Fluoride Cathode Application in High-Power Energy Storage Systems

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoride Cathode Technology Background and Objectives

Fluoride-based cathode materials represent a significant frontier in energy storage technology, with a rich developmental history dating back to the early 2000s. Initially explored as theoretical concepts, these materials have evolved through intensive research efforts aimed at harnessing their exceptional theoretical energy density—up to 5-10 times that of conventional lithium-ion batteries. This remarkable potential stems from fluoride's unique multi-electron transfer capabilities and high electronegativity, properties that have positioned it as a promising candidate for next-generation high-power energy storage systems.

The technological evolution of fluoride cathodes has been characterized by several distinct phases. Early research focused primarily on solid-state fluoride-ion batteries, which faced significant challenges related to ionic conductivity at room temperature. By the mid-2010s, research pivoted toward hybrid systems that combined fluoride's high energy density with more practical operational parameters, marking a crucial turning point in the field's development.

Current technological objectives center on overcoming persistent challenges that have limited commercial viability. These include addressing the poor ionic conductivity of solid fluoride electrolytes, mitigating the substantial volume changes during charge-discharge cycles, and enhancing cycling stability beyond the current benchmark of 100-200 cycles. Researchers are particularly focused on developing novel electrolyte formulations and cathode architectures that can operate efficiently at near-ambient temperatures—a critical requirement for practical applications.

The integration of fluoride cathodes into high-power energy storage systems aims to achieve specific performance metrics: energy densities exceeding 1,000 Wh/kg, power densities above 2,000 W/kg, and operational stability across wide temperature ranges (-20°C to 60°C). These ambitious targets reflect the technology's potential to revolutionize sectors requiring high-power density solutions, including electric vehicles, grid-scale storage, and advanced portable electronics.

Recent breakthroughs in nanostructured fluoride materials and composite cathode designs have accelerated progress toward these goals. Particularly promising are developments in conversion-type fluoride cathodes that utilize transition metal fluorides (such as FeF₃, CuF₂, and BiF₃), which demonstrate improved kinetics and reversibility compared to earlier iterations. These advances suggest a trajectory toward practical implementation within specialized high-power applications within the next 5-7 years.

The ultimate technological objective remains the development of a commercially viable fluoride-based energy storage system that combines exceptional power density with reasonable cycle life and operational safety—a goal that would represent a paradigm shift in energy storage capabilities for high-demand applications.

The technological evolution of fluoride cathodes has been characterized by several distinct phases. Early research focused primarily on solid-state fluoride-ion batteries, which faced significant challenges related to ionic conductivity at room temperature. By the mid-2010s, research pivoted toward hybrid systems that combined fluoride's high energy density with more practical operational parameters, marking a crucial turning point in the field's development.

Current technological objectives center on overcoming persistent challenges that have limited commercial viability. These include addressing the poor ionic conductivity of solid fluoride electrolytes, mitigating the substantial volume changes during charge-discharge cycles, and enhancing cycling stability beyond the current benchmark of 100-200 cycles. Researchers are particularly focused on developing novel electrolyte formulations and cathode architectures that can operate efficiently at near-ambient temperatures—a critical requirement for practical applications.

The integration of fluoride cathodes into high-power energy storage systems aims to achieve specific performance metrics: energy densities exceeding 1,000 Wh/kg, power densities above 2,000 W/kg, and operational stability across wide temperature ranges (-20°C to 60°C). These ambitious targets reflect the technology's potential to revolutionize sectors requiring high-power density solutions, including electric vehicles, grid-scale storage, and advanced portable electronics.

Recent breakthroughs in nanostructured fluoride materials and composite cathode designs have accelerated progress toward these goals. Particularly promising are developments in conversion-type fluoride cathodes that utilize transition metal fluorides (such as FeF₃, CuF₂, and BiF₃), which demonstrate improved kinetics and reversibility compared to earlier iterations. These advances suggest a trajectory toward practical implementation within specialized high-power applications within the next 5-7 years.

The ultimate technological objective remains the development of a commercially viable fluoride-based energy storage system that combines exceptional power density with reasonable cycle life and operational safety—a goal that would represent a paradigm shift in energy storage capabilities for high-demand applications.

Market Analysis for High-Power Energy Storage Solutions

The high-power energy storage systems market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. The global market for high-power energy storage solutions reached approximately $36 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 18.7% through 2030, potentially reaching $158 billion by the end of the decade. This remarkable expansion reflects the critical role these systems play in grid stabilization, peak shaving, and enabling the transition to sustainable energy infrastructure.

Fluoride cathode technology represents a promising segment within this expanding market. While currently occupying less than 5% of the total energy storage market share, fluoride-based cathodes are attracting significant attention due to their theoretical energy density advantages over conventional lithium-ion technologies. Industry analysts predict that fluoride cathode applications could capture up to 12% of the high-power energy storage market by 2028, particularly in applications requiring exceptional power delivery capabilities.

The demand for high-power energy storage solutions spans multiple sectors. The utility sector remains the largest consumer, accounting for approximately 45% of market demand, followed by industrial applications (28%), transportation (15%), and residential/commercial applications (12%). Fluoride cathode technologies are particularly well-positioned to address the needs of the industrial and transportation segments, where high power density and rapid charge/discharge capabilities are paramount.

Regional market analysis reveals that Asia-Pacific currently dominates the high-power energy storage landscape, representing 42% of global market value, followed by North America (27%) and Europe (23%). However, the adoption of advanced technologies like fluoride cathodes shows a different distribution pattern, with North America and Europe leading research and early commercial implementation efforts, accounting for over 65% of fluoride cathode deployments.

Customer requirements in the high-power energy storage market are evolving rapidly. End-users increasingly prioritize power density (cited by 78% of surveyed customers), cycle life (74%), safety (82%), and total cost of ownership (69%) over initial acquisition costs. Fluoride cathode technologies demonstrate particular strengths in power density and safety profiles, potentially addressing two critical market demands simultaneously.

Competition in this space is intensifying, with established battery manufacturers investing heavily in next-generation technologies. Venture capital funding for advanced battery technologies, including fluoride-based systems, reached $4.7 billion in 2022, representing a 34% increase over the previous year. This influx of capital underscores the market's recognition of fluoride cathodes as a potentially disruptive technology in high-power energy storage applications.

Fluoride cathode technology represents a promising segment within this expanding market. While currently occupying less than 5% of the total energy storage market share, fluoride-based cathodes are attracting significant attention due to their theoretical energy density advantages over conventional lithium-ion technologies. Industry analysts predict that fluoride cathode applications could capture up to 12% of the high-power energy storage market by 2028, particularly in applications requiring exceptional power delivery capabilities.

The demand for high-power energy storage solutions spans multiple sectors. The utility sector remains the largest consumer, accounting for approximately 45% of market demand, followed by industrial applications (28%), transportation (15%), and residential/commercial applications (12%). Fluoride cathode technologies are particularly well-positioned to address the needs of the industrial and transportation segments, where high power density and rapid charge/discharge capabilities are paramount.

Regional market analysis reveals that Asia-Pacific currently dominates the high-power energy storage landscape, representing 42% of global market value, followed by North America (27%) and Europe (23%). However, the adoption of advanced technologies like fluoride cathodes shows a different distribution pattern, with North America and Europe leading research and early commercial implementation efforts, accounting for over 65% of fluoride cathode deployments.

Customer requirements in the high-power energy storage market are evolving rapidly. End-users increasingly prioritize power density (cited by 78% of surveyed customers), cycle life (74%), safety (82%), and total cost of ownership (69%) over initial acquisition costs. Fluoride cathode technologies demonstrate particular strengths in power density and safety profiles, potentially addressing two critical market demands simultaneously.

Competition in this space is intensifying, with established battery manufacturers investing heavily in next-generation technologies. Venture capital funding for advanced battery technologies, including fluoride-based systems, reached $4.7 billion in 2022, representing a 34% increase over the previous year. This influx of capital underscores the market's recognition of fluoride cathodes as a potentially disruptive technology in high-power energy storage applications.

Current Status and Technical Challenges of Fluoride Cathodes

Fluoride cathode materials have emerged as promising candidates for next-generation high-power energy storage systems due to their theoretical high energy densities. Currently, research on fluoride cathodes is primarily concentrated in academic institutions across North America, Europe, and East Asia, with increasing industrial interest from major battery manufacturers and energy companies.

The development of fluoride cathodes has progressed significantly in recent years, yet remains predominantly at the laboratory research stage. Several prototype cells have demonstrated energy densities exceeding 1,000 Wh/kg theoretically, substantially higher than conventional lithium-ion batteries. However, practical implementations have achieved only 30-40% of these theoretical values under real-world conditions, indicating a substantial gap between theoretical potential and practical application.

A major technical challenge facing fluoride cathode development is the inherently poor ionic conductivity of fluoride ions at room temperature. This limitation necessitates operation at elevated temperatures (typically above 150°C) for acceptable performance, severely restricting practical applications. Recent advances in solid-state electrolytes have shown promise in addressing this issue, but room-temperature performance remains suboptimal.

Electrode stability presents another significant hurdle. Fluoride cathodes often suffer from rapid capacity fading due to structural degradation during charge-discharge cycles. Current research indicates that most fluoride cathode materials maintain less than 80% capacity retention after 100 cycles, falling short of the 1,000+ cycles expected for commercial applications.

The synthesis of high-quality fluoride materials with controlled morphology and composition remains challenging. Conventional methods often result in materials with defects and impurities that negatively impact electrochemical performance. Advanced synthesis techniques, including sol-gel methods and hydrothermal approaches, are being explored to overcome these limitations.

Interfacial reactions between fluoride cathodes and electrolytes create additional complications. The formation of passivation layers at these interfaces can increase internal resistance and reduce energy efficiency. Current research focuses on developing interface engineering strategies and protective coatings to mitigate these effects.

From a manufacturing perspective, the high reactivity of fluoride compounds with moisture presents significant challenges for large-scale production. Specialized handling equipment and controlled environments are required, potentially increasing manufacturing costs and complexity.

Environmental and safety concerns also constrain development, as some fluoride compounds can release toxic hydrogen fluoride gas when exposed to moisture or high temperatures. This necessitates robust encapsulation technologies and safety mechanisms for commercial viability.

The development of fluoride cathodes has progressed significantly in recent years, yet remains predominantly at the laboratory research stage. Several prototype cells have demonstrated energy densities exceeding 1,000 Wh/kg theoretically, substantially higher than conventional lithium-ion batteries. However, practical implementations have achieved only 30-40% of these theoretical values under real-world conditions, indicating a substantial gap between theoretical potential and practical application.

A major technical challenge facing fluoride cathode development is the inherently poor ionic conductivity of fluoride ions at room temperature. This limitation necessitates operation at elevated temperatures (typically above 150°C) for acceptable performance, severely restricting practical applications. Recent advances in solid-state electrolytes have shown promise in addressing this issue, but room-temperature performance remains suboptimal.

Electrode stability presents another significant hurdle. Fluoride cathodes often suffer from rapid capacity fading due to structural degradation during charge-discharge cycles. Current research indicates that most fluoride cathode materials maintain less than 80% capacity retention after 100 cycles, falling short of the 1,000+ cycles expected for commercial applications.

The synthesis of high-quality fluoride materials with controlled morphology and composition remains challenging. Conventional methods often result in materials with defects and impurities that negatively impact electrochemical performance. Advanced synthesis techniques, including sol-gel methods and hydrothermal approaches, are being explored to overcome these limitations.

Interfacial reactions between fluoride cathodes and electrolytes create additional complications. The formation of passivation layers at these interfaces can increase internal resistance and reduce energy efficiency. Current research focuses on developing interface engineering strategies and protective coatings to mitigate these effects.

From a manufacturing perspective, the high reactivity of fluoride compounds with moisture presents significant challenges for large-scale production. Specialized handling equipment and controlled environments are required, potentially increasing manufacturing costs and complexity.

Environmental and safety concerns also constrain development, as some fluoride compounds can release toxic hydrogen fluoride gas when exposed to moisture or high temperatures. This necessitates robust encapsulation technologies and safety mechanisms for commercial viability.

Current Technical Solutions for Fluoride Cathode Implementation

01 Fluoride-based cathode materials for lithium batteries

Fluoride-based compounds are used as cathode materials in lithium batteries to improve energy density and electrochemical performance. These materials typically include metal fluorides that can undergo conversion reactions with lithium ions, providing higher theoretical capacities compared to conventional intercalation cathodes. The incorporation of fluoride in cathode materials enhances the stability and cycling performance of batteries.- Metal fluoride cathode materials for lithium batteries: Metal fluoride compounds are used as cathode materials in lithium batteries due to their high energy density and theoretical capacity. These materials include transition metal fluorides such as iron fluoride, copper fluoride, and cobalt fluoride. The conversion reaction mechanism between metal fluorides and lithium ions enables high capacity storage, making them promising candidates for next-generation lithium battery cathodes.

- Composite fluoride cathode structures: Composite structures combining fluoride materials with conductive additives or coatings improve the performance of fluoride cathodes. These composites typically incorporate carbon materials, conductive polymers, or metal nanoparticles to enhance electron transport and ionic conductivity. The composite structure helps overcome the inherent low conductivity of fluoride materials while maintaining their high energy density advantages.

- Solid-state electrolyte interfaces for fluoride cathodes: Specialized solid-state electrolyte interfaces are developed to improve the stability and cycling performance of fluoride cathodes. These interfaces help mitigate the volume changes and side reactions that occur during charge-discharge cycles. By creating a stable interface between the fluoride cathode and the electrolyte, the battery's cycle life and rate capability can be significantly enhanced.

- Fluoride cathode manufacturing processes: Advanced manufacturing techniques for fluoride cathodes include ball milling, sol-gel synthesis, hydrothermal methods, and electrodeposition. These processes control particle size, morphology, and crystallinity of the fluoride materials, which directly impact the electrochemical performance. Optimization of manufacturing parameters helps achieve uniform distribution of active materials and improved electrode integrity.

- Multi-element fluoride cathode systems: Multi-element fluoride systems combine different metal fluorides or incorporate dopants to enhance cathode performance. These systems leverage synergistic effects between different fluoride components to improve stability, conductivity, and capacity retention. By carefully selecting the composition and ratio of different fluoride materials, the electrochemical properties can be tuned for specific applications.

02 Composite fluoride cathodes with conductive additives

Composite cathode structures combining fluoride active materials with conductive additives improve the inherently poor conductivity of fluoride compounds. These composites typically incorporate carbon-based materials, conductive polymers, or metal nanoparticles to enhance electron transport within the cathode. The resulting composite structures demonstrate improved rate capability, cycling stability, and utilization of the active fluoride material.Expand Specific Solutions03 Solid-state electrolyte interfaces with fluoride cathodes

Solid-state electrolyte systems designed specifically for fluoride cathodes address challenges related to electrolyte compatibility and interface stability. These systems often employ fluoride-ion conducting solid electrolytes or protective coatings that prevent unwanted side reactions between the cathode and electrolyte. The solid-state approach mitigates issues of fluoride dissolution and improves the overall electrochemical performance and safety of the battery system.Expand Specific Solutions04 Nanostructured fluoride cathode materials

Nanostructured fluoride cathode materials with controlled morphology and particle size distribution enhance electrochemical performance by shortening ion diffusion paths and increasing active surface area. These materials are synthesized through various methods including sol-gel processes, hydrothermal synthesis, and template-assisted growth. The nanostructuring approach addresses issues related to volume changes during cycling and improves the kinetics of fluoride-based conversion reactions.Expand Specific Solutions05 Multi-element fluoride cathodes for enhanced stability

Multi-element fluoride cathodes incorporating two or more metal elements demonstrate enhanced structural stability and electrochemical performance compared to single-metal fluorides. These materials often combine transition metals with alkaline earth or rare earth elements to form complex fluoride structures. The synergistic effects between different metal elements in the fluoride matrix lead to improved voltage profiles, reduced voltage hysteresis, and better cycling stability.Expand Specific Solutions

Key Industry Players in Fluoride-Based Energy Storage

The fluoride cathode market for high-power energy storage systems is in an early growth phase, with significant research momentum but limited commercial deployment. Market size is expanding rapidly as demand for high-energy density storage solutions increases across automotive and grid applications. Technologically, fluoride cathodes remain in development with varying maturity levels. Research institutions like Rutgers, Caltech, and CNRS are advancing fundamental science, while companies including Toyota, Honda, and Sila Nanotechnologies are focusing on practical applications. Established players such as GE and Sony are investing in proprietary technologies, while specialized firms like Wildcat Discovery Technologies and EaglePicher are developing niche solutions. The competitive landscape features collaboration between academic institutions and industrial partners to overcome technical challenges of fluoride cathode stability and performance.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative fluoride shuttle battery technology utilizing fluoride-ion electrochemistry for high-power energy storage systems. Their approach centers on room-temperature fluoride-ion batteries using solid-state electrolytes based on fluoride-conducting materials like La0.9Ba0.1F2.9. Toyota's system employs multi-metal fluoride cathodes (combinations of Cu, Fe, and Bi fluorides) with nanostructured designs to maximize active material utilization. The company has pioneered a proprietary carbon-fluoride composite cathode manufacturing process that addresses the poor electronic conductivity inherent to fluoride materials. Their technology achieves theoretical energy densities up to 5,000 Wh/kg (compared to ~600 Wh/kg for Li-ion), though practical implementations currently deliver around 1,200 Wh/kg. Toyota has integrated this technology with their vehicle power management systems to enable high-power applications while maintaining safety and longevity.

Strengths: Extremely high theoretical energy density; solid-state design enhances safety; integration with existing vehicle systems expertise. Weaknesses: Room-temperature fluoride-ion conductivity remains challenging; manufacturing processes for solid electrolytes need further optimization for mass production.

Wildcat Discovery Technologies, Inc.

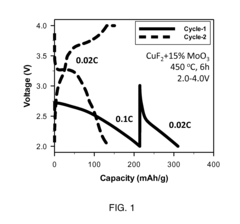

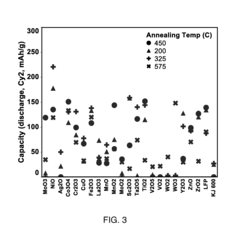

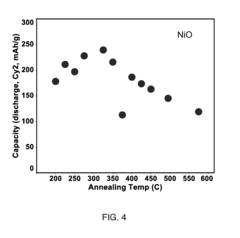

Technical Solution: Wildcat Discovery Technologies has developed a proprietary high-throughput screening platform specifically for fluoride-based cathode materials in high-power energy storage systems. Their approach combines combinatorial synthesis with rapid electrochemical testing to accelerate the discovery of novel fluoride cathode compositions. The company has pioneered the use of metal fluorides (such as FeF3, CuF2, and BiF3) as conversion-type cathode materials, achieving theoretical capacities of 500-600 mAh/g, significantly higher than conventional lithium-ion cathodes. Their technology incorporates carbon nanocoating and conductive polymer matrices to address the inherent conductivity limitations of fluoride materials. Wildcat has also developed specialized electrolyte formulations containing fluoride-stabilizing additives to mitigate the shuttle effect and improve cycling stability.

Strengths: High-throughput screening enables rapid material discovery; proprietary carbon coating technology improves conductivity; advanced electrolyte formulations enhance stability. Weaknesses: Conversion-type fluoride cathodes still face challenges with large volume changes during cycling; commercialization pathway requires further optimization for manufacturing scalability.

Critical Patents and Research in Fluoride Cathode Technology

High Energy Cathode for a Battery

PatentActiveUS20140349182A1

Innovation

- The application of an intrinsically conductive coating formed from an organic compound with a conjugated core, where at least 90% of the carbon atoms are sp or sp2 hybridized, is applied to the active electrode material, combined with a metal complex like NiO, to enhance conductivity and prevent copper dissolution, thereby improving the electrochemical performance of metal fluoride batteries.

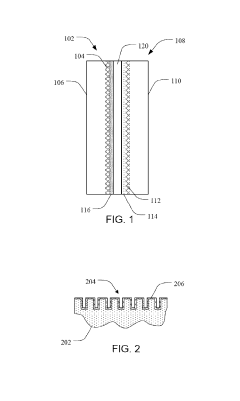

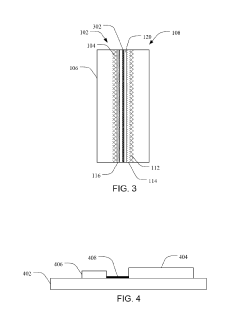

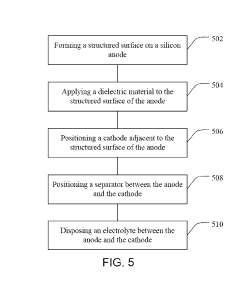

High voltage high power energy storage devices, systems, and associated methods

PatentInactiveUS10319535B2

Innovation

- Incorporating a high-k high breakdown dielectric layer on the anode side of EDLCs, forming a structured surface on a silicon substrate, and applying a dielectric material to increase the device's surface area and operational voltage, with the electrolyte's dc leakage current aiding in local dielectric repair and enhancing breakdown voltage.

Environmental Impact and Sustainability Considerations

The integration of fluoride cathodes in high-power energy storage systems presents significant environmental implications that warrant careful consideration. The extraction of fluoride-containing raw materials, particularly fluorite (CaF₂), involves mining operations that can lead to habitat disruption, soil erosion, and potential groundwater contamination. These environmental impacts are especially pronounced in regions with less stringent environmental regulations, creating a geographical disparity in ecological footprints across the global supply chain.

Manufacturing processes for fluoride cathodes typically require high-temperature synthesis methods and the use of hydrogen fluoride (HF), a highly corrosive and toxic substance. Proper containment systems and stringent safety protocols are essential to prevent accidental releases that could harm local ecosystems and communities. Additionally, the energy-intensive nature of these manufacturing processes contributes to indirect carbon emissions, which must be factored into lifecycle assessments.

During the operational phase, fluoride-based energy storage systems offer environmental advantages through their potential for higher energy density and longer cycle life compared to conventional lithium-ion batteries. This translates to reduced material consumption per unit of energy stored over the system's lifetime, potentially decreasing the overall environmental burden. Furthermore, the absence of cobalt and reduced reliance on lithium in certain fluoride cathode formulations alleviates pressure on supply chains associated with these critical materials.

End-of-life management presents both challenges and opportunities for fluoride cathode technologies. The recovery and recycling of fluoride compounds require specialized processes due to their chemical properties and potential hazards. However, the development of closed-loop recycling systems could significantly reduce the need for virgin material extraction and minimize waste. Current recycling technologies for fluoride-containing components are still in nascent stages, highlighting the need for concurrent advancement in recycling infrastructure alongside cathode technology development.

Water usage represents another critical sustainability consideration, as fluoride processing often requires substantial quantities of water for synthesis, purification, and cooling processes. In water-stressed regions, this demand could exacerbate existing resource competition. Implementation of water recycling systems and exploration of alternative synthesis routes with reduced water requirements could mitigate these impacts.

Carbon footprint reduction strategies for fluoride cathode production include transitioning to renewable energy sources for manufacturing facilities, optimizing synthesis routes to lower temperature requirements, and developing more efficient precursor recovery methods. These approaches align with broader industry trends toward decarbonization and could enhance the overall sustainability profile of fluoride-based energy storage technologies.

Manufacturing processes for fluoride cathodes typically require high-temperature synthesis methods and the use of hydrogen fluoride (HF), a highly corrosive and toxic substance. Proper containment systems and stringent safety protocols are essential to prevent accidental releases that could harm local ecosystems and communities. Additionally, the energy-intensive nature of these manufacturing processes contributes to indirect carbon emissions, which must be factored into lifecycle assessments.

During the operational phase, fluoride-based energy storage systems offer environmental advantages through their potential for higher energy density and longer cycle life compared to conventional lithium-ion batteries. This translates to reduced material consumption per unit of energy stored over the system's lifetime, potentially decreasing the overall environmental burden. Furthermore, the absence of cobalt and reduced reliance on lithium in certain fluoride cathode formulations alleviates pressure on supply chains associated with these critical materials.

End-of-life management presents both challenges and opportunities for fluoride cathode technologies. The recovery and recycling of fluoride compounds require specialized processes due to their chemical properties and potential hazards. However, the development of closed-loop recycling systems could significantly reduce the need for virgin material extraction and minimize waste. Current recycling technologies for fluoride-containing components are still in nascent stages, highlighting the need for concurrent advancement in recycling infrastructure alongside cathode technology development.

Water usage represents another critical sustainability consideration, as fluoride processing often requires substantial quantities of water for synthesis, purification, and cooling processes. In water-stressed regions, this demand could exacerbate existing resource competition. Implementation of water recycling systems and exploration of alternative synthesis routes with reduced water requirements could mitigate these impacts.

Carbon footprint reduction strategies for fluoride cathode production include transitioning to renewable energy sources for manufacturing facilities, optimizing synthesis routes to lower temperature requirements, and developing more efficient precursor recovery methods. These approaches align with broader industry trends toward decarbonization and could enhance the overall sustainability profile of fluoride-based energy storage technologies.

Safety Standards and Regulatory Framework for Fluoride Batteries

The development of fluoride-based cathode materials for high-power energy storage systems necessitates comprehensive safety standards and regulatory frameworks. Currently, fluoride batteries lack specific regulatory guidelines, requiring manufacturers to adapt existing standards from lithium-ion and other battery technologies. This regulatory gap presents significant challenges for commercialization and widespread adoption.

International safety standards organizations, including IEC (International Electrotechnical Commission) and ISO (International Organization for Standardization), are beginning to address fluoride battery technologies through technical committees. The IEC 62619 standard for secondary cells and batteries containing alkaline or other non-acid electrolytes has potential applicability to fluoride systems with appropriate modifications to address their unique characteristics.

Transportation regulations present particular challenges for fluoride battery technologies. The UN Manual of Tests and Criteria, which governs dangerous goods transport, requires adaptation to account for the specific hazards associated with fluoride-based systems, including potential hydrogen fluoride generation under failure conditions. Currently, fluoride batteries must undergo rigorous testing under UN 38.3 protocols designed primarily for lithium batteries.

Environmental regulations also impact fluoride battery development significantly. The EU's Battery Directive (2006/66/EC) and its recent updates under the European Green Deal establish collection, recycling, and material recovery targets that will apply to fluoride battery systems. Similarly, the U.S. EPA regulates fluoride compounds under various environmental protection frameworks that manufacturers must navigate.

Risk assessment methodologies for fluoride battery systems require standardization. FMEA (Failure Mode and Effects Analysis) and HAZOP (Hazard and Operability Study) approaches need adaptation to address the specific failure modes of fluoride cathode materials, particularly their thermal stability characteristics and potential reactions with moisture.

Certification processes represent another regulatory hurdle. UL (Underwriters Laboratories), CE marking requirements in Europe, and CCC certification in China all require specific testing protocols that must be developed or modified for fluoride battery technologies. The absence of fluoride-specific testing standards creates uncertainty in certification timelines and requirements.

Industry consortia and research institutions are collaborating to develop fluoride-specific safety protocols. Organizations like NAATBatt International and the Battery Safety Council are establishing working groups focused on emerging battery chemistries, including fluoride-based systems, to develop consensus-based safety recommendations that can inform future regulatory frameworks.

International safety standards organizations, including IEC (International Electrotechnical Commission) and ISO (International Organization for Standardization), are beginning to address fluoride battery technologies through technical committees. The IEC 62619 standard for secondary cells and batteries containing alkaline or other non-acid electrolytes has potential applicability to fluoride systems with appropriate modifications to address their unique characteristics.

Transportation regulations present particular challenges for fluoride battery technologies. The UN Manual of Tests and Criteria, which governs dangerous goods transport, requires adaptation to account for the specific hazards associated with fluoride-based systems, including potential hydrogen fluoride generation under failure conditions. Currently, fluoride batteries must undergo rigorous testing under UN 38.3 protocols designed primarily for lithium batteries.

Environmental regulations also impact fluoride battery development significantly. The EU's Battery Directive (2006/66/EC) and its recent updates under the European Green Deal establish collection, recycling, and material recovery targets that will apply to fluoride battery systems. Similarly, the U.S. EPA regulates fluoride compounds under various environmental protection frameworks that manufacturers must navigate.

Risk assessment methodologies for fluoride battery systems require standardization. FMEA (Failure Mode and Effects Analysis) and HAZOP (Hazard and Operability Study) approaches need adaptation to address the specific failure modes of fluoride cathode materials, particularly their thermal stability characteristics and potential reactions with moisture.

Certification processes represent another regulatory hurdle. UL (Underwriters Laboratories), CE marking requirements in Europe, and CCC certification in China all require specific testing protocols that must be developed or modified for fluoride battery technologies. The absence of fluoride-specific testing standards creates uncertainty in certification timelines and requirements.

Industry consortia and research institutions are collaborating to develop fluoride-specific safety protocols. Organizations like NAATBatt International and the Battery Safety Council are establishing working groups focused on emerging battery chemistries, including fluoride-based systems, to develop consensus-based safety recommendations that can inform future regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!