Analysis of Thermal Conductivity in SERS Substrate Synthesis

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Thermal Conductivity Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from an interesting optical phenomenon to a powerful analytical technique with applications spanning from biomedical diagnostics to environmental monitoring. The thermal conductivity properties of SERS substrates represent a critical yet often overlooked aspect of their performance characteristics. Understanding these thermal properties is essential as they directly influence substrate stability, signal reproducibility, and overall detection sensitivity.

Historically, SERS substrate development has focused primarily on enhancing electromagnetic field amplification through plasmonic nanostructures, with less attention paid to thermal management. This imbalance has led to performance limitations, particularly in high-power laser applications where thermal degradation can significantly compromise analytical results. Recent research trends indicate a growing recognition of thermal conductivity as a design parameter rather than merely a secondary consideration.

The evolution of SERS substrate materials has progressed from simple roughened metal surfaces to sophisticated engineered nanostructures. Throughout this development, thermal considerations have gradually gained prominence, especially as applications have expanded into areas requiring higher laser powers or sustained illumination periods. The interplay between plasmonic properties and thermal characteristics represents a frontier in SERS substrate engineering that demands systematic investigation.

Current technological trajectories suggest that next-generation SERS substrates will need to balance optimal plasmonic performance with superior thermal management capabilities. This balance becomes particularly crucial for emerging applications in real-time monitoring, portable sensing devices, and integrated analytical systems where operational stability under varying conditions is paramount.

The primary objective of this technical research is to comprehensively analyze the role of thermal conductivity in SERS substrate synthesis and performance. Specifically, we aim to establish quantitative relationships between thermal properties and key performance metrics, identify optimal material combinations and structural designs that maximize both plasmonic enhancement and thermal stability, and develop predictive models that can guide future substrate engineering efforts.

Secondary objectives include mapping the thermal behavior of various substrate architectures under different laser excitation conditions, evaluating the impact of thermal gradients on signal consistency across substrate surfaces, and exploring novel fabrication approaches that can simultaneously address both electromagnetic and thermal requirements. These investigations will provide valuable insights for advancing SERS technology toward more robust, reliable analytical applications.

Through this research, we anticipate establishing design principles that will enable the development of thermally optimized SERS substrates capable of maintaining consistent performance under demanding operational conditions, ultimately expanding the practical utility of SERS-based analytical methods across diverse scientific and industrial domains.

Historically, SERS substrate development has focused primarily on enhancing electromagnetic field amplification through plasmonic nanostructures, with less attention paid to thermal management. This imbalance has led to performance limitations, particularly in high-power laser applications where thermal degradation can significantly compromise analytical results. Recent research trends indicate a growing recognition of thermal conductivity as a design parameter rather than merely a secondary consideration.

The evolution of SERS substrate materials has progressed from simple roughened metal surfaces to sophisticated engineered nanostructures. Throughout this development, thermal considerations have gradually gained prominence, especially as applications have expanded into areas requiring higher laser powers or sustained illumination periods. The interplay between plasmonic properties and thermal characteristics represents a frontier in SERS substrate engineering that demands systematic investigation.

Current technological trajectories suggest that next-generation SERS substrates will need to balance optimal plasmonic performance with superior thermal management capabilities. This balance becomes particularly crucial for emerging applications in real-time monitoring, portable sensing devices, and integrated analytical systems where operational stability under varying conditions is paramount.

The primary objective of this technical research is to comprehensively analyze the role of thermal conductivity in SERS substrate synthesis and performance. Specifically, we aim to establish quantitative relationships between thermal properties and key performance metrics, identify optimal material combinations and structural designs that maximize both plasmonic enhancement and thermal stability, and develop predictive models that can guide future substrate engineering efforts.

Secondary objectives include mapping the thermal behavior of various substrate architectures under different laser excitation conditions, evaluating the impact of thermal gradients on signal consistency across substrate surfaces, and exploring novel fabrication approaches that can simultaneously address both electromagnetic and thermal requirements. These investigations will provide valuable insights for advancing SERS technology toward more robust, reliable analytical applications.

Through this research, we anticipate establishing design principles that will enable the development of thermally optimized SERS substrates capable of maintaining consistent performance under demanding operational conditions, ultimately expanding the practical utility of SERS-based analytical methods across diverse scientific and industrial domains.

Market Analysis for SERS Substrate Applications

The Surface-Enhanced Raman Spectroscopy (SERS) substrate market has witnessed substantial growth in recent years, driven primarily by increasing applications in analytical chemistry, biomedical diagnostics, and environmental monitoring. The global SERS substrate market was valued at approximately 125 million USD in 2022 and is projected to reach 210 million USD by 2027, representing a compound annual growth rate of 10.9%.

Healthcare and life sciences currently dominate the application landscape, accounting for nearly 45% of the total market share. This dominance stems from the critical need for highly sensitive detection methods in disease diagnosis, drug discovery, and biological research. The pharmaceutical industry follows closely, utilizing SERS substrates for quality control, counterfeit detection, and process monitoring.

Environmental monitoring represents the fastest-growing application segment, with increasing regulatory pressure driving adoption for detecting trace contaminants in water, soil, and air. Food safety applications are similarly expanding, particularly in detecting pesticides, antibiotics, and foodborne pathogens at concentrations below conventional detection limits.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the highest growth rate, fueled by expanding research infrastructure in China, Japan, and South Korea, alongside increasing industrial applications.

The thermal conductivity characteristics of SERS substrates significantly influence market dynamics. End-users increasingly demand thermally stable substrates that maintain enhancement properties across varying temperature conditions. This requirement is particularly crucial in industrial applications where operating environments may fluctuate considerably.

Market analysis reveals a price sensitivity curve that varies by application sector. Research institutions demonstrate higher tolerance for premium-priced, high-performance substrates, while industrial applications prioritize cost-effectiveness and reliability. The average price point for commercial SERS substrates ranges from 15-200 USD per unit, depending on enhancement factor, uniformity, and stability characteristics.

Customer feedback indicates growing demand for substrates with optimized thermal properties that enable consistent performance in field conditions. This trend is driving manufacturers to develop thermally engineered SERS platforms that maintain structural integrity and enhancement capabilities across broader temperature ranges, creating a distinct market segment for thermally optimized SERS substrates with potential premium pricing opportunities.

Healthcare and life sciences currently dominate the application landscape, accounting for nearly 45% of the total market share. This dominance stems from the critical need for highly sensitive detection methods in disease diagnosis, drug discovery, and biological research. The pharmaceutical industry follows closely, utilizing SERS substrates for quality control, counterfeit detection, and process monitoring.

Environmental monitoring represents the fastest-growing application segment, with increasing regulatory pressure driving adoption for detecting trace contaminants in water, soil, and air. Food safety applications are similarly expanding, particularly in detecting pesticides, antibiotics, and foodborne pathogens at concentrations below conventional detection limits.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the highest growth rate, fueled by expanding research infrastructure in China, Japan, and South Korea, alongside increasing industrial applications.

The thermal conductivity characteristics of SERS substrates significantly influence market dynamics. End-users increasingly demand thermally stable substrates that maintain enhancement properties across varying temperature conditions. This requirement is particularly crucial in industrial applications where operating environments may fluctuate considerably.

Market analysis reveals a price sensitivity curve that varies by application sector. Research institutions demonstrate higher tolerance for premium-priced, high-performance substrates, while industrial applications prioritize cost-effectiveness and reliability. The average price point for commercial SERS substrates ranges from 15-200 USD per unit, depending on enhancement factor, uniformity, and stability characteristics.

Customer feedback indicates growing demand for substrates with optimized thermal properties that enable consistent performance in field conditions. This trend is driving manufacturers to develop thermally engineered SERS platforms that maintain structural integrity and enhancement capabilities across broader temperature ranges, creating a distinct market segment for thermally optimized SERS substrates with potential premium pricing opportunities.

Thermal Conductivity Challenges in SERS Synthesis

Thermal conductivity represents a critical parameter in the synthesis of Surface-Enhanced Raman Spectroscopy (SERS) substrates, significantly influencing both the fabrication process and the ultimate performance of these analytical platforms. The challenges associated with thermal conductivity management during SERS substrate synthesis stem from multiple interconnected factors that demand careful consideration and innovative solutions.

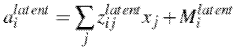

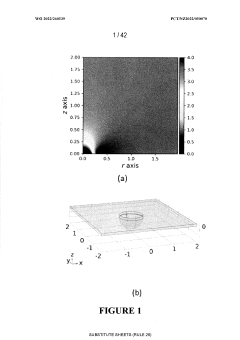

The primary challenge lies in achieving precise temperature control during nanofabrication processes. SERS substrates typically require the formation of specific nanostructures with controlled morphology, spacing, and orientation—all of which are highly temperature-dependent. Variations in thermal conductivity across the substrate material can lead to temperature gradients, resulting in heterogeneous nanostructure formation and compromised analytical performance.

For metal-based SERS substrates, which remain the most common type, thermal conductivity issues become particularly pronounced during processes like thermal evaporation, sputtering, and annealing. The high thermal conductivity of metals like gold and silver (310 W/m·K and 429 W/m·K respectively) creates challenges in maintaining uniform heating profiles, especially when these metals are deposited on substrates with significantly different thermal properties, such as glass or polymers.

Composite SERS substrates face additional complications due to the thermal conductivity mismatch between different materials. For instance, when incorporating metal nanoparticles into polymer matrices or onto semiconductor surfaces, the disparate thermal expansion coefficients and conductivities can generate internal stresses during temperature fluctuations, potentially leading to delamination, cracking, or distortion of the nanostructured features.

The miniaturization trend in SERS device fabrication further exacerbates thermal management challenges. As dimensions decrease to the nanoscale, heat dissipation becomes increasingly difficult, and localized heating effects become more pronounced. This is particularly problematic for in-situ or real-time SERS applications where laser irradiation during measurement can induce significant local temperature increases.

Advanced SERS substrates incorporating plasmonic heating capabilities face a paradoxical challenge: they must efficiently conduct heat during synthesis to ensure uniform structure formation, yet also provide controlled thermal responses during analytical applications. This dual requirement necessitates sophisticated thermal engineering approaches that few current fabrication methods adequately address.

The scaling of SERS substrate production from laboratory to industrial levels introduces additional thermal conductivity challenges. Maintaining uniform thermal conditions across larger substrate areas requires specialized equipment and process modifications that significantly impact production costs and complexity. Heat transfer modeling becomes essential but is complicated by the multi-scale nature of SERS substrates, spanning from nanometer features to centimeter-sized analytical platforms.

The primary challenge lies in achieving precise temperature control during nanofabrication processes. SERS substrates typically require the formation of specific nanostructures with controlled morphology, spacing, and orientation—all of which are highly temperature-dependent. Variations in thermal conductivity across the substrate material can lead to temperature gradients, resulting in heterogeneous nanostructure formation and compromised analytical performance.

For metal-based SERS substrates, which remain the most common type, thermal conductivity issues become particularly pronounced during processes like thermal evaporation, sputtering, and annealing. The high thermal conductivity of metals like gold and silver (310 W/m·K and 429 W/m·K respectively) creates challenges in maintaining uniform heating profiles, especially when these metals are deposited on substrates with significantly different thermal properties, such as glass or polymers.

Composite SERS substrates face additional complications due to the thermal conductivity mismatch between different materials. For instance, when incorporating metal nanoparticles into polymer matrices or onto semiconductor surfaces, the disparate thermal expansion coefficients and conductivities can generate internal stresses during temperature fluctuations, potentially leading to delamination, cracking, or distortion of the nanostructured features.

The miniaturization trend in SERS device fabrication further exacerbates thermal management challenges. As dimensions decrease to the nanoscale, heat dissipation becomes increasingly difficult, and localized heating effects become more pronounced. This is particularly problematic for in-situ or real-time SERS applications where laser irradiation during measurement can induce significant local temperature increases.

Advanced SERS substrates incorporating plasmonic heating capabilities face a paradoxical challenge: they must efficiently conduct heat during synthesis to ensure uniform structure formation, yet also provide controlled thermal responses during analytical applications. This dual requirement necessitates sophisticated thermal engineering approaches that few current fabrication methods adequately address.

The scaling of SERS substrate production from laboratory to industrial levels introduces additional thermal conductivity challenges. Maintaining uniform thermal conditions across larger substrate areas requires specialized equipment and process modifications that significantly impact production costs and complexity. Heat transfer modeling becomes essential but is complicated by the multi-scale nature of SERS substrates, spanning from nanometer features to centimeter-sized analytical platforms.

Current Thermal Control Methods in SERS Substrate Synthesis

01 Metal-based SERS substrates with enhanced thermal conductivity

Metal-based materials such as gold, silver, and copper are commonly used as SERS substrates due to their excellent plasmonic properties. These metals also possess high thermal conductivity, which helps dissipate heat generated during SERS measurements, preventing sample degradation and maintaining signal stability. Enhanced thermal management in these substrates allows for more intense laser excitation without damaging the analyte or substrate structure.- Metal-based SERS substrates with enhanced thermal conductivity: Metal-based materials such as gold, silver, and copper are commonly used as SERS substrates due to their excellent plasmonic properties. These metals also possess high thermal conductivity, which helps dissipate heat generated during SERS measurements, preventing sample degradation and maintaining signal stability. Enhanced thermal management in these substrates allows for more reliable and consistent SERS measurements, especially at higher laser powers.

- Semiconductor and carbon-based SERS substrates: Semiconductor materials and carbon-based structures (such as graphene, carbon nanotubes) are being utilized as SERS substrates with tailored thermal conductivity properties. These materials offer advantages in terms of heat dissipation while maintaining SERS enhancement capabilities. The thermal conductivity of these substrates can be engineered by controlling doping levels, structural configurations, and composite formations, allowing for optimized performance in various SERS applications.

- Composite and hybrid SERS substrates for thermal management: Composite and hybrid SERS substrates combine different materials to achieve optimal thermal conductivity while maintaining high SERS enhancement. These substrates typically incorporate a thermally conductive base layer with plasmonic nanostructures on the surface. The layered design allows for efficient heat dissipation through the substrate while preserving the SERS-active surface. Various combinations of metals, ceramics, polymers, and 2D materials are used to create these hybrid structures with tailored thermal properties.

- Thermal management systems for SERS substrates: Dedicated thermal management systems are being developed to control the temperature of SERS substrates during measurements. These systems include active cooling mechanisms, heat sinks, and thermally conductive mounting platforms that help maintain optimal operating temperatures. Advanced thermal management approaches enable the use of higher laser powers without damaging samples or substrates, resulting in improved SERS sensitivity and reproducibility for demanding analytical applications.

- Nanostructured SERS substrates with optimized thermal properties: Nanostructured SERS substrates with specifically engineered geometries can provide both enhanced SERS activity and improved thermal conductivity. The size, shape, spacing, and arrangement of nanostructures on these substrates are carefully designed to optimize plasmonic properties while facilitating heat dissipation. Various fabrication techniques including lithography, template-assisted growth, and self-assembly are employed to create these thermally optimized nanostructured SERS platforms for high-performance sensing applications.

02 Semiconductor materials for thermally stable SERS substrates

Semiconductor materials like silicon, gallium arsenide, and graphene are being incorporated into SERS substrates to improve thermal stability. These materials offer controlled thermal conductivity properties that can be tuned through doping or structural modifications. The integration of semiconductors with plasmonic metals creates hybrid SERS platforms with optimized heat dissipation capabilities, allowing for higher power laser excitation and improved sensitivity.Expand Specific Solutions03 Nanostructured SERS substrates with tailored thermal properties

Nanostructured SERS substrates with precisely engineered geometries can exhibit tailored thermal conductivity properties. These include nanopillars, nanoholes, nanogratings, and hierarchical structures that optimize both plasmonic enhancement and heat dissipation. The controlled spacing and dimensions of these nanostructures create effective pathways for thermal transport while maintaining strong electromagnetic field enhancement, resulting in more stable and sensitive SERS detection.Expand Specific Solutions04 Substrate cooling mechanisms for high-power SERS applications

Various cooling mechanisms have been developed to manage thermal effects in SERS substrates during high-power laser excitation. These include integrated heat sinks, microfluidic cooling channels, thermoelectric elements, and phase-change materials. Active thermal management systems allow for precise temperature control during SERS measurements, preventing thermal drift and enabling more reproducible and quantitative analysis, especially for heat-sensitive samples or high-power applications.Expand Specific Solutions05 Composite materials with optimized thermal conductivity for SERS

Composite materials combining different thermal conductors with plasmonic elements offer optimized performance for SERS applications. These include metal-polymer composites, ceramic-metal hybrids, and carbon-based nanocomposites that balance optical properties with thermal management. The strategic layering or mixing of materials with complementary thermal and optical properties creates SERS substrates with enhanced stability under intense laser illumination while maintaining high enhancement factors.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SERS Technology

The thermal conductivity analysis in SERS substrate synthesis market is currently in a growth phase, with increasing applications in analytical chemistry and materials science. The global market size for SERS technologies is expanding rapidly, projected to reach significant value as industries recognize its potential for molecular detection and characterization. Technologically, the field shows varying maturity levels across different applications. Leading companies like Corning and Samsung Electronics have established strong positions through advanced materials engineering, while research institutions such as Tsinghua University and Fraunhofer-Gesellschaft drive innovation through fundamental research. Companies including Sumitomo Chemical, Robert Bosch, and Semiconductor Energy Laboratory are developing specialized applications, particularly in electronics and automotive sectors, creating a competitive landscape balanced between established materials giants and specialized technology providers.

Corning, Inc.

Technical Solution: Corning has developed advanced SERS substrate synthesis techniques focusing on thermal conductivity optimization. Their approach involves creating glass-ceramic composite substrates with precisely controlled thermal properties. The company utilizes proprietary microstructure engineering to create nanoporous structures that enhance SERS signal while managing heat dissipation. Their technology incorporates thermally conductive nanoparticles embedded in glass matrices, allowing for efficient heat transfer during laser excitation. This prevents sample degradation and signal fluctuation during SERS analysis. Corning's thermal management system includes specialized coatings that help distribute heat evenly across the substrate surface, maintaining temperature uniformity during measurements. Their manufacturing process involves precision thermal annealing steps that optimize the crystalline structure for both SERS enhancement and thermal conductivity.

Strengths: Superior thermal stability during high-power laser excitation; excellent reproducibility of SERS signals due to uniform heat distribution; long substrate lifetime due to resistance to thermal degradation. Weaknesses: Higher production costs compared to standard substrates; limited flexibility in substrate geometry due to manufacturing constraints.

Fundació Institut de Ciencies Fotoniques

Technical Solution: The Fundació Institut de Ciencies Fotoniques (ICFO) has developed advanced SERS substrates with optimized thermal conductivity through their pioneering work in nanophotonics. Their approach combines plasmonic nanostructures with thermally engineered supporting layers to create substrates that efficiently manage heat during SERS measurements. ICFO's technology utilizes precisely arranged noble metal nanoparticles on thermally conductive crystalline supports, creating a system that enhances electromagnetic fields while dissipating generated heat. Their research has demonstrated that controlling thermal gradients at the nanoscale significantly improves measurement stability and reproducibility. ICFO has pioneered the use of computational models to predict thermal behavior during SERS analysis, allowing for substrate optimization based on specific application requirements. Their fabrication process includes advanced lithography techniques combined with thermal annealing steps that optimize both plasmonic properties and thermal conductivity. The institute has also developed specialized coatings that enhance thermal transfer between the substrate layers while maintaining optical transparency.

Strengths: Superior thermal management during high-intensity laser excitation; excellent reproducibility due to uniform thermal conditions; strong theoretical foundation for thermal behavior prediction. Weaknesses: Complex fabrication process requiring specialized equipment; higher production costs compared to standard substrates; primarily research-focused with limited commercial availability.

Critical Patents and Literature on SERS Thermal Conductivity

Controllable surface enhanced raman spectroscopy

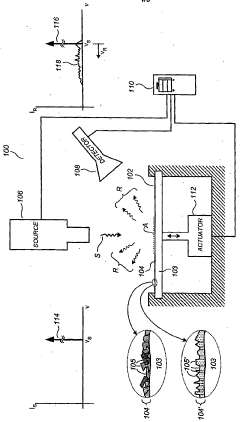

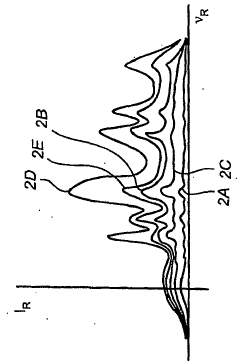

PatentWO2008013683A2

Innovation

- A SERS system with a deformable SERS-active structure actuated by mechanical, electrostatic, or pneumatic means to control the intensity of Raman-scattered radiation, allowing for real-time tuning of hot-spot conditions by varying the deformation of the SERS-active structure near analyte molecules.

Substrates, methods of patterning thin films, and their use

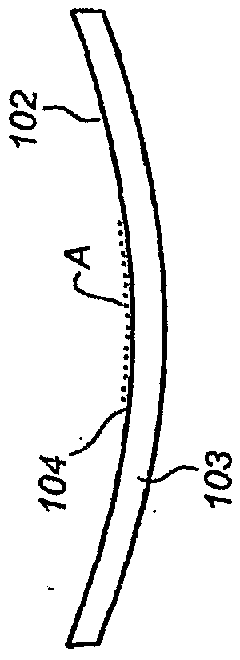

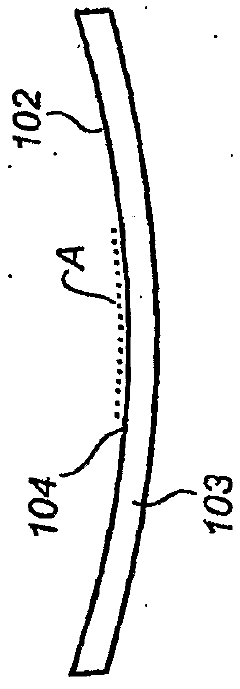

PatentWO2022260539A1

Innovation

- A method involving the use of a pulsed laser source with a pulse width less than one picosecond to pattern SERS substrates, creating a patterned area with repeated scans and adjusting the separation between scanned lines to match the effective beam waist, combined with a base layer and a Raman signal-enhancing material like gold or silver, to produce substrates with both positive and negative curvature and nanoparticles, enhancing the Raman signal for EV detection.

Materials Science Innovations for Enhanced SERS Performance

Recent advancements in materials science have significantly enhanced Surface-Enhanced Raman Spectroscopy (SERS) performance through innovative substrate designs. The thermal conductivity properties of materials used in SERS substrate synthesis have emerged as a critical factor influencing both fabrication processes and ultimate sensing capabilities. Materials with optimized thermal conductivity profiles enable more precise control during nanofabrication, resulting in more uniform and reproducible SERS-active structures.

Noble metal nanostructures, particularly those based on silver and gold, remain the foundation of high-performance SERS substrates due to their exceptional plasmonic properties. However, their thermal management during synthesis presents challenges. Recent innovations have focused on composite materials that combine plasmonic metals with thermally conductive supports such as graphene, reduced graphene oxide, and silicon carbide. These composites demonstrate superior heat dissipation during laser excitation, preventing structural degradation while maintaining strong electromagnetic field enhancement.

Hierarchical nanostructures represent another frontier in SERS substrate development. Multi-scale architectures incorporating both microscale and nanoscale features have demonstrated remarkable enhancement factors exceeding 10^9. The thermal gradients formed during synthesis of these structures can be precisely manipulated to create "hot spots" with extraordinary field enhancement capabilities. Materials scientists have developed novel thermal annealing protocols that leverage controlled thermal conductivity to fine-tune the spacing and morphology of these hot spots.

Porous materials with engineered thermal transport properties have shown particular promise for SERS applications requiring high sensitivity and reproducibility. Metal-organic frameworks (MOFs) and aerogels modified with plasmonic nanoparticles combine large surface areas with tunable thermal conductivity, enabling both efficient heat dissipation during measurement and controlled thermal environments during synthesis. These materials demonstrate exceptional stability under high-power laser excitation, extending the operational lifetime of SERS substrates.

Biomimetic approaches have also yielded innovative SERS materials with unique thermal properties. Structures inspired by natural systems, such as butterfly wing scales and plant leaf architectures, have been adapted to create SERS substrates with optimized thermal management capabilities. These bio-inspired designs often feature sophisticated hierarchical structures that would be difficult to achieve through conventional fabrication methods, offering new paradigms for substrate engineering.

The integration of phase-change materials into SERS substrates represents an emerging direction with significant potential. These materials undergo structural transformations at specific temperatures, enabling thermally triggered reconfiguration of the substrate's optical and plasmonic properties. This approach offers possibilities for dynamic SERS sensing platforms with tunable enhancement factors and selectivity profiles based on thermal stimuli.

Noble metal nanostructures, particularly those based on silver and gold, remain the foundation of high-performance SERS substrates due to their exceptional plasmonic properties. However, their thermal management during synthesis presents challenges. Recent innovations have focused on composite materials that combine plasmonic metals with thermally conductive supports such as graphene, reduced graphene oxide, and silicon carbide. These composites demonstrate superior heat dissipation during laser excitation, preventing structural degradation while maintaining strong electromagnetic field enhancement.

Hierarchical nanostructures represent another frontier in SERS substrate development. Multi-scale architectures incorporating both microscale and nanoscale features have demonstrated remarkable enhancement factors exceeding 10^9. The thermal gradients formed during synthesis of these structures can be precisely manipulated to create "hot spots" with extraordinary field enhancement capabilities. Materials scientists have developed novel thermal annealing protocols that leverage controlled thermal conductivity to fine-tune the spacing and morphology of these hot spots.

Porous materials with engineered thermal transport properties have shown particular promise for SERS applications requiring high sensitivity and reproducibility. Metal-organic frameworks (MOFs) and aerogels modified with plasmonic nanoparticles combine large surface areas with tunable thermal conductivity, enabling both efficient heat dissipation during measurement and controlled thermal environments during synthesis. These materials demonstrate exceptional stability under high-power laser excitation, extending the operational lifetime of SERS substrates.

Biomimetic approaches have also yielded innovative SERS materials with unique thermal properties. Structures inspired by natural systems, such as butterfly wing scales and plant leaf architectures, have been adapted to create SERS substrates with optimized thermal management capabilities. These bio-inspired designs often feature sophisticated hierarchical structures that would be difficult to achieve through conventional fabrication methods, offering new paradigms for substrate engineering.

The integration of phase-change materials into SERS substrates represents an emerging direction with significant potential. These materials undergo structural transformations at specific temperatures, enabling thermally triggered reconfiguration of the substrate's optical and plasmonic properties. This approach offers possibilities for dynamic SERS sensing platforms with tunable enhancement factors and selectivity profiles based on thermal stimuli.

Scalability and Cost Considerations in SERS Manufacturing

The scalability of SERS substrate manufacturing represents a critical challenge in transitioning from laboratory-scale production to commercial applications. Current manufacturing processes often involve complex multi-step procedures that are difficult to scale efficiently. Thermal conductivity management during synthesis becomes increasingly problematic at larger scales, as heat distribution uniformity significantly impacts the quality and consistency of SERS substrates. Industrial-scale production requires precise thermal control systems that can maintain optimal conditions across larger substrate areas, which substantially increases equipment complexity and cost.

Material costs constitute a significant portion of SERS manufacturing expenses, particularly when precious metals like gold and silver are utilized as plasmonic materials. These metals provide excellent enhancement factors but at premium prices that limit widespread adoption. Alternative materials such as copper, aluminum, or hybrid structures incorporating less expensive components are being explored, though these often present trade-offs between cost and performance. The development of more cost-effective materials that maintain high enhancement factors remains an active research area with significant commercial implications.

Production yield represents another crucial economic factor in SERS manufacturing. Thermal conductivity variations during synthesis can lead to inconsistent nanostructure formation, resulting in substrate rejection rates as high as 30-40% in some manufacturing processes. Improving thermal management systems and developing more robust synthesis protocols could significantly reduce waste and lower per-unit costs. Statistical process control methodologies specifically adapted for SERS manufacturing are being implemented to identify critical thermal parameters that affect yield rates.

Equipment investment presents a substantial barrier to entry for SERS manufacturing. Specialized deposition systems, lithography equipment, and thermal management infrastructure require capital investments often exceeding $1-2 million for moderate production capacity. This high initial cost necessitates significant production volume to achieve reasonable return on investment, creating a challenging economic landscape for new market entrants. Shared manufacturing facilities and contract manufacturing models are emerging as potential solutions to distribute these capital costs across multiple stakeholders.

Automation opportunities exist throughout the SERS substrate manufacturing process, particularly in thermal monitoring and control systems. Advanced sensors and feedback mechanisms can maintain precise thermal conditions during synthesis, improving consistency while reducing labor costs. However, the integration of these automated systems requires additional upfront investment that must be balanced against projected production volumes and market demand. The development of standardized, modular manufacturing platforms could significantly reduce implementation costs and accelerate industry-wide adoption of SERS technology.

Material costs constitute a significant portion of SERS manufacturing expenses, particularly when precious metals like gold and silver are utilized as plasmonic materials. These metals provide excellent enhancement factors but at premium prices that limit widespread adoption. Alternative materials such as copper, aluminum, or hybrid structures incorporating less expensive components are being explored, though these often present trade-offs between cost and performance. The development of more cost-effective materials that maintain high enhancement factors remains an active research area with significant commercial implications.

Production yield represents another crucial economic factor in SERS manufacturing. Thermal conductivity variations during synthesis can lead to inconsistent nanostructure formation, resulting in substrate rejection rates as high as 30-40% in some manufacturing processes. Improving thermal management systems and developing more robust synthesis protocols could significantly reduce waste and lower per-unit costs. Statistical process control methodologies specifically adapted for SERS manufacturing are being implemented to identify critical thermal parameters that affect yield rates.

Equipment investment presents a substantial barrier to entry for SERS manufacturing. Specialized deposition systems, lithography equipment, and thermal management infrastructure require capital investments often exceeding $1-2 million for moderate production capacity. This high initial cost necessitates significant production volume to achieve reasonable return on investment, creating a challenging economic landscape for new market entrants. Shared manufacturing facilities and contract manufacturing models are emerging as potential solutions to distribute these capital costs across multiple stakeholders.

Automation opportunities exist throughout the SERS substrate manufacturing process, particularly in thermal monitoring and control systems. Advanced sensors and feedback mechanisms can maintain precise thermal conditions during synthesis, improving consistency while reducing labor costs. However, the integration of these automated systems requires additional upfront investment that must be balanced against projected production volumes and market demand. The development of standardized, modular manufacturing platforms could significantly reduce implementation costs and accelerate industry-wide adoption of SERS technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!