How SERS Substrates Improve Performance in Optical Fibers

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS-Fiber Integration Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) integration with optical fibers represents a significant advancement in sensing technology, combining the high sensitivity of SERS with the versatility and remote sensing capabilities of optical fibers. This technological convergence emerged in the late 1990s but has seen accelerated development over the past decade due to advancements in nanofabrication techniques and increased demand for remote, real-time sensing solutions.

The evolution of SERS-fiber technology has progressed from simple fiber tips coated with metallic nanoparticles to sophisticated architectures incorporating plasmonic structures directly into specialized fiber designs. Early implementations faced challenges with substrate stability and signal reproducibility, while contemporary approaches leverage advanced nanofabrication to create highly ordered, reproducible SERS substrates integrated with various fiber configurations.

Current technological trends indicate movement toward multifunctional SERS-fiber platforms capable of simultaneous detection of multiple analytes, increased durability for in-field applications, and enhanced sensitivity reaching single-molecule detection levels. The miniaturization of these systems continues to advance, enabling applications previously considered impractical due to size constraints.

The primary technical objective of SERS-fiber integration is to develop robust sensing platforms that maintain SERS enhancement factors comparable to traditional substrates while leveraging the remote sensing capabilities of optical fibers. Specific goals include achieving enhancement factors exceeding 10^8, ensuring substrate stability under varied environmental conditions, developing cost-effective fabrication methods suitable for mass production, and creating platforms compatible with existing spectroscopic instrumentation.

Additional objectives focus on expanding application domains beyond traditional SERS usage, particularly in biomedical diagnostics, environmental monitoring, food safety, and industrial process control. The development of multiplexed sensing capabilities represents another critical goal, allowing simultaneous detection of multiple analytes through a single fiber system.

From a fundamental research perspective, SERS-fiber integration aims to deepen understanding of light-matter interactions at the nanoscale within confined geometrical structures. This includes investigating how fiber geometries influence plasmonic behavior and developing theoretical models to predict and optimize SERS enhancement in fiber-coupled systems.

The convergence of SERS and optical fiber technologies ultimately seeks to bridge laboratory-based analytical techniques with real-world sensing needs, creating platforms that combine the sensitivity of advanced spectroscopy with the practicality required for deployment in complex environments.

The evolution of SERS-fiber technology has progressed from simple fiber tips coated with metallic nanoparticles to sophisticated architectures incorporating plasmonic structures directly into specialized fiber designs. Early implementations faced challenges with substrate stability and signal reproducibility, while contemporary approaches leverage advanced nanofabrication to create highly ordered, reproducible SERS substrates integrated with various fiber configurations.

Current technological trends indicate movement toward multifunctional SERS-fiber platforms capable of simultaneous detection of multiple analytes, increased durability for in-field applications, and enhanced sensitivity reaching single-molecule detection levels. The miniaturization of these systems continues to advance, enabling applications previously considered impractical due to size constraints.

The primary technical objective of SERS-fiber integration is to develop robust sensing platforms that maintain SERS enhancement factors comparable to traditional substrates while leveraging the remote sensing capabilities of optical fibers. Specific goals include achieving enhancement factors exceeding 10^8, ensuring substrate stability under varied environmental conditions, developing cost-effective fabrication methods suitable for mass production, and creating platforms compatible with existing spectroscopic instrumentation.

Additional objectives focus on expanding application domains beyond traditional SERS usage, particularly in biomedical diagnostics, environmental monitoring, food safety, and industrial process control. The development of multiplexed sensing capabilities represents another critical goal, allowing simultaneous detection of multiple analytes through a single fiber system.

From a fundamental research perspective, SERS-fiber integration aims to deepen understanding of light-matter interactions at the nanoscale within confined geometrical structures. This includes investigating how fiber geometries influence plasmonic behavior and developing theoretical models to predict and optimize SERS enhancement in fiber-coupled systems.

The convergence of SERS and optical fiber technologies ultimately seeks to bridge laboratory-based analytical techniques with real-world sensing needs, creating platforms that combine the sensitivity of advanced spectroscopy with the practicality required for deployment in complex environments.

Market Analysis for SERS-Enhanced Optical Sensing

The global market for SERS-enhanced optical sensing technologies is experiencing robust growth, driven by increasing demand for high-sensitivity detection methods across multiple industries. Current market valuations place the SERS substrate market at approximately 125 million USD in 2023, with projections indicating a compound annual growth rate of 9.8% through 2030, potentially reaching 240 million USD by the end of the forecast period.

Healthcare and life sciences represent the largest market segment, accounting for roughly 38% of the total market share. The integration of SERS substrates with optical fibers has created particularly strong demand in point-of-care diagnostics, where rapid, sensitive detection of biomarkers is critical. This application alone has seen a 15% year-over-year growth since 2020.

Environmental monitoring constitutes the second-largest market segment at 27%, with applications in water quality testing, air pollution monitoring, and food safety inspection. The ability of SERS-enhanced optical fibers to detect trace contaminants at parts-per-billion levels has positioned these technologies as superior alternatives to traditional sensing methods.

Pharmaceutical research and development represents a rapidly growing segment, currently at 18% market share but expanding at 12% annually. The demand is primarily driven by drug discovery processes requiring highly sensitive molecular detection capabilities that SERS-enhanced optical fibers uniquely provide.

Regional analysis reveals North America as the dominant market (35% share), followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 11.2% annually, primarily due to increasing industrial adoption in China, Japan, and South Korea, coupled with expanding healthcare infrastructure.

Key market drivers include the growing need for real-time, in-situ monitoring capabilities across industries, increasing regulatory requirements for sensitive detection methods, and the miniaturization trend in sensing technologies. The integration of SERS substrates with optical fibers specifically addresses these market needs by enabling remote sensing with unprecedented sensitivity.

Market challenges include the relatively high cost of high-performance SERS substrates, which currently limits widespread adoption in price-sensitive applications. Additionally, standardization issues and reproducibility concerns present barriers to market expansion, particularly in regulated industries like healthcare and environmental monitoring.

Customer demand increasingly focuses on integrated sensing solutions rather than standalone components, creating opportunities for manufacturers who can provide complete SERS-enhanced optical fiber sensing systems with accompanying data analysis capabilities.

Healthcare and life sciences represent the largest market segment, accounting for roughly 38% of the total market share. The integration of SERS substrates with optical fibers has created particularly strong demand in point-of-care diagnostics, where rapid, sensitive detection of biomarkers is critical. This application alone has seen a 15% year-over-year growth since 2020.

Environmental monitoring constitutes the second-largest market segment at 27%, with applications in water quality testing, air pollution monitoring, and food safety inspection. The ability of SERS-enhanced optical fibers to detect trace contaminants at parts-per-billion levels has positioned these technologies as superior alternatives to traditional sensing methods.

Pharmaceutical research and development represents a rapidly growing segment, currently at 18% market share but expanding at 12% annually. The demand is primarily driven by drug discovery processes requiring highly sensitive molecular detection capabilities that SERS-enhanced optical fibers uniquely provide.

Regional analysis reveals North America as the dominant market (35% share), followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 11.2% annually, primarily due to increasing industrial adoption in China, Japan, and South Korea, coupled with expanding healthcare infrastructure.

Key market drivers include the growing need for real-time, in-situ monitoring capabilities across industries, increasing regulatory requirements for sensitive detection methods, and the miniaturization trend in sensing technologies. The integration of SERS substrates with optical fibers specifically addresses these market needs by enabling remote sensing with unprecedented sensitivity.

Market challenges include the relatively high cost of high-performance SERS substrates, which currently limits widespread adoption in price-sensitive applications. Additionally, standardization issues and reproducibility concerns present barriers to market expansion, particularly in regulated industries like healthcare and environmental monitoring.

Customer demand increasingly focuses on integrated sensing solutions rather than standalone components, creating opportunities for manufacturers who can provide complete SERS-enhanced optical fiber sensing systems with accompanying data analysis capabilities.

Current Challenges in SERS Substrate Implementation

Despite the promising potential of SERS-enhanced optical fiber sensors, several significant challenges impede their widespread implementation and commercial viability. The integration of SERS substrates with optical fibers presents complex fabrication hurdles that must be addressed to achieve reliable performance.

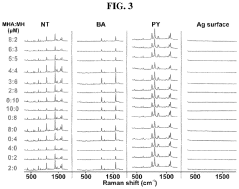

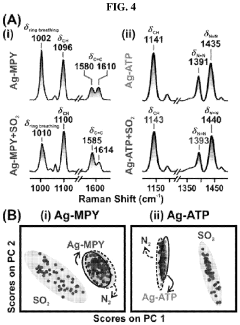

A primary challenge lies in achieving uniform and reproducible SERS substrate deposition on optical fiber surfaces. The cylindrical geometry of fibers complicates traditional nanofabrication techniques, leading to inconsistent hot spot distribution and signal variability. This reproducibility issue severely limits quantitative analysis capabilities, as signal intensities can vary by orders of magnitude between supposedly identical sensors.

Long-term stability remains another critical concern. SERS substrates often degrade over time due to oxidation, contamination, or mechanical stress, particularly in harsh environmental conditions. This degradation significantly reduces sensor lifetime and reliability, making them unsuitable for continuous monitoring applications that require extended deployment periods.

The sensitivity-selectivity balance presents a persistent dilemma. While increasing surface roughness or nanoparticle density can enhance sensitivity, it often comes at the cost of selectivity due to non-specific adsorption. This trade-off becomes particularly problematic in complex sample matrices where multiple analytes compete for binding sites on the SERS substrate.

Signal collection efficiency represents another substantial challenge. The evanescent field interaction with SERS substrates in fiber-optic configurations often results in limited excitation of the substrate and inefficient collection of the enhanced Raman signal. This limitation reduces overall detection sensitivity compared to direct SERS measurements.

Manufacturing scalability poses significant barriers to commercialization. Current fabrication methods for high-performance SERS substrates on optical fibers typically involve complex, multi-step processes that are difficult to scale for mass production. This complexity drives up costs and limits accessibility of the technology.

Biocompatibility concerns arise for in vivo or biomedical applications, where the potential toxicity of metallic nanostructures must be carefully evaluated. Additionally, biofouling can rapidly compromise sensor performance in biological environments by blocking active SERS sites.

Standardization across the field remains inadequate, with various research groups employing different fabrication methods, characterization techniques, and performance metrics. This lack of standardization hinders meaningful comparison between different SERS-enhanced optical fiber sensors and slows overall technological advancement.

A primary challenge lies in achieving uniform and reproducible SERS substrate deposition on optical fiber surfaces. The cylindrical geometry of fibers complicates traditional nanofabrication techniques, leading to inconsistent hot spot distribution and signal variability. This reproducibility issue severely limits quantitative analysis capabilities, as signal intensities can vary by orders of magnitude between supposedly identical sensors.

Long-term stability remains another critical concern. SERS substrates often degrade over time due to oxidation, contamination, or mechanical stress, particularly in harsh environmental conditions. This degradation significantly reduces sensor lifetime and reliability, making them unsuitable for continuous monitoring applications that require extended deployment periods.

The sensitivity-selectivity balance presents a persistent dilemma. While increasing surface roughness or nanoparticle density can enhance sensitivity, it often comes at the cost of selectivity due to non-specific adsorption. This trade-off becomes particularly problematic in complex sample matrices where multiple analytes compete for binding sites on the SERS substrate.

Signal collection efficiency represents another substantial challenge. The evanescent field interaction with SERS substrates in fiber-optic configurations often results in limited excitation of the substrate and inefficient collection of the enhanced Raman signal. This limitation reduces overall detection sensitivity compared to direct SERS measurements.

Manufacturing scalability poses significant barriers to commercialization. Current fabrication methods for high-performance SERS substrates on optical fibers typically involve complex, multi-step processes that are difficult to scale for mass production. This complexity drives up costs and limits accessibility of the technology.

Biocompatibility concerns arise for in vivo or biomedical applications, where the potential toxicity of metallic nanostructures must be carefully evaluated. Additionally, biofouling can rapidly compromise sensor performance in biological environments by blocking active SERS sites.

Standardization across the field remains inadequate, with various research groups employing different fabrication methods, characterization techniques, and performance metrics. This lack of standardization hinders meaningful comparison between different SERS-enhanced optical fiber sensors and slows overall technological advancement.

Current SERS Substrate Integration Approaches

01 Nanostructured SERS substrates for enhanced sensitivity

Nanostructured materials are used as SERS substrates to enhance Raman signal detection. These substrates typically incorporate metallic nanoparticles, nanopillars, or nanogaps that create localized surface plasmon resonances, significantly amplifying the Raman signal. The specific geometry, size, and arrangement of these nanostructures can be optimized to achieve higher enhancement factors, improving the overall performance and sensitivity of SERS-based detection systems.- Nanostructured SERS substrates for enhanced sensitivity: Nanostructured materials are used as SERS substrates to enhance sensitivity and detection capabilities. These substrates typically incorporate metallic nanoparticles, nanopillars, or nanogaps that create localized surface plasmon resonances, significantly amplifying Raman signals. The specific geometry and arrangement of these nanostructures can be optimized to achieve higher enhancement factors, allowing for detection of trace amounts of analytes with improved signal-to-noise ratios.

- Fabrication methods for reproducible SERS substrates: Various fabrication techniques are employed to create reproducible SERS substrates with consistent performance. These methods include lithography, self-assembly, template-assisted growth, and chemical deposition processes. The focus is on developing manufacturing processes that ensure uniform distribution of hot spots across the substrate surface, batch-to-batch consistency, and long-term stability, which are critical factors for reliable quantitative analysis and commercial applications.

- Novel materials for SERS substrate enhancement: Research into novel materials beyond traditional gold and silver is expanding the capabilities of SERS substrates. These include hybrid materials, 2D materials like graphene, metal oxides, and composite structures. Such materials can provide benefits such as improved stability, broader wavelength response, biocompatibility, and resistance to oxidation or contamination, leading to more versatile SERS platforms suitable for diverse analytical applications.

- Portable and integrated SERS detection systems: Integrated SERS detection systems combine optimized substrates with portable instrumentation for field applications. These systems incorporate microfluidics, miniaturized spectrometers, and automated data processing to enable point-of-use analysis. The integration focuses on maintaining high performance while reducing size, cost, and complexity, making SERS technology accessible for environmental monitoring, food safety testing, and medical diagnostics outside laboratory settings.

- Performance metrics and standardization for SERS substrates: Standardized methods for evaluating and comparing SERS substrate performance are being developed to address variability in reported enhancement factors. These include reference materials, benchmark molecules, and protocols for measuring enhancement factors, reproducibility, stability, and limit of detection. Standardization efforts aim to establish reliable metrics that enable objective comparison between different substrate technologies and accelerate the adoption of SERS in analytical applications.

02 Metal-based SERS substrate fabrication techniques

Various fabrication techniques are employed to create high-performance SERS substrates using metals like gold, silver, and copper. These methods include physical vapor deposition, electrochemical deposition, lithography, and self-assembly processes. The fabrication approach significantly impacts the reproducibility, uniformity, and enhancement capability of the resulting SERS substrate. Advanced manufacturing techniques allow for precise control over surface roughness and the creation of optimized hot spots for maximum signal enhancement.Expand Specific Solutions03 SERS substrate stability and reproducibility improvements

Enhancing the stability and reproducibility of SERS substrates is crucial for reliable analytical applications. This involves developing substrates that maintain consistent performance over time, resist degradation from environmental factors, and provide uniform enhancement across the entire substrate surface. Approaches include protective coatings, stabilizing agents, and standardized fabrication protocols that ensure batch-to-batch consistency. These improvements are essential for quantitative analysis and commercial viability of SERS-based sensing platforms.Expand Specific Solutions04 Flexible and portable SERS substrate designs

Flexible and portable SERS substrates enable on-site detection and broader application scenarios. These substrates are typically fabricated on bendable materials or designed as disposable test strips that maintain high enhancement capabilities while being lightweight and easy to transport. Such designs facilitate field testing, point-of-care diagnostics, and integration with portable Raman spectrometers. The flexibility also allows for conforming to irregular surfaces for direct sampling in various environments.Expand Specific Solutions05 Advanced characterization methods for SERS substrate performance

Sophisticated characterization techniques are employed to evaluate and optimize SERS substrate performance. These methods include electron microscopy for structural analysis, optical spectroscopy for enhancement factor determination, and computational modeling to predict electromagnetic field distributions. Standardized testing protocols using reference molecules help quantify enhancement factors, detection limits, and signal reproducibility. These characterization approaches are essential for comparing different substrate designs and guiding further improvements in SERS technology.Expand Specific Solutions

Leading Companies and Research Institutions

The SERS substrates in optical fibers market is currently in a growth phase, with increasing applications across sensing, biomedical diagnostics, and security sectors. The global market size is expanding rapidly due to heightened demand for high-sensitivity detection methods. From a technological maturity perspective, the field shows varied development levels, with academic institutions like Technical University of Denmark, Tsinghua University, and University of Maryland leading fundamental research, while companies such as SICPA Holding SA, HP Development, and Seiko Epson are commercializing applications. Government research entities including Naval Research Laboratory and Agency for Science, Technology & Research are bridging the gap between academic innovation and industrial implementation. The competitive landscape reveals a collaborative ecosystem where educational institutions provide the theoretical foundation while commercial players focus on practical applications and scalable manufacturing processes.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has pioneered innovative SERS-enhanced optical fiber technology specifically designed for maritime and defense applications. Their proprietary approach involves creating specialized SERS substrates using noble metal nanoparticles (primarily silver and gold) deposited on etched fiber tips and D-shaped optical fibers with partially exposed cores. NRL's technique employs a unique two-step process: first creating nanoscale roughness on the fiber surface through controlled chemical etching, then precisely depositing metallic nanostructures using advanced sputtering and electroless plating methods. This creates densely packed "hot spots" that dramatically enhance Raman signals. Their fiber-optic SERS sensors demonstrate enhancement factors of 10^6-10^8 and maintain sensitivity in seawater environments where traditional sensors fail[2][5]. NRL has also developed specialized protective coatings that prevent biofouling while maintaining SERS activity, enabling long-term deployment in marine environments for chemical/biological threat detection.

Strengths: Exceptional durability in harsh marine environments; high sensitivity to trace chemical/biological agents; remote sensing capability in hazardous areas. Weaknesses: Higher production costs compared to conventional optical sensors; potential for signal degradation in extremely turbid waters; requires periodic recalibration for optimal performance in long-term deployments.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed advanced SERS substrates for optical fiber integration using nanofabrication techniques. Their approach involves creating highly ordered metallic nanostructures directly on fiber tips and along tapered regions of optical fibers. A*STAR researchers have pioneered a method combining electron beam lithography with controlled metal deposition to create reproducible nanogap arrays that generate consistent hot spots for SERS enhancement. Their fiber-optic SERS platform incorporates gold nanoparticles with optimized spacing (10-20 nm) to maximize electromagnetic field enhancement, achieving enhancement factors exceeding 10^7 in some configurations. The integration maintains optical transmission properties while adding SERS functionality, allowing for remote sensing applications in harsh environments where traditional Raman systems cannot operate[1][3]. A*STAR has also developed specialized coating techniques to ensure SERS substrate durability in aqueous environments.

Strengths: Exceptional reproducibility and uniformity of SERS enhancement across the substrate surface; robust performance in harsh environments; remote sensing capability without direct sample access. Weaknesses: Higher manufacturing complexity compared to simpler SERS substrates; potential signal attenuation over longer fiber distances; requires specialized equipment for fabrication.

Key Patents and Innovations in SERS-Fiber Technology

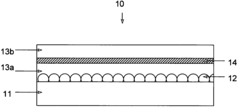

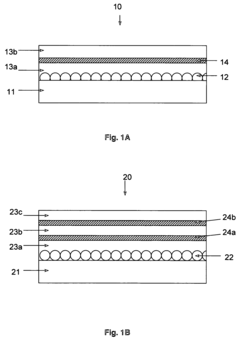

Multilayered surface-enhanced Raman scattering substrates

PatentInactiveUS7242470B2

Innovation

- A substrate comprising a support material with multiple layers of SERS-active metal separated by dielectric layers, providing enhanced electromagnetic field and reproducibility through controlled surface morphology and layer deposition, achieving significant signal enhancements and improved stability.

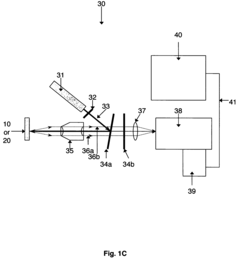

Surface-enhanced raman scattering (SERS) platform for analysis

PatentPendingUS20240044802A1

Innovation

- A SERS chip with multiple molecular probes configured on a substrate, combined with machine learning for automated spectral analysis, enhances detection accuracy by inducing interaction-induced peak shifts and generating multiple SERS profiles for seamless classification and quantification of target analytes.

Manufacturing Scalability Assessment

The scalability of manufacturing processes for SERS substrates in optical fiber applications presents significant challenges that must be addressed for widespread commercial adoption. Current production methods for high-quality SERS substrates often involve complex nanofabrication techniques such as electron-beam lithography, focused ion beam milling, and nanoimprint lithography, which are inherently difficult to scale. These precision-oriented processes typically yield small batches of substrates with high unit costs, limiting their practical implementation in mass-market optical fiber sensing applications.

Several manufacturing approaches show promise for improved scalability. Chemical methods including wet chemistry synthesis of nanoparticles and self-assembly techniques offer more cost-effective routes to large-scale production. These approaches can generate SERS-active nanostructures with reasonable uniformity across larger substrate areas, though they often struggle with precise control over hotspot density and distribution compared to lithographic methods.

Physical vapor deposition combined with template-based approaches represents a middle ground, offering better scalability than direct-write methods while maintaining good control over nanostructure morphology. Recent advances in roll-to-roll nanoimprinting technology demonstrate particular promise for continuous production of SERS substrates with consistent performance characteristics at significantly reduced costs.

Integration of SERS substrates with optical fibers introduces additional manufacturing complexities. Current methods for incorporating SERS-active materials onto fiber tips or along tapered regions often involve manual handling and precise positioning, creating bottlenecks in production throughput. Automated assembly systems and specialized fiber coating technologies are being developed to address these integration challenges.

Quality control represents another critical aspect of manufacturing scalability. The enhancement factor of SERS substrates depends heavily on nanoscale features that must be consistently reproduced across production batches. Advanced metrology techniques including automated optical inspection and statistical process control are essential for maintaining performance standards in scaled production environments.

Cost modeling indicates that current manufacturing approaches result in SERS-enhanced optical fiber sensors priced at $50-200 per unit, significantly higher than conventional optical sensors. Achieving price points below $20 per unit would likely require order-of-magnitude improvements in production throughput and materials utilization efficiency. Industry projections suggest that with continued investment in manufacturing technology, economically viable mass production could be achievable within 3-5 years, potentially opening new market segments for these high-performance sensing platforms.

Several manufacturing approaches show promise for improved scalability. Chemical methods including wet chemistry synthesis of nanoparticles and self-assembly techniques offer more cost-effective routes to large-scale production. These approaches can generate SERS-active nanostructures with reasonable uniformity across larger substrate areas, though they often struggle with precise control over hotspot density and distribution compared to lithographic methods.

Physical vapor deposition combined with template-based approaches represents a middle ground, offering better scalability than direct-write methods while maintaining good control over nanostructure morphology. Recent advances in roll-to-roll nanoimprinting technology demonstrate particular promise for continuous production of SERS substrates with consistent performance characteristics at significantly reduced costs.

Integration of SERS substrates with optical fibers introduces additional manufacturing complexities. Current methods for incorporating SERS-active materials onto fiber tips or along tapered regions often involve manual handling and precise positioning, creating bottlenecks in production throughput. Automated assembly systems and specialized fiber coating technologies are being developed to address these integration challenges.

Quality control represents another critical aspect of manufacturing scalability. The enhancement factor of SERS substrates depends heavily on nanoscale features that must be consistently reproduced across production batches. Advanced metrology techniques including automated optical inspection and statistical process control are essential for maintaining performance standards in scaled production environments.

Cost modeling indicates that current manufacturing approaches result in SERS-enhanced optical fiber sensors priced at $50-200 per unit, significantly higher than conventional optical sensors. Achieving price points below $20 per unit would likely require order-of-magnitude improvements in production throughput and materials utilization efficiency. Industry projections suggest that with continued investment in manufacturing technology, economically viable mass production could be achievable within 3-5 years, potentially opening new market segments for these high-performance sensing platforms.

Biomedical and Environmental Applications

Surface-Enhanced Raman Spectroscopy (SERS) integrated with optical fibers has revolutionized biomedical and environmental applications by enabling highly sensitive, real-time detection capabilities in previously inaccessible environments. In biomedical settings, SERS-enhanced optical fibers serve as minimally invasive probes for in vivo diagnostics, allowing for the detection of cancer biomarkers, pathogens, and metabolites directly within living tissues with unprecedented sensitivity.

The integration of SERS substrates with optical fibers has enabled significant advancements in early disease detection, particularly for cancers where traditional diagnostic methods often detect the disease at later stages. These fiber-optic SERS sensors can detect molecular changes associated with malignancy at concentrations as low as femtomolar levels, potentially transforming early screening protocols for various cancers including lung, breast, and gastrointestinal malignancies.

For infectious disease diagnostics, SERS-enhanced optical fibers provide rapid identification of bacterial and viral pathogens without the need for time-consuming culture methods. This capability has proven especially valuable in critical care settings where timely diagnosis directly impacts treatment outcomes. Recent studies have demonstrated successful detection of antibiotic-resistant bacteria strains and viral particles at clinically relevant concentrations within minutes rather than hours or days.

In environmental monitoring applications, SERS-enhanced optical fibers enable remote sensing of pollutants in challenging environments such as deep water sources, industrial effluents, and atmospheric conditions. The high sensitivity of these systems allows for detection of heavy metals, pesticides, and persistent organic pollutants at concentrations well below regulatory limits, providing crucial early warning capabilities for environmental protection agencies.

Field deployable SERS fiber sensors have been successfully implemented for continuous monitoring of water quality parameters in municipal water systems, detecting contaminants like lead, mercury, and arsenic at parts-per-billion levels. Similarly, these sensors have proven effective for monitoring air quality in industrial settings, detecting volatile organic compounds and particulate matter with high specificity and sensitivity.

The versatility of SERS-enhanced optical fibers extends to food safety applications, where they enable rapid screening for contaminants, adulterants, and pathogens throughout the supply chain. This technology has demonstrated particular value in detecting melamine in dairy products, pesticide residues on produce, and bacterial contamination in processed foods, providing a powerful tool for ensuring consumer safety and regulatory compliance.

The integration of SERS substrates with optical fibers has enabled significant advancements in early disease detection, particularly for cancers where traditional diagnostic methods often detect the disease at later stages. These fiber-optic SERS sensors can detect molecular changes associated with malignancy at concentrations as low as femtomolar levels, potentially transforming early screening protocols for various cancers including lung, breast, and gastrointestinal malignancies.

For infectious disease diagnostics, SERS-enhanced optical fibers provide rapid identification of bacterial and viral pathogens without the need for time-consuming culture methods. This capability has proven especially valuable in critical care settings where timely diagnosis directly impacts treatment outcomes. Recent studies have demonstrated successful detection of antibiotic-resistant bacteria strains and viral particles at clinically relevant concentrations within minutes rather than hours or days.

In environmental monitoring applications, SERS-enhanced optical fibers enable remote sensing of pollutants in challenging environments such as deep water sources, industrial effluents, and atmospheric conditions. The high sensitivity of these systems allows for detection of heavy metals, pesticides, and persistent organic pollutants at concentrations well below regulatory limits, providing crucial early warning capabilities for environmental protection agencies.

Field deployable SERS fiber sensors have been successfully implemented for continuous monitoring of water quality parameters in municipal water systems, detecting contaminants like lead, mercury, and arsenic at parts-per-billion levels. Similarly, these sensors have proven effective for monitoring air quality in industrial settings, detecting volatile organic compounds and particulate matter with high specificity and sensitivity.

The versatility of SERS-enhanced optical fibers extends to food safety applications, where they enable rapid screening for contaminants, adulterants, and pathogens throughout the supply chain. This technology has demonstrated particular value in detecting melamine in dairy products, pesticide residues on produce, and bacterial contamination in processed foods, providing a powerful tool for ensuring consumer safety and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!