What Drives SERS Substrates Efficiency in Analytical Chemistry

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Technology Background and Objectives

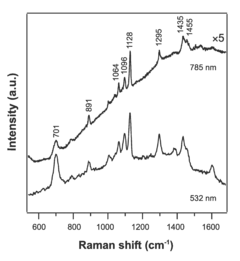

Surface-Enhanced Raman Spectroscopy (SERS) emerged in the late 1970s when researchers observed anomalously intense Raman signals from pyridine molecules adsorbed on roughened silver electrodes. This discovery marked the beginning of a revolutionary analytical technique that combines the specificity of Raman spectroscopy with significantly enhanced sensitivity. The enhancement factors, which can reach 10^10-10^11, enable detection limits down to single-molecule levels, transforming analytical capabilities across multiple scientific disciplines.

The evolution of SERS technology has been characterized by three distinct phases. The initial discovery phase (1977-1990) focused on understanding the fundamental mechanisms behind the enhancement effect. The development phase (1990-2010) saw significant advancements in substrate fabrication techniques and theoretical models. The current application expansion phase (2010-present) is marked by the integration of SERS into practical analytical solutions across diverse fields including biomedical diagnostics, environmental monitoring, food safety, and security applications.

The primary enhancement mechanisms driving SERS efficiency are electromagnetic enhancement and chemical enhancement. Electromagnetic enhancement, contributing factors of 10^4-10^8, results from localized surface plasmon resonances at metal nanostructures that amplify both incident and scattered radiation. Chemical enhancement, providing factors of 10-100, arises from charge transfer between the analyte and substrate, altering the molecular polarizability and consequently the Raman cross-section.

The technological objectives in SERS substrate development are multifaceted. Researchers aim to create substrates with consistently high enhancement factors, excellent reproducibility, long-term stability, and broad applicability across diverse analytes. Additionally, there is a growing emphasis on developing cost-effective fabrication methods suitable for mass production, which would facilitate wider adoption of SERS technology in routine analytical applications.

Current research trends focus on rational design of nanostructured substrates with optimized hot spots, development of flexible and adaptable SERS platforms, and integration with complementary techniques such as microfluidics and machine learning algorithms. The field is moving toward multifunctional SERS substrates that combine detection capabilities with additional functionalities such as separation, concentration, or catalytic activity.

The ultimate goal of SERS technology development is to transition from primarily research-oriented applications to widespread implementation in real-world analytical scenarios. This requires addressing key challenges including batch-to-batch reproducibility, signal uniformity across substrate surfaces, and development of standardized protocols for quantitative analysis. Success in these areas would position SERS as a mainstream analytical technique with transformative impact across scientific and industrial domains.

The evolution of SERS technology has been characterized by three distinct phases. The initial discovery phase (1977-1990) focused on understanding the fundamental mechanisms behind the enhancement effect. The development phase (1990-2010) saw significant advancements in substrate fabrication techniques and theoretical models. The current application expansion phase (2010-present) is marked by the integration of SERS into practical analytical solutions across diverse fields including biomedical diagnostics, environmental monitoring, food safety, and security applications.

The primary enhancement mechanisms driving SERS efficiency are electromagnetic enhancement and chemical enhancement. Electromagnetic enhancement, contributing factors of 10^4-10^8, results from localized surface plasmon resonances at metal nanostructures that amplify both incident and scattered radiation. Chemical enhancement, providing factors of 10-100, arises from charge transfer between the analyte and substrate, altering the molecular polarizability and consequently the Raman cross-section.

The technological objectives in SERS substrate development are multifaceted. Researchers aim to create substrates with consistently high enhancement factors, excellent reproducibility, long-term stability, and broad applicability across diverse analytes. Additionally, there is a growing emphasis on developing cost-effective fabrication methods suitable for mass production, which would facilitate wider adoption of SERS technology in routine analytical applications.

Current research trends focus on rational design of nanostructured substrates with optimized hot spots, development of flexible and adaptable SERS platforms, and integration with complementary techniques such as microfluidics and machine learning algorithms. The field is moving toward multifunctional SERS substrates that combine detection capabilities with additional functionalities such as separation, concentration, or catalytic activity.

The ultimate goal of SERS technology development is to transition from primarily research-oriented applications to widespread implementation in real-world analytical scenarios. This requires addressing key challenges including batch-to-batch reproducibility, signal uniformity across substrate surfaces, and development of standardized protocols for quantitative analysis. Success in these areas would position SERS as a mainstream analytical technique with transformative impact across scientific and industrial domains.

Market Analysis for SERS Applications in Analytical Chemistry

The global market for Surface-Enhanced Raman Spectroscopy (SERS) applications in analytical chemistry has experienced significant growth in recent years, driven by increasing demand for highly sensitive detection methods across multiple industries. The current market size is estimated at approximately 1.5 billion USD with a compound annual growth rate (CAGR) of 10-12%, projected to reach 2.7 billion USD by 2027.

Pharmaceutical and life sciences sectors represent the largest market segments, accounting for nearly 40% of SERS applications. These industries leverage SERS technology for drug discovery, biomarker detection, and quality control processes. The ability to detect trace amounts of substances with high specificity makes SERS particularly valuable in these high-stakes environments where analytical precision is paramount.

Food safety and environmental monitoring constitute the fastest-growing application segments, with 15-18% annual growth rates. Regulatory pressures and increasing consumer awareness regarding contaminants have accelerated adoption in these sectors. SERS substrates enable rapid detection of pesticides, antibiotics, and microbial contaminants at concentrations previously requiring more complex analytical methods.

Geographically, North America dominates the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the most rapid growth at 14-16% annually, primarily driven by expanding research infrastructure in China, Japan, and South Korea, alongside increasing industrial applications.

Market segmentation by substrate type reveals that nanoparticle-based substrates hold the largest market share (45%), followed by nanopatterned surfaces (30%) and hybrid substrates (15%). The remaining 10% comprises emerging substrate technologies. This distribution reflects the balance between performance characteristics and manufacturing scalability that influences market adoption.

End-user analysis indicates that research institutions and analytical laboratories remain the primary consumers (55%), while industrial applications account for 35% of the market. Clinical and point-of-care applications, though currently representing only 10% of the market, are projected to grow at 20% annually as portable SERS devices gain traction.

Key market drivers include increasing demand for rapid, sensitive analytical techniques, growing applications in biomedical diagnostics, and technological advancements improving substrate reproducibility and shelf-life. The push toward standardization of SERS substrates is also catalyzing market expansion by increasing confidence in result reliability across different laboratories and applications.

Pharmaceutical and life sciences sectors represent the largest market segments, accounting for nearly 40% of SERS applications. These industries leverage SERS technology for drug discovery, biomarker detection, and quality control processes. The ability to detect trace amounts of substances with high specificity makes SERS particularly valuable in these high-stakes environments where analytical precision is paramount.

Food safety and environmental monitoring constitute the fastest-growing application segments, with 15-18% annual growth rates. Regulatory pressures and increasing consumer awareness regarding contaminants have accelerated adoption in these sectors. SERS substrates enable rapid detection of pesticides, antibiotics, and microbial contaminants at concentrations previously requiring more complex analytical methods.

Geographically, North America dominates the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the most rapid growth at 14-16% annually, primarily driven by expanding research infrastructure in China, Japan, and South Korea, alongside increasing industrial applications.

Market segmentation by substrate type reveals that nanoparticle-based substrates hold the largest market share (45%), followed by nanopatterned surfaces (30%) and hybrid substrates (15%). The remaining 10% comprises emerging substrate technologies. This distribution reflects the balance between performance characteristics and manufacturing scalability that influences market adoption.

End-user analysis indicates that research institutions and analytical laboratories remain the primary consumers (55%), while industrial applications account for 35% of the market. Clinical and point-of-care applications, though currently representing only 10% of the market, are projected to grow at 20% annually as portable SERS devices gain traction.

Key market drivers include increasing demand for rapid, sensitive analytical techniques, growing applications in biomedical diagnostics, and technological advancements improving substrate reproducibility and shelf-life. The push toward standardization of SERS substrates is also catalyzing market expansion by increasing confidence in result reliability across different laboratories and applications.

Current SERS Substrate Limitations and Challenges

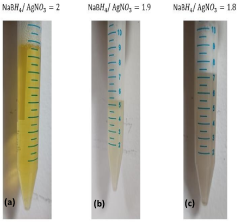

Despite significant advancements in Surface-Enhanced Raman Spectroscopy (SERS) technology, current SERS substrates face several critical limitations that hinder their widespread adoption in analytical chemistry applications. Reproducibility remains one of the most significant challenges, as many substrates exhibit substantial signal variations between batches and even within the same substrate. This inconsistency stems from difficulties in precisely controlling nanoscale features during fabrication processes, resulting in unpredictable enhancement factors that compromise quantitative analysis reliability.

Stability issues present another major obstacle, with many high-performance SERS substrates demonstrating rapid degradation under ambient conditions. Metal nanostructures, particularly silver-based substrates, are prone to oxidation and surface contamination, significantly reducing their shelf-life and practical utility in field applications. Additionally, the enhancement factor stability over time varies considerably, making long-term studies and standardized protocols difficult to establish.

Sensitivity and detection limits continue to challenge researchers, especially for trace analysis applications. While theoretical enhancement factors can reach 10^10-10^11, practical substrates typically achieve only 10^6-10^8, creating a substantial gap between theoretical potential and real-world performance. This limitation becomes particularly problematic when analyzing complex matrices where target analytes exist at ultra-low concentrations.

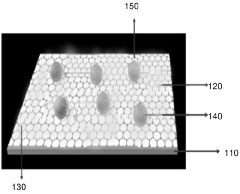

Uniformity across substrate surfaces represents another persistent challenge. "Hot spots" - areas of exceptionally high enhancement - often distribute unevenly across substrates, leading to significant spatial variations in signal intensity. This non-uniformity complicates quantitative analysis and reduces measurement reliability, particularly when automated scanning or mapping techniques are employed.

Cost-effectiveness and scalability issues further restrict widespread adoption. Many high-performance SERS substrates rely on expensive nanofabrication techniques like electron-beam lithography or complex chemical synthesis routes, making mass production economically unfeasible. The trade-off between performance and production cost continues to limit commercial viability for routine analytical applications.

Substrate specificity and selectivity present additional challenges, as most current substrates lack molecular recognition capabilities. In complex biological or environmental samples, this non-specific enhancement leads to spectral interference and difficulty in target analyte identification. While functionalization strategies exist, they often reduce overall enhancement factors or introduce additional spectral features that complicate analysis.

Standardization across the field remains inadequate, with various research groups using different metrics and testing protocols to evaluate substrate performance. This lack of standardized benchmarking makes direct comparisons between different substrate technologies challenging and slows progress toward optimized solutions for specific analytical applications.

Stability issues present another major obstacle, with many high-performance SERS substrates demonstrating rapid degradation under ambient conditions. Metal nanostructures, particularly silver-based substrates, are prone to oxidation and surface contamination, significantly reducing their shelf-life and practical utility in field applications. Additionally, the enhancement factor stability over time varies considerably, making long-term studies and standardized protocols difficult to establish.

Sensitivity and detection limits continue to challenge researchers, especially for trace analysis applications. While theoretical enhancement factors can reach 10^10-10^11, practical substrates typically achieve only 10^6-10^8, creating a substantial gap between theoretical potential and real-world performance. This limitation becomes particularly problematic when analyzing complex matrices where target analytes exist at ultra-low concentrations.

Uniformity across substrate surfaces represents another persistent challenge. "Hot spots" - areas of exceptionally high enhancement - often distribute unevenly across substrates, leading to significant spatial variations in signal intensity. This non-uniformity complicates quantitative analysis and reduces measurement reliability, particularly when automated scanning or mapping techniques are employed.

Cost-effectiveness and scalability issues further restrict widespread adoption. Many high-performance SERS substrates rely on expensive nanofabrication techniques like electron-beam lithography or complex chemical synthesis routes, making mass production economically unfeasible. The trade-off between performance and production cost continues to limit commercial viability for routine analytical applications.

Substrate specificity and selectivity present additional challenges, as most current substrates lack molecular recognition capabilities. In complex biological or environmental samples, this non-specific enhancement leads to spectral interference and difficulty in target analyte identification. While functionalization strategies exist, they often reduce overall enhancement factors or introduce additional spectral features that complicate analysis.

Standardization across the field remains inadequate, with various research groups using different metrics and testing protocols to evaluate substrate performance. This lack of standardized benchmarking makes direct comparisons between different substrate technologies challenging and slows progress toward optimized solutions for specific analytical applications.

Current SERS Substrate Design Approaches

01 Nanostructured SERS substrates for enhanced efficiency

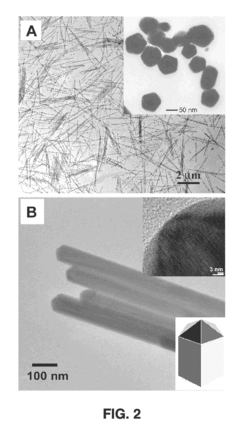

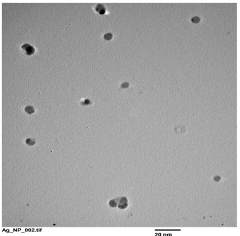

Nanostructured materials are used as SERS substrates to enhance detection efficiency. These include metal nanoparticles, nanorods, and nanopatterned surfaces that create strong electromagnetic field enhancements at their surfaces. The specific geometry and arrangement of these nanostructures can be optimized to create 'hot spots' where the Raman signal is significantly amplified, leading to improved sensitivity and detection limits for various analytes.- Nanostructured SERS substrates for enhanced efficiency: Nanostructured materials are used as SERS substrates to enhance detection efficiency. These substrates typically incorporate metallic nanoparticles, nanopillars, or nanogaps that create localized surface plasmon resonances, significantly amplifying the Raman signal. The specific geometry, size, and arrangement of these nanostructures can be optimized to maximize the enhancement factor and improve detection sensitivity for various analytes.

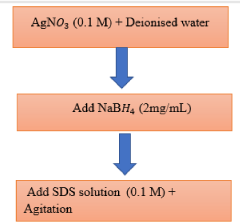

- Metal-based SERS substrate fabrication techniques: Various fabrication techniques are employed to create efficient metal-based SERS substrates. These include physical vapor deposition, electrochemical deposition, lithography, and self-assembly methods. The choice of metal (commonly gold, silver, or copper), deposition parameters, and post-processing treatments significantly impact the resulting SERS efficiency. Advanced fabrication approaches focus on creating reproducible hot spots with high enhancement factors while maintaining manufacturing scalability.

- Hybrid and composite SERS substrates: Hybrid and composite materials combine different components to create SERS substrates with superior efficiency. These may include metal-semiconductor composites, metal-polymer structures, or multi-layered architectures. The synergistic effects between different materials can enhance plasmonic properties, improve stability, and provide additional functionalities such as selectivity or reusability. These composite substrates often demonstrate higher enhancement factors and broader applicability than single-material alternatives.

- SERS substrate characterization and performance metrics: Methods and systems for characterizing SERS substrate efficiency involve various analytical techniques and performance metrics. Enhancement factor calculation, spatial uniformity assessment, reproducibility testing, and stability evaluation are critical for determining substrate quality. Advanced characterization approaches include mapping techniques, statistical analysis of signal distribution, and standardized testing protocols using reference analytes. These measurements help optimize substrate design and manufacturing processes for maximum efficiency.

- Application-specific SERS substrate optimization: SERS substrates can be specifically optimized for different applications to maximize efficiency in particular detection scenarios. This includes surface functionalization for selective binding, environmental adaptations for in-situ measurements, and integration with microfluidic or sensing platforms. Substrate designs may be tailored for specific analyte classes, concentration ranges, or measurement conditions, with considerations for factors such as pH stability, solvent compatibility, and reusability in the target application environment.

02 Metal-based SERS substrate fabrication techniques

Various fabrication techniques are employed to create efficient SERS substrates using noble metals like gold and silver. These include electron beam lithography, nanoimprint lithography, colloidal self-assembly, and electrochemical deposition. Each technique offers different advantages in terms of reproducibility, scalability, and cost-effectiveness. The fabrication process significantly impacts the uniformity and stability of the SERS enhancement factor, which are critical parameters for quantitative analysis applications.Expand Specific Solutions03 Hybrid and composite SERS substrates

Hybrid and composite materials combine different components to achieve superior SERS performance. These may include metal-semiconductor composites, metal-polymer structures, or graphene-enhanced substrates. The synergistic effects between different materials can lead to improved stability, broader detection ranges, and higher enhancement factors. These composite substrates often address limitations of traditional single-material SERS platforms, such as photostability issues or limited substrate versatility.Expand Specific Solutions04 SERS substrate characterization and performance metrics

Methods and systems for characterizing SERS substrate efficiency include enhancement factor calculation, uniformity assessment, and reproducibility testing. Advanced analytical techniques such as mapping spectroscopy, electron microscopy, and computational modeling are used to evaluate substrate performance. Standardized protocols for measuring enhancement factors and comparing different substrate designs help in optimizing SERS platforms for specific applications and ensuring reliable analytical results.Expand Specific Solutions05 Application-specific SERS substrate optimization

SERS substrates can be tailored for specific applications such as biosensing, environmental monitoring, or pharmaceutical analysis. This involves optimizing the substrate's surface chemistry, selectivity, and sensitivity for particular target molecules. Functionalization with recognition elements like antibodies or aptamers can enhance specificity, while environmental considerations such as pH stability or solvent compatibility are addressed through protective coatings or specialized materials. These optimizations maximize the practical utility of SERS technology in real-world analytical scenarios.Expand Specific Solutions

Leading Companies and Research Groups in SERS Technology

Surface-Enhanced Raman Spectroscopy (SERS) substrate technology is currently in a growth phase, with the global analytical chemistry market expanding at approximately 6-8% annually. The SERS substrate market specifically is projected to reach $250-300 million by 2025, driven by increasing demand for sensitive detection methods in pharmaceutical, environmental, and security applications. Technologically, SERS substrates are advancing from early commercial adoption toward standardization, with companies like Beckman Coulter and Hamamatsu Photonics developing commercial platforms. Academic institutions including University of South Carolina and University of California lead fundamental research, while specialized firms like Yash Nanotech focus on application-specific solutions. Intel and Corning are leveraging their materials expertise to develop next-generation substrates with improved reproducibility and sensitivity, addressing key challenges in SERS technology commercialization.

University of South Carolina

Technical Solution: University of South Carolina has developed advanced SERS substrates using controlled nanofabrication techniques to create highly ordered metallic nanostructures. Their approach focuses on creating reproducible hot spots through precise control of nanoparticle spacing and geometry. They've pioneered the development of shell-isolated nanoparticle-enhanced Raman spectroscopy (SHINERS) substrates that combine gold nanoparticles with ultrathin silica shells, allowing for enhanced sensitivity while protecting the metallic core from chemical interference. Their research has demonstrated detection limits in the femtomolar range for various analytes, making these substrates particularly valuable for trace chemical detection. The university has also explored the integration of these SERS platforms with microfluidic systems for real-time monitoring applications in environmental and biomedical fields.

Strengths: Exceptional reproducibility and stability of signal enhancement across substrate surface; protection against chemical interference while maintaining high sensitivity. Weaknesses: Relatively complex fabrication process requiring specialized equipment; potential challenges in scaling up production for commercial applications.

Hefei Institutes of Physical Science

Technical Solution: Hefei Institutes of Physical Science has developed innovative SERS substrates based on hierarchical nanostructures combining multiple metallic elements. Their approach utilizes controlled electrochemical deposition to create bimetallic (Au-Ag) nanostructures with optimized plasmon resonance properties. These substrates feature precisely engineered nanogaps that function as electromagnetic hot spots, significantly enhancing the local field intensity. Their research has demonstrated enhancement factors exceeding 10^8 for various target molecules. A distinctive aspect of their technology is the incorporation of graphene oxide layers as molecular trapping elements, which increases analyte concentration near hot spots while providing additional chemical enhancement mechanisms. This combination has enabled detection limits in the picomolar range for environmental pollutants and biological markers, with particular success in detecting pesticide residues in agricultural products.

Strengths: Exceptional sensitivity through synergistic electromagnetic and chemical enhancement mechanisms; versatility across different analytical applications. Weaknesses: Potential batch-to-batch variation in enhancement factors; limited long-term stability under certain environmental conditions.

Key Innovations in Enhancement Mechanism Research

Surface-enhanced raman spectroscopy substrate for arsenic sensing in groundwater

PatentActiveUS9057705B2

Innovation

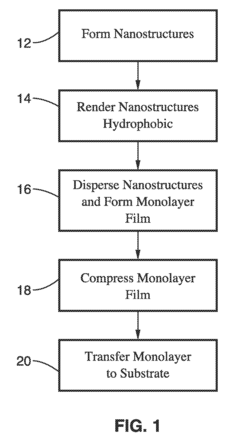

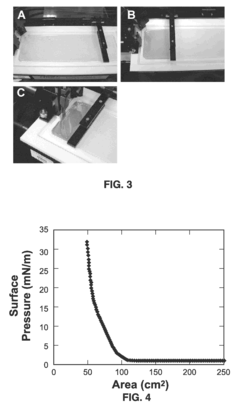

- The Langmuir-Blodgett technique is adapted to assemble monolayers of nanostructures by surface functionalization, allowing for the formation of ordered monolayers of silver nanowires with controlled shapes, such as cube-shaped, plate-shaped, rod-shaped, and hexagon-shaped nanostructures, and their subsequent compression to create aligned, close-packed arrays that function as surface-enhanced Raman spectroscopy (SERS) substrates.

Substrate for surface enhanced raman spectroscopy

PatentActiveIN202011041435A

Innovation

- A flexible SERS substrate is developed using a paper-based platform with a monolayer of graphene, coated with gold or silver nanoparticles and a thiol layer, enhancing Raman signals through electromagnetic and chemical mechanisms, allowing for label-free detection of trace molecules.

Standardization and Reproducibility Considerations

Standardization remains a critical challenge in the widespread adoption of SERS technology for analytical chemistry applications. Despite the remarkable sensitivity and detection capabilities of SERS substrates, the lack of consistent manufacturing protocols and quality control measures has hindered their transition from research laboratories to commercial analytical platforms. Current SERS substrate production exhibits significant batch-to-batch variations, with enhancement factors sometimes differing by orders of magnitude even within the same production run.

The reproducibility issues stem from multiple factors, including nanoscale structural variations, surface chemistry inconsistencies, and environmental contamination during fabrication. These challenges are particularly pronounced in colloidal SERS systems, where aggregation dynamics significantly impact performance but remain difficult to control precisely. Solid-state substrates offer somewhat better reproducibility but still face challenges in maintaining uniform hot spot distribution across their surfaces.

Several international organizations, including ASTM International and the National Institute of Standards and Technology (NIST), have initiated efforts to establish standardized protocols for SERS substrate characterization. These include recommendations for reference materials, measurement conditions, and data reporting formats. The development of standard reference materials, such as well-characterized gold nanoparticle assemblies with known enhancement factors, represents a significant step toward enabling cross-laboratory comparisons.

Quality control methodologies are evolving to address reproducibility concerns. Advanced imaging techniques like electron microscopy and atomic force microscopy are increasingly employed to verify structural uniformity, while spectroscopic mapping helps identify performance variations across substrate surfaces. Statistical approaches to characterization, including large-area sampling and multiple-point measurements, are becoming standard practice to ensure representative performance assessment.

Computational modeling is emerging as a valuable tool for predicting SERS substrate performance and establishing tolerance limits for manufacturing variations. Simulation approaches can identify critical parameters that most significantly impact enhancement factors, guiding quality control efforts toward the most influential variables. This computational guidance helps establish practical specifications that balance manufacturing feasibility with performance requirements.

The commercial sector has responded to these challenges by developing automated fabrication systems that minimize human intervention and environmental variations. Companies like Hamamatsu, Horiba, and Mesophotonics have invested in production technologies that prioritize reproducibility, even sometimes at the expense of maximum enhancement factors. This pragmatic approach recognizes that consistent, reliable performance is often more valuable for analytical applications than occasionally achieving extreme sensitivity.

The reproducibility issues stem from multiple factors, including nanoscale structural variations, surface chemistry inconsistencies, and environmental contamination during fabrication. These challenges are particularly pronounced in colloidal SERS systems, where aggregation dynamics significantly impact performance but remain difficult to control precisely. Solid-state substrates offer somewhat better reproducibility but still face challenges in maintaining uniform hot spot distribution across their surfaces.

Several international organizations, including ASTM International and the National Institute of Standards and Technology (NIST), have initiated efforts to establish standardized protocols for SERS substrate characterization. These include recommendations for reference materials, measurement conditions, and data reporting formats. The development of standard reference materials, such as well-characterized gold nanoparticle assemblies with known enhancement factors, represents a significant step toward enabling cross-laboratory comparisons.

Quality control methodologies are evolving to address reproducibility concerns. Advanced imaging techniques like electron microscopy and atomic force microscopy are increasingly employed to verify structural uniformity, while spectroscopic mapping helps identify performance variations across substrate surfaces. Statistical approaches to characterization, including large-area sampling and multiple-point measurements, are becoming standard practice to ensure representative performance assessment.

Computational modeling is emerging as a valuable tool for predicting SERS substrate performance and establishing tolerance limits for manufacturing variations. Simulation approaches can identify critical parameters that most significantly impact enhancement factors, guiding quality control efforts toward the most influential variables. This computational guidance helps establish practical specifications that balance manufacturing feasibility with performance requirements.

The commercial sector has responded to these challenges by developing automated fabrication systems that minimize human intervention and environmental variations. Companies like Hamamatsu, Horiba, and Mesophotonics have invested in production technologies that prioritize reproducibility, even sometimes at the expense of maximum enhancement factors. This pragmatic approach recognizes that consistent, reliable performance is often more valuable for analytical applications than occasionally achieving extreme sensitivity.

Environmental and Safety Implications of SERS Materials

The environmental and safety implications of SERS materials represent critical considerations as Surface-Enhanced Raman Spectroscopy (SERS) technologies gain wider adoption in analytical chemistry applications. The nanomaterials commonly used as SERS substrates—particularly noble metal nanoparticles such as gold, silver, and copper—pose potential environmental and health risks that warrant careful assessment.

Metal nanoparticles used in SERS substrates can potentially leach into aquatic environments during disposal or through wastewater systems. Studies have demonstrated that silver nanoparticles, which are among the most efficient SERS materials, exhibit toxicity toward various aquatic organisms and may disrupt microbial communities essential for ecosystem functioning. The small size of these particles enables them to penetrate biological barriers and accumulate in tissues, raising concerns about bioaccumulation in food chains.

Laboratory safety considerations are equally important when handling SERS materials. The synthesis of many high-efficiency SERS substrates involves hazardous chemicals such as strong reducing agents, organic solvents, and metal precursors. Researchers and analytical chemists must implement appropriate safety protocols, including proper ventilation systems, personal protective equipment, and waste management procedures to minimize exposure risks.

The lifecycle assessment of SERS materials reveals additional environmental concerns. The production of noble metal nanoparticles is resource-intensive and generates significant carbon footprints. Mining and refining processes for gold and silver contribute to habitat destruction, water pollution, and greenhouse gas emissions. As SERS applications expand, the demand for these materials will increase, potentially exacerbating these environmental impacts.

Recent research has focused on developing more sustainable alternatives to traditional SERS substrates. These include biodegradable polymer-based SERS platforms, recyclable substrates, and materials utilizing more abundant elements. Green synthesis methods employing plant extracts or microorganisms as reducing agents represent promising approaches to minimize the environmental impact of SERS material production.

Regulatory frameworks governing nanomaterial safety continue to evolve as scientific understanding advances. Current regulations often struggle to address the unique properties of nanomaterials used in SERS applications. The development of standardized testing protocols specifically designed for assessing the environmental fate and toxicity of SERS materials is essential for ensuring their safe implementation in analytical chemistry.

As SERS technology transitions from research laboratories to commercial applications, manufacturers and end-users must consider the entire lifecycle of these materials, from production through disposal. Implementing closed-loop systems for recovering precious metals from spent SERS substrates could simultaneously address economic and environmental concerns while promoting sustainable analytical practices.

Metal nanoparticles used in SERS substrates can potentially leach into aquatic environments during disposal or through wastewater systems. Studies have demonstrated that silver nanoparticles, which are among the most efficient SERS materials, exhibit toxicity toward various aquatic organisms and may disrupt microbial communities essential for ecosystem functioning. The small size of these particles enables them to penetrate biological barriers and accumulate in tissues, raising concerns about bioaccumulation in food chains.

Laboratory safety considerations are equally important when handling SERS materials. The synthesis of many high-efficiency SERS substrates involves hazardous chemicals such as strong reducing agents, organic solvents, and metal precursors. Researchers and analytical chemists must implement appropriate safety protocols, including proper ventilation systems, personal protective equipment, and waste management procedures to minimize exposure risks.

The lifecycle assessment of SERS materials reveals additional environmental concerns. The production of noble metal nanoparticles is resource-intensive and generates significant carbon footprints. Mining and refining processes for gold and silver contribute to habitat destruction, water pollution, and greenhouse gas emissions. As SERS applications expand, the demand for these materials will increase, potentially exacerbating these environmental impacts.

Recent research has focused on developing more sustainable alternatives to traditional SERS substrates. These include biodegradable polymer-based SERS platforms, recyclable substrates, and materials utilizing more abundant elements. Green synthesis methods employing plant extracts or microorganisms as reducing agents represent promising approaches to minimize the environmental impact of SERS material production.

Regulatory frameworks governing nanomaterial safety continue to evolve as scientific understanding advances. Current regulations often struggle to address the unique properties of nanomaterials used in SERS applications. The development of standardized testing protocols specifically designed for assessing the environmental fate and toxicity of SERS materials is essential for ensuring their safe implementation in analytical chemistry.

As SERS technology transitions from research laboratories to commercial applications, manufacturers and end-users must consider the entire lifecycle of these materials, from production through disposal. Implementing closed-loop systems for recovering precious metals from spent SERS substrates could simultaneously address economic and environmental concerns while promoting sustainable analytical practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!