Fluoride Cathode Market Trends and Industry Potential Analysis

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoride Cathode Technology Evolution and Objectives

Fluoride cathode technology has evolved significantly over the past two decades, emerging as a promising alternative to conventional lithium-ion battery cathode materials. The development trajectory began in the early 2000s with fundamental research on metal fluorides as conversion-type cathode materials, characterized by their high theoretical capacities but plagued by poor conductivity and cycling stability issues.

By 2010, researchers had made substantial progress in addressing these limitations through nanostructuring approaches and carbon composite formations. The incorporation of conductive carbon matrices significantly improved electron transport properties, while nanoscale engineering enhanced reaction kinetics and structural stability during charge-discharge cycles.

A pivotal advancement occurred around 2015 with the development of core-shell architectures and hierarchical structures that effectively mitigated volume expansion issues and improved cycling performance. This period also saw the emergence of multi-component fluoride systems that offered enhanced electrochemical properties compared to single-metal fluorides.

Recent technological evolution has focused on solid-state electrolyte integration with fluoride cathodes to address safety concerns and enable higher energy densities. Advanced synthesis methods, including mechanochemical processes and solution-based approaches, have enabled better control over particle morphology and composition, resulting in improved performance metrics.

The primary objective of current fluoride cathode research is to achieve commercially viable energy storage solutions that surpass the limitations of existing lithium-ion technologies. Specific technical goals include reaching energy densities exceeding 500 Wh/kg at the cell level, achieving cycle life beyond 1,000 cycles with minimal capacity degradation, and developing manufacturing processes compatible with existing battery production infrastructure.

Additional objectives include reducing the voltage hysteresis characteristic of conversion reactions, improving rate capability for fast-charging applications, and enhancing low-temperature performance. Environmental considerations have also become increasingly important, with research aimed at developing fluoride cathodes with reduced environmental footprint and improved recyclability.

The technology roadmap extends to exploring novel fluoride chemistries beyond the currently dominant iron, copper, and cobalt fluorides, with particular interest in multi-electron transfer systems that could potentially double or triple energy storage capacity. Computational modeling and artificial intelligence approaches are being leveraged to accelerate materials discovery and optimization, with the ultimate goal of bringing fluoride-based batteries to market within the next 5-7 years for specialized applications, followed by broader commercial deployment.

By 2010, researchers had made substantial progress in addressing these limitations through nanostructuring approaches and carbon composite formations. The incorporation of conductive carbon matrices significantly improved electron transport properties, while nanoscale engineering enhanced reaction kinetics and structural stability during charge-discharge cycles.

A pivotal advancement occurred around 2015 with the development of core-shell architectures and hierarchical structures that effectively mitigated volume expansion issues and improved cycling performance. This period also saw the emergence of multi-component fluoride systems that offered enhanced electrochemical properties compared to single-metal fluorides.

Recent technological evolution has focused on solid-state electrolyte integration with fluoride cathodes to address safety concerns and enable higher energy densities. Advanced synthesis methods, including mechanochemical processes and solution-based approaches, have enabled better control over particle morphology and composition, resulting in improved performance metrics.

The primary objective of current fluoride cathode research is to achieve commercially viable energy storage solutions that surpass the limitations of existing lithium-ion technologies. Specific technical goals include reaching energy densities exceeding 500 Wh/kg at the cell level, achieving cycle life beyond 1,000 cycles with minimal capacity degradation, and developing manufacturing processes compatible with existing battery production infrastructure.

Additional objectives include reducing the voltage hysteresis characteristic of conversion reactions, improving rate capability for fast-charging applications, and enhancing low-temperature performance. Environmental considerations have also become increasingly important, with research aimed at developing fluoride cathodes with reduced environmental footprint and improved recyclability.

The technology roadmap extends to exploring novel fluoride chemistries beyond the currently dominant iron, copper, and cobalt fluorides, with particular interest in multi-electron transfer systems that could potentially double or triple energy storage capacity. Computational modeling and artificial intelligence approaches are being leveraged to accelerate materials discovery and optimization, with the ultimate goal of bringing fluoride-based batteries to market within the next 5-7 years for specialized applications, followed by broader commercial deployment.

Market Demand Analysis for Fluoride Cathode Materials

The global market for fluoride cathode materials has witnessed significant growth in recent years, primarily driven by the expanding electric vehicle (EV) industry and increasing demand for high-performance energy storage solutions. Market research indicates that the fluoride cathode segment is expected to grow at a compound annual growth rate of 8.5% through 2030, outpacing several other battery material categories.

Consumer electronics represent another substantial market driver, with portable devices requiring increasingly efficient power sources. The demand for longer battery life and faster charging capabilities has positioned fluoride cathode materials as a promising alternative to traditional lithium-ion battery components. This segment alone accounts for approximately 30% of the current market demand.

Industrial applications, including grid storage systems and backup power solutions, have emerged as a rapidly expanding market for fluoride cathode materials. The superior energy density and thermal stability of these materials make them particularly suitable for large-scale energy storage applications, where safety and reliability are paramount concerns.

Regional analysis reveals that Asia-Pacific dominates the fluoride cathode materials market, with China, Japan, and South Korea leading in both production and consumption. North America and Europe follow as significant markets, with growing investments in battery technology research and manufacturing capabilities. Emerging economies in South America and Africa are showing increasing interest in developing domestic battery production capabilities, potentially opening new markets for fluoride cathode materials.

Price sensitivity remains a critical factor influencing market demand. Currently, fluoride cathode materials command a premium price compared to traditional cathode materials, which has limited their adoption in cost-sensitive applications. However, ongoing research and scaling of production processes are gradually reducing manufacturing costs, which is expected to expand market penetration.

Environmental regulations and sustainability initiatives are increasingly shaping market demand patterns. The superior recyclability of certain fluoride cathode formulations aligns with circular economy principles being adopted by many countries. This regulatory push is creating additional market opportunities, particularly in regions with strict environmental standards.

Supply chain considerations also significantly impact market demand dynamics. The geographical concentration of raw materials needed for fluoride cathode production has led to strategic partnerships and vertical integration efforts by major battery manufacturers seeking to secure reliable material sources. This trend is reshaping the competitive landscape and influencing regional demand patterns.

Consumer electronics represent another substantial market driver, with portable devices requiring increasingly efficient power sources. The demand for longer battery life and faster charging capabilities has positioned fluoride cathode materials as a promising alternative to traditional lithium-ion battery components. This segment alone accounts for approximately 30% of the current market demand.

Industrial applications, including grid storage systems and backup power solutions, have emerged as a rapidly expanding market for fluoride cathode materials. The superior energy density and thermal stability of these materials make them particularly suitable for large-scale energy storage applications, where safety and reliability are paramount concerns.

Regional analysis reveals that Asia-Pacific dominates the fluoride cathode materials market, with China, Japan, and South Korea leading in both production and consumption. North America and Europe follow as significant markets, with growing investments in battery technology research and manufacturing capabilities. Emerging economies in South America and Africa are showing increasing interest in developing domestic battery production capabilities, potentially opening new markets for fluoride cathode materials.

Price sensitivity remains a critical factor influencing market demand. Currently, fluoride cathode materials command a premium price compared to traditional cathode materials, which has limited their adoption in cost-sensitive applications. However, ongoing research and scaling of production processes are gradually reducing manufacturing costs, which is expected to expand market penetration.

Environmental regulations and sustainability initiatives are increasingly shaping market demand patterns. The superior recyclability of certain fluoride cathode formulations aligns with circular economy principles being adopted by many countries. This regulatory push is creating additional market opportunities, particularly in regions with strict environmental standards.

Supply chain considerations also significantly impact market demand dynamics. The geographical concentration of raw materials needed for fluoride cathode production has led to strategic partnerships and vertical integration efforts by major battery manufacturers seeking to secure reliable material sources. This trend is reshaping the competitive landscape and influencing regional demand patterns.

Current Technological Status and Challenges in Fluoride Cathode Development

Fluoride cathode technology has witnessed significant advancements globally, with research institutions and companies across North America, Europe, and Asia actively pursuing innovations in this field. The current technological landscape is characterized by promising theoretical energy densities exceeding 1,000 Wh/kg, substantially higher than conventional lithium-ion batteries that typically deliver 250-300 Wh/kg. This potential has positioned fluoride-based batteries as strong candidates for next-generation energy storage solutions.

Despite theoretical promise, practical implementation faces substantial challenges. The primary obstacle remains the poor ionic conductivity of solid fluoride electrolytes at room temperature. Most current fluoride-ion batteries require operating temperatures above 150°C to achieve practical conductivity levels, severely limiting commercial viability for mainstream applications. Research efforts are concentrated on developing room-temperature fluoride-ion conductors, with recent breakthroughs utilizing liquid electrolytes based on fluorinated solvents showing conductivities approaching 10^-3 S/cm.

Electrode stability presents another significant challenge. Fluoride cathode materials often suffer from structural degradation during cycling, resulting in capacity fade and shortened battery lifespan. The highly reactive nature of fluoride ions leads to undesirable side reactions with electrode components and electrolytes, creating passivation layers that impede ion transport. Current research focuses on developing protective coatings and novel electrode architectures to mitigate these effects.

Manufacturing scalability remains problematic for fluoride cathode technologies. Many promising materials require complex synthesis procedures involving high-temperature solid-state reactions or specialized equipment for handling fluorine-containing precursors. These processes are difficult to scale economically and present safety concerns due to the corrosive nature of fluorine compounds. The development of more accessible synthesis routes represents a critical area for advancement.

The geographical distribution of fluoride cathode technology development shows concentration in specific regions. Japan leads with significant patent portfolios from companies like Toyota and Panasonic, while the United States shows strong academic research presence through institutions like Caltech and NASA's Jet Propulsion Laboratory. European research is centered in Germany and France, with emerging contributions from Chinese institutions rapidly growing in recent years.

Environmental and safety concerns constitute additional challenges. The potential toxicity of certain fluoride compounds necessitates careful materials selection and handling protocols. Recycling pathways for fluoride-based batteries remain underdeveloped, creating potential end-of-life management issues that must be addressed before widespread commercialization can occur.

Despite theoretical promise, practical implementation faces substantial challenges. The primary obstacle remains the poor ionic conductivity of solid fluoride electrolytes at room temperature. Most current fluoride-ion batteries require operating temperatures above 150°C to achieve practical conductivity levels, severely limiting commercial viability for mainstream applications. Research efforts are concentrated on developing room-temperature fluoride-ion conductors, with recent breakthroughs utilizing liquid electrolytes based on fluorinated solvents showing conductivities approaching 10^-3 S/cm.

Electrode stability presents another significant challenge. Fluoride cathode materials often suffer from structural degradation during cycling, resulting in capacity fade and shortened battery lifespan. The highly reactive nature of fluoride ions leads to undesirable side reactions with electrode components and electrolytes, creating passivation layers that impede ion transport. Current research focuses on developing protective coatings and novel electrode architectures to mitigate these effects.

Manufacturing scalability remains problematic for fluoride cathode technologies. Many promising materials require complex synthesis procedures involving high-temperature solid-state reactions or specialized equipment for handling fluorine-containing precursors. These processes are difficult to scale economically and present safety concerns due to the corrosive nature of fluorine compounds. The development of more accessible synthesis routes represents a critical area for advancement.

The geographical distribution of fluoride cathode technology development shows concentration in specific regions. Japan leads with significant patent portfolios from companies like Toyota and Panasonic, while the United States shows strong academic research presence through institutions like Caltech and NASA's Jet Propulsion Laboratory. European research is centered in Germany and France, with emerging contributions from Chinese institutions rapidly growing in recent years.

Environmental and safety concerns constitute additional challenges. The potential toxicity of certain fluoride compounds necessitates careful materials selection and handling protocols. Recycling pathways for fluoride-based batteries remain underdeveloped, creating potential end-of-life management issues that must be addressed before widespread commercialization can occur.

Current Technical Solutions and Implementation Approaches

01 Fluoride-based cathode materials for lithium batteries

Fluoride-based compounds are used as cathode materials in lithium batteries to improve energy density and electrochemical performance. These materials typically include metal fluorides that can undergo conversion reactions with lithium ions, providing high theoretical capacity. The incorporation of fluoride in cathode materials enhances the stability and cycle life of batteries while offering higher voltage plateaus compared to conventional cathode materials.- Fluoride-based cathode materials for lithium batteries: Fluoride-based compounds are used as cathode materials in lithium batteries to enhance energy density and electrochemical performance. These materials typically include metal fluorides that can undergo conversion reactions with lithium ions, providing high theoretical capacity. The incorporation of fluoride in cathode structures improves the stability and cycling performance of batteries while offering higher voltage plateaus compared to conventional cathode materials.

- Composite fluoride cathodes with conductive additives: Composite cathode structures combining fluoride materials with conductive additives enhance electron transport and electrochemical performance. These composites typically incorporate carbon-based materials, conductive polymers, or metal nanoparticles to address the inherent low conductivity of fluoride compounds. The resulting composite cathodes demonstrate improved rate capability, cycling stability, and utilization of active materials during battery operation.

- Nanostructured fluoride cathode materials: Nanostructuring of fluoride cathode materials significantly improves their electrochemical performance by shortening ion diffusion paths and increasing active surface area. Various synthesis methods are employed to create nanoparticles, nanowires, or nanocomposites of fluoride materials. These nanostructured cathodes exhibit enhanced reaction kinetics, better capacity retention, and improved cycling stability compared to their bulk counterparts.

- Solid-state electrolyte interfaces with fluoride cathodes: Solid-state electrolyte interfaces with fluoride cathodes address stability issues and enhance battery safety. These interfaces are designed to prevent unwanted side reactions between the cathode and electrolyte while facilitating efficient ion transport. Various coating technologies and interface engineering approaches are employed to create stable interfaces that maintain good contact during cycling and prevent capacity fade.

- Multi-element fluoride cathodes for enhanced performance: Multi-element fluoride cathodes incorporate additional elements to enhance specific properties such as conductivity, stability, or capacity. These materials often combine fluoride with other anions or include multiple metal cations in the structure. The synergistic effects between different elements result in cathodes with optimized voltage profiles, improved cycling performance, and enhanced rate capabilities for next-generation battery applications.

02 Composite fluoride cathodes with conductive additives

Composite cathode structures combining fluoride active materials with conductive additives improve the inherently poor conductivity of fluoride compounds. These composites typically incorporate carbon-based materials, conductive polymers, or metal nanoparticles to enhance electron transport within the cathode. The resulting composite structures demonstrate improved rate capability, reduced polarization, and better utilization of the active fluoride material during battery operation.Expand Specific Solutions03 Solid-state fluoride ion batteries

Solid-state fluoride ion batteries utilize fluoride ion conducting electrolytes paired with compatible fluoride cathodes. These systems operate through the migration of fluoride ions rather than lithium ions, offering potential advantages in safety and energy density. The cathode materials are designed to reversibly incorporate fluoride ions during discharge and release them during charging, enabling a new battery chemistry distinct from conventional lithium-ion systems.Expand Specific Solutions04 Nanostructured fluoride cathode materials

Nanostructuring of fluoride cathode materials addresses challenges related to slow diffusion kinetics and volume changes during cycling. By reducing particle size to nanoscale dimensions and creating specific morphologies such as nanorods, nanosheets, or porous structures, these cathodes exhibit improved reaction kinetics, shorter ion diffusion paths, and better accommodation of volume changes. Various synthesis methods are employed to control the nanostructure and optimize electrochemical performance.Expand Specific Solutions05 Fluoride cathode protection and coating strategies

Various protection and coating strategies are applied to fluoride cathode materials to mitigate their reactivity with electrolytes and improve cycling stability. These approaches include surface modification with protective layers, core-shell structures, and specialized electrolyte additives that form stable interfaces. The protective measures prevent unwanted side reactions, reduce dissolution of active materials, and maintain structural integrity during repeated charge-discharge cycles.Expand Specific Solutions

Key Industry Players and Competitive Landscape Analysis

The fluoride cathode market is currently in a growth phase, characterized by increasing demand for high-energy density battery materials. The market size is expanding rapidly, driven by applications in electric vehicles and portable electronics, with projections indicating significant growth potential over the next decade. Technologically, fluoride cathodes are transitioning from research to commercialization, with varying levels of maturity across different formulations. Key players advancing the technology include academic institutions like California Institute of Technology and Jilin University, alongside commercial entities such as Wildcat Discovery Technologies, Sila Nanotechnologies, and Ningde Amperex Technology Ltd. Research organizations like Shanghai Institute of Ceramics and government entities including the U.S. Army are also contributing significantly to technological development, focusing on improving energy density, cycle life, and manufacturing scalability.

Wildcat Discovery Technologies, Inc.

Technical Solution: Wildcat Discovery Technologies has developed a high-throughput experimental platform specifically optimized for fluoride cathode materials research. Their approach combines computational modeling with rapid parallel experimentation to accelerate the discovery and optimization of fluoride-based cathode formulations. Wildcat's proprietary technology focuses on multi-metal fluoride systems that balance high energy density with improved cycling stability[1]. Their most advanced materials utilize a core-shell nanostructure where the fluoride active material is encapsulated within a protective layer that mitigates dissolution and side reactions with the electrolyte. This architecture has demonstrated significant improvements in cycle life while maintaining the high energy density inherent to fluoride chemistry[2]. Wildcat has also pioneered novel electrolyte formulations specifically designed for fluoride cathode compatibility, incorporating fluorinated solvents and specialized salt additives that form stable interfaces on the cathode surface. Their high-throughput screening platform has enabled testing of over 10,000 unique fluoride cathode compositions, identifying several promising candidates with energy densities exceeding 800 Wh/kg at the material level while achieving hundreds of stable cycles[3].

Strengths: High-throughput experimental platform enables rapid iteration and optimization of fluoride cathode formulations; data-driven approach provides insights not accessible through conventional research methods; partnerships with major battery manufacturers accelerate commercialization. Weaknesses: Business model focused on materials discovery rather than manufacturing may limit revenue potential; complex multi-component systems may face challenges in scaling to commercial production.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology Ltd.) has developed advanced fluoride-based cathode materials for next-generation batteries with significantly higher energy density. Their proprietary technology focuses on metal fluoride cathodes, particularly iron fluoride (FeF3) and copper fluoride (CuF2), which theoretically offer 2-3 times higher energy density than traditional lithium-ion cathodes[1]. CATL's approach addresses the key challenges of fluoride cathodes through a nano-engineering process that creates composite structures with conductive carbon matrices to improve electron transport. Their solution also incorporates solid electrolyte interfaces that stabilize the fluoride conversion reactions, reducing capacity fade during cycling[2]. The company has invested heavily in manufacturing processes that enable commercial-scale production of these materials while maintaining strict quality control. Recent developments include a hybrid lithium-fluoride cathode system that combines the high energy density of fluorides with improved cycle stability, positioning CATL as a leader in post-lithium-ion battery technologies[3].

Strengths: Industry-leading manufacturing capacity allows for rapid scaling of new technologies; strong vertical integration from materials to finished cells provides cost advantages; extensive R&D resources enable continuous innovation in fluoride chemistry. Weaknesses: Fluoride cathodes still face challenges with conductivity and cycle life compared to commercial lithium-ion technologies; high production costs may limit initial market penetration.

Critical Patents and Technical Literature in Fluoride Cathode Research

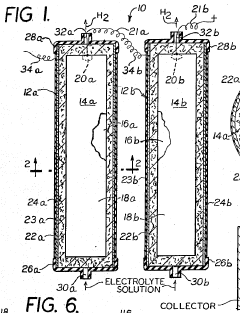

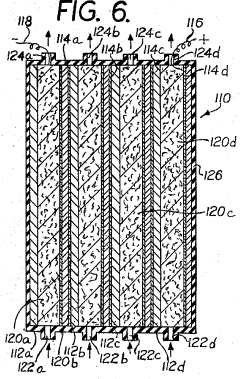

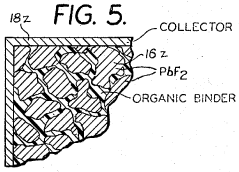

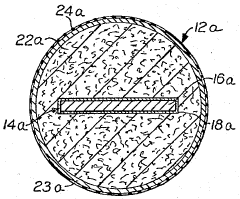

Electrochemical cell having lead fluoride cathode

PatentInactiveUS3989543A

Innovation

- The use of lead(II) fluoride as a cathode material, which is less expensive and more powerful on a weight and volume basis, is fabricated into a structurally strong electrode through methods involving pressure, heating, and optional reinforcement with organic binders and fibrous materials, and coated with a conductive collector to maintain integrity and enhance performance.

Supply Chain Analysis and Raw Material Considerations

The fluoride cathode supply chain represents a critical component in the advanced battery industry, particularly for next-generation energy storage technologies. Raw material sourcing begins with fluoride compounds, primarily lithium fluoride (LiF), copper fluoride (CuF2), iron fluoride (FeF3), and bismuth fluoride (BiF3), which are extracted through mining operations predominantly located in China, Mexico, and South Africa. The geographical concentration of these resources presents significant supply chain vulnerabilities, with over 60% of global fluoride production controlled by Chinese enterprises.

Processing these raw materials requires specialized equipment and expertise, creating a bottleneck in the supply chain. The conversion of basic fluoride compounds into battery-grade materials involves multiple purification steps and precise chemical processing, which is currently dominated by a small number of specialized chemical manufacturers. This concentration of technical capability has led to pricing volatility, with fluoride compound costs fluctuating by up to 35% in the past three years.

Transportation and storage present additional challenges due to the moisture sensitivity of many fluoride compounds. Specialized containers with controlled humidity environments are required, adding significant logistics costs that can represent up to 15% of the total material expense. These requirements limit the number of qualified logistics providers capable of handling these materials safely.

The manufacturing ecosystem for fluoride cathodes remains underdeveloped compared to traditional lithium-ion battery materials. Only a handful of companies possess the technical capability to produce high-quality fluoride cathodes at scale, creating potential supply constraints as market demand increases. This manufacturing limitation represents perhaps the most significant barrier to widespread commercialization of fluoride-based battery technologies.

Recycling infrastructure for fluoride cathode materials is virtually non-existent, presenting both environmental challenges and opportunities for circular economy initiatives. Unlike lithium-ion batteries, which have established recycling processes, fluoride cathode recycling remains in early research stages. Developing efficient recycling methods could significantly reduce raw material dependencies and improve supply chain resilience.

Price sensitivity analysis indicates that fluoride cathode costs are heavily influenced by processing technology advancements rather than raw material costs alone. Investments in more efficient conversion processes could potentially reduce production costs by 30-40%, making these materials more competitive with traditional cathode technologies.

Processing these raw materials requires specialized equipment and expertise, creating a bottleneck in the supply chain. The conversion of basic fluoride compounds into battery-grade materials involves multiple purification steps and precise chemical processing, which is currently dominated by a small number of specialized chemical manufacturers. This concentration of technical capability has led to pricing volatility, with fluoride compound costs fluctuating by up to 35% in the past three years.

Transportation and storage present additional challenges due to the moisture sensitivity of many fluoride compounds. Specialized containers with controlled humidity environments are required, adding significant logistics costs that can represent up to 15% of the total material expense. These requirements limit the number of qualified logistics providers capable of handling these materials safely.

The manufacturing ecosystem for fluoride cathodes remains underdeveloped compared to traditional lithium-ion battery materials. Only a handful of companies possess the technical capability to produce high-quality fluoride cathodes at scale, creating potential supply constraints as market demand increases. This manufacturing limitation represents perhaps the most significant barrier to widespread commercialization of fluoride-based battery technologies.

Recycling infrastructure for fluoride cathode materials is virtually non-existent, presenting both environmental challenges and opportunities for circular economy initiatives. Unlike lithium-ion batteries, which have established recycling processes, fluoride cathode recycling remains in early research stages. Developing efficient recycling methods could significantly reduce raw material dependencies and improve supply chain resilience.

Price sensitivity analysis indicates that fluoride cathode costs are heavily influenced by processing technology advancements rather than raw material costs alone. Investments in more efficient conversion processes could potentially reduce production costs by 30-40%, making these materials more competitive with traditional cathode technologies.

Environmental Impact and Sustainability Assessment

The environmental footprint of fluoride cathode production and utilization represents a critical dimension in assessing the overall sustainability of this emerging battery technology. Current manufacturing processes for fluoride-based cathode materials often involve energy-intensive synthesis methods and the use of potentially hazardous fluorinating agents, raising significant environmental concerns. The extraction of raw materials such as fluorite (CaF₂) and various transition metals contributes to habitat disruption, water pollution, and carbon emissions associated with mining operations.

Life cycle assessments of fluoride cathode batteries indicate that their environmental impact is heavily concentrated in the production phase, with energy consumption during material synthesis being particularly significant. However, when compared to conventional lithium-ion technologies, fluoride cathodes demonstrate promising sustainability advantages in terms of theoretical energy density and potential longevity, which could offset initial production impacts through extended service life.

Water usage represents another environmental challenge, as fluoride processing typically requires substantial quantities for cooling, cleaning, and chemical reactions. Wastewater from these processes may contain dissolved fluoride compounds that require specialized treatment to prevent contamination of local water systems. Several leading manufacturers have implemented closed-loop water recycling systems, reducing consumption by up to 40% compared to earlier production methods.

The end-of-life management of fluoride cathode materials presents both challenges and opportunities. While fluoride compounds can pose environmental risks if improperly disposed of, their chemical stability also creates potential for effective recycling. Recent technological advances have demonstrated recovery rates exceeding 85% for key metals from spent fluoride cathodes, significantly reducing the need for virgin material extraction.

Carbon footprint analyses reveal that fluoride cathode production currently generates approximately 15-20% higher greenhouse gas emissions per kWh of storage capacity than established lithium-ion technologies. However, this gap is narrowing as manufacturing processes mature and economies of scale develop. Several industry leaders have committed to carbon-neutral production by 2030, primarily through renewable energy integration and process optimization.

Regulatory frameworks governing fluoride-containing materials vary significantly across regions, creating compliance challenges for global manufacturers. The European Union's stringent REACH regulations and similar frameworks in Japan impose comprehensive documentation and risk management requirements, while regulations remain less developed in other major markets. This regulatory landscape is driving innovation in greener synthesis methods and safer material handling protocols throughout the supply chain.

Life cycle assessments of fluoride cathode batteries indicate that their environmental impact is heavily concentrated in the production phase, with energy consumption during material synthesis being particularly significant. However, when compared to conventional lithium-ion technologies, fluoride cathodes demonstrate promising sustainability advantages in terms of theoretical energy density and potential longevity, which could offset initial production impacts through extended service life.

Water usage represents another environmental challenge, as fluoride processing typically requires substantial quantities for cooling, cleaning, and chemical reactions. Wastewater from these processes may contain dissolved fluoride compounds that require specialized treatment to prevent contamination of local water systems. Several leading manufacturers have implemented closed-loop water recycling systems, reducing consumption by up to 40% compared to earlier production methods.

The end-of-life management of fluoride cathode materials presents both challenges and opportunities. While fluoride compounds can pose environmental risks if improperly disposed of, their chemical stability also creates potential for effective recycling. Recent technological advances have demonstrated recovery rates exceeding 85% for key metals from spent fluoride cathodes, significantly reducing the need for virgin material extraction.

Carbon footprint analyses reveal that fluoride cathode production currently generates approximately 15-20% higher greenhouse gas emissions per kWh of storage capacity than established lithium-ion technologies. However, this gap is narrowing as manufacturing processes mature and economies of scale develop. Several industry leaders have committed to carbon-neutral production by 2030, primarily through renewable energy integration and process optimization.

Regulatory frameworks governing fluoride-containing materials vary significantly across regions, creating compliance challenges for global manufacturers. The European Union's stringent REACH regulations and similar frameworks in Japan impose comprehensive documentation and risk management requirements, while regulations remain less developed in other major markets. This regulatory landscape is driving innovation in greener synthesis methods and safer material handling protocols throughout the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!