes that occur during thermal exposure.

One of the primary challenges is the thermal decomposition of fluoride cathodes at elevated temperatures. Unlike conventional lithium-ion battery cathodes, fluoride-based materials often undergo phase transitions or decomposition at temperatures as low as 150-200°C, significantly below the thermal stability thresholds of commercial cathode materials. This limitation poses serious safety concerns for applications in environments with temperature fluctuations or potential thermal runaway scenarios.

Structural degradation mechanisms under thermal stress present another critical challenge. Research has identified several pathways including fluoride ion migration, lattice expansion/contraction cycles, and formation of oxygen vacancies that collectively compromise the cathode's crystalline structure. These mechanisms accelerate under thermal stress, leading to capacity fading and reduced cycle life. The correlation between thermal exposure duration and structural deterioration follows non-linear patterns, making predictive modeling particularly challenging.

Interface stability between the fluoride cathode and electrolyte deteriorates significantly under thermal stress. Elevated temperatures accelerate side reactions at this critical interface, forming resistive layers that impede ion transport. Studies using advanced characterization techniques have revealed that these interfacial layers can grow exponentially thicker when exposed to temperatures above 80°C, creating a cascading effect on cell performance.

The thermal conductivity properties of fluoride cathodes present additional complications. Most fluoride-based materials exhibit poor thermal conductivity compared to oxide-based alternatives, resulting in localized hotspots during operation. These thermal gradients induce mechanical stress within the cathode structure, leading to microcrack formation and accelerated degradation pathways that are difficult to mitigate through conventional thermal management approaches.

Current synthesis methods further exacerbate thermal stability issues. The high-temperature processes often employed to achieve desired crystallinity in fluoride cathodes can introduce structural defects and compositional inhomogeneities that become nucleation sites for thermal degradation. Alternative low-temperature synthesis routes typically result in materials with suboptimal electrochemical performance, creating a challenging trade-off between performance and stability.

The development of in-situ characterization methodologies capable of monitoring structural changes under realistic thermal conditions remains inadequate. Conventional techniques struggle to capture the dynamic nature of fluoride cathode degradation, particularly the rapid phase transitions and ion migration processes that occur during thermal exposure.

Current Approaches to Enhance Structural Stability

01 Fluoride-based cathode material compositions

Various fluoride-based compositions are used to enhance cathode structural stability in batteries. These include metal fluorides, fluorophosphates, and composite materials that incorporate fluoride components. The specific chemical composition affects the crystal structure, ionic conductivity, and overall stability during charge-discharge cycles. These materials often demonstrate improved electrochemical performance and reduced capacity fading compared to conventional cathode materials.- Structural stabilization methods for fluoride cathodes: Various methods are employed to enhance the structural stability of fluoride cathodes in battery applications. These include surface coating techniques, doping with stabilizing elements, and creating composite structures. These approaches help maintain the cathode's integrity during charge-discharge cycles, preventing structural collapse and capacity fading. The stabilization methods significantly improve the electrochemical performance and cycle life of fluoride-based cathode materials.

- Nanostructured fluoride cathode materials: Nanostructuring of fluoride cathode materials offers improved structural stability through reduced diffusion paths and better accommodation of volume changes during cycling. Nanoscale architectures such as nanoparticles, nanowires, and nanocomposites provide enhanced mechanical integrity and electrochemical performance. These nanostructured materials exhibit superior cycling stability and rate capability compared to their bulk counterparts, making them promising for next-generation battery applications.

- Binder and electrolyte compatibility for fluoride cathode stability: The selection of appropriate binders and electrolytes plays a crucial role in maintaining the structural stability of fluoride cathodes. Compatible binders help preserve the electrode integrity during cycling, while suitable electrolytes minimize side reactions that could degrade the cathode structure. Optimized formulations can significantly reduce structural deterioration, improve ionic conductivity, and enhance the overall electrochemical performance and longevity of fluoride-based battery systems.

- Temperature and pressure effects on fluoride cathode stability: Operating conditions, particularly temperature and pressure, significantly impact the structural stability of fluoride cathodes. High temperatures can accelerate degradation mechanisms, while controlled pressure conditions may enhance structural integrity. Understanding these effects is crucial for designing robust fluoride cathode materials and optimizing battery operating parameters. Research focuses on developing cathode materials with enhanced thermal stability and resistance to structural changes under various operating conditions.

- Advanced characterization techniques for monitoring fluoride cathode stability: Advanced analytical and characterization techniques are essential for monitoring and understanding the structural stability of fluoride cathodes. Methods such as in-situ X-ray diffraction, electron microscopy, spectroscopic techniques, and computational modeling provide valuable insights into degradation mechanisms and structural changes during battery operation. These techniques help in the rational design of more stable fluoride cathode materials by identifying failure modes and guiding the development of effective stabilization strategies.

02 Structural stabilization techniques for fluoride cathodes

Several techniques are employed to improve the structural stability of fluoride cathodes, including surface coating, doping with stabilizing elements, and creating core-shell structures. These methods help prevent structural degradation during cycling, reduce volume changes, and mitigate fluoride dissolution. The enhanced structural integrity leads to better cycling performance, higher capacity retention, and extended battery life.Expand Specific Solutions03 Electrolyte compatibility with fluoride cathodes

The interaction between electrolytes and fluoride cathodes significantly impacts structural stability. Specialized electrolyte formulations containing additives that form stable solid-electrolyte interfaces can protect fluoride cathodes from degradation. Electrolyte engineering focuses on preventing fluoride dissolution, suppressing side reactions, and maintaining interfacial stability during battery operation, which collectively enhance the structural integrity of fluoride cathode materials.Expand Specific Solutions04 Nanostructured fluoride cathode designs

Nanostructuring approaches are applied to fluoride cathode materials to improve structural stability. These include creating nanoparticles, nanowires, nanocomposites, and hierarchical structures that can better accommodate volume changes during cycling. The reduced particle size shortens ion diffusion paths, while specific nanoarchitectures provide mechanical reinforcement. These designs help maintain structural integrity during repeated lithiation and delithiation processes.Expand Specific Solutions05 Carbon integration for fluoride cathode stabilization

Carbon materials are integrated with fluoride cathodes to enhance structural stability and electrochemical performance. Carbon coating, carbon matrix encapsulation, and fluoride-carbon composites improve electrical conductivity, buffer volume changes, and prevent particle agglomeration. These carbon-integrated structures provide mechanical support and conductive networks that maintain cathode integrity during cycling, resulting in improved capacity retention and rate capability.Expand Specific Solutions

Leading Research Groups and Industrial Players

The fluoride cathode structural stability market under thermal stress is in an early growth phase, characterized by increasing research intensity but limited commercial applications. The market size is expanding as energy storage demands grow, particularly in high-temperature environments where thermal stability is critical. Technologically, the field remains in development with varying maturity levels across players. Leading companies like DAIKIN INDUSTRIES and 3M Innovative Properties bring established fluorine chemistry expertise, while battery manufacturers such as Ningde Amperex Technology (CATL) focus on practical applications. Research institutions including Karlsruher Institut für Technologie and UT-Battelle contribute fundamental scientific advancements. Chemical specialists Solvay Specialty Polymers, Asahi Kasei, and ZEON Corp provide specialized materials knowledge, creating a competitive landscape balanced between academic research and industrial implementation.

UT-Battelle LLC

Technical Solution: UT-Battelle LLC, which manages Oak Ridge National Laboratory (ORNL), has developed comprehensive research programs on fluoride cathode materials with emphasis on structural stability under extreme thermal conditions. Their approach leverages ORNL's world-class neutron scattering facilities to probe atomic-level structural changes during thermal cycling. UT-Battelle researchers have pioneered the development of core-shell structured fluoride cathodes with thermally stable shells that protect the electrochemically active cores from degradation at high temperatures. Their studies have demonstrated that strategic doping with rare earth elements can significantly enhance the thermal stability of fluoride cathodes by strengthening metal-fluorine bonds[3]. The research team has developed novel synthesis routes using low-temperature ionic liquids that produce fluoride cathodes with superior crystallinity and reduced defect concentration, resulting in improved thermal stability. Additionally, they've created advanced computational models that accurately predict thermal expansion behavior and identify potential failure mechanisms in fluoride cathode structures under various thermal stress scenarios.

Strengths: Unparalleled characterization capabilities through access to national laboratory facilities; multidisciplinary approach combining experimental and computational methods; strong connections to both academic and industrial partners. Weaknesses: Research sometimes constrained by government funding priorities; technology transfer processes can be lengthy due to institutional requirements; focus sometimes divided across multiple energy storage technologies.

Karlsruher Institut für Technologie

Technical Solution: Karlsruher Institut für Technologie (KIT) has established a specialized research program focused on fluoride-based cathode materials with enhanced thermal stability. Their approach combines advanced materials synthesis techniques with comprehensive thermal characterization methods. KIT researchers have developed novel fluoride cathode compositions incorporating thermally stable ceramic phases that act as structural buffers during thermal expansion. Their work has demonstrated that controlled introduction of oxygen into fluoride structures can create oxyfluoride phases with superior thermal stability while maintaining high electrochemical performance[4]. The institute has pioneered the use of atomic layer deposition to create ultrathin protective coatings on fluoride cathode particles that prevent structural degradation during thermal cycling. KIT's research has identified optimal particle size distributions and morphologies that minimize internal stress accumulation during temperature fluctuations. Additionally, they've developed specialized electrolyte formulations containing flame-retardant additives that enhance overall cell safety while maintaining compatibility with fluoride cathode surfaces at elevated temperatures.

Strengths: Excellent integration of fundamental research with practical applications; strong focus on safety aspects of fluoride-based battery systems; extensive experience with scale-up processes for laboratory discoveries. Weaknesses: More limited resources compared to larger industrial players; geographic concentration of research partners primarily in Europe; some promising technologies still at relatively low technology readiness levels.

Key Patents and Literature on Fluoride Cathode Stability

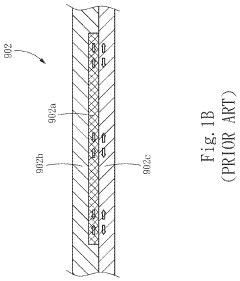

Structure of thermal stress release of photo-excited thermal infrared emitter

PatentPendingUS20230273123A1

Innovation

- A reticulated mosaic layout is introduced for the light absorbing and thermal infrared emitting layer, sandwiched between two light-transparent passivation layers, to minimize thermal expansion mismatch and induced stress by creating gaps between mosaic blocks that can accommodate thermal expansion, thereby reducing thermal stress.

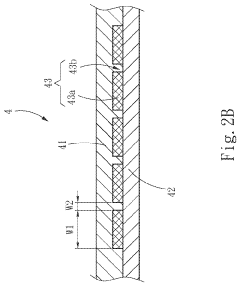

Thermal stress releasing structure of a light-emitting diode

PatentInactiveUS8552457B1

Innovation

- A thermal stress-releasing structure is introduced in the LED, featuring a buffer layer with alternately stacked first and second material layers forming a concave-convex or elastic corrugated structure, which absorbs deformation caused by thermal stress, preventing damage and cracks.

Safety Standards and Testing Protocols

The development of safety standards and testing protocols for fluoride cathode materials under thermal stress conditions is critical for the advancement and commercial viability of fluoride-based battery technologies. Current international standards, such as IEC 62660 and UL 1642, provide general guidelines for lithium-ion batteries but lack specific provisions for fluoride cathode materials, which exhibit unique thermal behavior and potential hazards.

Thermal runaway testing represents a cornerstone of safety evaluation for fluoride cathodes. These tests typically involve controlled heating of battery cells to temperatures ranging from 100°C to 250°C while monitoring structural changes, gas emissions, and potential ignition events. The Accelerated Rate Calorimetry (ARC) method has emerged as a particularly valuable technique for quantifying the onset temperature of exothermic reactions in fluoride cathode materials.

Differential Scanning Calorimetry (DSC) protocols have been standardized to evaluate the thermal stability thresholds of various fluoride cathode compositions. These protocols typically require sample preparation under inert atmospheres and heating rates of 5-10°C/min to accurately capture phase transitions and decomposition events. Recent modifications to DSC protocols specifically for fluoride materials include extended equilibration periods to account for their unique thermal response characteristics.

Mechanical integrity testing under thermal stress conditions has been formalized through crush tests performed at elevated temperatures (60-80°C). These tests evaluate the structural stability of fluoride cathodes when subjected to simultaneous mechanical and thermal stressors, simulating potential abuse scenarios in real-world applications.

Gas evolution analysis during thermal events has been standardized using Gas Chromatography-Mass Spectrometry (GC-MS) techniques. The detection and quantification of fluorine-containing gaseous species, particularly hydrogen fluoride (HF), is mandated in safety evaluations due to their corrosive and toxic properties. Current protocols require detection sensitivity of at least 1 ppm for HF.

Industry-academic consortia have recently proposed new testing standards specifically for fluoride-based battery systems. These include cycling stability tests under thermal gradient conditions and long-term storage tests at elevated temperatures (45-60°C) to evaluate structural degradation mechanisms. The Battery Safety Testing Consortium (BSTC) has published draft guidelines that recommend a minimum of 500 cycles under thermal stress conditions before safety certification.

Regulatory bodies, including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), are currently reviewing proposals for fluoride-specific safety standards, with publication expected within the next 18-24 months. These forthcoming standards will likely mandate more stringent thermal abuse testing protocols compared to conventional lithium-ion technologies.

Thermal runaway testing represents a cornerstone of safety evaluation for fluoride cathodes. These tests typically involve controlled heating of battery cells to temperatures ranging from 100°C to 250°C while monitoring structural changes, gas emissions, and potential ignition events. The Accelerated Rate Calorimetry (ARC) method has emerged as a particularly valuable technique for quantifying the onset temperature of exothermic reactions in fluoride cathode materials.

Differential Scanning Calorimetry (DSC) protocols have been standardized to evaluate the thermal stability thresholds of various fluoride cathode compositions. These protocols typically require sample preparation under inert atmospheres and heating rates of 5-10°C/min to accurately capture phase transitions and decomposition events. Recent modifications to DSC protocols specifically for fluoride materials include extended equilibration periods to account for their unique thermal response characteristics.

Mechanical integrity testing under thermal stress conditions has been formalized through crush tests performed at elevated temperatures (60-80°C). These tests evaluate the structural stability of fluoride cathodes when subjected to simultaneous mechanical and thermal stressors, simulating potential abuse scenarios in real-world applications.

Gas evolution analysis during thermal events has been standardized using Gas Chromatography-Mass Spectrometry (GC-MS) techniques. The detection and quantification of fluorine-containing gaseous species, particularly hydrogen fluoride (HF), is mandated in safety evaluations due to their corrosive and toxic properties. Current protocols require detection sensitivity of at least 1 ppm for HF.

Industry-academic consortia have recently proposed new testing standards specifically for fluoride-based battery systems. These include cycling stability tests under thermal gradient conditions and long-term storage tests at elevated temperatures (45-60°C) to evaluate structural degradation mechanisms. The Battery Safety Testing Consortium (BSTC) has published draft guidelines that recommend a minimum of 500 cycles under thermal stress conditions before safety certification.

Regulatory bodies, including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), are currently reviewing proposals for fluoride-specific safety standards, with publication expected within the next 18-24 months. These forthcoming standards will likely mandate more stringent thermal abuse testing protocols compared to conventional lithium-ion technologies.

Environmental Impact and Recycling Considerations

The environmental implications of fluoride cathode materials under thermal stress extend beyond performance considerations to ecological sustainability. Fluoride-based battery systems, while promising for energy storage, present unique environmental challenges particularly when subjected to thermal degradation. The release of fluoride compounds during thermal decomposition can lead to potential soil and water contamination if not properly contained, necessitating robust safety protocols in both manufacturing and disposal processes.

Current lifecycle assessments indicate that fluoride cathode materials have a complex environmental footprint. While their energy density advantages may reduce overall material requirements compared to conventional lithium-ion batteries, the environmental costs of fluoride extraction and processing remain significant. Thermal stress events can accelerate the release of these compounds, potentially increasing environmental exposure risks throughout the battery lifecycle.

Recycling considerations for fluoride cathodes present both challenges and opportunities. The structural changes induced by thermal stress can complicate separation processes in recycling facilities, as degraded materials may form new compounds with different physical and chemical properties. However, advanced recycling technologies specifically designed for fluoride-containing materials are emerging, including hydrometallurgical processes that can selectively recover fluoride compounds while minimizing environmental release.

Regulatory frameworks worldwide are increasingly addressing the specific concerns of fluoride-containing energy storage systems. The European Union's Battery Directive and similar regulations in North America and Asia are evolving to include specific provisions for fluoride material handling, with particular attention to thermal management requirements throughout the product lifecycle. These regulations aim to minimize environmental impact while supporting the development of this promising technology.

Research into bio-based stabilizers and environmentally benign thermal management systems represents a promising frontier for reducing the ecological footprint of fluoride cathodes. These approaches focus on developing materials that maintain structural integrity under thermal stress while being derived from renewable resources. Additionally, green chemistry principles are being applied to develop fluoride cathode recycling processes that minimize energy consumption and hazardous waste generation.

The economic viability of fluoride cathode recycling is closely tied to thermal stability improvements. More stable structures under thermal stress not only enhance battery performance but also preserve material value for second-life applications and eventual recycling. This creates a positive feedback loop where investments in thermal stability research yield both performance and environmental sustainability benefits.

Current lifecycle assessments indicate that fluoride cathode materials have a complex environmental footprint. While their energy density advantages may reduce overall material requirements compared to conventional lithium-ion batteries, the environmental costs of fluoride extraction and processing remain significant. Thermal stress events can accelerate the release of these compounds, potentially increasing environmental exposure risks throughout the battery lifecycle.

Recycling considerations for fluoride cathodes present both challenges and opportunities. The structural changes induced by thermal stress can complicate separation processes in recycling facilities, as degraded materials may form new compounds with different physical and chemical properties. However, advanced recycling technologies specifically designed for fluoride-containing materials are emerging, including hydrometallurgical processes that can selectively recover fluoride compounds while minimizing environmental release.

Regulatory frameworks worldwide are increasingly addressing the specific concerns of fluoride-containing energy storage systems. The European Union's Battery Directive and similar regulations in North America and Asia are evolving to include specific provisions for fluoride material handling, with particular attention to thermal management requirements throughout the product lifecycle. These regulations aim to minimize environmental impact while supporting the development of this promising technology.

Research into bio-based stabilizers and environmentally benign thermal management systems represents a promising frontier for reducing the ecological footprint of fluoride cathodes. These approaches focus on developing materials that maintain structural integrity under thermal stress while being derived from renewable resources. Additionally, green chemistry principles are being applied to develop fluoride cathode recycling processes that minimize energy consumption and hazardous waste generation.

The economic viability of fluoride cathode recycling is closely tied to thermal stability improvements. More stable structures under thermal stress not only enhance battery performance but also preserve material value for second-life applications and eventual recycling. This creates a positive feedback loop where investments in thermal stability research yield both performance and environmental sustainability benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!