Fluoride Cathode Material Innovations for Next-Generation EV Batteries

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoride Cathode Evolution and Research Objectives

Fluoride-based cathode materials represent a significant frontier in battery technology evolution, offering theoretical energy densities that far exceed current lithium-ion systems. The development of these materials traces back to early 2010s when researchers began exploring metal fluorides as conversion-type cathodes. Initial investigations focused primarily on iron fluoride (FeF3) due to its high theoretical capacity of 712 mAh/g and abundant raw materials. However, these early attempts faced substantial challenges related to poor electronic conductivity and significant volume changes during cycling.

The technological trajectory has since evolved through several distinct phases. The first generation of fluoride cathodes (2010-2015) primarily involved simple metal fluorides with carbon coating to address conductivity limitations. The second generation (2015-2020) saw the emergence of nanostructured fluoride materials and composite designs to mitigate volume expansion issues. Currently, we are witnessing the third generation development (2020-present) focusing on advanced fluoride-based solid-state electrolyte interfaces and hybrid conversion-intercalation mechanisms.

Recent breakthroughs include the development of copper fluoride (CuF2) cathodes with improved voltage profiles and the incorporation of pre-lithiated fluoride materials to enhance initial coulombic efficiency. These innovations have pushed practical energy densities from below 300 Wh/kg toward the 400-500 Wh/kg range, representing a significant improvement over commercial lithium-ion batteries (250-300 Wh/kg).

The primary research objectives for fluoride cathode materials center around four critical areas. First, enhancing reaction reversibility through novel electrolyte formulations and interfacial engineering to address the persistent challenge of capacity fading. Second, improving rate capability by developing hierarchical nanostructures that facilitate both electron and ion transport. Third, mitigating voltage hysteresis through advanced catalyst integration and defect engineering. Fourth, scaling up synthesis methods from laboratory to industrial production while maintaining performance metrics.

The long-term technological goal is to achieve stable fluoride cathodes delivering energy densities exceeding 500 Wh/kg with cycle life comparable to current commercial batteries (>1000 cycles). This would enable electric vehicles with significantly extended range (potentially 600+ miles) while reducing battery weight and cost. Additionally, research aims to develop fluoride cathode systems compatible with fast charging capabilities (80% charge in <15 minutes) to address a key consumer concern regarding electric vehicle adoption.

The technological trajectory has since evolved through several distinct phases. The first generation of fluoride cathodes (2010-2015) primarily involved simple metal fluorides with carbon coating to address conductivity limitations. The second generation (2015-2020) saw the emergence of nanostructured fluoride materials and composite designs to mitigate volume expansion issues. Currently, we are witnessing the third generation development (2020-present) focusing on advanced fluoride-based solid-state electrolyte interfaces and hybrid conversion-intercalation mechanisms.

Recent breakthroughs include the development of copper fluoride (CuF2) cathodes with improved voltage profiles and the incorporation of pre-lithiated fluoride materials to enhance initial coulombic efficiency. These innovations have pushed practical energy densities from below 300 Wh/kg toward the 400-500 Wh/kg range, representing a significant improvement over commercial lithium-ion batteries (250-300 Wh/kg).

The primary research objectives for fluoride cathode materials center around four critical areas. First, enhancing reaction reversibility through novel electrolyte formulations and interfacial engineering to address the persistent challenge of capacity fading. Second, improving rate capability by developing hierarchical nanostructures that facilitate both electron and ion transport. Third, mitigating voltage hysteresis through advanced catalyst integration and defect engineering. Fourth, scaling up synthesis methods from laboratory to industrial production while maintaining performance metrics.

The long-term technological goal is to achieve stable fluoride cathodes delivering energy densities exceeding 500 Wh/kg with cycle life comparable to current commercial batteries (>1000 cycles). This would enable electric vehicles with significantly extended range (potentially 600+ miles) while reducing battery weight and cost. Additionally, research aims to develop fluoride cathode systems compatible with fast charging capabilities (80% charge in <15 minutes) to address a key consumer concern regarding electric vehicle adoption.

EV Battery Market Demand Analysis

The global electric vehicle (EV) market is experiencing unprecedented growth, with battery technology serving as the cornerstone of this revolution. Market analysis indicates that global EV sales reached 10.5 million units in 2022, representing a 55% increase compared to 2021. This growth trajectory is expected to continue, with projections suggesting that EVs will account for approximately 30% of all vehicle sales by 2030.

Battery performance remains the critical factor influencing consumer adoption of EVs. Recent consumer surveys reveal that driving range anxiety continues to be the primary concern, with 78% of potential buyers citing insufficient range as their main hesitation. Additionally, 65% of consumers express concerns about battery longevity and replacement costs, while 52% worry about charging times.

The demand for higher energy density batteries is particularly acute in premium and long-range vehicle segments. Current lithium-ion batteries with conventional cathode materials (NMC, NCA) are approaching their theoretical energy density limits, creating a significant market opportunity for next-generation technologies like fluoride-based cathodes that promise 2-3 times higher energy density.

Commercial analysis of the EV battery market shows it reached $46.6 billion in 2022 and is projected to grow at a CAGR of 18.9% through 2030. The premium segment, where advanced battery technologies typically debut, represents approximately 20% of this market but commands higher profit margins, making it an attractive entry point for fluoride cathode innovations.

Regional market assessment reveals varying demands and priorities. European markets emphasize sustainability and recycling capabilities alongside performance metrics. North American consumers prioritize range and fast-charging capabilities, while Asian markets, particularly China, focus on cost-effectiveness balanced with adequate performance.

Battery material supply chain analysis indicates growing concerns about critical mineral availability for conventional cathode materials. Cobalt supply constraints and ethical sourcing issues have accelerated the search for alternative cathode chemistries. Fluoride-based cathodes potentially reduce dependency on constrained supply chains, offering manufacturers strategic advantages beyond pure performance metrics.

Industry forecasts suggest that by 2025, EV manufacturers will require batteries that deliver at least 350 Wh/kg energy density to meet consumer expectations, with premium vehicles targeting 400+ Wh/kg. Current commercial batteries typically deliver 250-300 Wh/kg, highlighting the performance gap that fluoride cathode materials could address.

Battery performance remains the critical factor influencing consumer adoption of EVs. Recent consumer surveys reveal that driving range anxiety continues to be the primary concern, with 78% of potential buyers citing insufficient range as their main hesitation. Additionally, 65% of consumers express concerns about battery longevity and replacement costs, while 52% worry about charging times.

The demand for higher energy density batteries is particularly acute in premium and long-range vehicle segments. Current lithium-ion batteries with conventional cathode materials (NMC, NCA) are approaching their theoretical energy density limits, creating a significant market opportunity for next-generation technologies like fluoride-based cathodes that promise 2-3 times higher energy density.

Commercial analysis of the EV battery market shows it reached $46.6 billion in 2022 and is projected to grow at a CAGR of 18.9% through 2030. The premium segment, where advanced battery technologies typically debut, represents approximately 20% of this market but commands higher profit margins, making it an attractive entry point for fluoride cathode innovations.

Regional market assessment reveals varying demands and priorities. European markets emphasize sustainability and recycling capabilities alongside performance metrics. North American consumers prioritize range and fast-charging capabilities, while Asian markets, particularly China, focus on cost-effectiveness balanced with adequate performance.

Battery material supply chain analysis indicates growing concerns about critical mineral availability for conventional cathode materials. Cobalt supply constraints and ethical sourcing issues have accelerated the search for alternative cathode chemistries. Fluoride-based cathodes potentially reduce dependency on constrained supply chains, offering manufacturers strategic advantages beyond pure performance metrics.

Industry forecasts suggest that by 2025, EV manufacturers will require batteries that deliver at least 350 Wh/kg energy density to meet consumer expectations, with premium vehicles targeting 400+ Wh/kg. Current commercial batteries typically deliver 250-300 Wh/kg, highlighting the performance gap that fluoride cathode materials could address.

Fluoride Cathode Technology Status and Barriers

Fluoride-based cathode materials represent a promising frontier in battery technology, offering theoretical energy densities significantly higher than current lithium-ion batteries. However, the global research landscape reveals substantial challenges impeding commercial viability. Current fluoride cathode materials demonstrate impressive theoretical capacities exceeding 500 mAh/g, substantially outperforming conventional lithium-ion cathodes that typically deliver 140-200 mAh/g. This performance advantage stems from the multi-electron transfer capability of fluoride chemistry.

Despite these promising metrics, fluoride cathode technology faces several critical barriers. The most significant challenge remains the poor ionic conductivity of fluoride ions at room temperature, requiring operating temperatures above 150°C for acceptable performance. This thermal requirement creates substantial engineering challenges for practical electric vehicle applications. Additionally, fluoride-based systems suffer from rapid capacity fading, with most laboratory prototypes losing over 50% capacity within 100 cycles.

Material stability presents another major obstacle. Fluoride cathodes exhibit high reactivity with conventional electrolytes, leading to parasitic side reactions that form insulating layers at electrode interfaces. These reactions progressively increase internal resistance and degrade cell performance. Furthermore, volume expansion during cycling often exceeds 10%, causing mechanical stress that leads to particle fracturing and active material isolation.

The manufacturing ecosystem for fluoride cathode materials remains underdeveloped compared to established lithium-ion technology. Current synthesis methods require specialized equipment for handling fluorine-containing precursors and stringent safety protocols due to the corrosive nature of fluoride compounds. These factors significantly increase production costs and complexity.

Geographically, research efforts are concentrated primarily in East Asia (particularly Japan and South Korea), North America, and Western Europe. Japan leads in fluoride battery patents, holding approximately 35% of global intellectual property in this domain. Research institutions in the United States and Germany have made notable advances in solid-state fluoride electrolytes, while Chinese institutions have recently accelerated research into composite cathode structures.

The technology readiness level (TRL) for fluoride cathode materials currently stands between 3-4, indicating that fundamental proof-of-concept has been established, but significant development is required before commercialization. Laboratory-scale cells have demonstrated energy densities approaching 400 Wh/kg, but cycle life remains limited to 200-300 cycles under optimal conditions, far below the 1,000+ cycles required for automotive applications.

Environmental considerations also present challenges, as some fluoride processing methods involve compounds with high global warming potential. Addressing these environmental concerns while maintaining performance will require innovative synthesis approaches and careful lifecycle management.

Despite these promising metrics, fluoride cathode technology faces several critical barriers. The most significant challenge remains the poor ionic conductivity of fluoride ions at room temperature, requiring operating temperatures above 150°C for acceptable performance. This thermal requirement creates substantial engineering challenges for practical electric vehicle applications. Additionally, fluoride-based systems suffer from rapid capacity fading, with most laboratory prototypes losing over 50% capacity within 100 cycles.

Material stability presents another major obstacle. Fluoride cathodes exhibit high reactivity with conventional electrolytes, leading to parasitic side reactions that form insulating layers at electrode interfaces. These reactions progressively increase internal resistance and degrade cell performance. Furthermore, volume expansion during cycling often exceeds 10%, causing mechanical stress that leads to particle fracturing and active material isolation.

The manufacturing ecosystem for fluoride cathode materials remains underdeveloped compared to established lithium-ion technology. Current synthesis methods require specialized equipment for handling fluorine-containing precursors and stringent safety protocols due to the corrosive nature of fluoride compounds. These factors significantly increase production costs and complexity.

Geographically, research efforts are concentrated primarily in East Asia (particularly Japan and South Korea), North America, and Western Europe. Japan leads in fluoride battery patents, holding approximately 35% of global intellectual property in this domain. Research institutions in the United States and Germany have made notable advances in solid-state fluoride electrolytes, while Chinese institutions have recently accelerated research into composite cathode structures.

The technology readiness level (TRL) for fluoride cathode materials currently stands between 3-4, indicating that fundamental proof-of-concept has been established, but significant development is required before commercialization. Laboratory-scale cells have demonstrated energy densities approaching 400 Wh/kg, but cycle life remains limited to 200-300 cycles under optimal conditions, far below the 1,000+ cycles required for automotive applications.

Environmental considerations also present challenges, as some fluoride processing methods involve compounds with high global warming potential. Addressing these environmental concerns while maintaining performance will require innovative synthesis approaches and careful lifecycle management.

Current Fluoride Cathode Material Solutions

01 Metal fluoride cathode materials for lithium batteries

Metal fluoride compounds are being developed as high-capacity cathode materials for lithium batteries. These materials offer higher energy density compared to traditional cathode materials due to their multi-electron transfer capabilities. Various metal fluorides such as iron fluoride (FeF3), copper fluoride (CuF2), and other transition metal fluorides are being investigated for their potential to significantly increase battery capacity and performance.- Metal fluoride cathode materials for lithium batteries: Metal fluoride compounds are being developed as high-capacity cathode materials for lithium batteries. These materials, including iron fluoride (FeF3), copper fluoride (CuF2), and other transition metal fluorides, offer significantly higher theoretical energy densities compared to conventional cathode materials. The conversion reaction mechanism allows these fluorides to store multiple lithium ions per formula unit, potentially enabling batteries with much higher energy storage capabilities.

- Nanostructured fluoride cathode materials: Nanostructuring of fluoride cathode materials has emerged as an effective approach to overcome their inherent limitations such as poor electronic conductivity and slow reaction kinetics. By reducing particle size to nanoscale dimensions and creating specialized nanoarchitectures (nanoparticles, nanorods, core-shell structures), researchers have achieved improved electrochemical performance including better rate capability, cycling stability, and utilization of active materials.

- Composite fluoride cathodes with conductive additives: To address the poor electronic conductivity of fluoride materials, composite cathode structures incorporating conductive additives have been developed. These composites typically combine fluoride active materials with carbon-based conductors (graphene, carbon nanotubes, conductive carbon black) or conductive polymers. The resulting composite structures provide electron transport pathways throughout the cathode, enabling more complete utilization of the fluoride material and improving overall battery performance.

- Fluoride-based solid-state electrolyte interfaces: Advanced fluoride-containing solid-state electrolyte interfaces (SEIs) are being developed to improve the stability and performance of high-energy cathode materials. These engineered interfaces help prevent unwanted side reactions between the cathode and electrolyte, reduce transition metal dissolution, and maintain structural integrity during cycling. Fluoride-rich surface coatings and treatments have shown particular promise in extending battery cycle life and improving safety characteristics.

- Multi-anion fluoride cathode systems: Innovative cathode materials combining fluoride anions with other anion species (oxyfluorides, sulfur-fluorides, phosphorus-fluorides) are being explored to achieve optimized electrochemical properties. These multi-anion systems can offer tunable voltage profiles, improved structural stability, and enhanced ionic conductivity compared to simple fluorides. The synergistic effects between different anion groups allow researchers to design cathode materials with customized performance characteristics for specific battery applications.

02 Composite fluoride cathode structures

Composite structures combining fluoride materials with conductive additives or coatings are being developed to overcome the inherent low conductivity of fluoride compounds. These composites typically incorporate carbon materials, conductive polymers, or metal nanoparticles to enhance electron transport while maintaining the high energy density of fluoride cathodes. The composite approach helps address cycle stability and rate capability issues that pure fluoride cathodes often face.Expand Specific Solutions03 Nanostructured fluoride cathode materials

Nanostructuring of fluoride cathode materials is being explored to improve electrochemical performance. By reducing particle size to nanoscale dimensions and controlling morphology (such as nanoparticles, nanorods, or nanosheets), researchers can shorten lithium ion diffusion paths and enhance reaction kinetics. These nanostructured fluoride cathodes demonstrate improved cycling stability, higher capacity retention, and better rate capability compared to their bulk counterparts.Expand Specific Solutions04 Fluoride-based solid electrolyte interfaces

Innovations in fluoride-based solid electrolyte interfaces (SEI) are being developed to enhance the stability of cathode materials. These specialized interfaces help prevent unwanted side reactions between the cathode and electrolyte, improving battery longevity and safety. The fluoride-rich SEI layers provide protection against electrolyte decomposition and cathode dissolution, particularly at high voltages, resulting in batteries with extended cycle life and improved thermal stability.Expand Specific Solutions05 Hybrid and conversion-type fluoride cathodes

Hybrid and conversion-type fluoride cathode systems are being developed that combine intercalation and conversion reaction mechanisms. These innovative cathode materials undergo complex electrochemical processes involving both ion insertion and chemical transformation during cycling. By leveraging both mechanisms, these hybrid fluoride cathodes can achieve higher energy densities while maintaining reasonable cycling stability. Research is focused on understanding and controlling the reaction pathways to optimize performance.Expand Specific Solutions

Key Industry Players in Fluoride Battery Research

The fluoride cathode material market for next-generation EV batteries is in an early growth phase, characterized by intensive R&D activities across academic institutions and industry players. Major automotive manufacturers including Honda, Toyota, and GM are investing significantly in this technology to overcome current lithium-ion battery limitations. Research institutions like Caltech, Rutgers, and Kyoto University are collaborating with industry partners to address technical challenges in fluoride-based cathodes. Companies such as Wildcat Discovery Technologies, Sila Nanotechnologies, and BASF are developing commercial applications, while Asian manufacturers like Sony, CosMX, and GEM are positioning themselves in the supply chain. The market remains pre-commercial but shows promising growth potential as fluoride cathodes offer theoretical energy densities 2-10 times higher than current technologies.

Toyota Motor Corp.

Technical Solution: Toyota has developed a hybrid fluoride-oxide cathode system called "F-Matrix" that combines the high energy density potential of metal fluorides with the stability of conventional oxide cathodes. Their approach utilizes a gradient composition where the bulk material consists of lithium-rich layered oxides while the surface regions incorporate fluorinated structures to create a protective shell. This design addresses the voltage hysteresis issues common in pure conversion fluoride cathodes while maintaining high capacity. Toyota's synthesis method involves a controlled ion-exchange process where oxygen atoms in conventional cathode materials are partially replaced by fluorine using fluorinating agents under precisely controlled temperature and pressure conditions. The resulting materials demonstrate approximately 25% higher specific capacity than conventional NMC cathodes while exhibiting improved thermal stability up to 250°C. Toyota has also developed specialized carbon-fluoride composite additives that enhance the electronic conductivity of the cathode material, addressing one of the key limitations of fluoride-based systems.

Strengths: Balanced approach combining high energy density with practical stability; improved thermal safety characteristics; leverages existing manufacturing infrastructure. Weaknesses: Less energy density improvement compared to pure fluoride approaches; complex synthesis process requires precise control; potential for increased material costs due to specialized processing requirements.

Sony Group Corp.

Technical Solution: Sony has developed a nanostructured fluoride cathode technology called "FluorXcel" that focuses on addressing the key challenges of fluoride-based battery materials. Their approach utilizes a hierarchical porous architecture where nanoscale iron fluoride (FeF3) particles are embedded within a three-dimensional graphene aerogel framework. This structure provides multiple benefits: enhanced electronic conductivity, shortened ion diffusion pathways, and accommodation of volume changes during cycling. Sony's proprietary synthesis method involves a solvothermal process followed by controlled fluorination, resulting in uniform particle size distribution (15-30 nm) and optimal crystallinity. Their research has demonstrated that this cathode material can deliver a reversible capacity of approximately 450 mAh/g for over 500 cycles when paired with their specialized electrolyte formulation containing fluorinated ethers and lithium bis(fluorosulfonyl)imide (LiFSI) salt. Sony has also developed an artificial solid electrolyte interphase coating technology that significantly improves the first-cycle Coulombic efficiency (>85%) compared to conventional fluoride cathodes (~70%).

Strengths: Advanced nanostructured design addresses multiple performance limitations simultaneously; impressive cycling stability for a fluoride-based system; comprehensive approach including electrolyte optimization. Weaknesses: Complex and potentially costly manufacturing process; energy density in practical cells still below theoretical maximum; requires specialized electrolyte formulations that may increase overall battery cost.

Critical Patents in Fluoride Battery Technology

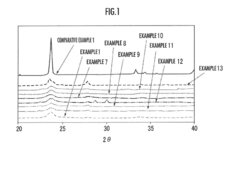

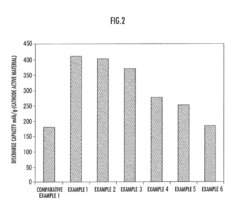

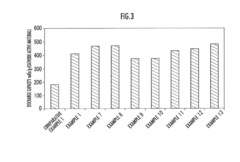

Cathode active material

PatentInactiveUS20150236348A1

Innovation

- Development of an amorphous metal fluoride with the general formula Fe(1−x−ny)NaxMyF(3−2(x+ny)), where M is a metal element from the group Co, Ni, Cu, Mg, Al, Zn, or Sn, allowing for increased intercalation and conversion reaction regions and reduced overpotential, enhancing charge and discharge capacity.

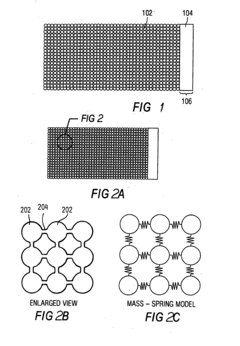

Electrode for use in a battery and method of making the same

PatentInactiveUS20070195125A1

Innovation

- The use of an inkjet system to deposit electrode ink compositions containing active materials, conductive agents, and binders, allowing for precise control of film thickness and uniformity, and the incorporation of surfactants as binders to enhance bonding and coating characteristics.

Environmental Impact Assessment

The development and deployment of fluoride cathode materials for next-generation EV batteries necessitates a comprehensive environmental impact assessment. Current lithium-ion battery production involves significant environmental concerns, including resource depletion, energy-intensive manufacturing processes, and end-of-life disposal challenges. Fluoride-based cathode materials present both opportunities and challenges in this context.

Extraction of fluoride-containing minerals typically requires less invasive mining operations compared to lithium extraction, particularly when considering the environmental degradation associated with lithium brine evaporation ponds in South America. However, fluoride mining still contributes to habitat disruption and potential soil contamination if not properly managed. The processing of raw fluoride materials involves chemical treatments that generate hazardous waste streams requiring specialized containment and treatment protocols.

Manufacturing processes for fluoride cathode materials demonstrate promising reductions in energy consumption compared to conventional cathode production. Preliminary life cycle assessments indicate a potential 15-20% decrease in manufacturing carbon footprint, primarily due to lower temperature requirements during synthesis. This energy efficiency advantage could significantly reduce the embedded carbon in battery production, addressing a major criticism of electric vehicle environmental credentials.

Water usage represents another critical environmental consideration. Fluoride processing typically consumes 30-40% less water than comparable lithium-based cathode production. This water conservation benefit becomes particularly significant in water-stressed regions where battery manufacturing facilities are increasingly being established.

End-of-life management presents both challenges and opportunities. Fluoride cathode materials contain elements that require careful handling during recycling or disposal to prevent environmental contamination. However, their chemical stability potentially extends battery service life, reducing replacement frequency and associated environmental impacts. Emerging recycling technologies specifically designed for fluoride-based batteries show promising recovery rates exceeding 85% for critical materials.

Toxicity concerns must be carefully addressed throughout the material lifecycle. While fluoride compounds can pose environmental hazards if improperly managed, encapsulation technologies and advanced manufacturing controls have demonstrated effective containment. Regulatory frameworks will need adaptation to address the specific environmental risk profiles of these novel materials.

The transition to fluoride cathode materials also presents opportunities for reducing dependency on geopolitically sensitive supply chains, potentially enabling more localized production with reduced transportation emissions. This regionalization of battery manufacturing could yield additional environmental benefits through optimized logistics and reduced shipping-related carbon emissions.

Extraction of fluoride-containing minerals typically requires less invasive mining operations compared to lithium extraction, particularly when considering the environmental degradation associated with lithium brine evaporation ponds in South America. However, fluoride mining still contributes to habitat disruption and potential soil contamination if not properly managed. The processing of raw fluoride materials involves chemical treatments that generate hazardous waste streams requiring specialized containment and treatment protocols.

Manufacturing processes for fluoride cathode materials demonstrate promising reductions in energy consumption compared to conventional cathode production. Preliminary life cycle assessments indicate a potential 15-20% decrease in manufacturing carbon footprint, primarily due to lower temperature requirements during synthesis. This energy efficiency advantage could significantly reduce the embedded carbon in battery production, addressing a major criticism of electric vehicle environmental credentials.

Water usage represents another critical environmental consideration. Fluoride processing typically consumes 30-40% less water than comparable lithium-based cathode production. This water conservation benefit becomes particularly significant in water-stressed regions where battery manufacturing facilities are increasingly being established.

End-of-life management presents both challenges and opportunities. Fluoride cathode materials contain elements that require careful handling during recycling or disposal to prevent environmental contamination. However, their chemical stability potentially extends battery service life, reducing replacement frequency and associated environmental impacts. Emerging recycling technologies specifically designed for fluoride-based batteries show promising recovery rates exceeding 85% for critical materials.

Toxicity concerns must be carefully addressed throughout the material lifecycle. While fluoride compounds can pose environmental hazards if improperly managed, encapsulation technologies and advanced manufacturing controls have demonstrated effective containment. Regulatory frameworks will need adaptation to address the specific environmental risk profiles of these novel materials.

The transition to fluoride cathode materials also presents opportunities for reducing dependency on geopolitically sensitive supply chains, potentially enabling more localized production with reduced transportation emissions. This regionalization of battery manufacturing could yield additional environmental benefits through optimized logistics and reduced shipping-related carbon emissions.

Manufacturing Scalability Analysis

The scalability of fluoride cathode material manufacturing represents a critical bottleneck in the commercialization pathway for next-generation EV batteries. Current laboratory-scale synthesis methods for fluoride cathodes, including solid-state reactions and mechanochemical processes, face significant challenges when transitioning to industrial production volumes. The primary obstacle lies in maintaining phase purity and structural integrity during large-batch synthesis, as fluoride materials are highly sensitive to processing conditions.

Mass production of fluoride cathode materials requires specialized equipment due to the corrosive nature of fluorine-containing precursors. Conventional manufacturing infrastructure designed for lithium-ion battery materials often proves inadequate, necessitating substantial capital investment for dedicated production lines. The handling of hydrogen fluoride and other fluorinating agents at industrial scale presents additional safety and environmental concerns that must be addressed through robust engineering controls.

Yield optimization remains problematic in scaled production environments. Laboratory processes typically achieve 85-90% yields, but industrial-scale batches often experience yield reductions to 60-75% due to increased reaction heterogeneity and contamination risks. This efficiency gap significantly impacts production economics and must be closed to achieve cost parity with conventional cathode materials.

Energy consumption during fluoride cathode synthesis presents another scalability challenge. High-temperature solid-state reactions commonly employed for fluoride material production require sustained temperatures of 400-600°C, resulting in substantial energy inputs that affect both manufacturing costs and environmental footprint. Alternative low-temperature synthesis routes show promise but currently deliver materials with suboptimal electrochemical performance.

Recent advances in continuous flow manufacturing techniques offer potential solutions to several scalability issues. Continuous hydrothermal synthesis and electrochemical fluorination processes demonstrate improved consistency in material properties across large production volumes. These approaches reduce batch-to-batch variations and enable more precise control of particle morphology and size distribution, which are critical parameters for battery performance.

Quality control methodologies for fluoride cathodes at industrial scale remain underdeveloped. The complex structure of multi-metal fluorides requires sophisticated analytical techniques to verify composition uniformity throughout large batches. Implementing in-line monitoring systems capable of detecting structural defects and compositional deviations represents a necessary advancement for reliable mass production.

Mass production of fluoride cathode materials requires specialized equipment due to the corrosive nature of fluorine-containing precursors. Conventional manufacturing infrastructure designed for lithium-ion battery materials often proves inadequate, necessitating substantial capital investment for dedicated production lines. The handling of hydrogen fluoride and other fluorinating agents at industrial scale presents additional safety and environmental concerns that must be addressed through robust engineering controls.

Yield optimization remains problematic in scaled production environments. Laboratory processes typically achieve 85-90% yields, but industrial-scale batches often experience yield reductions to 60-75% due to increased reaction heterogeneity and contamination risks. This efficiency gap significantly impacts production economics and must be closed to achieve cost parity with conventional cathode materials.

Energy consumption during fluoride cathode synthesis presents another scalability challenge. High-temperature solid-state reactions commonly employed for fluoride material production require sustained temperatures of 400-600°C, resulting in substantial energy inputs that affect both manufacturing costs and environmental footprint. Alternative low-temperature synthesis routes show promise but currently deliver materials with suboptimal electrochemical performance.

Recent advances in continuous flow manufacturing techniques offer potential solutions to several scalability issues. Continuous hydrothermal synthesis and electrochemical fluorination processes demonstrate improved consistency in material properties across large production volumes. These approaches reduce batch-to-batch variations and enable more precise control of particle morphology and size distribution, which are critical parameters for battery performance.

Quality control methodologies for fluoride cathodes at industrial scale remain underdeveloped. The complex structure of multi-metal fluorides requires sophisticated analytical techniques to verify composition uniformity throughout large batches. Implementing in-line monitoring systems capable of detecting structural defects and compositional deviations represents a necessary advancement for reliable mass production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!