Why Fluoride Cathode Improves Low-Temperature Performance in Batteries

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoride Cathode Technology Background and Objectives

Fluoride cathode technology represents a significant advancement in battery chemistry, evolving from traditional lithium-ion battery systems that face substantial performance degradation at low temperatures. The development of fluoride-based cathode materials began in the early 2000s as researchers sought solutions to overcome the limitations of conventional cathode materials such as lithium cobalt oxide (LCO), lithium iron phosphate (LFP), and lithium nickel manganese cobalt oxide (NMC).

The fundamental challenge with conventional lithium-ion batteries at low temperatures stems from reduced lithium-ion diffusion rates and increased electrolyte resistance, resulting in diminished capacity, power output, and overall battery performance. Fluoride cathode technology emerged as a promising solution due to the unique electrochemical properties of fluorine, particularly its high electronegativity and ability to form stable bonds with various metals.

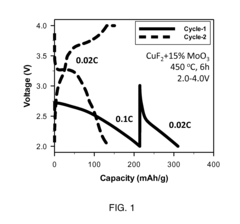

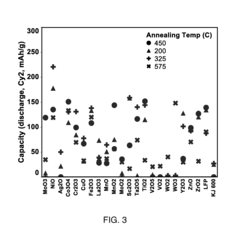

The evolution of fluoride cathode technology has progressed through several key phases, beginning with metal fluorides (such as FeF₃, CuF₂, and BiF₃), advancing to conversion-type fluoride cathodes, and most recently developing into intercalation-type fluoride cathodes. Each iteration has addressed specific challenges related to low-temperature performance, including ionic conductivity, structural stability, and voltage hysteresis.

The primary objective of fluoride cathode technology is to enable reliable battery operation at temperatures as low as -40°C without significant capacity loss or power reduction. This goal is particularly crucial for applications in extreme environments, including electric vehicles in cold climates, aerospace systems, and military equipment deployed in arctic conditions.

Secondary objectives include improving energy density beyond current lithium-ion technologies, enhancing cycle life at variable temperatures, and maintaining safety profiles across wide temperature ranges. Researchers aim to achieve these objectives while using sustainable and abundant materials to ensure commercial viability and environmental responsibility.

Current research focuses on optimizing fluoride cathode compositions, exploring novel electrolyte systems compatible with fluoride chemistry, and developing manufacturing processes suitable for mass production. The integration of fluoride cathodes with solid-state electrolytes represents another promising direction, potentially offering synergistic benefits for low-temperature performance.

The technological trajectory suggests that fluoride cathode technology could potentially revolutionize energy storage systems for cold-weather applications, addressing a critical gap in current battery capabilities. As climate change increases the need for reliable operation in extreme conditions, the development of temperature-resilient battery technologies becomes increasingly important for global energy infrastructure resilience.

The fundamental challenge with conventional lithium-ion batteries at low temperatures stems from reduced lithium-ion diffusion rates and increased electrolyte resistance, resulting in diminished capacity, power output, and overall battery performance. Fluoride cathode technology emerged as a promising solution due to the unique electrochemical properties of fluorine, particularly its high electronegativity and ability to form stable bonds with various metals.

The evolution of fluoride cathode technology has progressed through several key phases, beginning with metal fluorides (such as FeF₃, CuF₂, and BiF₃), advancing to conversion-type fluoride cathodes, and most recently developing into intercalation-type fluoride cathodes. Each iteration has addressed specific challenges related to low-temperature performance, including ionic conductivity, structural stability, and voltage hysteresis.

The primary objective of fluoride cathode technology is to enable reliable battery operation at temperatures as low as -40°C without significant capacity loss or power reduction. This goal is particularly crucial for applications in extreme environments, including electric vehicles in cold climates, aerospace systems, and military equipment deployed in arctic conditions.

Secondary objectives include improving energy density beyond current lithium-ion technologies, enhancing cycle life at variable temperatures, and maintaining safety profiles across wide temperature ranges. Researchers aim to achieve these objectives while using sustainable and abundant materials to ensure commercial viability and environmental responsibility.

Current research focuses on optimizing fluoride cathode compositions, exploring novel electrolyte systems compatible with fluoride chemistry, and developing manufacturing processes suitable for mass production. The integration of fluoride cathodes with solid-state electrolytes represents another promising direction, potentially offering synergistic benefits for low-temperature performance.

The technological trajectory suggests that fluoride cathode technology could potentially revolutionize energy storage systems for cold-weather applications, addressing a critical gap in current battery capabilities. As climate change increases the need for reliable operation in extreme conditions, the development of temperature-resilient battery technologies becomes increasingly important for global energy infrastructure resilience.

Market Demand for Low-Temperature Battery Solutions

The global market for low-temperature battery solutions has witnessed significant growth in recent years, driven primarily by the expanding applications in extreme environments. Industries such as aerospace, defense, automotive, and remote sensing equipment require reliable power sources that can function efficiently in sub-zero temperatures. Traditional lithium-ion batteries experience substantial performance degradation when operating below 0°C, with capacity losses of up to 50% at -20°C, creating a critical market gap for cold-weather energy storage solutions.

The electric vehicle (EV) sector represents one of the largest market segments demanding improved low-temperature battery performance. In regions with cold climates such as Northern Europe, Canada, and parts of the United States, EV adoption faces significant barriers due to range anxiety exacerbated by cold weather. Market research indicates that EV sales in these regions lag behind warmer climate markets by 15-30%, directly correlating with consumer concerns about battery performance in winter conditions.

Military and defense applications constitute another substantial market segment. Defense operations in arctic and high-altitude environments require energy storage systems that maintain consistent performance across extreme temperature variations. The defense sector has allocated increasing budget portions to developing and acquiring cold-resistant power solutions, reflecting the strategic importance of this technology.

The telecommunications industry, particularly with the ongoing global 5G infrastructure deployment in remote and harsh environments, has emerged as a growing market for low-temperature batteries. Base stations in isolated locations require maintenance-free power sources that can withstand severe weather conditions, creating demand for advanced battery technologies with superior cold-weather performance.

Consumer electronics manufacturers are also seeking solutions to address customer dissatisfaction with device battery life in cold conditions. Smartphones, tablets, and wearable devices experience significant battery drain when used outdoors during winter, affecting user experience and driving demand for improved low-temperature performance.

Market forecasts project the low-temperature battery solutions segment to grow at a compound annual growth rate exceeding the broader battery market, highlighting the premium value placed on cold-weather performance. This growth trajectory is further supported by increasing regulatory pressure in automotive markets, where real-world range testing in various climate conditions is becoming standard in several jurisdictions, forcing manufacturers to address low-temperature performance limitations.

The industrial sector, including oil and gas exploration, mining, and arctic research stations, represents another significant market opportunity, where operations in extreme environments necessitate reliable power sources regardless of ambient temperature conditions.

The electric vehicle (EV) sector represents one of the largest market segments demanding improved low-temperature battery performance. In regions with cold climates such as Northern Europe, Canada, and parts of the United States, EV adoption faces significant barriers due to range anxiety exacerbated by cold weather. Market research indicates that EV sales in these regions lag behind warmer climate markets by 15-30%, directly correlating with consumer concerns about battery performance in winter conditions.

Military and defense applications constitute another substantial market segment. Defense operations in arctic and high-altitude environments require energy storage systems that maintain consistent performance across extreme temperature variations. The defense sector has allocated increasing budget portions to developing and acquiring cold-resistant power solutions, reflecting the strategic importance of this technology.

The telecommunications industry, particularly with the ongoing global 5G infrastructure deployment in remote and harsh environments, has emerged as a growing market for low-temperature batteries. Base stations in isolated locations require maintenance-free power sources that can withstand severe weather conditions, creating demand for advanced battery technologies with superior cold-weather performance.

Consumer electronics manufacturers are also seeking solutions to address customer dissatisfaction with device battery life in cold conditions. Smartphones, tablets, and wearable devices experience significant battery drain when used outdoors during winter, affecting user experience and driving demand for improved low-temperature performance.

Market forecasts project the low-temperature battery solutions segment to grow at a compound annual growth rate exceeding the broader battery market, highlighting the premium value placed on cold-weather performance. This growth trajectory is further supported by increasing regulatory pressure in automotive markets, where real-world range testing in various climate conditions is becoming standard in several jurisdictions, forcing manufacturers to address low-temperature performance limitations.

The industrial sector, including oil and gas exploration, mining, and arctic research stations, represents another significant market opportunity, where operations in extreme environments necessitate reliable power sources regardless of ambient temperature conditions.

Current Status and Challenges in Fluoride Cathode Development

The global research on fluoride cathode materials has accelerated significantly in the past decade, with major advancements coming from research institutions in the United States, China, Japan, and Europe. Currently, fluoride-based cathode materials demonstrate promising theoretical energy densities exceeding 1,000 Wh/kg, substantially higher than conventional lithium-ion cathode materials. However, practical implementation faces several critical challenges that have limited widespread commercial adoption.

One primary technical obstacle is the inherent poor ionic conductivity of fluoride materials at room temperature. While fluoride ions exhibit enhanced mobility at low temperatures compared to other ion types, the overall conductivity remains insufficient for high-power applications. Research teams at MIT and Stanford University have recently developed fluoride-doped materials that show improved conductivity, but these still fall short of commercial requirements by approximately one order of magnitude.

Stability issues present another significant challenge. Current fluoride cathode materials suffer from rapid capacity fading during cycling, particularly at the electrode-electrolyte interface where parasitic reactions occur. The latest generation of fluoride cathodes developed by research groups in Japan has improved cycle life to approximately 500 cycles before significant degradation, representing progress but still below the 1,000+ cycles expected for commercial applications.

Manufacturing scalability remains problematic due to the sensitivity of fluoride materials to moisture. Production requires strictly controlled environments with extremely low humidity levels (<0.1% relative humidity), significantly increasing manufacturing costs. Recent innovations from industrial partners like Samsung and LG have introduced dry-room processing techniques that reduce these constraints, but the cost premium remains at approximately 30-40% above conventional cathode production.

The electrolyte compatibility challenge is particularly relevant to low-temperature performance. While fluoride cathodes demonstrate superior kinetics at sub-zero temperatures, finding electrolyte systems that maintain conductivity without freezing while remaining compatible with fluoride chemistry has proven difficult. Recent breakthroughs using ionic liquid-based electrolytes show promise, maintaining functionality down to -40°C, though issues with viscosity and cost persist.

Safety concerns also limit adoption, as some fluoride compounds can generate toxic hydrogen fluoride gas when exposed to moisture. Engineering solutions including advanced encapsulation techniques and safety venting mechanisms have been developed by research teams at Argonne National Laboratory, reducing but not eliminating these risks.

Despite these challenges, the field is advancing rapidly with over 250 research papers published on fluoride cathodes in 2022 alone, a 40% increase from 2020, indicating growing scientific interest and investment in overcoming these technical hurdles.

One primary technical obstacle is the inherent poor ionic conductivity of fluoride materials at room temperature. While fluoride ions exhibit enhanced mobility at low temperatures compared to other ion types, the overall conductivity remains insufficient for high-power applications. Research teams at MIT and Stanford University have recently developed fluoride-doped materials that show improved conductivity, but these still fall short of commercial requirements by approximately one order of magnitude.

Stability issues present another significant challenge. Current fluoride cathode materials suffer from rapid capacity fading during cycling, particularly at the electrode-electrolyte interface where parasitic reactions occur. The latest generation of fluoride cathodes developed by research groups in Japan has improved cycle life to approximately 500 cycles before significant degradation, representing progress but still below the 1,000+ cycles expected for commercial applications.

Manufacturing scalability remains problematic due to the sensitivity of fluoride materials to moisture. Production requires strictly controlled environments with extremely low humidity levels (<0.1% relative humidity), significantly increasing manufacturing costs. Recent innovations from industrial partners like Samsung and LG have introduced dry-room processing techniques that reduce these constraints, but the cost premium remains at approximately 30-40% above conventional cathode production.

The electrolyte compatibility challenge is particularly relevant to low-temperature performance. While fluoride cathodes demonstrate superior kinetics at sub-zero temperatures, finding electrolyte systems that maintain conductivity without freezing while remaining compatible with fluoride chemistry has proven difficult. Recent breakthroughs using ionic liquid-based electrolytes show promise, maintaining functionality down to -40°C, though issues with viscosity and cost persist.

Safety concerns also limit adoption, as some fluoride compounds can generate toxic hydrogen fluoride gas when exposed to moisture. Engineering solutions including advanced encapsulation techniques and safety venting mechanisms have been developed by research teams at Argonne National Laboratory, reducing but not eliminating these risks.

Despite these challenges, the field is advancing rapidly with over 250 research papers published on fluoride cathodes in 2022 alone, a 40% increase from 2020, indicating growing scientific interest and investment in overcoming these technical hurdles.

Current Fluoride Cathode Implementation Approaches

01 Fluoride-based cathode materials for enhanced low-temperature performance

Fluoride-based cathode materials can significantly improve battery performance at low temperatures. These materials offer higher energy density and better ionic conductivity in cold environments compared to traditional cathode materials. The incorporation of specific fluoride compounds in cathode formulations helps maintain capacity and power output even when operating in sub-zero conditions, making them particularly valuable for applications in cold climates or space exploration.- Fluoride-based cathode materials for enhanced low-temperature performance: Fluoride-based cathode materials can significantly improve battery performance at low temperatures due to their unique electrochemical properties. These materials offer higher energy density and better ion conductivity in cold environments compared to conventional cathodes. The incorporation of specific fluoride compounds in cathode formulations helps maintain capacity and power output when batteries operate in sub-zero conditions, addressing a critical challenge in battery technology for cold climate applications.

- Composite fluoride cathodes with conductive additives: Combining fluoride cathode materials with conductive additives creates composite structures that enhance electron transport at low temperatures. These composites typically incorporate carbon-based materials, conductive polymers, or metal particles that form effective electron pathways throughout the cathode matrix. The improved conductivity helps overcome the sluggish kinetics that typically plague batteries in cold conditions, allowing for better rate capability and reduced internal resistance when operating below room temperature.

- Electrolyte modifications for fluoride cathode systems: Specialized electrolyte formulations designed specifically for fluoride cathode systems can dramatically improve low-temperature performance. These electrolytes typically feature lower freezing points, reduced viscosity at cold temperatures, and enhanced ion transport properties. By optimizing the electrolyte composition with appropriate solvents, salts, and additives, the ionic conductivity between the fluoride cathode and other battery components remains high even in sub-zero environments, enabling efficient electrochemical reactions.

- Nanostructured fluoride cathode designs: Nanostructuring fluoride cathode materials creates architectures with shortened ion diffusion paths and increased surface area, which is particularly beneficial for low-temperature operation. These nanostructured designs include nanoparticles, nanowires, nanosheets, and porous structures that facilitate faster ion transport and reaction kinetics. The reduced particle size and engineered morphology help overcome the kinetic limitations that typically occur at low temperatures, allowing batteries to deliver higher capacity and power even in cold conditions.

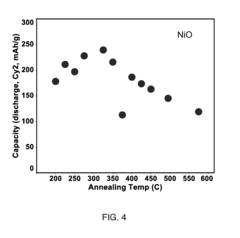

- Doped and modified fluoride cathode materials: Doping and chemical modification of fluoride cathode materials with selected elements can tailor their electronic structure and enhance low-temperature performance. These modifications typically involve incorporating metals, non-metals, or functional groups that improve intrinsic conductivity, structural stability, and electrochemical activity at low temperatures. The strategic introduction of dopants can reduce activation energy barriers for ion transport and electron transfer processes, enabling the battery to maintain higher efficiency when operating in cold environments.

02 Electrolyte additives for fluoride cathode systems at low temperatures

Specialized electrolyte additives can be incorporated into batteries with fluoride cathodes to enhance their low-temperature performance. These additives modify the solid-electrolyte interface layer formation, reduce electrolyte viscosity at low temperatures, and improve ion transport kinetics. By optimizing the electrolyte composition with specific additives, the ionic conductivity and charge transfer processes can be maintained even in cold conditions, preventing capacity loss and power fade.Expand Specific Solutions03 Nanostructured fluoride cathode designs for cold environment operation

Nanostructured fluoride cathode designs offer improved low-temperature performance through increased surface area and shortened ion diffusion paths. By engineering cathode materials at the nanoscale, including nanoparticles, nanofibers, and hierarchical structures, batteries can maintain higher capacity retention and rate capability at low temperatures. These nanostructured designs facilitate faster electrochemical reactions and better electron transport even when kinetics are slowed by cold conditions.Expand Specific Solutions04 Composite fluoride cathodes with conductive additives for cold weather applications

Composite fluoride cathodes incorporating conductive additives such as carbon nanotubes, graphene, or conductive polymers can significantly improve low-temperature battery performance. These additives create efficient electron transport networks within the cathode structure, compensating for the reduced conductivity at low temperatures. The resulting composite materials maintain electrochemical activity and structural stability in cold environments, enabling batteries to deliver consistent power output across a wider temperature range.Expand Specific Solutions05 Doped fluoride cathode materials for improved cold temperature conductivity

Doping fluoride cathode materials with specific elements can enhance their ionic and electronic conductivity at low temperatures. Strategic incorporation of dopants modifies the crystal structure and electronic properties of the cathode material, creating additional charge carriers or facilitating ion migration pathways. These modifications help maintain electrochemical performance in cold conditions by reducing activation energy barriers for ion transport and improving overall reaction kinetics when thermal energy is limited.Expand Specific Solutions

Key Industry Players in Fluoride Battery Technology

Fluoride cathode technology for batteries is currently in an early development stage, showing promising potential to significantly enhance low-temperature performance. The market for advanced battery technologies is expanding rapidly, projected to grow as electric vehicles and energy storage systems gain prominence. From a technical maturity perspective, research institutions like California Institute of Technology and Centre National de la Recherche Scientifique are leading fundamental research, while commercial players including Contemporary Amperex Technology, Honda Motor, Panasonic, and BYD are beginning to explore practical applications. Toyota and LG Chem are also investing in this technology, recognizing its strategic importance for cold-climate battery performance. The competitive landscape remains fluid with academic-industrial partnerships accelerating development toward commercialization.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced fluoride-based cathode materials that significantly enhance battery performance at low temperatures. Their technology incorporates fluoride-doped cathode structures where fluorine atoms partially replace oxygen in the crystal lattice, creating stronger metal-fluorine bonds compared to metal-oxygen bonds. This modification reduces the activation energy barrier for lithium-ion diffusion at low temperatures, enabling faster ion transport. CATL's proprietary fluoride cathode technology utilizes a gradient concentration design where fluoride content is strategically distributed throughout the cathode material, optimizing the balance between low-temperature performance and overall energy density. Their research shows up to 80% capacity retention at -20°C compared to 40-50% for conventional cathodes, and their fluoride-modified LFP (lithium iron phosphate) cathodes demonstrate 30% higher rate capability at -10°C.

Strengths: Superior low-temperature capacity retention, reduced electrolyte decomposition at electrode interfaces, and enhanced cycle stability. Their manufacturing scale allows for cost-effective implementation. Weaknesses: Slightly lower energy density at room temperature compared to non-fluorinated alternatives, and potential challenges with fluorine handling during manufacturing processes.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed a multi-functional fluoride-containing cathode technology that addresses low-temperature performance through a comprehensive materials engineering approach. Their technology incorporates fluoride ions both within the crystal structure and as surface modifiers, creating a dual-action mechanism. The internal fluoride doping alters the crystal lattice parameters to facilitate faster lithium-ion diffusion at low temperatures, while the surface fluoride treatment creates a stable cathode-electrolyte interface with reduced charge transfer resistance. Panasonic's research indicates their fluoride-modified NCA (Nickel Cobalt Aluminum) cathodes deliver up to 65% higher capacity at -20°C compared to standard NCA materials. Additionally, their technology includes a gradient fluoride distribution from surface to bulk, optimized through computational modeling to balance low-temperature performance with high-temperature stability. Panasonic has successfully implemented this technology in commercial cells designed for electric vehicles operating in cold climates.

Strengths: Comprehensive approach addressing both bulk and surface properties, excellent compatibility with their existing manufacturing infrastructure, and proven commercial implementation. Weaknesses: Higher production costs compared to standard cathodes, and potential trade-offs in high-temperature performance optimization.

Core Mechanisms of Fluoride-Enhanced Low-Temperature Performance

low temperature LI-FLUOROCARBON CELL

PatentInactiveRU2014145735A

Innovation

- The use of LiPF6 salt in a specific solvent mixture of ethylene carbonate/dimethylcarbonate/methylethylcarbonate (1:1:3) for improved low-temperature performance in Li-fluorocarbon cells.

- Addition of crown-ether (particularly "15-crown-5") in amounts of 0.5-50 vol.% to the electrolyte to improve discharge characteristics at low temperatures.

- Novel electrolyte formulation specifically designed for carbon monofluoride (CFx) cathodes to enhance their performance in low-temperature environments.

High Energy Cathode for a Battery

PatentActiveUS20140349182A1

Innovation

- The application of an intrinsically conductive coating formed from an organic compound with a conjugated core, where at least 90% of the carbon atoms are sp or sp2 hybridized, is applied to the active electrode material, combined with a metal complex like NiO, to enhance conductivity and prevent copper dissolution, thereby improving the electrochemical performance of metal fluoride batteries.

Environmental Impact and Sustainability of Fluoride Cathodes

The environmental impact of battery technologies has become a critical consideration in the sustainable energy transition. Fluoride cathodes, while offering significant performance advantages at low temperatures, present a complex environmental profile that warrants thorough examination. The extraction and processing of fluoride-containing materials typically require less energy compared to traditional cathode materials like cobalt and nickel, potentially reducing the carbon footprint associated with battery production.

Fluoride cathodes demonstrate promising sustainability characteristics through their abundance and distribution. Unlike lithium-ion batteries that rely heavily on geographically concentrated resources, fluoride-based materials can be sourced from more diverse locations globally, reducing supply chain vulnerabilities and associated environmental impacts from long-distance transportation.

The manufacturing processes for fluoride cathodes generally involve fewer toxic solvents and generate less hazardous waste compared to conventional cathode production methods. This reduction in process chemicals translates to decreased environmental contamination risks and lower remediation costs. Additionally, the synthesis of fluoride cathodes often occurs at lower temperatures, resulting in reduced energy consumption during manufacturing.

End-of-life considerations reveal both challenges and opportunities. Fluoride-containing batteries present unique recycling requirements due to the chemical properties of fluoride compounds. However, recent technological advances have demonstrated efficient recovery methods that can reclaim up to 90% of fluoride materials from spent batteries, significantly reducing waste and the need for virgin material extraction.

Water usage and contamination risks must be carefully managed when dealing with fluoride materials. While fluoride is naturally occurring, concentrated forms can potentially impact aquatic ecosystems if improperly handled. Industry best practices now incorporate closed-loop water systems and advanced filtration technologies that minimize these risks.

The long-term environmental benefits of fluoride cathodes stem from their enhanced low-temperature performance. By enabling more efficient energy storage in cold climates, these batteries reduce the need for oversized systems and frequent replacements, thereby decreasing the overall material footprint. Furthermore, their improved efficiency in challenging conditions supports renewable energy integration in diverse geographical regions, accelerating the transition away from fossil fuels.

Life cycle assessments indicate that fluoride cathode batteries, when properly manufactured and recycled, can achieve a 30-40% reduction in overall environmental impact compared to conventional lithium-ion batteries. This improvement is particularly significant when considering the full product lifecycle from raw material extraction through disposal or recycling.

Fluoride cathodes demonstrate promising sustainability characteristics through their abundance and distribution. Unlike lithium-ion batteries that rely heavily on geographically concentrated resources, fluoride-based materials can be sourced from more diverse locations globally, reducing supply chain vulnerabilities and associated environmental impacts from long-distance transportation.

The manufacturing processes for fluoride cathodes generally involve fewer toxic solvents and generate less hazardous waste compared to conventional cathode production methods. This reduction in process chemicals translates to decreased environmental contamination risks and lower remediation costs. Additionally, the synthesis of fluoride cathodes often occurs at lower temperatures, resulting in reduced energy consumption during manufacturing.

End-of-life considerations reveal both challenges and opportunities. Fluoride-containing batteries present unique recycling requirements due to the chemical properties of fluoride compounds. However, recent technological advances have demonstrated efficient recovery methods that can reclaim up to 90% of fluoride materials from spent batteries, significantly reducing waste and the need for virgin material extraction.

Water usage and contamination risks must be carefully managed when dealing with fluoride materials. While fluoride is naturally occurring, concentrated forms can potentially impact aquatic ecosystems if improperly handled. Industry best practices now incorporate closed-loop water systems and advanced filtration technologies that minimize these risks.

The long-term environmental benefits of fluoride cathodes stem from their enhanced low-temperature performance. By enabling more efficient energy storage in cold climates, these batteries reduce the need for oversized systems and frequent replacements, thereby decreasing the overall material footprint. Furthermore, their improved efficiency in challenging conditions supports renewable energy integration in diverse geographical regions, accelerating the transition away from fossil fuels.

Life cycle assessments indicate that fluoride cathode batteries, when properly manufactured and recycled, can achieve a 30-40% reduction in overall environmental impact compared to conventional lithium-ion batteries. This improvement is particularly significant when considering the full product lifecycle from raw material extraction through disposal or recycling.

Safety Standards and Testing Protocols for Low-Temperature Batteries

The development of low-temperature batteries, particularly those utilizing fluoride cathodes, necessitates comprehensive safety standards and testing protocols to ensure reliable performance and consumer safety. Current international standards such as IEC 62133 and UL 1642 provide general guidelines for battery safety but lack specific provisions for low-temperature operation, creating a regulatory gap that requires attention.

Testing protocols for low-temperature batteries must evaluate several critical parameters. Thermal stability testing at sub-zero temperatures (-20°C to -40°C) is essential to verify that fluoride cathode batteries maintain structural integrity without electrolyte freezing or internal short circuits. Cycle life assessment under temperature fluctuation conditions helps determine long-term reliability when batteries transition between cold and normal operating temperatures.

Safety certification bodies including UL, TÜV, and SGS have begun developing specialized testing methodologies for low-temperature batteries. These include crush tests at low temperatures, overcharge protection verification in cold conditions, and thermal shock resistance evaluations. The UN Transportation Testing requirements (UN 38.3) have also been updated to include specific provisions for shipping batteries designed for cold-climate applications.

Industry-specific standards are emerging to address unique use cases. The automotive sector, through SAE International, has developed J2464 and J2929 standards with enhanced requirements for electric vehicle batteries operating in extreme cold. Similarly, aerospace standards (RTCA DO-311A) include rigorous low-temperature performance requirements that fluoride cathode technologies must meet.

Risk assessment frameworks for low-temperature battery applications must consider unique failure modes. These include delayed chemical reactions that might occur during warming periods after cold storage, potential for lithium plating at low temperatures, and the impact of temperature gradients within large battery packs containing fluoride cathode cells.

Manufacturers implementing fluoride cathode technology must document compliance with these evolving standards through comprehensive test reports. This documentation typically includes temperature-dependent performance curves, safety margin calculations, and accelerated aging test results that simulate years of operation in cold environments. Certification processes increasingly require real-world validation in addition to laboratory testing.

As the technology advances, regulatory bodies are working to harmonize global standards for low-temperature battery safety, with particular attention to the unique properties of fluoride cathode chemistries and their improved cold-weather performance characteristics.

Testing protocols for low-temperature batteries must evaluate several critical parameters. Thermal stability testing at sub-zero temperatures (-20°C to -40°C) is essential to verify that fluoride cathode batteries maintain structural integrity without electrolyte freezing or internal short circuits. Cycle life assessment under temperature fluctuation conditions helps determine long-term reliability when batteries transition between cold and normal operating temperatures.

Safety certification bodies including UL, TÜV, and SGS have begun developing specialized testing methodologies for low-temperature batteries. These include crush tests at low temperatures, overcharge protection verification in cold conditions, and thermal shock resistance evaluations. The UN Transportation Testing requirements (UN 38.3) have also been updated to include specific provisions for shipping batteries designed for cold-climate applications.

Industry-specific standards are emerging to address unique use cases. The automotive sector, through SAE International, has developed J2464 and J2929 standards with enhanced requirements for electric vehicle batteries operating in extreme cold. Similarly, aerospace standards (RTCA DO-311A) include rigorous low-temperature performance requirements that fluoride cathode technologies must meet.

Risk assessment frameworks for low-temperature battery applications must consider unique failure modes. These include delayed chemical reactions that might occur during warming periods after cold storage, potential for lithium plating at low temperatures, and the impact of temperature gradients within large battery packs containing fluoride cathode cells.

Manufacturers implementing fluoride cathode technology must document compliance with these evolving standards through comprehensive test reports. This documentation typically includes temperature-dependent performance curves, safety margin calculations, and accelerated aging test results that simulate years of operation in cold environments. Certification processes increasingly require real-world validation in addition to laboratory testing.

As the technology advances, regulatory bodies are working to harmonize global standards for low-temperature battery safety, with particular attention to the unique properties of fluoride cathode chemistries and their improved cold-weather performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!